Automatic assembly machine of solar panel frame

An automatic assembly machine and solar panel technology, applied to metal processing equipment, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, large output of flat-panel solar panels, etc., and achieve the effect of good product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

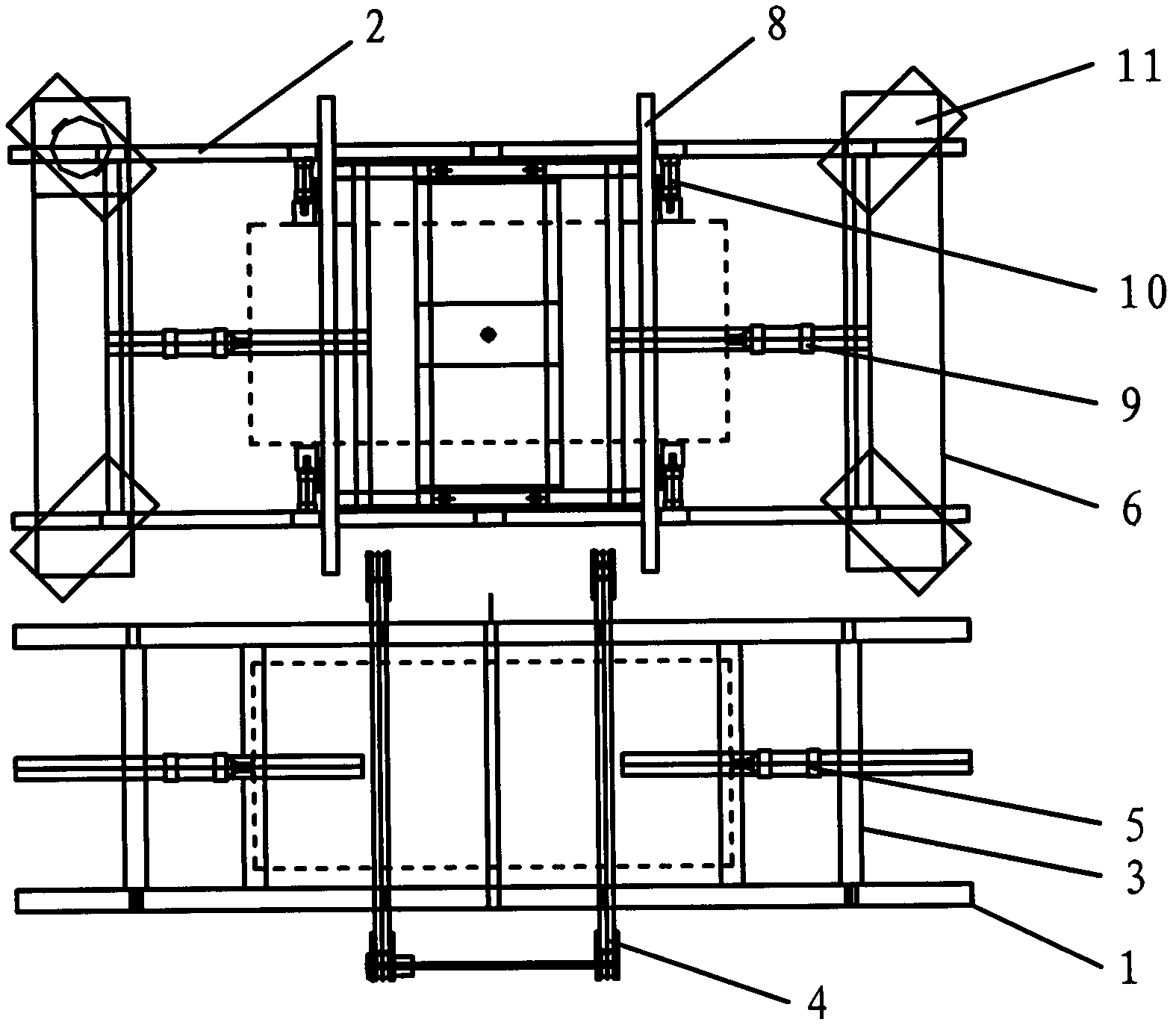

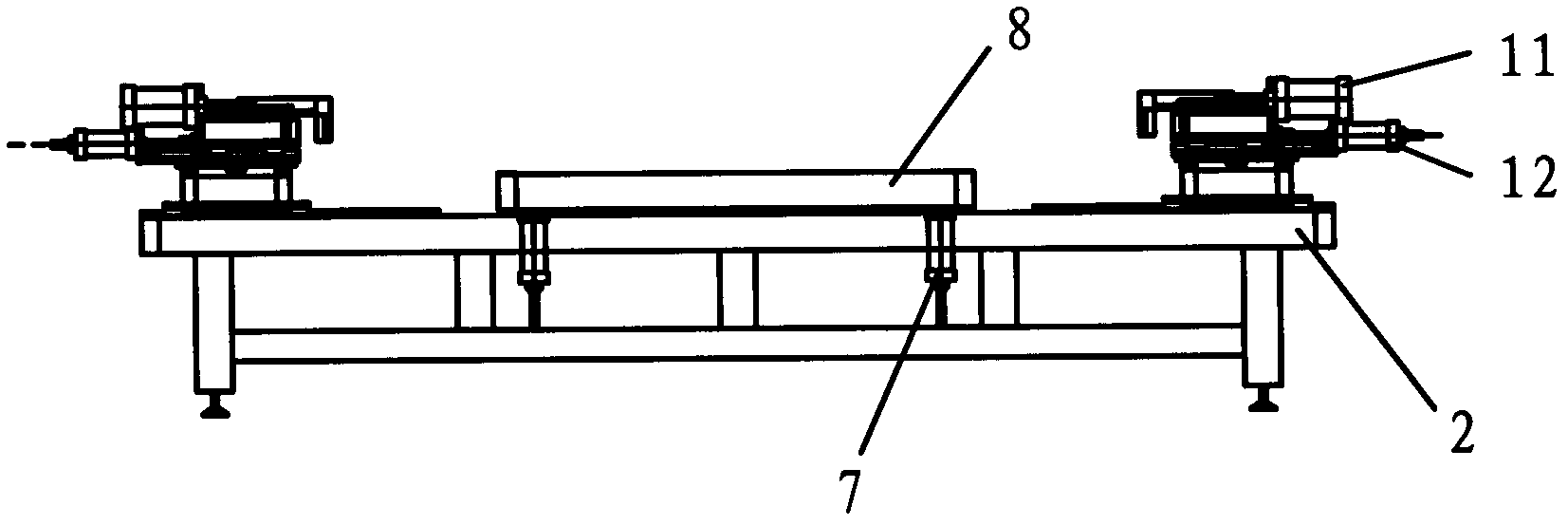

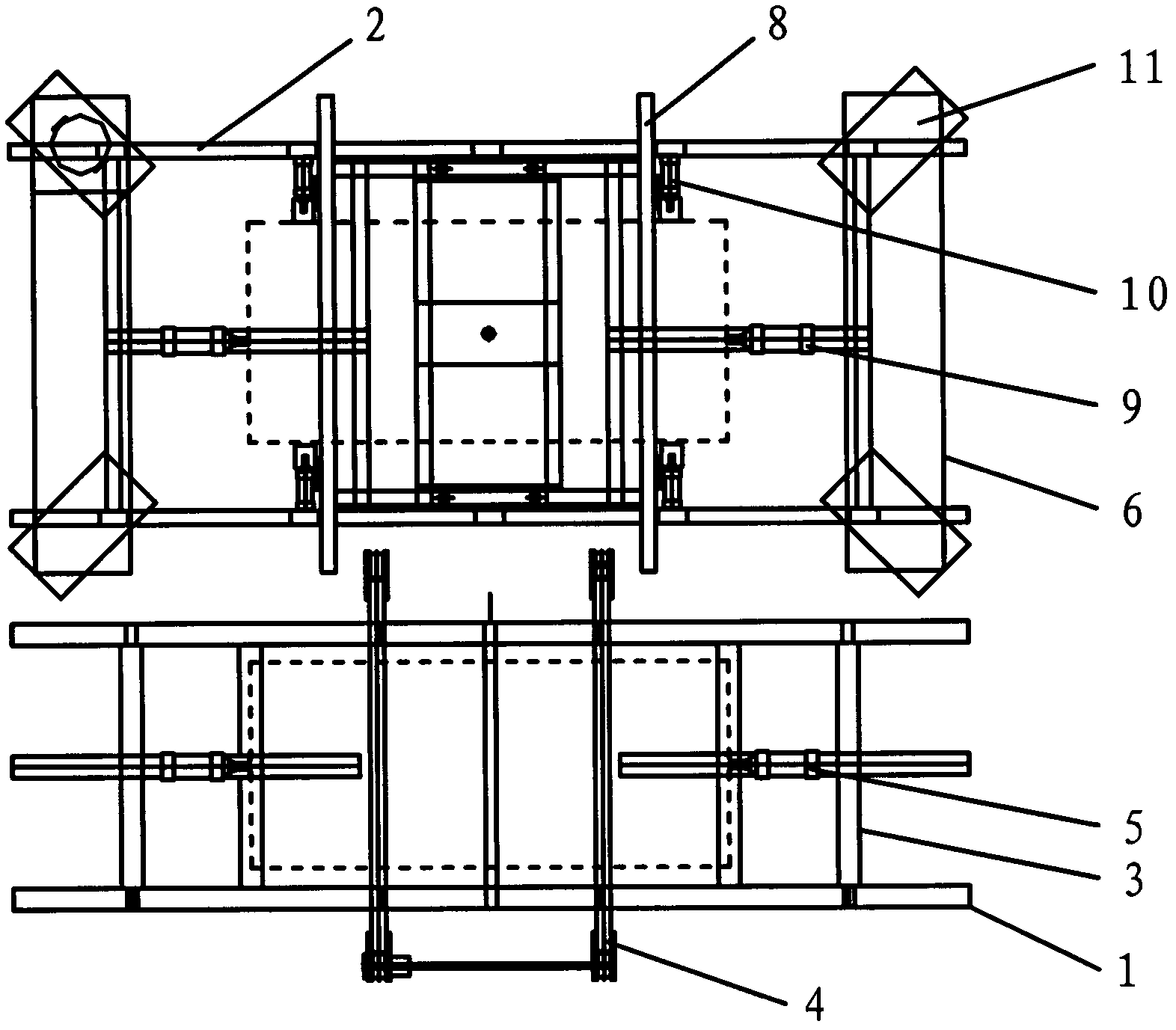

[0012] An automatic solar panel frame assembly machine, including a pre-installation station 1 and an assembly station 2, the pre-installation station 1 includes a frame 3, a power belt 4 is provided in the middle of the top of the frame 3, and pre-positioning cylinders are provided on both sides of the power belt 4 5; the assembly platform 2 includes a frame 6, a belt conveyor 8 is provided in the middle of the top of the frame 6, a lifting cylinder 7 is provided at the bottom of the belt conveyor 8, a left and right positioning cylinder 9 is provided in the middle of both sides of the belt conveyor 8, and the belt conveyor 8 is two The front and rear ends of the side are provided with a flap cylinder 10 for front and rear positioning, and the diagonal position of the belt conveyor 8 is provided with four riveting cylinders 11, and the bottom of the riveting cylinder 11 is provided with an adjustment cylinder 12 and an adjustment handwheel. A flap is provided, and an induction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com