Tea cup production line, and method for producing tea cup by using production line

A production line and tea cup technology, applied in the field of tea cup production lines, can solve the problems of poor operation regulation, troublesome cleaning, affecting the uniform effect of glazing, etc., and achieve the effect of improving the utilization rate and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Such as figure 1 As shown, this embodiment discloses a production line for tea cups, which includes a embryo making mechanism, a glazing mechanism, and a glaze firing kiln in sequence from front to back according to the technological process.

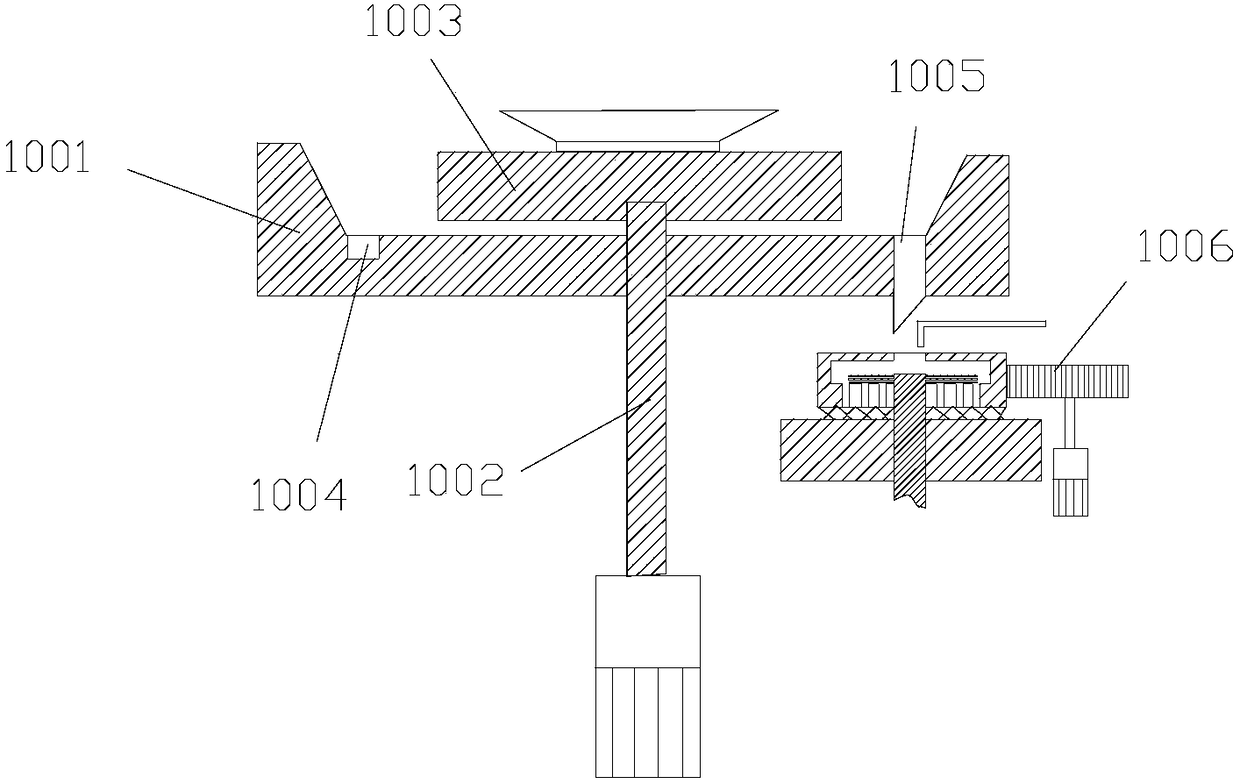

[0055] Such as Figure 2-4 As shown, the embryo-making mechanism includes a embryo-making table 1001, a embryo-making rotating shaft 1002, and a embryo-making turntable 1003. The edge of the upper surface of the embryo-making table 1001 extends upwards to form a wide-mouth structure. The embryo-making turntable 1003 is located in the cavity of the wide-mouth structure and is rotatably connected with the embryo-making table 1001 through the embryo-making rotating shaft 1002 . There is also a spiral guide groove 1004 on the embryo making table 1001, the thickness of the side wall of the guide groove 1004 gradually increases from its feed inlet to its discharge outlet 1005 and the discharge outlet 1005 communicates with the outside...

