A method for press-fitting and assembling gas meter metering chamber shells

A combined method and technology of measuring chambers, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve problems such as low efficiency and insufficient quality assurance capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

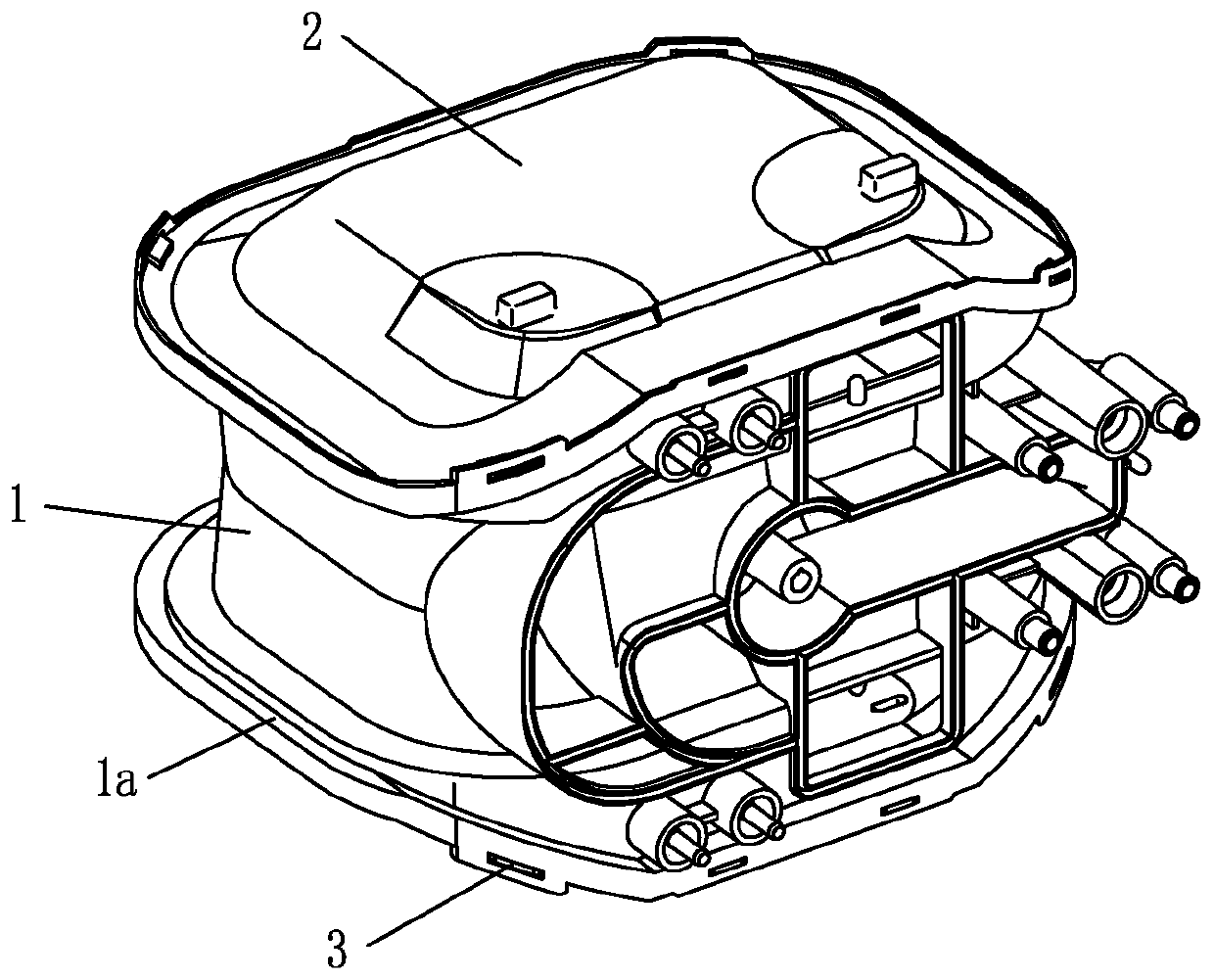

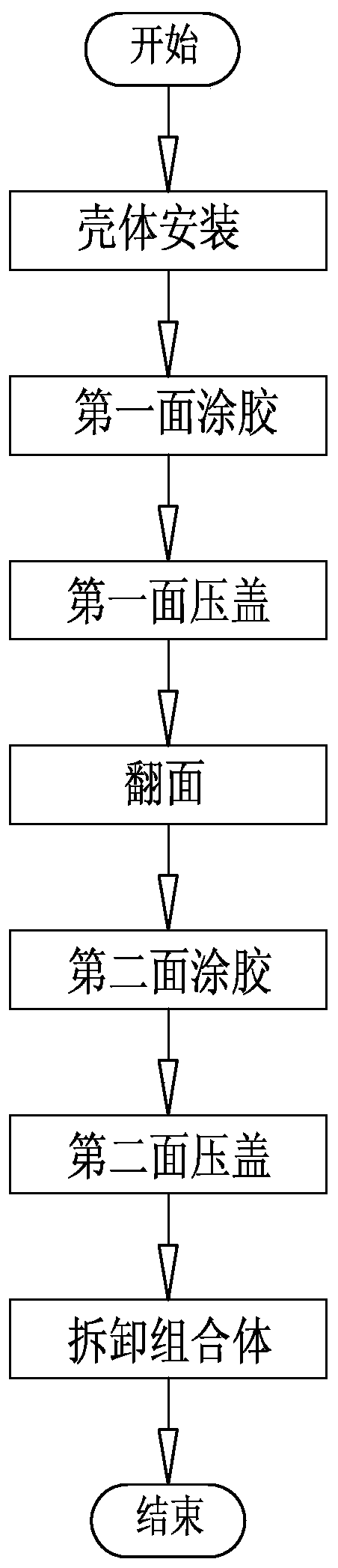

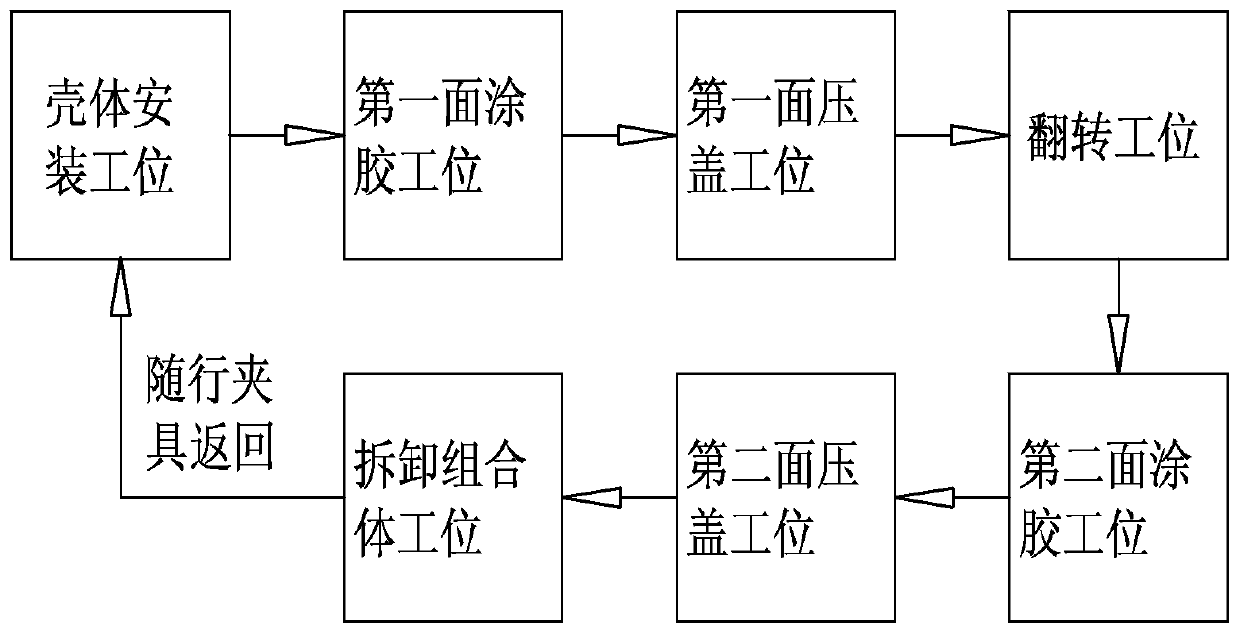

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a gas meter metering chamber casing press-fit combination method for combining the metering chamber casing 1 and the metering chamber cover on a press-fit assembly line to form a metering chamber casing assembly; comprising the following steps:

[0026] S1. Housing installation: At the housing installation station, the first side of the housing is facing upwards, and the measuring chamber housing 1 is fixed on the accompanying fixture 100 to form a clamp assembly;

[0027] S2. Gluing on the first side: at the first side gluing station, the first gluing machine 200 automatically applies gluing to the first side of the metering chamber housing 1 and heats it at a low temperature to make the colloid form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com