Split groove piece orbit determination loop chain hob roll riveting splicing equipment

A hob and riveting technology, which is applied to the field of hob riveting and splicing equipment for split groove parts, fixed track and chain hob, can solve the problems of non-corrosion resistance, unenvironmental production and high defect rate, and achieves a high degree of automation and improved Product quality, the effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

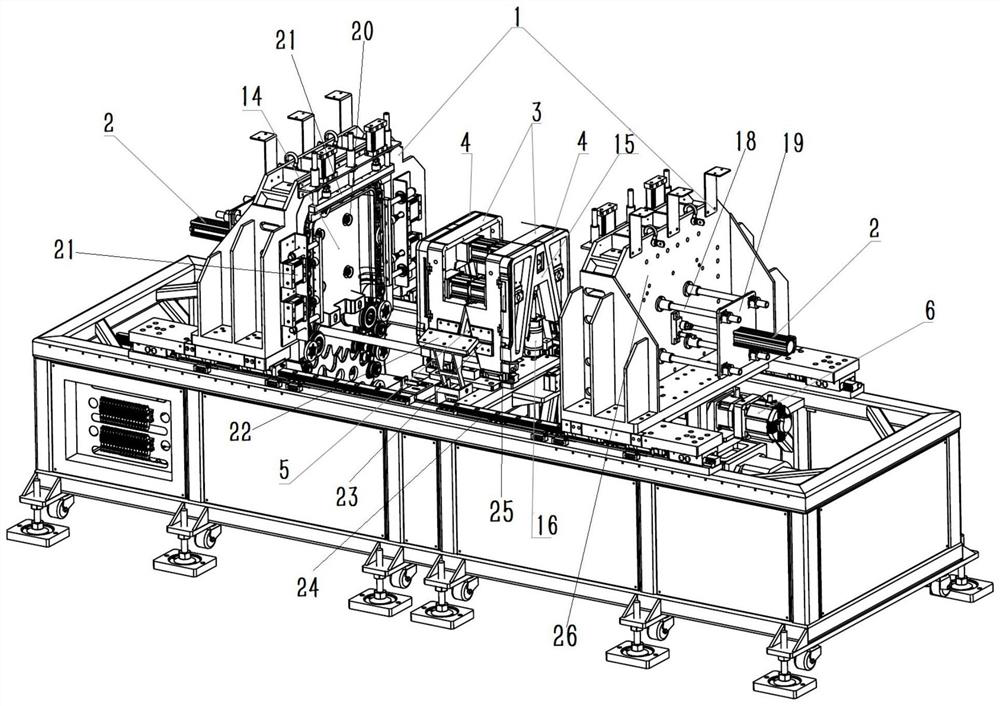

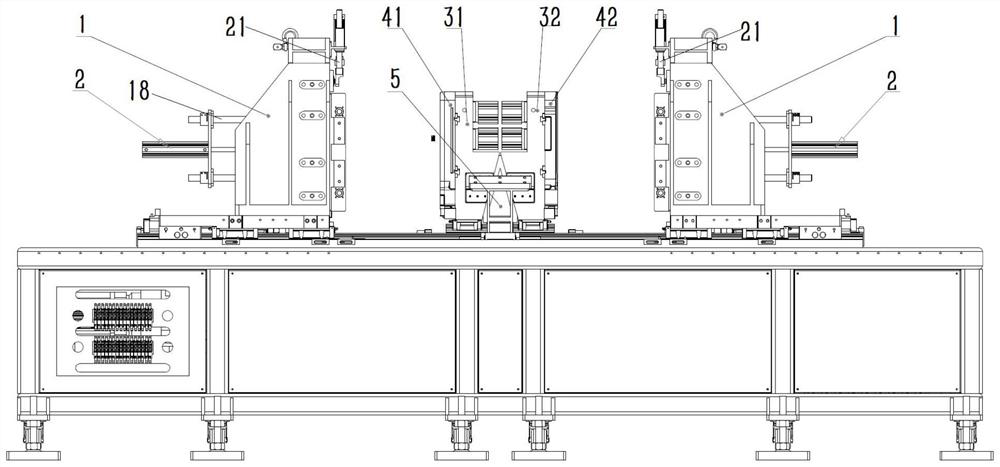

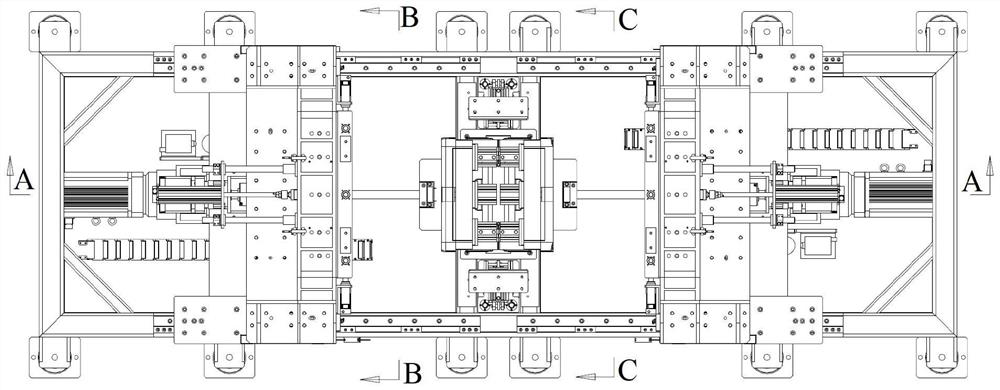

[0077] like Figure 1-7 As shown, this embodiment provides a rolling riveting and splicing equipment for a split groove piece, a fixed-track ring chain hob, and a hob. The split groove member in this embodiment includes a middle frame and cover plates on both sides of the middle frame. For the sink liner of the dishwasher and other equipment, its shape is generally a cuboid or a cube, the middle frame is a U-shaped sheet metal plate, the cover plate is a square or rectangular sheet metal plate, and the cover plate is connected to both sides of the middle frame as One piece to form the desired sink.

[0078] In this embodiment, the function of the rolling riveting and splicing equipment of the split groove piece fixed track ring chain hob is to rivete the cover plates on both sides of the middle frame to the middle frame respectively. The rolling riveting and splicing equipment of the fixed track ring chain hob of the split groove piece includes a support fixture assembly, a ...

Embodiment 2

[0114] This embodiment provides a method for riveting the water tank liner by using the split groove piece fixed track ring chain hob rolling riveting and splicing equipment of Embodiment 1, including the following steps:

[0115] S1: The manipulator grabs the middle frame and places the middle frame on the middle frame positioning fixture in the support fixture assembly.

[0116] S2: The suction assemblies on both sides of the support fixture assembly adsorb the cover plate respectively, so that the cover plate is installed in the cover plate cavity and fits into the cover plate cavity.

[0117] S3: The rolling modules on both sides of the support jig assembly move along the guide rails toward the direction close to the support jig assembly, until the support jig assembly is clamped, and the cover plate and the cover plate positioning fixture are attached.

[0118] S4: Start the power servo motor of the rolling riveting chain, drive the rolling riveting chain to rotate once, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com