Pneumatic vibration material feeding device

A feeding device and pneumatic vibration technology, which is applied in vibrating conveyors, conveyor control devices, transportation and packaging, etc., can solve problems such as low weighing accuracy, low safety, and incomplete explosion-proof measures, and achieve human-machine isolation , Improve the safety level and reduce the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

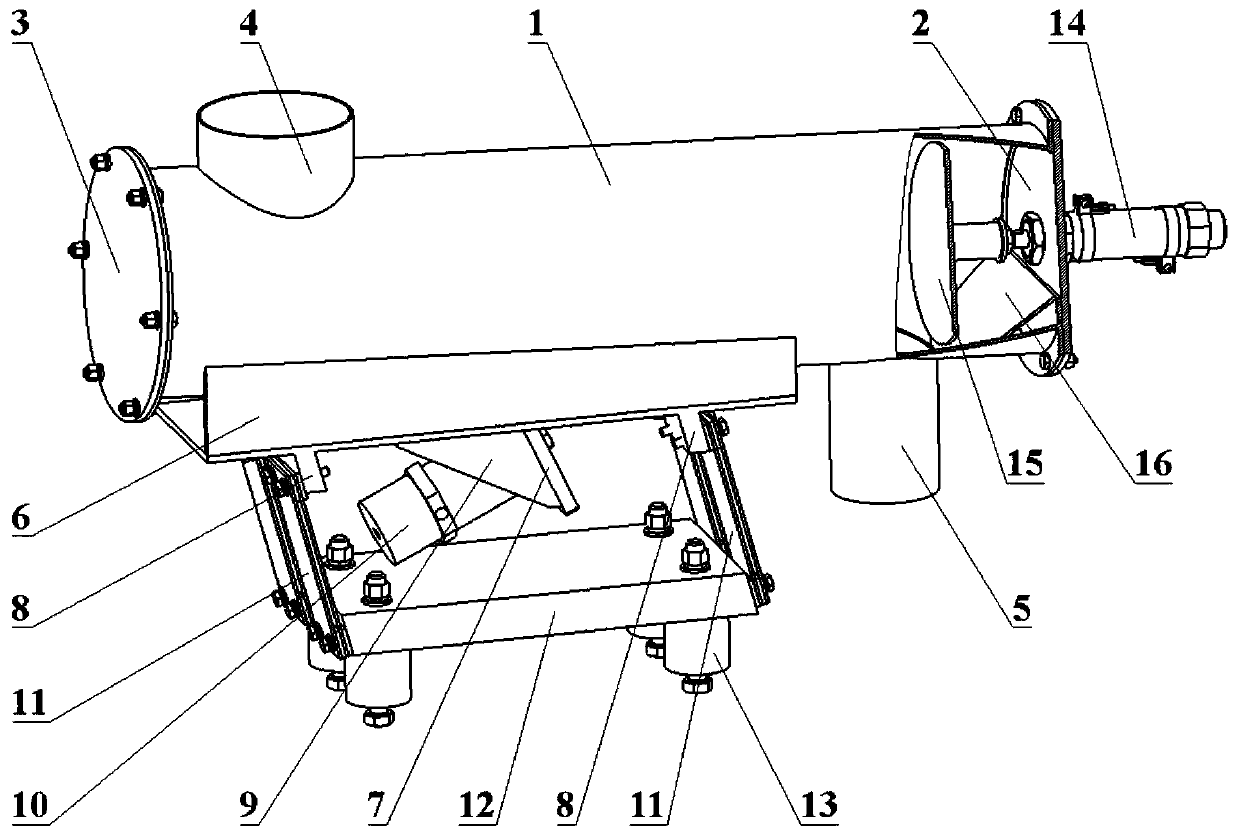

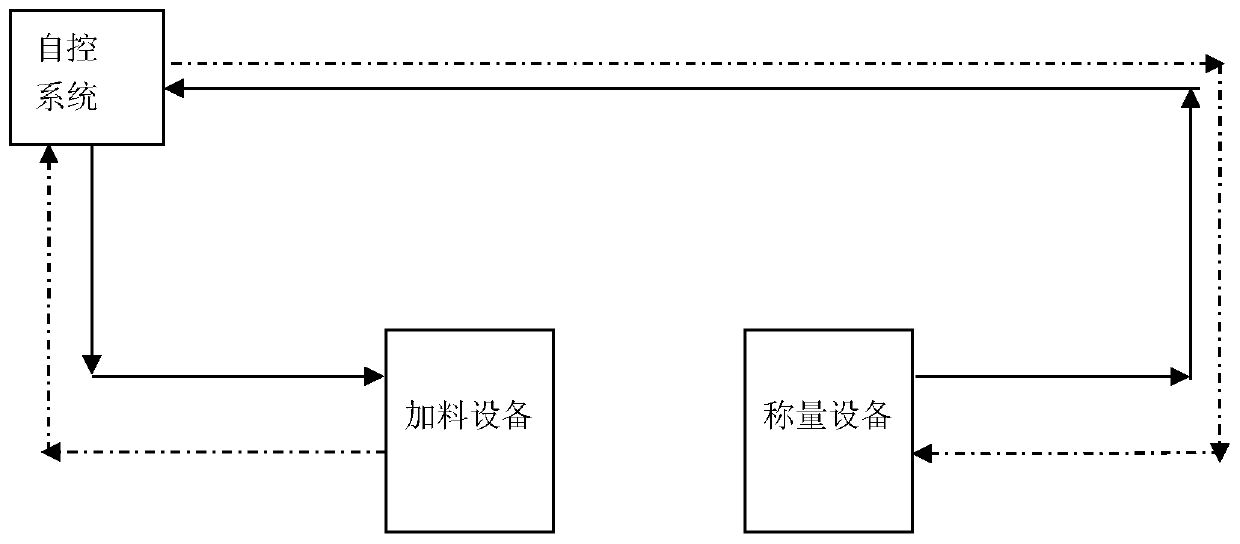

[0029] Embodiment 1: A pneumatic vibrating feeding device, including feeding equipment, weighing equipment, and an automatic control system; through the instructions given by the automatic control system, the present invention can realize the automatic work of the vibrating feeding equipment, and achieve the energy-containing powdery material. The purpose of precise metering and feeding.

