Self-starting radial riveting work station and riveting method

A self-starting, workstation technology, applied in the field of measuring equipment, can solve problems such as shortening processing time, and achieve the effect of improving safety and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

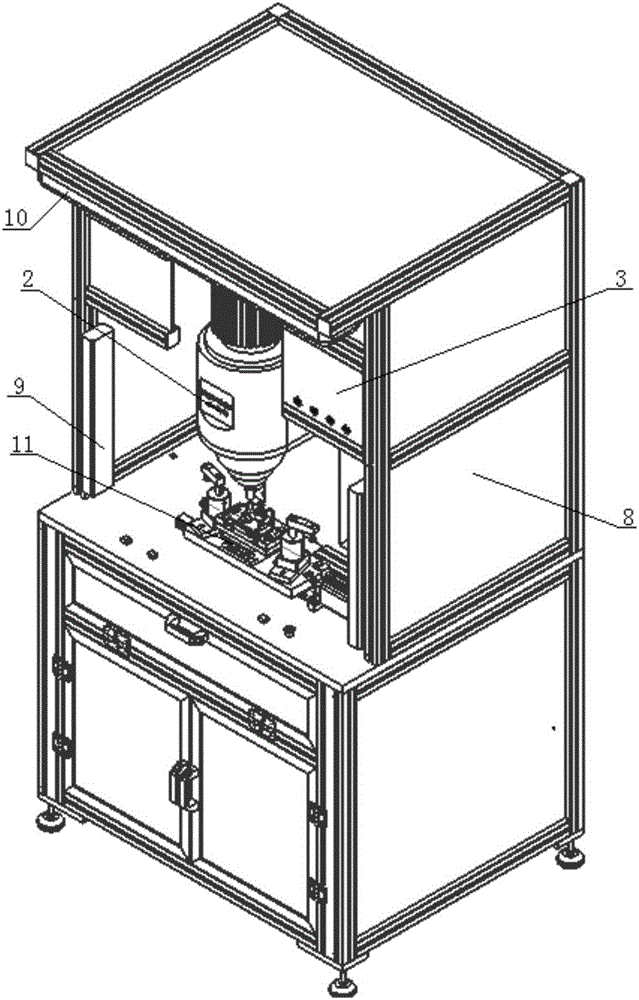

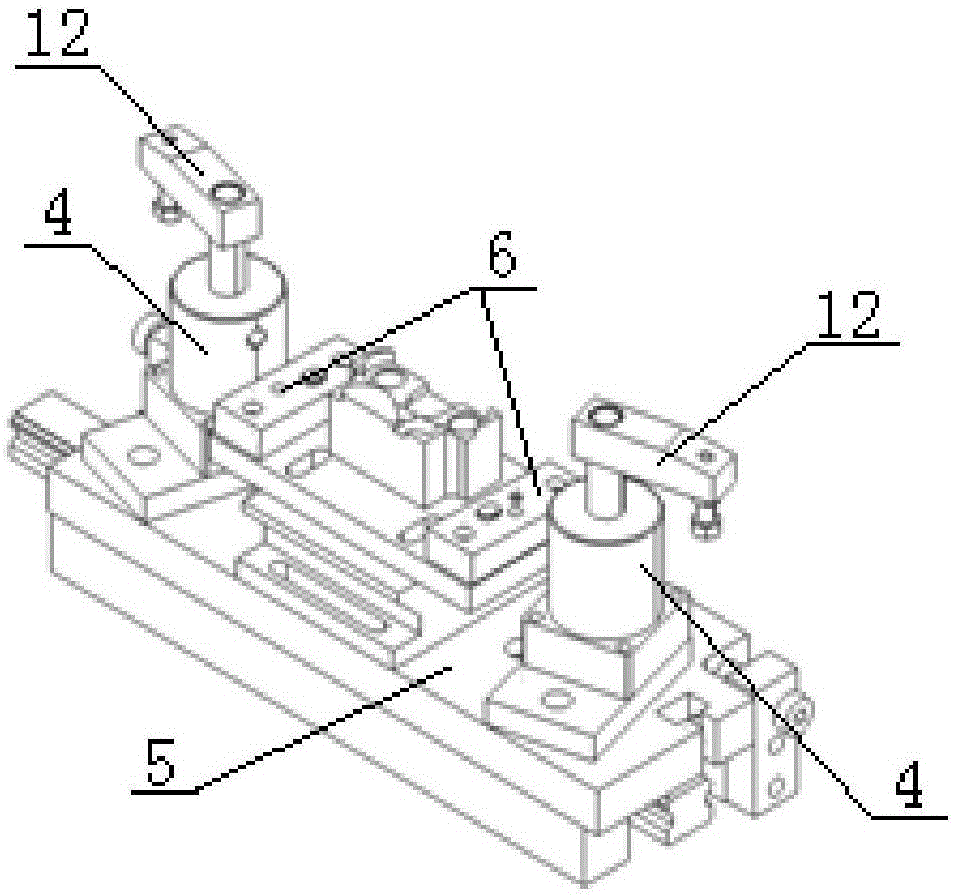

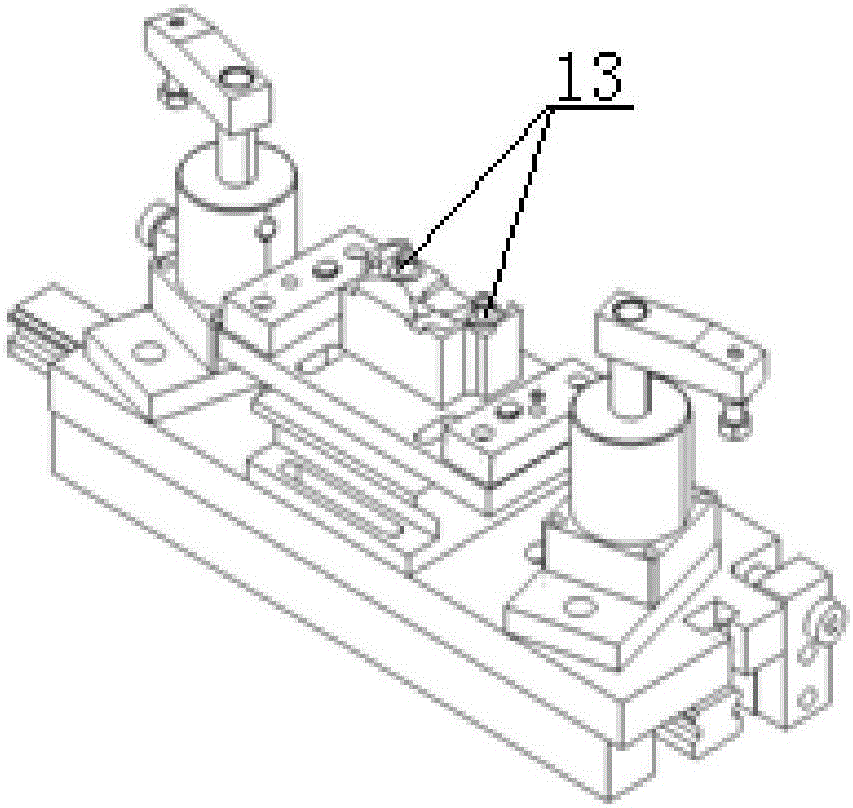

[0032] refer to Figure 1 to Figure 7 As shown in the figure, the self-starting radial riveting workstation in an embodiment provided by the present invention includes a workbench, a riveting fixture, a riveting machine and a control system. Above, there is a safety grating on the worktable; among them, the riveting fixture includes a pressing cylinder and a sliding clamp, the pressing cylinder is arranged on both sides of the sliding clamp, the sliding clamp is provided with a proximity sensor, and the piston rod of the pressing cylinder is provided with The control system is respectively connected with the safety grating, the pressing cylinder, the proximity sensor and the riveting machine; the riveting fixture realizes the accurate alignment of the riveting position and the riveting machine, and the control system detects whether the assembly parts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com