Automatic rivet pulling device

An automatic and mounting frame technology, applied in the field of machining, can solve the problems of poor riveting quality, high labor intensity and low efficiency, and achieve the effect of compact overall structure and size, high versatility and simple control form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

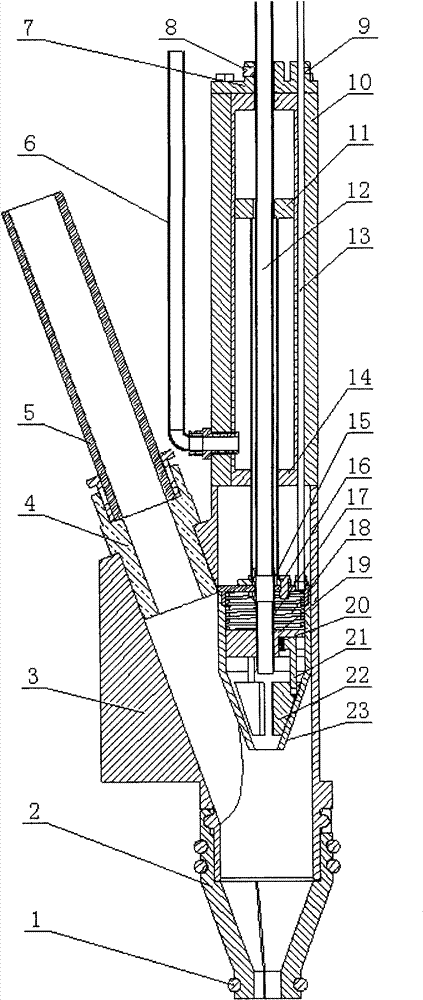

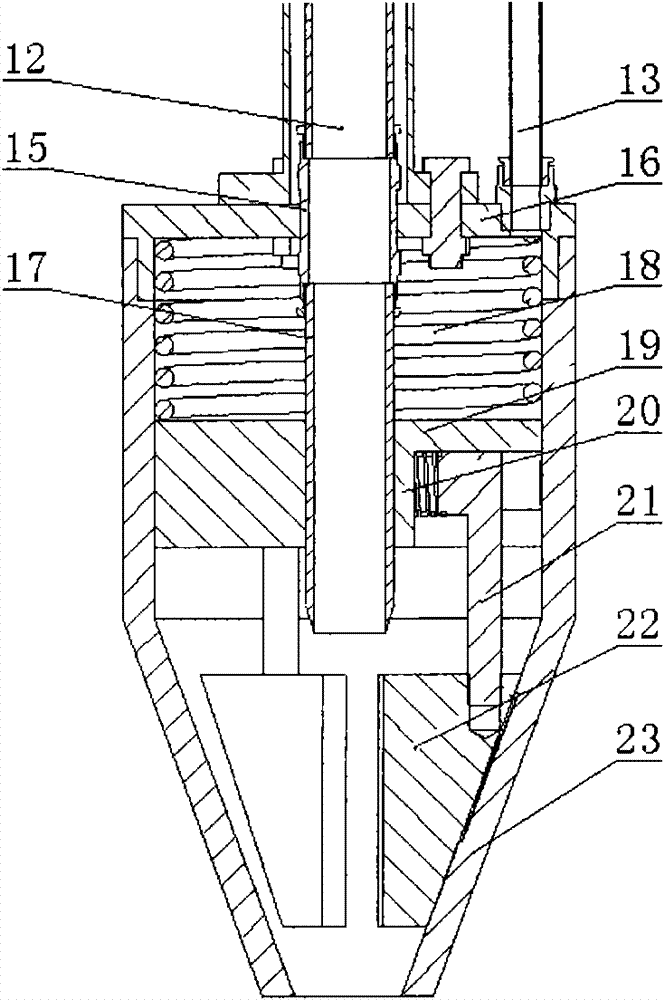

[0027] The automatic riveting device adopted in this embodiment includes a riveting chamber, a riveting chuck, a power unit and a core ejector tube 12 .

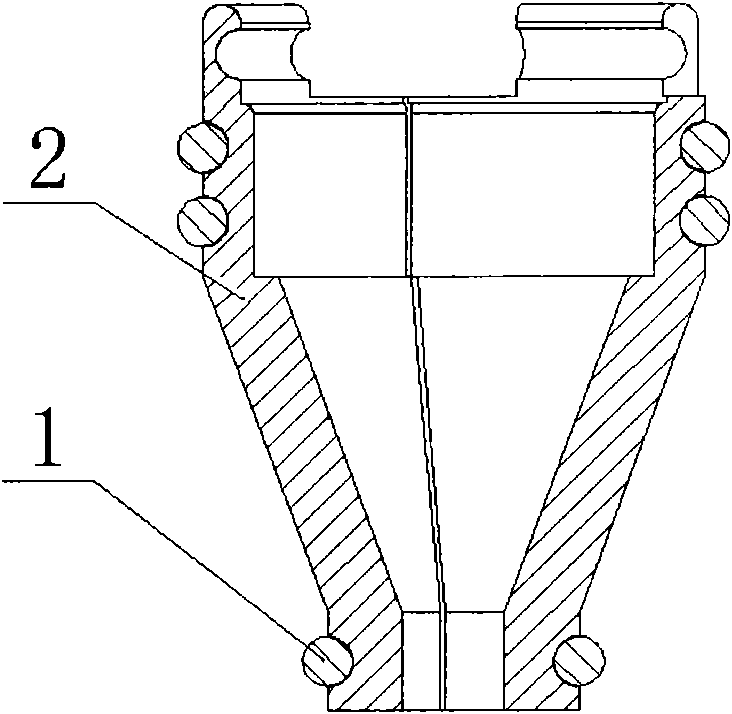

[0028] Refer to attached figure 1 , The riveting cavity includes a shell 3 and a separate collet, wherein the shell 3 has a through hole and an oblique hole, the oblique hole communicates with the through hole, and the central axis of the oblique hole intersects the central axis of the through hole. The through hole is the movement area of the riveting chuck, and the outer end of the inclined hole is used to clamp the joint 4, which communicates with the external high-pressure pneumatic riveting tube 5, so that the rivets enter the inclined hole through the external riveting tube 5 if needed. Obviously, the direction of the inclined hole should be towards the direction of the split collet, so that the fed rivet can be inserted into the split collet. In addition, in order to effectively feed the rivet from the inclined hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com