Intelligent control-based multifunctional small riveting production line

An intelligent control and multi-functional technology, applied in the field of intelligent control multi-functional small riveting production line, can solve the problems that multi-type tooling cannot be exchanged and small metal products cannot be automatically riveted, so as to improve product processing quality and processing efficiency, The effect of saving manpower and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

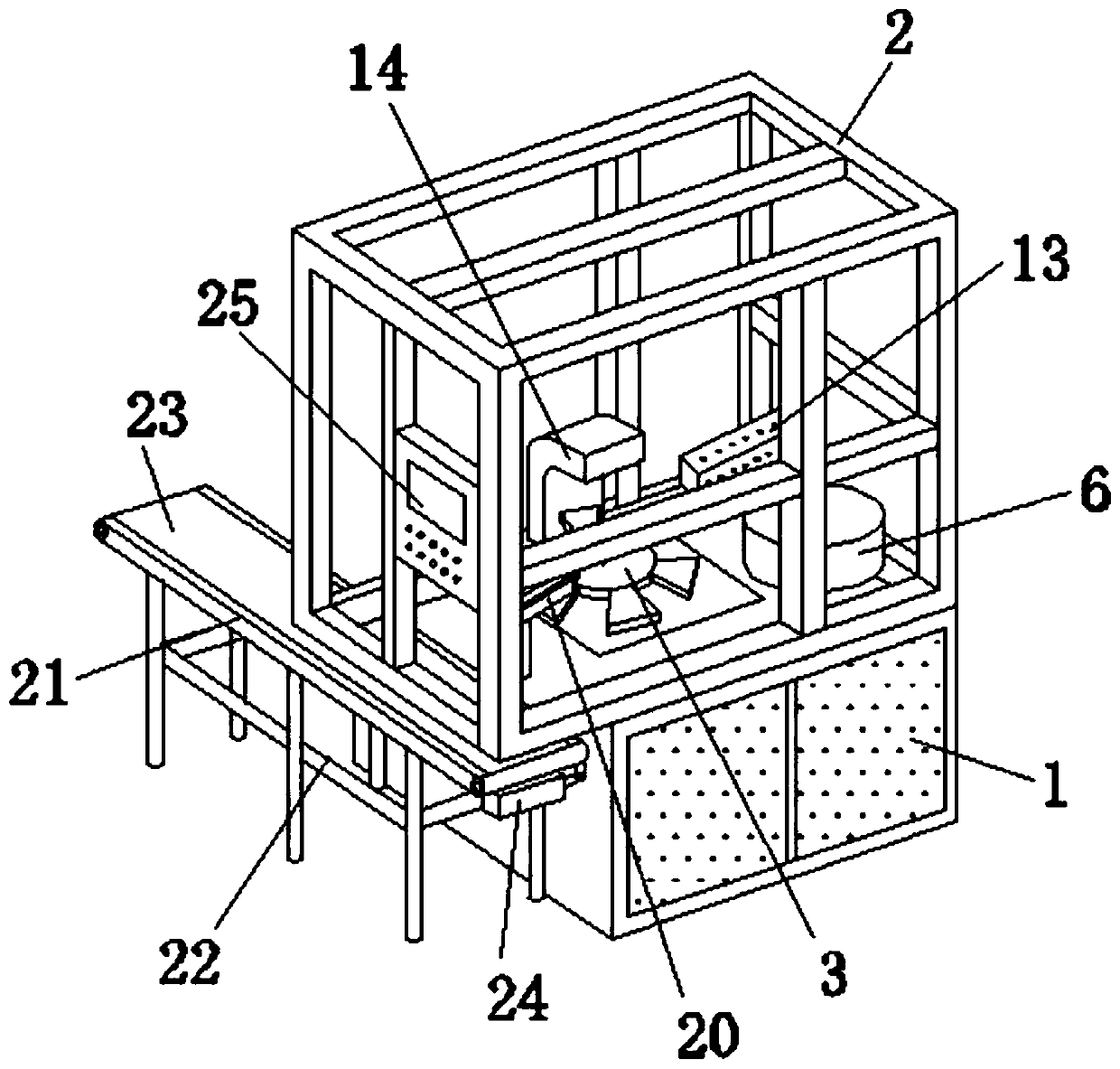

