Assembly riveting machine

A riveting press and riveting press technology, applied in the field of assembly riveting, can solve the problems of poor riveting quality, deformation of riveting parts, and insufficient assembly, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

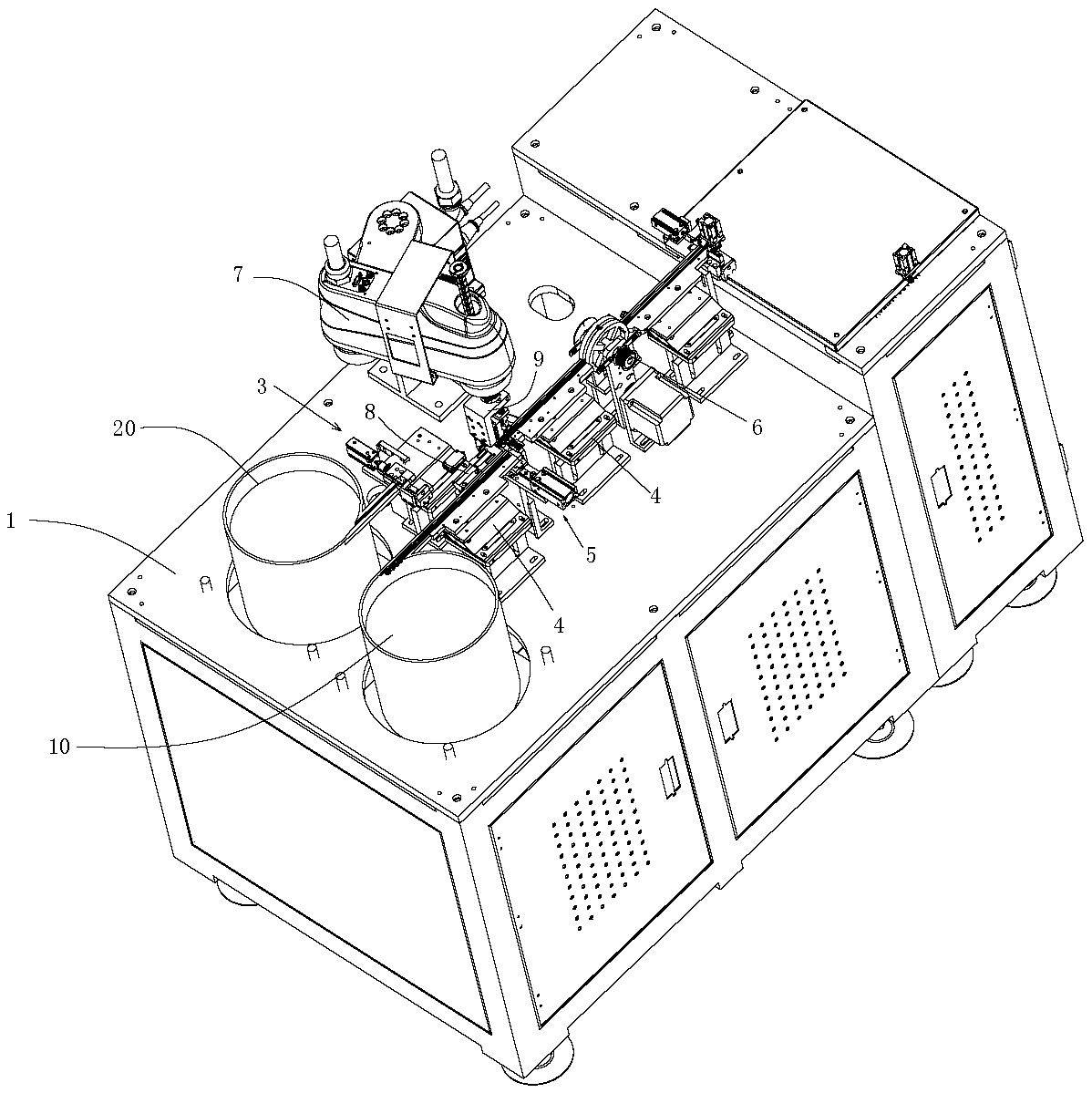

[0033] Embodiment: a kind of assembling riveting press machine, it comprises:

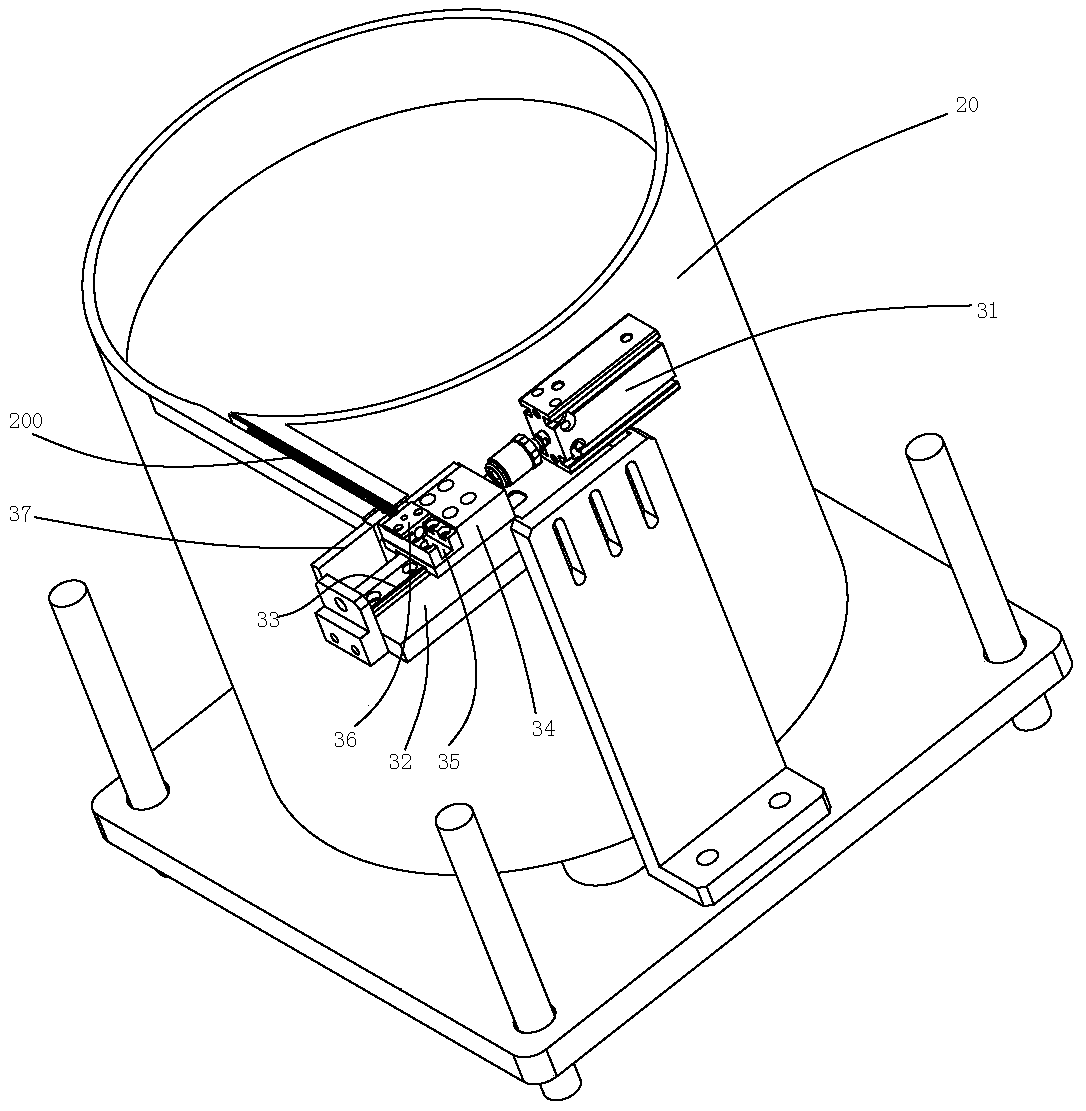

[0034] The first vibration plate 20 for transporting the connection core 200, the outlet of the first vibration plate 20 is connected with the receiving device 3 for receiving the connection core 200;

[0035] The second vibrating plate 10 for transporting the collar 100, the outlet of the second vibrating plate 10 is connected with the guide block 56 for transporting the collar 100;