[0030] The feeding equipment includes a vibrating barrel, a front cover, a rear cover, a barrel support, a vibrator mounting plate, a vibrating plate mounting plate, a material inlet, a material outlet, precise feeding components, a vibrator, a vibrating plate, a vibration damping Bottom plate, damping rubber pier;

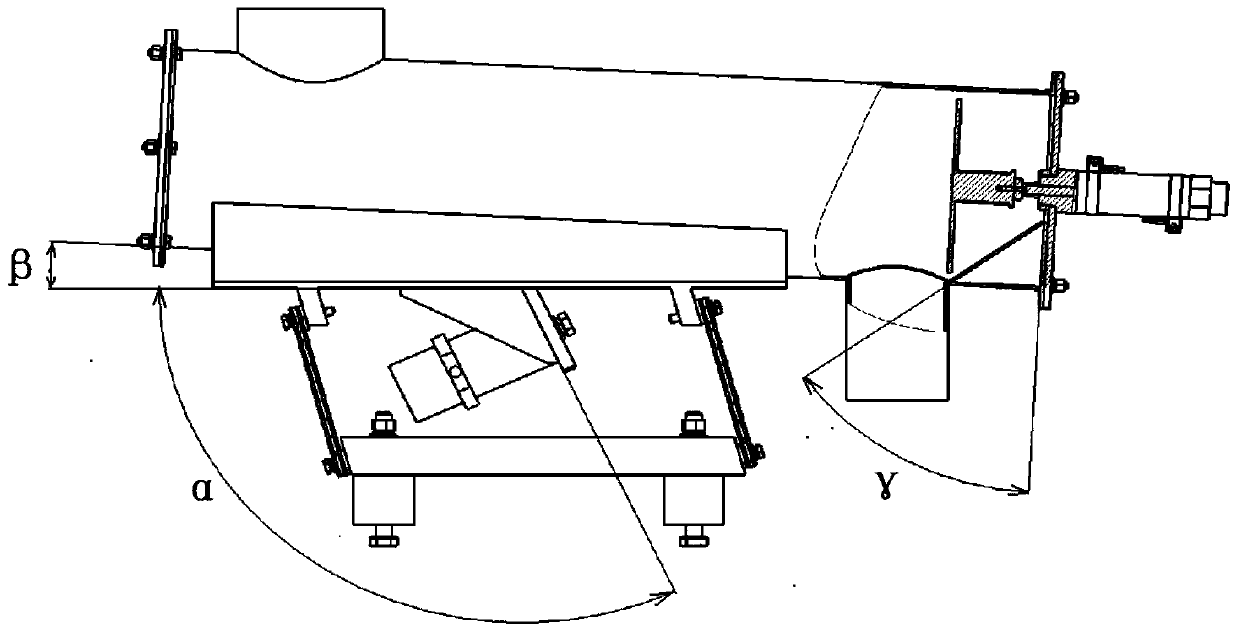

[0031] The vibrating barrel is installed on the barrel support, and the angle between the vibrating barrel and the horizontal plane is β=10°; the barrel support is arranged parallel to the horizontal plane;

[0032] The precise feeding assembly includes a cylinder, a feeding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com