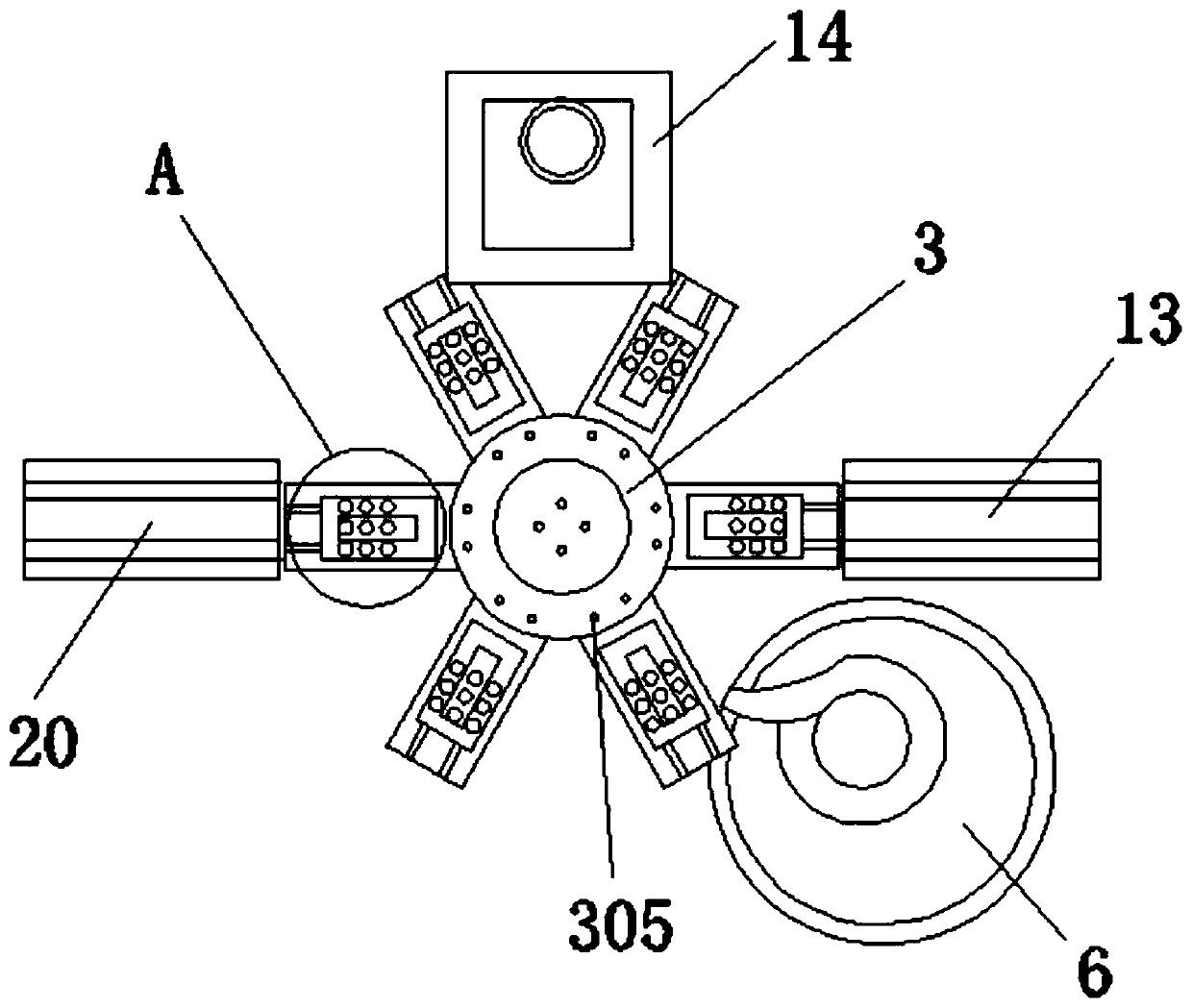

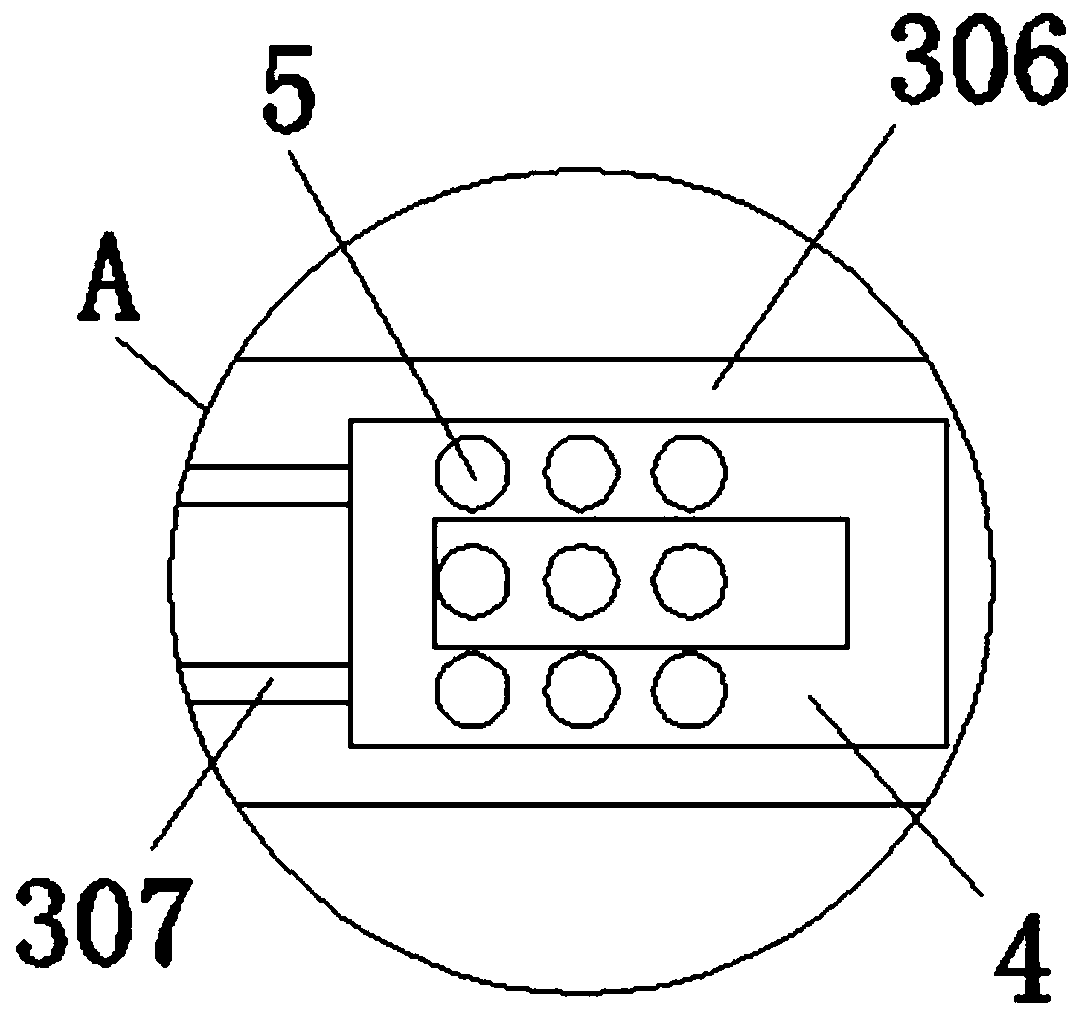

[0029] Such as Figure 1-6 As shown, the embodiment of the present invention provides an intelligent control multifunctional small riveting production line, including a lower frame 1, an aluminum alloy cover 2 is arranged on the top of the lower frame 1, an indexing device 3 is arranged at the center of the lower frame 1, and the indexing device The outer surface of 3 is equipped with a plurality of metal workpieces 4 corresponding to the accompanying tooling 306, and the center of the top of the metal workpiece 4 is provided with a plurality of riveting holes 5, and one side of the indexing device 3 is provided with a material alignment mechanism 6. One side of the degree device 3 is provided with a feeding mechanism corresponding to the material alignment mechanism 6, and a hydraulic riveting mechanism 14 is installed on the side opposite to the material alignment mechanism 6, and the center of the lower frame 1 is aligned with the feeding mechanism 6. A blanking mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com