A riveting assembly of a sensor protective cover

A sensor and protective cover technology, applied in the field of riveting and pressing assembly of sensor protective cover, can solve the problems of low work efficiency, low assembly efficiency, low work efficiency, etc., and achieve the effects of low cost, high production efficiency and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

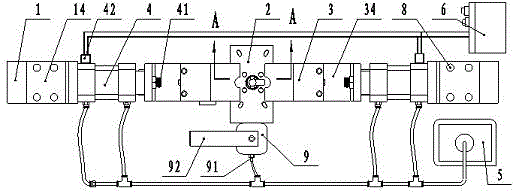

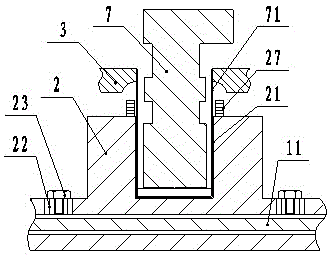

[0027] Embodiment one: combined with attached figure 1 , 2 , 3, a riveting assembly of a sensor protective cover, including a base plate 1, a fixed seat 2, two Huff molds 3, two cylinders 4, an air source 5 and a PLC electric control cabinet 6, a cylinder 4, and a fixed seat 2 It is fixedly connected with the bottom plate 1, the piston rod 41 of the cylinder 4 is fixedly connected with the half mold 3, the half mold 3 matches the sensor frame 7, the fixing seat 2 is provided with a positioning hole 21 matching the sensor protective cover 71, and the air source 5 is connected with the cylinder 4, and the PLC electric control cabinet 6 is connected with the electromagnetic valve 42 of the cylinder 4.

[0028]When installing, first fix the fixing seat on the bottom plate, then fix the two cylinders with the bottom plate according to the position of the fixing seat, then fix the two Huff molds to the piston rod on the cylinder respectively, and finally connect the cylinder Air ...

Embodiment 2

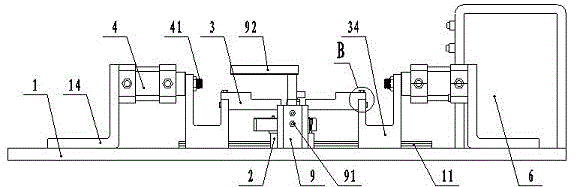

[0029] Embodiment two, combined with figure 1 , 2 , 3, 4, 5, a riveting assembly of a sensor protective cover, including a base plate 1, a guide rail 11 on the base plate 1, a fixing seat 2, a bracket 14, a connecting piece 34, two Huff molds 3, and two cylinders 4. Air source 5 and PLC electric control cabinet 6, fixed seat 2 and guide rail 11 are fixedly connected, cylinder 4 is connected with bottom plate 1 through bracket 14, bracket 14 is fixed with bottom plate 1 and cylinder 4 through hexagon socket bolt 8 respectively, and the connecting piece 34 is plugged with the guide rail 11, the cylinder 4 is connected with the half mold 3 through the connecting piece 34, the connecting piece 34 is threadedly connected with the piston rod 41 of the cylinder 4, and is fixedly connected with the half mold 3 through the inner hexagon bolt 8, and the half mold 3 Matching with the sensor frame 7, the fixed seat 2 is provided with a positioning hole 21 matching with the sensor protec...

Embodiment 3

[0031] Embodiment three, combined with the attached figure 1 , 2 , 3, 4, 5, 6, 7, a riveting assembly of a sensor protective cover, including a base plate 1, a guide rail 11 on the base plate 1, a fixing seat 2, a bracket 14, a connecting piece 34, and two Huff molds 3 , two cylinders 4, the rotary cylinder 9 on the fixed seat 2, the air source 5 and the PLC electric control cabinet 6, the fixed seat 2 is fixedly connected with the guide rail 11, the cylinder 4 is connected with the base plate 1 through the bracket 14, and the bracket 14 is connected with the base plate 1, Cylinders 4 are respectively fixed by hexagon socket bolts 8, connectors 34 are plugged into guide rails 11, cylinders 4 and Hough mold 3 are connected through connectors 34, connectors 34 are threaded with piston rod 41 of cylinder 4, and Huff mold 3 There are two hexagon socket bolt holes 81 matching the connecting piece 34 on the top, and one hexagon socket bolt hole 81 matching the connecting piece 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com