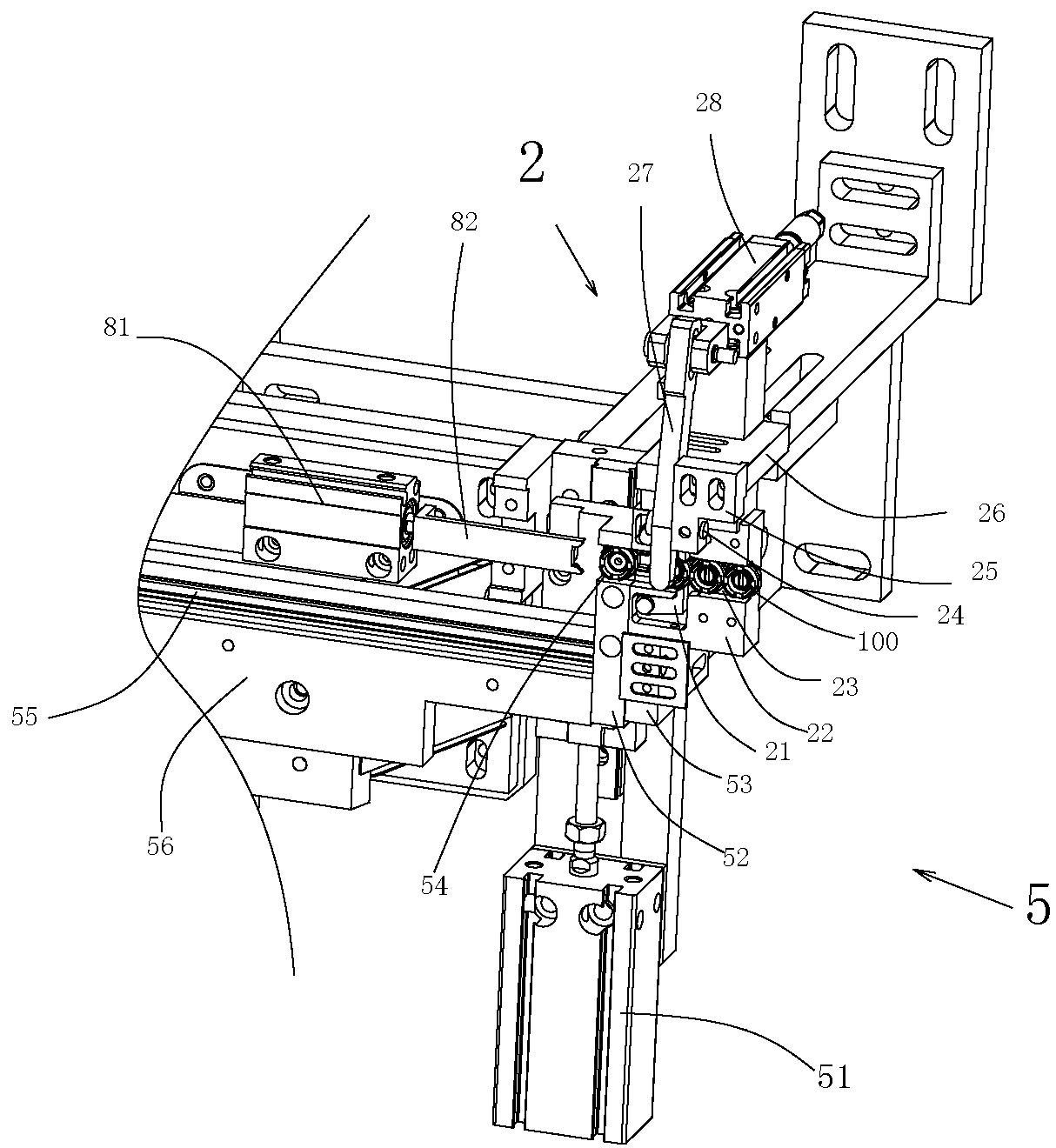

[0036] see figure 2 , the collar transfer device 5 includes a receiving block 57, the receiving block 57 is provided with a mounting hole 54 for accommodating the collar 100 and openings on both sides, and the receiving block 57 is connected with a longitudinal direction for driving the receiving block 57 to move to the assembly station Linear module 51; the longitudinal linear module 51 can adopt cylinder;

[0037] The connection core transfer device includes a clamp for clamping the connection core 200 and a mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com