Machining automatic conveying device

An automatic conveying device and machining technology, applied in the field of machining, can solve the problems of low efficiency of manual feeding and waste of labor, and achieve the effect of novel design and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

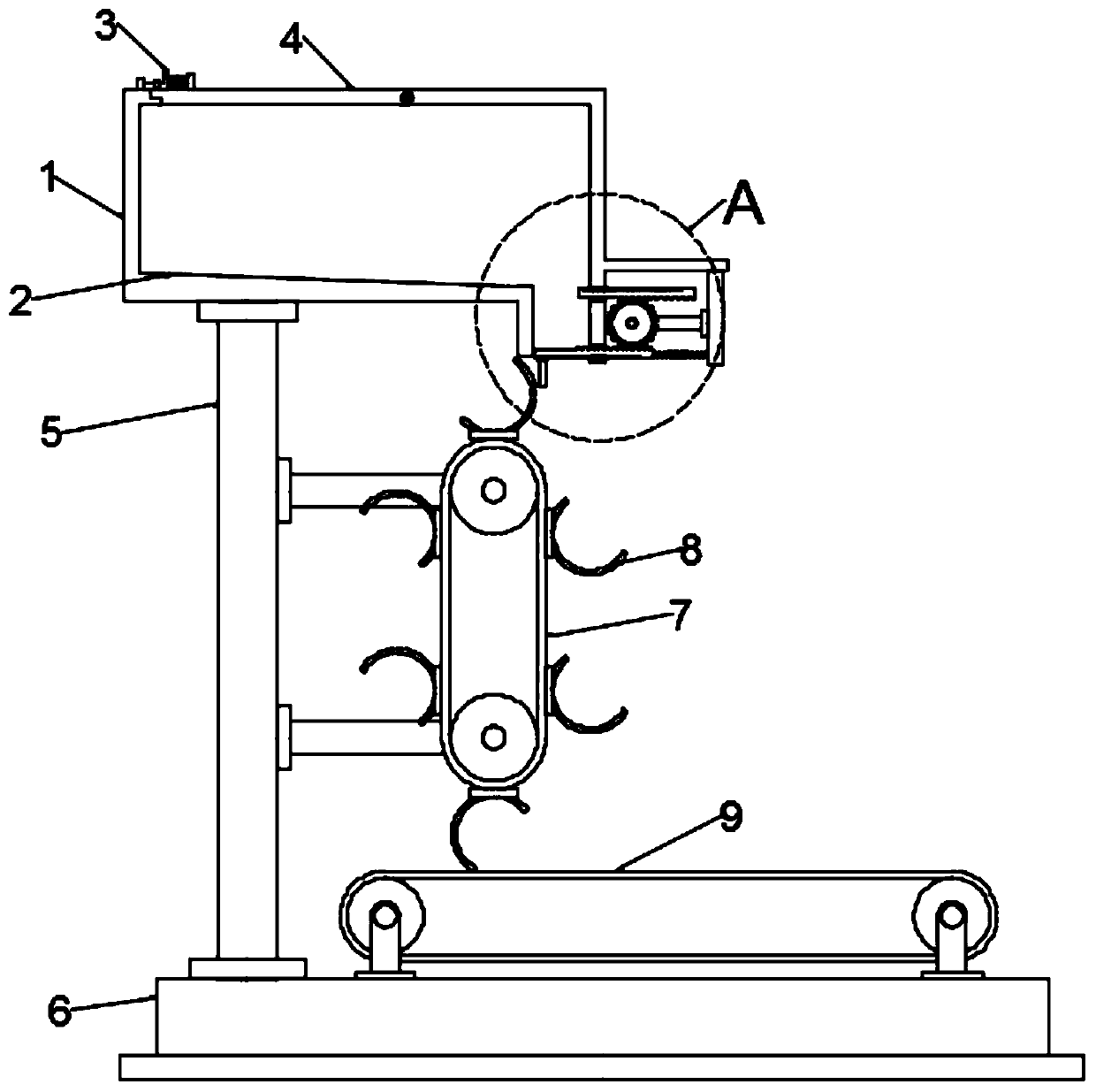

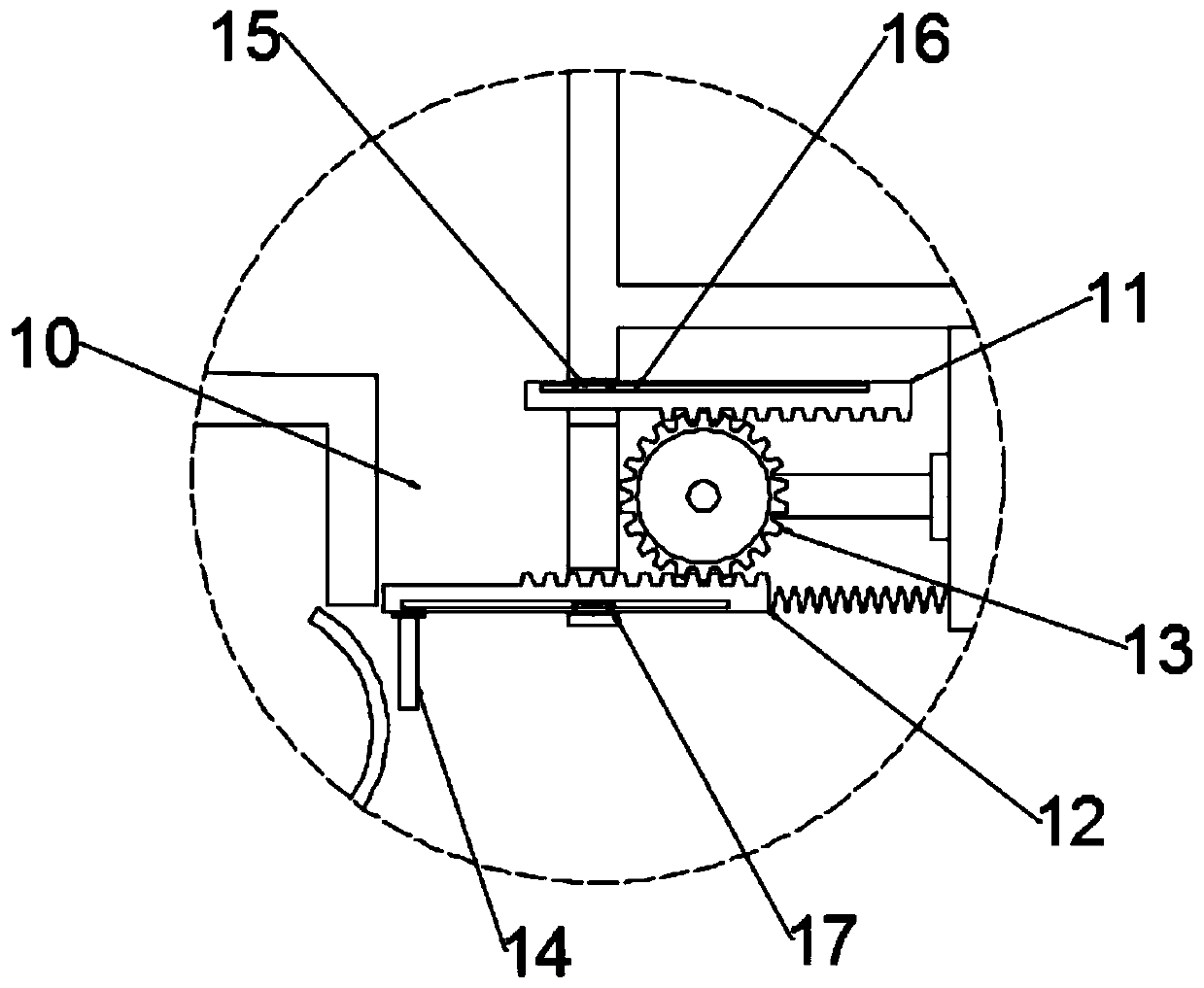

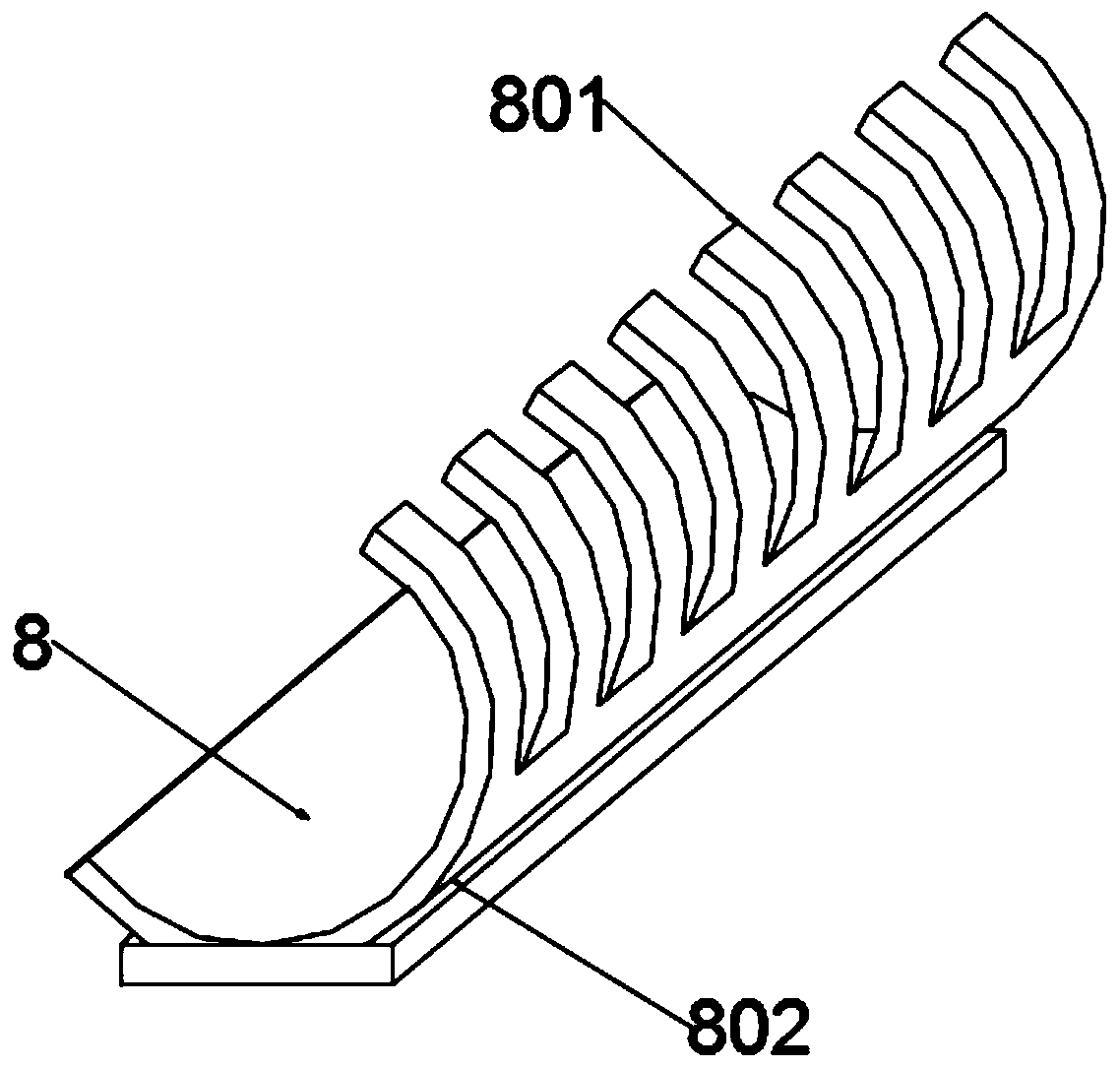

[0024] see Figure 1~3 , in an embodiment of the present invention, a mechanical processing automatic conveying device includes a placement cavity 1; the placement cavity 1 is fixed on the base 6 through a bracket 5, a buffer cavity 10 is provided at the lower end of the placement cavity 1, and The upper and lower ends of the buffer chamber 10 are provided with an upper rack plate 11 and a lower rack plate 12 with opposite moving directions, and a conveying chain assembly 7 mounted on a bracket 5 is arranged below the placement chamber 1, and the conveying chain assembly 7, etc. A plurality of arc-shaped claws 8 are installed at a distance. When one of the arc-shaped claws 8 moves to the upper end of the conveyor chain assembly 7, the arc-shaped claws 8 abut against the driving plate 14 fixed on the lower rack plate 12, and in the arc When the claw 8 continues to move, the drive plate 14 drives the lower rack plate 12 to open, and the cylindrical part falls into the arc claw 8...

Embodiment 2

[0033] see Figure 4 and 5 , during the specific implementation process of the present invention, another embodiment is proposed to perfect the present application. Specifically, the conveyor belt 9 is provided with a plurality of convex lines 18, and the convex lines 18 are composed of a mounting plate 1802 and a raised block 1801 Composition, the protruding blocks 1801 are provided with a plurality of them and fixed on the mounting plate 1802 equidistantly. When the cylindrical piece falls onto the conveyor belt 9, the position is limited by the convex strip 18 to prevent the cylindrical piece from rolling freely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com