Embodiment 2

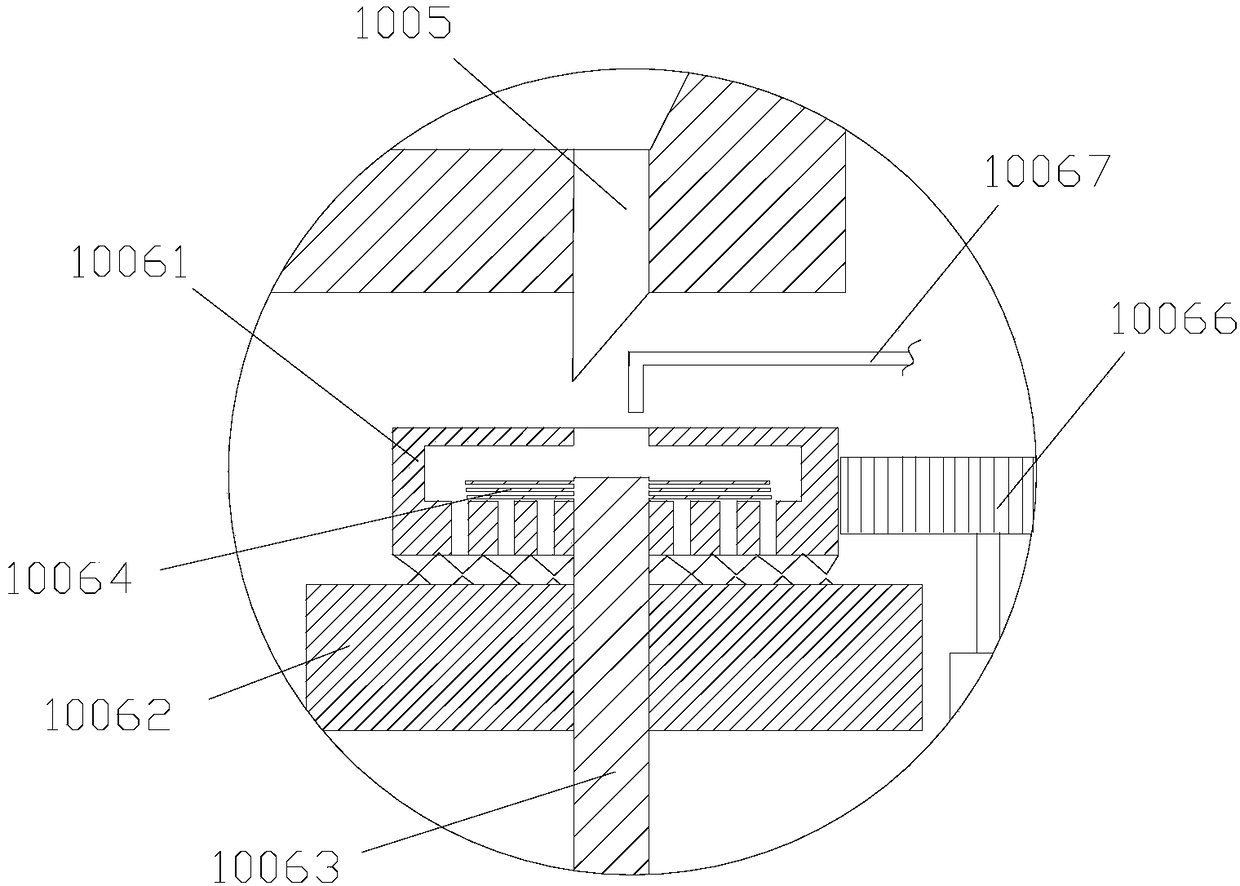

[0063] Such as Figure 2-3As shown, the difference between this embodiment and the above-mentioned embodiments is that the abrasive device 1006 includes an upper rotating grinding disc 10061 and a lower fixed grinding disc 10062, and the upper rotating grinding disc 10061 is located above the lower fixed grinding disc 10062 and is rotatably connected to the lower fixed grinding disc 10062 through the grinding disc rotating shaft 10063. . The top of the upper rotating millstone 10061 is provided with an upper rotating millstone 10061 feed port, and the bottom of the upper rotating millstone 10061 is provided with a plurality of upper rotating millstones 10061 feeding ports, and the upper rotating millstone 10061 feeding port is connected with a plurality of upper rotating millstones 10061 for discharging. The mouths are connected. Stirring impellers 10064 are provided on a section of the grinding disc rotating shaft 10063 extending into the inner cavity of the upper rotating g...

Embodiment 3

[0068] Such as Figure 7 , 10 , 11, the difference between this embodiment and the above embodiments is that the auxiliary intermittent lifting mechanism 113 includes an auxiliary fixing seat 1131 , an auxiliary lifting slider 1132 , and an auxiliary incomplete gear 1133 . The auxiliary lifting slider 1132 is L-shaped, including an auxiliary vertical section 11321 and an auxiliary horizontal section 11322 . The auxiliary elastic device 114 , the auxiliary intermittent push-out mechanism 115 , and the auxiliary clamping device 116 are all arranged on the auxiliary horizontal section 11322 .

[0069] Such as Figure 10 , 11 As shown, the auxiliary vertical section 11321 is slidingly matched with the auxiliary fixing seat 1131. Specifically, the auxiliary gear teeth 1134 may be rotatably connected to the auxiliary fixing seat 1131, and the side of the auxiliary vertical section 11321 is provided with a part meshing with the auxiliary gear teeth 1134. The auxiliary sawtooth ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com