Integral shrinking die with small shrinkage coefficient and high height-to-thickness ratio and its mold

A technology of necking and die, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of waste of materials, scrapped parts, easy instability of the lower half of the blank, etc., to improve the quality of forming and the difficulty of deformation. The effect of reducing and eliminating instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

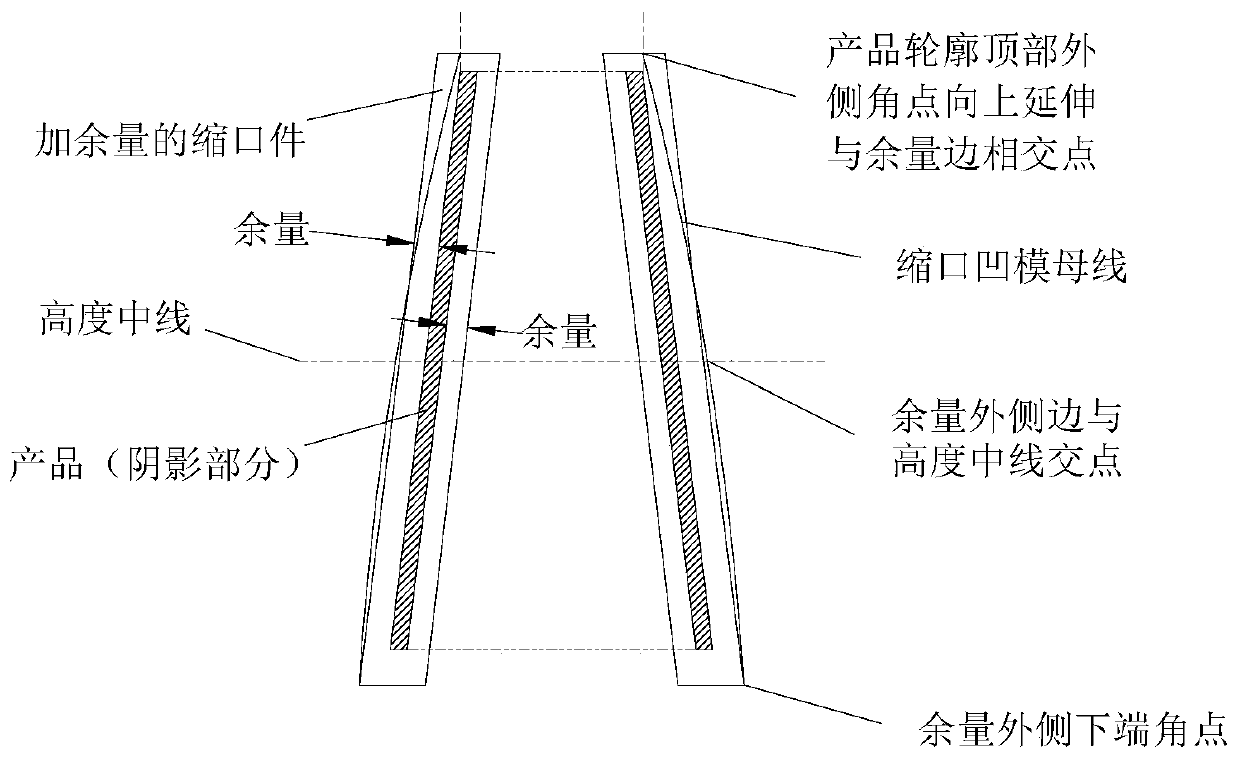

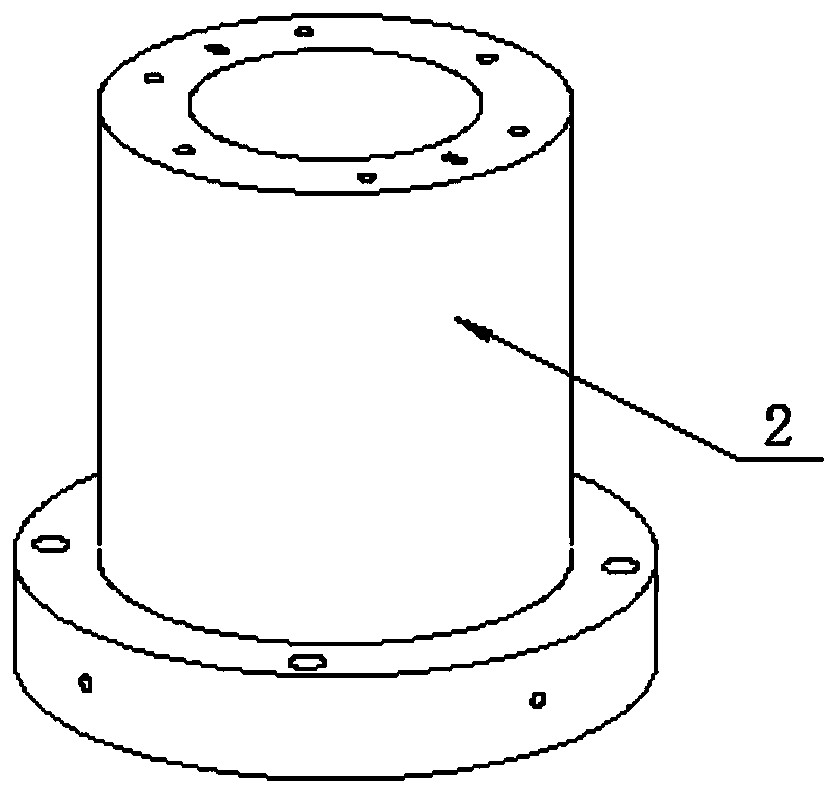

[0026] Such as figure 1 and image 3 As shown, in the overall shrinking die with small shrinkage coefficient and high height-to-thickness ratio in this embodiment, the shrinking die 2 is a hollow cylinder, and