Rivet pipe file binding machine capable of automatically cutting and taking rivets

A technology of binding machine and riveting tube, which is applied in metal processing and other directions, can solve the problems of skew, the inability of the drill to completely cut the head of the riveting tube on the riveting tube, and the trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

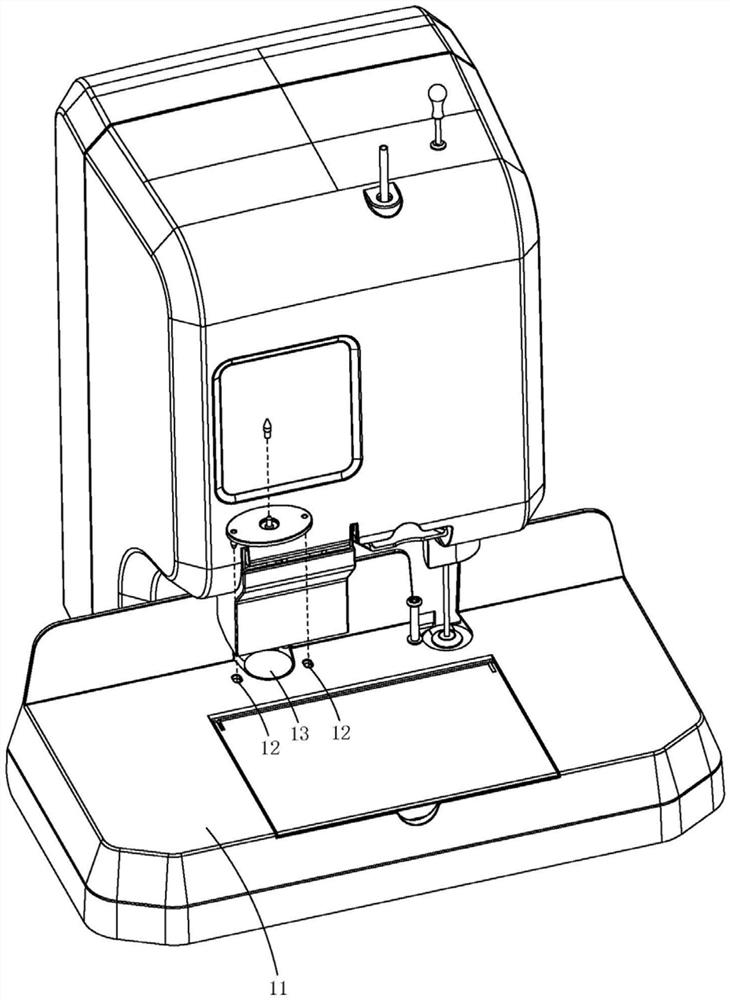

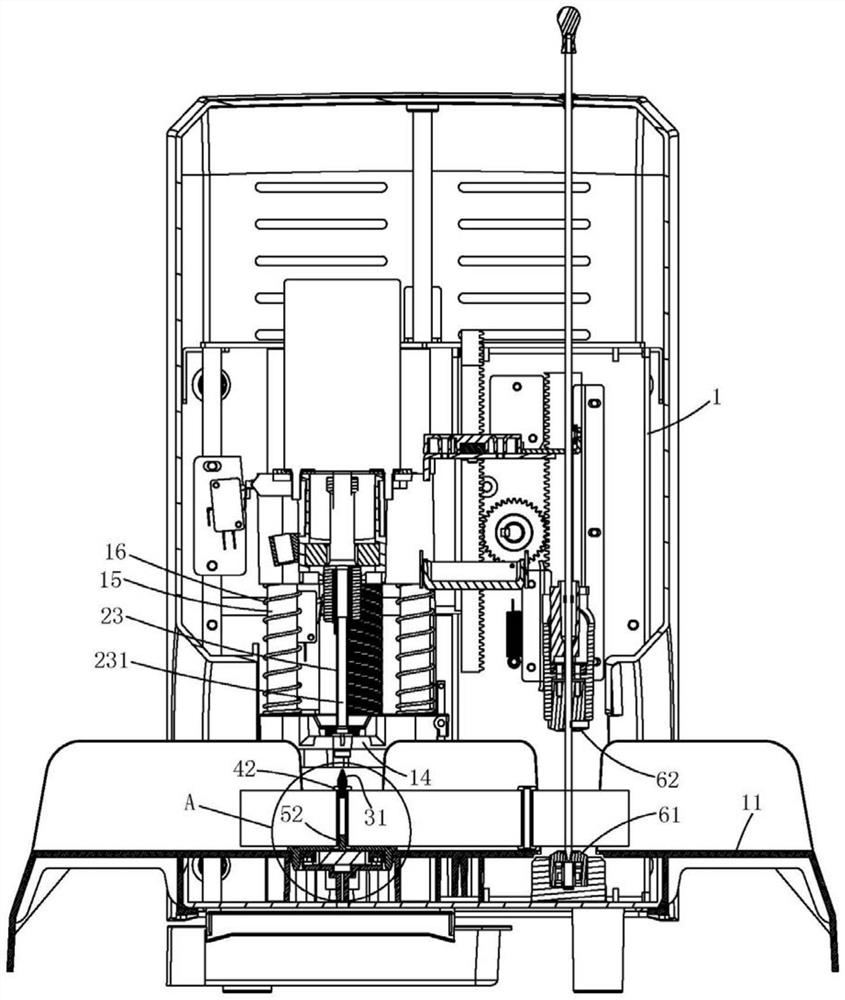

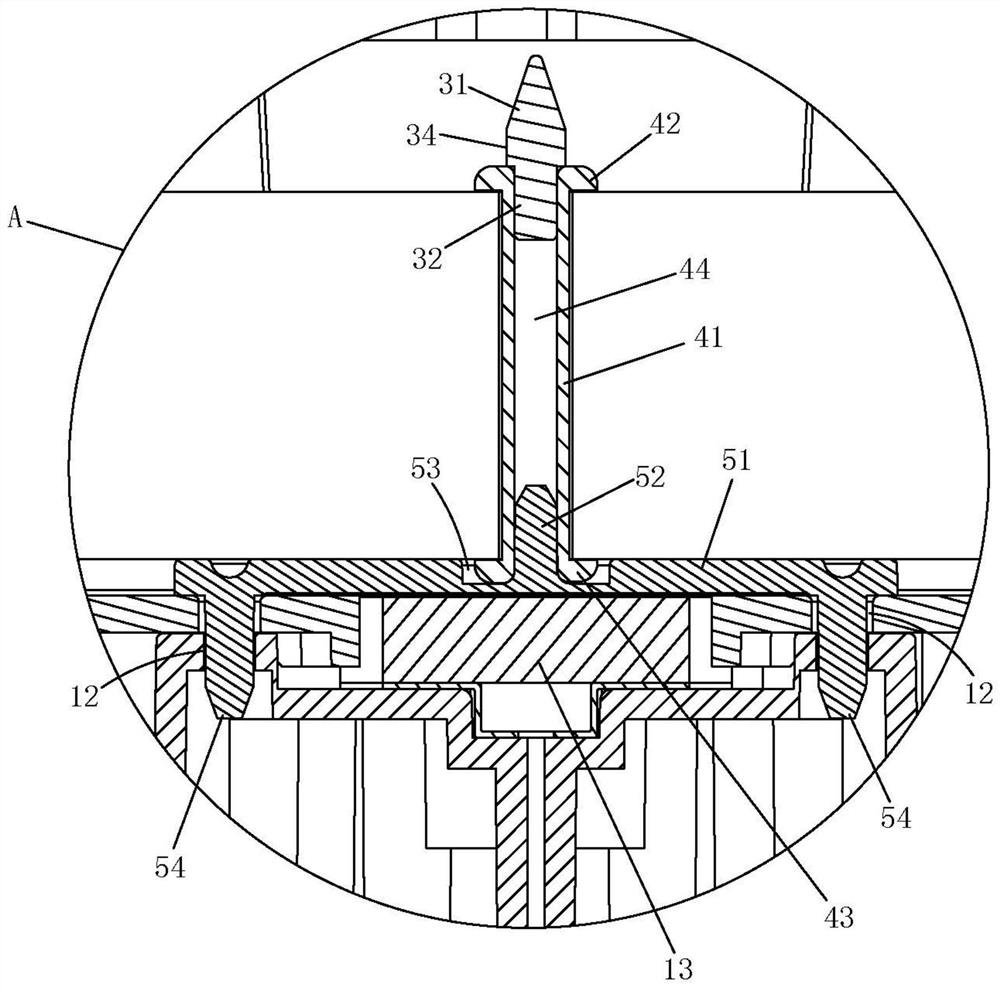

[0039] An automatic riveting cut taken rivet riveting pipe files binding machine, Figure 1 to 6Shown, comprises a control unit, a conductive pad 13, the frame 1, the frame 1 is attached to the document binding platform 11, the drilling means for drilling and riveting for hot press mechanism hot swaged tube riveting, drilling aperture means and the pressure means are hot riveting attached to the frame 1, the drilling mechanism is provided with a lifting mechanism drills, lifting up and down slidably attached to the base 21 of the chassis 1, the chassis 21 is fixed to the lifter bore 22 and a drive motor connected the motor 22 drills the borehole 23, the drill blade drive mechanism connected to drive the lift-down base 21, the control unit electrically connected to the insert lifting drive mechanism, the drilling motor 22 and a thermal riveting mechanism.

[0040] Specifically, the insert comprising a lifting drive mechanism and the lift motor drills lifting gear, drills elevating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com