Automatic riveting method and automatic riveting device

A technology of riveting and equipment, applied in the field of mechanical processing, can solve the problems of manual clamping difficulties, low production efficiency, low production efficiency, etc., and achieve the effect of ensuring the accuracy of riveting, maintaining the correct direction, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

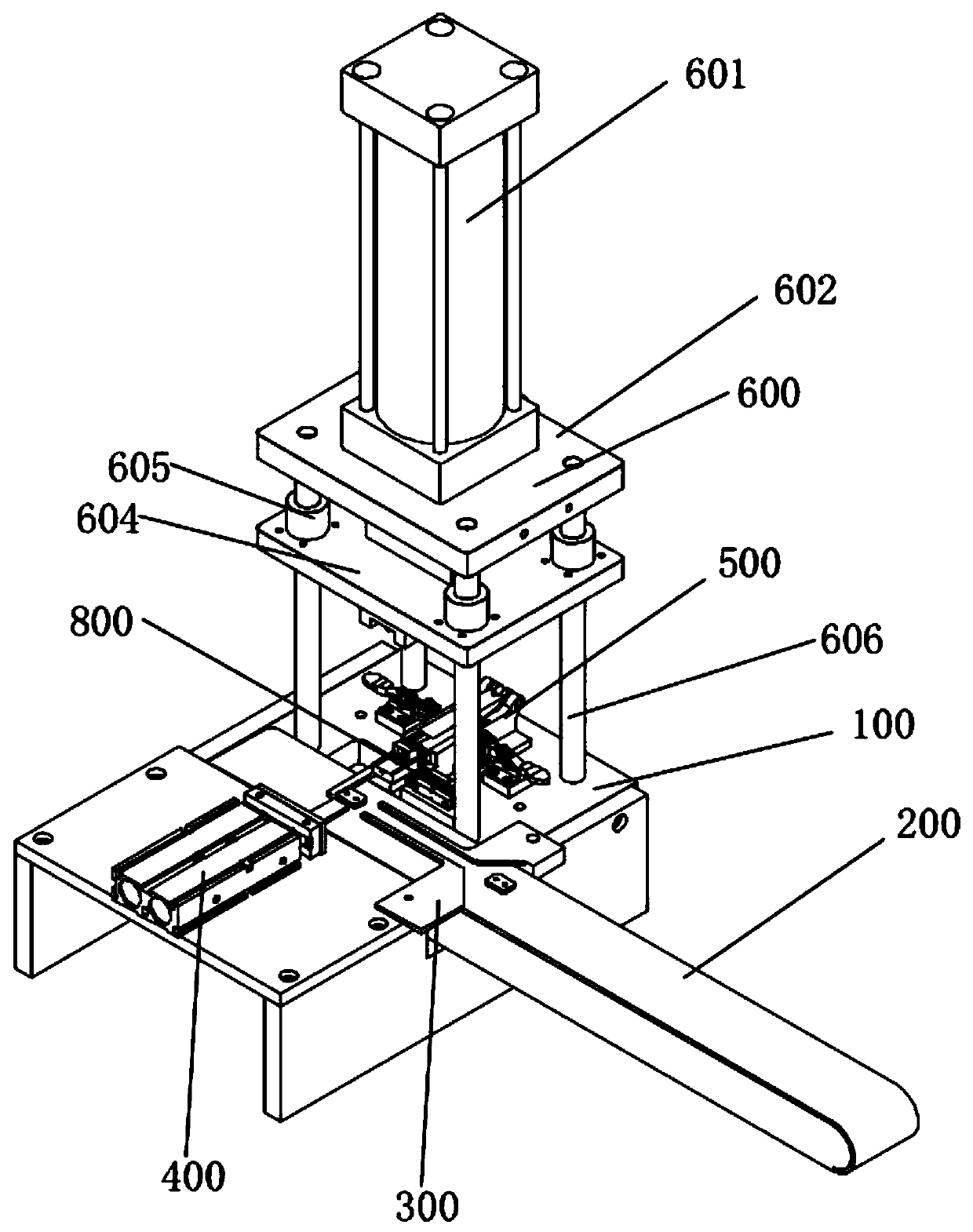

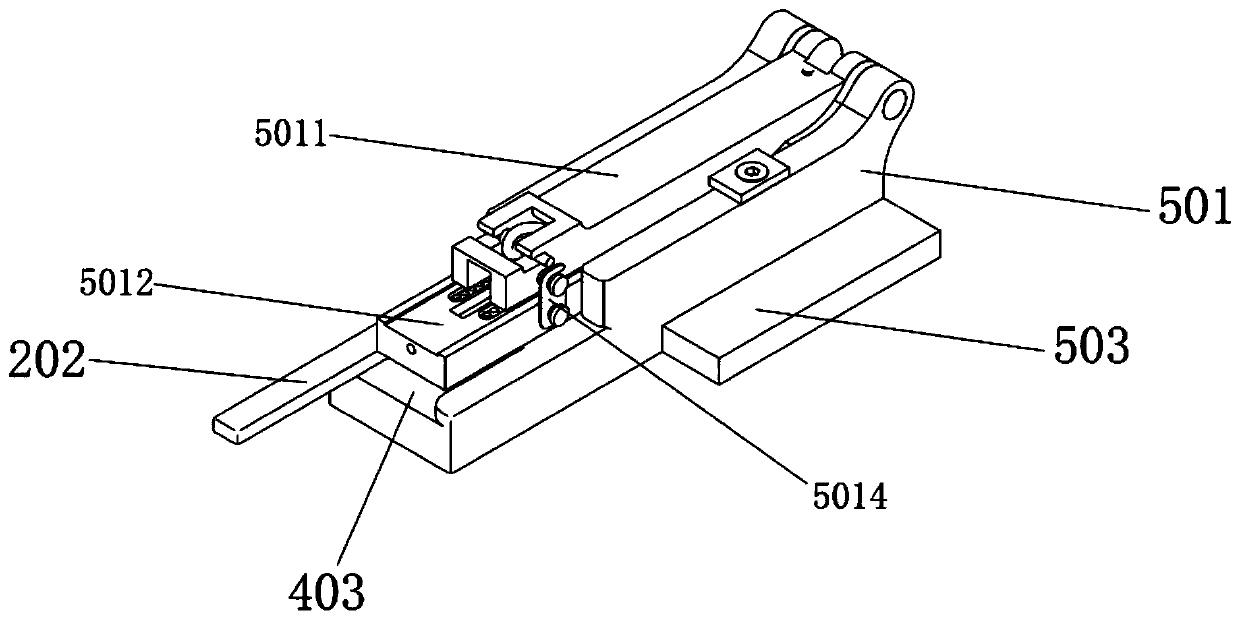

[0050] refer to figure 1 and Figure 7 , the automatic riveting equipment includes a bracket and a transmission mechanism 200, a direction correction mechanism 300, a workpiece clamping mechanism 400, a rivet clamping mechanism 500, a riveting mechanism 600, a positioning mechanism 700 and a blanking mechanism respectively arranged on the bracket 100. Collection agency 800.

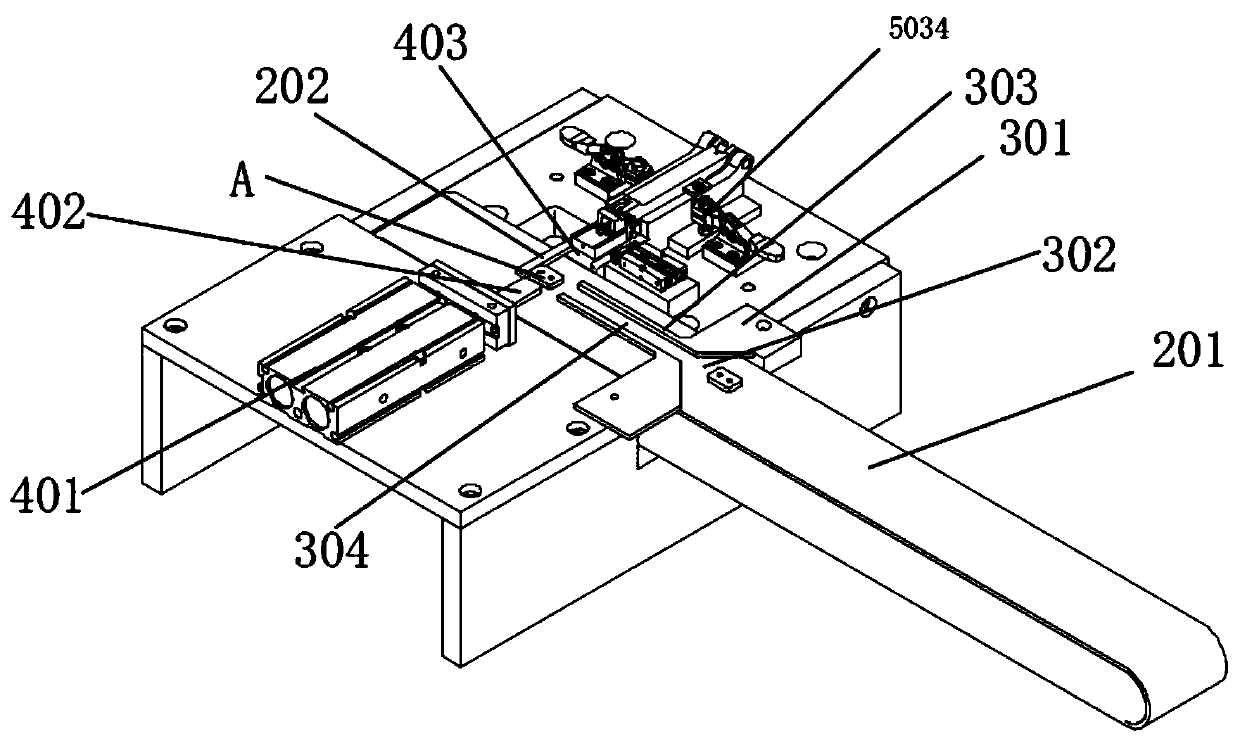

[0051] refer to figure 2 , the transmission mechanism includes a conveyor belt 201 for transporting the workpiece A and a material stop block 202 for stopping the workpiece, and the material stop block is arranged at the rear end of the conveyor belt and fixed above the conveyor belt.

[0052] refer to figure 2 , the direction correction mechanism includes a funnel-shaped correction groove 302 composed of two inclined blocks 301 with a wide front and a narrow rear, and an equal-width guide groove 304 with a width slightly larger than the width of the workpiece formed by two convex strips 303 arranged...

Embodiment 2

[0062] An automatic riveting method based on the above-mentioned automatic riveting equipment, comprising the following steps:

[0063] Step 1. Fix the rivet box loaded with rivets on the bracket. Specifically, the rivet box loaded with rivets is fixed on the interchangeable body, and then the interchangeable body is fixed on the bracket through quick clips.

[0064] Step 2, the conveyor belt transfers the workpiece.

[0065] Step 3. When the workpiece passes through the calibration groove, the calibration groove corrects the direction of the workpiece. The corrected workpiece is also guided to the stop block through the guide groove.

[0066] Step 4. The material stop block intercepts and stops the workpiece on the conveyor belt that has undergone direction correction and direction maintenance.

[0067] Step 5, the first driving cylinder drives the feeding block to push the stopped workpiece into the acupuncture point.

[0068] Step 6. The second driving cylinder drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com