Positioning device for spiral case oil guide groove and riveting system

A technology of positioning device and oil guide groove, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, poor riveting quality, etc., and achieves reduced labor intensity and high production efficiency. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

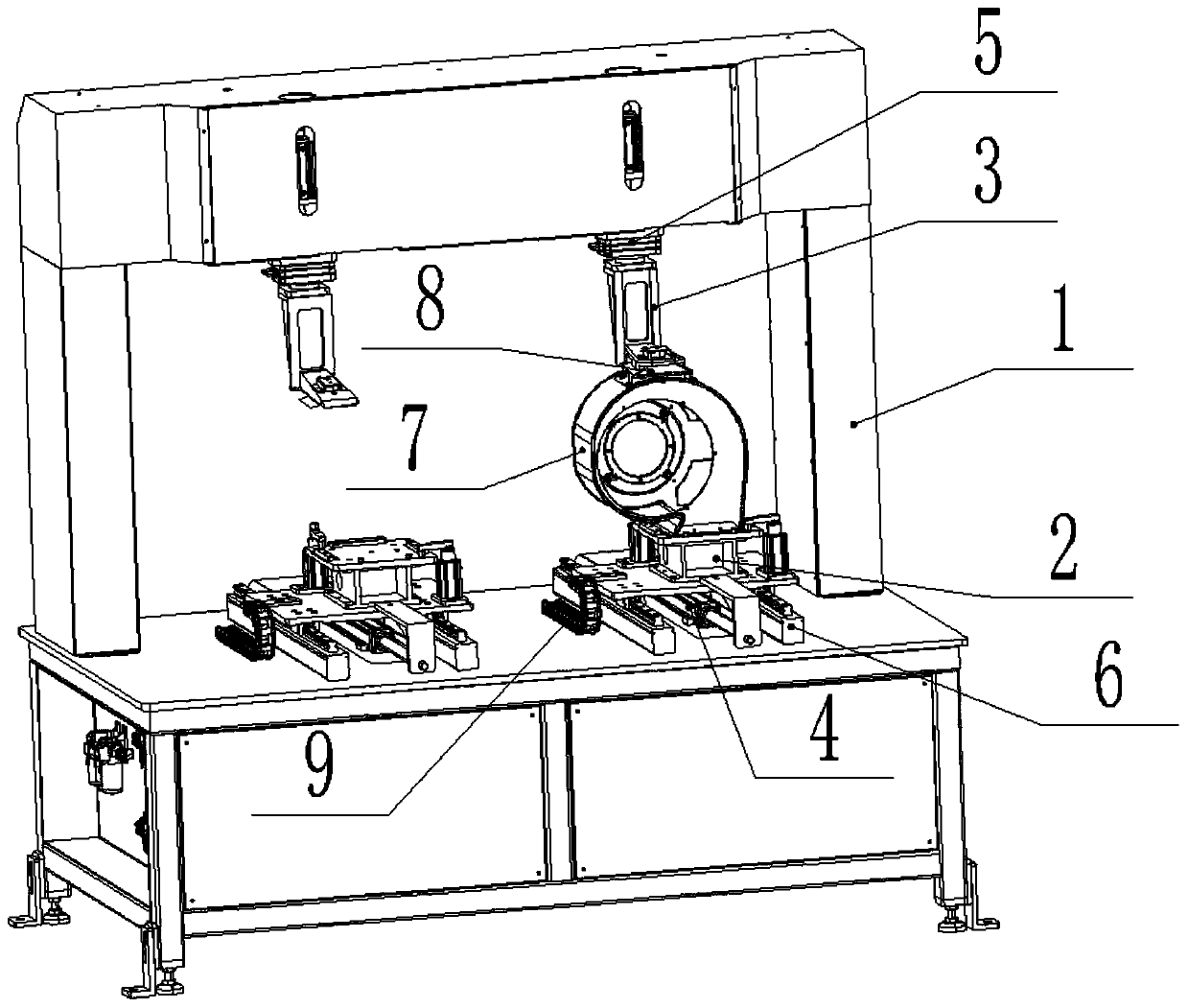

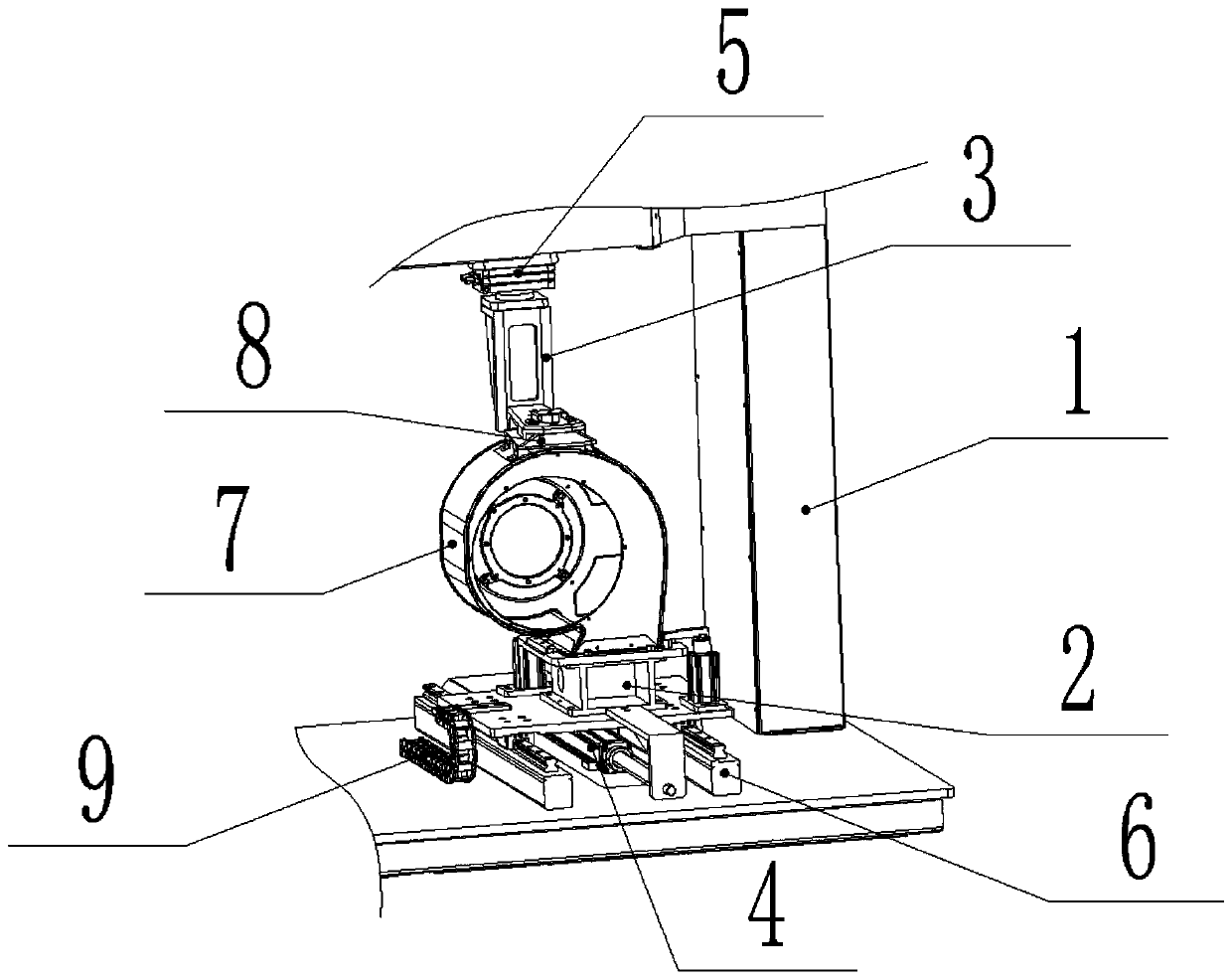

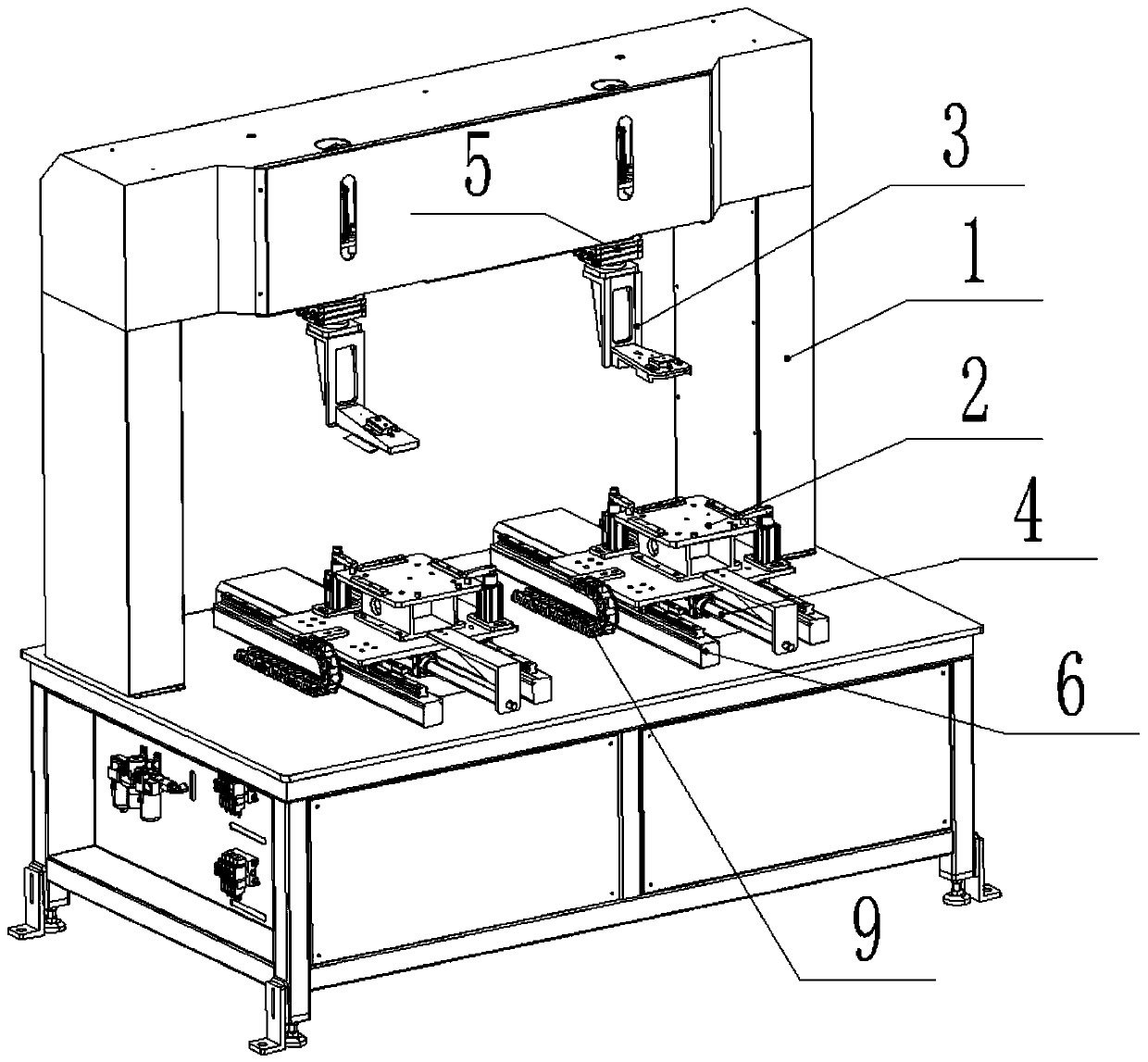

[0038] Such as Figure 1-7 As shown, a volute oil guiding groove positioning device provided in this embodiment includes:

[0039] fuselage 1;

[0040] A positioning and clamping mechanism 2 for positioning and clamping the volute 7;

[0041] The first driving mechanism 4 is arranged on the body 1 and connected with the positioning clamping mechanism 2, and is used to drive the positioning clamping mechanism 2 to move linearly;