a boss 9 is provided at the bottom of the shrinking die. , the boss 9 is evenly provided with a number of pull rod holes 10; the shape of the inner cavity busbar of the shrinking die is designed according to the principle of maximum tolerance, and three points form an arc. The intersection point of the margin side, the second point is the intersection point of the outer side of the margin and the midline of the product height, and the third point is the lower corner point of the outer side of the margin, drawing the three points into an arc is the inner cavity of the shrinking die busbar shape.

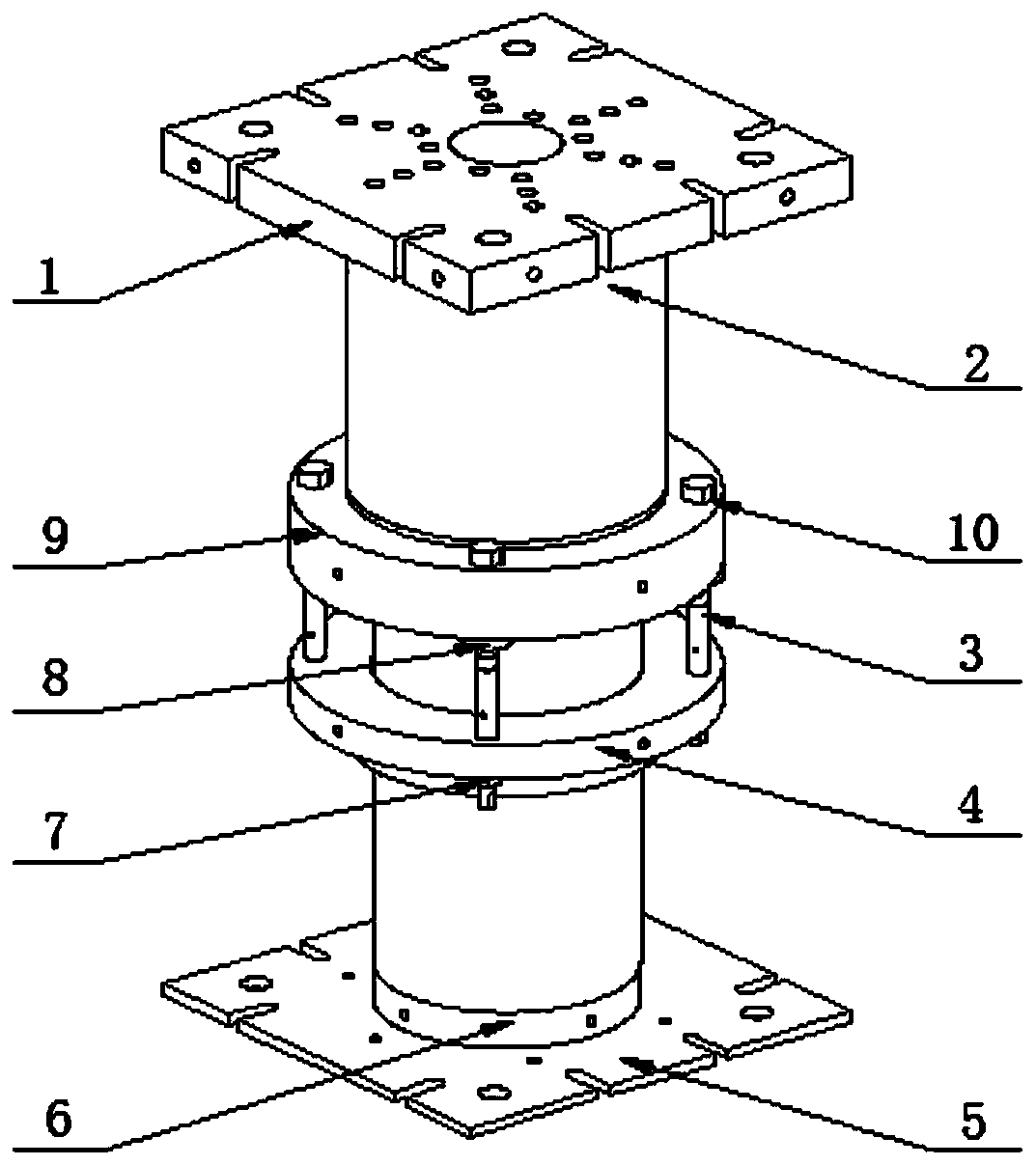

[0027] Such as Figure 2 ~ Figure 6 Shown, a ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com