Riveting tool and method for mounting bevel gear components by same

A technology for riveting tooling and bevel gears, which is applied in the field of riveting tooling and bevel gear assembly using the riveting tooling, and can solve problems such as high labor intensity, high technical requirements for operators, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

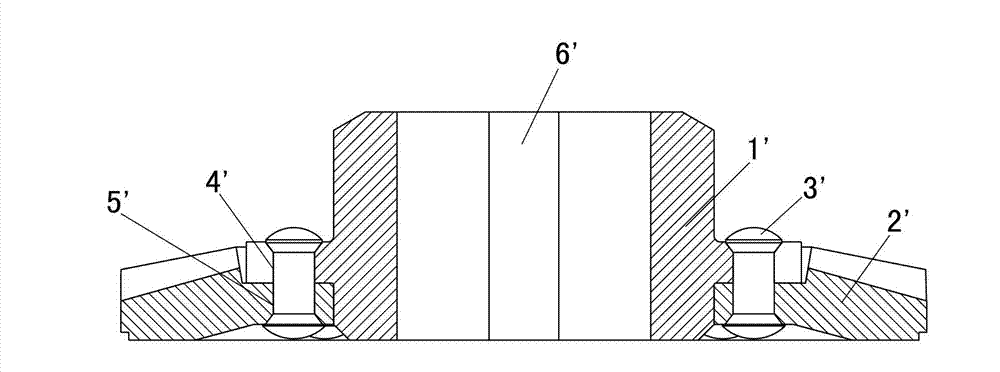

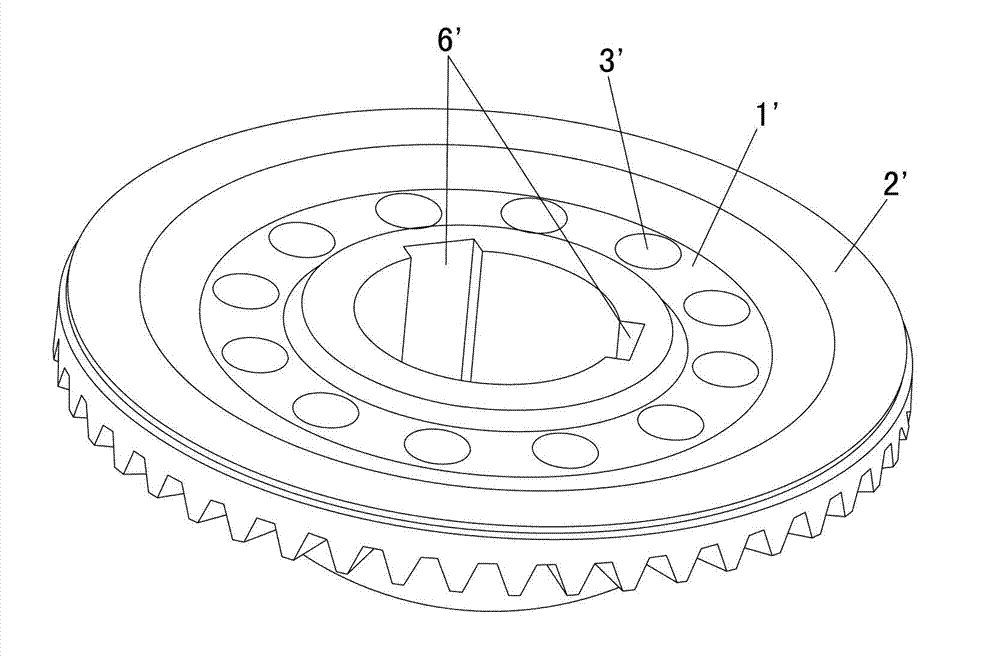

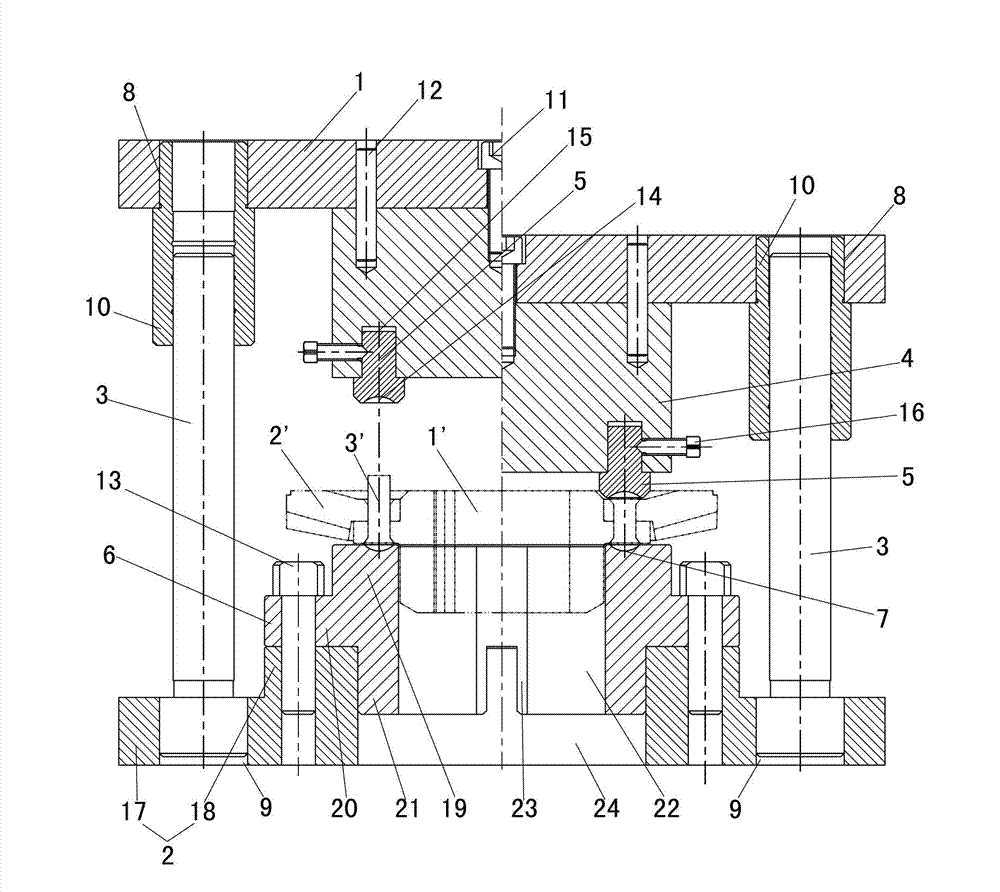

[0022] Such as image 3 with Figure 4 As shown, the riveting tooling of the present invention includes an upper template 1 and a lower template 2 distributed up and down parallel to each other.

[0023] First guide holes 8 are respectively processed on the left and right sides of the upper template 1 . Guide sleeves 10 are respectively welded in the two guide holes 8 . The lower middle part of the upper template 1 is connected with the upper mold 4 by five screws 11 and two pins 12 . Two groups of grooves 15 are processed on the bottom surface of the upper mold 4 . The number of grooves 15 in each group is three. Indenters 5 are respectively installed in each groove 15 . After six screws 16 penetrate the upper die 4 from the side of the upper die 4, they are vertically connected and fixed with each pressing head 5 respectively. Each indenter 5 is an inverted T-shaped cylinder. The bottom surface of each indenter 5 is respectively processed with a second dimple 14 . Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com