[0042] A clamp mechanism 3 for positioning and clamping the oil guide groove 8;

[0043] The second driving mechanism 5 is arranged on the body 1 and connected with the clamp mechanism 3 for driving the clamp mechanism 3 to move linearly.

[0044] When riveting in this embodiment, the positioning and clamping mechanism 2 realizes the positioning and clamping of the volute 4, and the clamp mechanism 3 realizes the positioning and clamping of the oil guide groove 8, which is stable and reliable, and improves the riveting efficiency and riveting of th...

Embodiment 2

[0060] Such as Figure 1-8 As shown, a volute oil guide groove riveting system provided in this embodiment includes the volute oil guide groove positioning device described in Embodiment 1, and also includes a riveting and retrieving device. The riveting and retrieving device includes a robot 10 and the The riveting pliers and the retrieving clip connected with the robot 10, wherein the riveting pliers and the retrieving clip are integrated into an integrated structure, corresponding to Figure 8 The reference numeral 11 in the figure, and the robot 10 is installed on the ground through the base 12, and the robot 10 adopts the IRB6700 robot of Shanghai ABB Engineering Co., Ltd. During riveting, the volute oil guide groove positioning device realizes the positioning and clamping of the volute 7 and the guide groove 8, and the riveting pliers are controlled by the robot 10 to complete the riveting of the volute 7 and the guide groove 8; The finished product is removed, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com