A kind of preparation method for metal composite board

A metal composite board and metal sheet technology, which is applied in the direction of metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problems that the work hardening of metal sheets cannot be eliminated, so as to ensure processing performance, improve performance and reduce deformation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

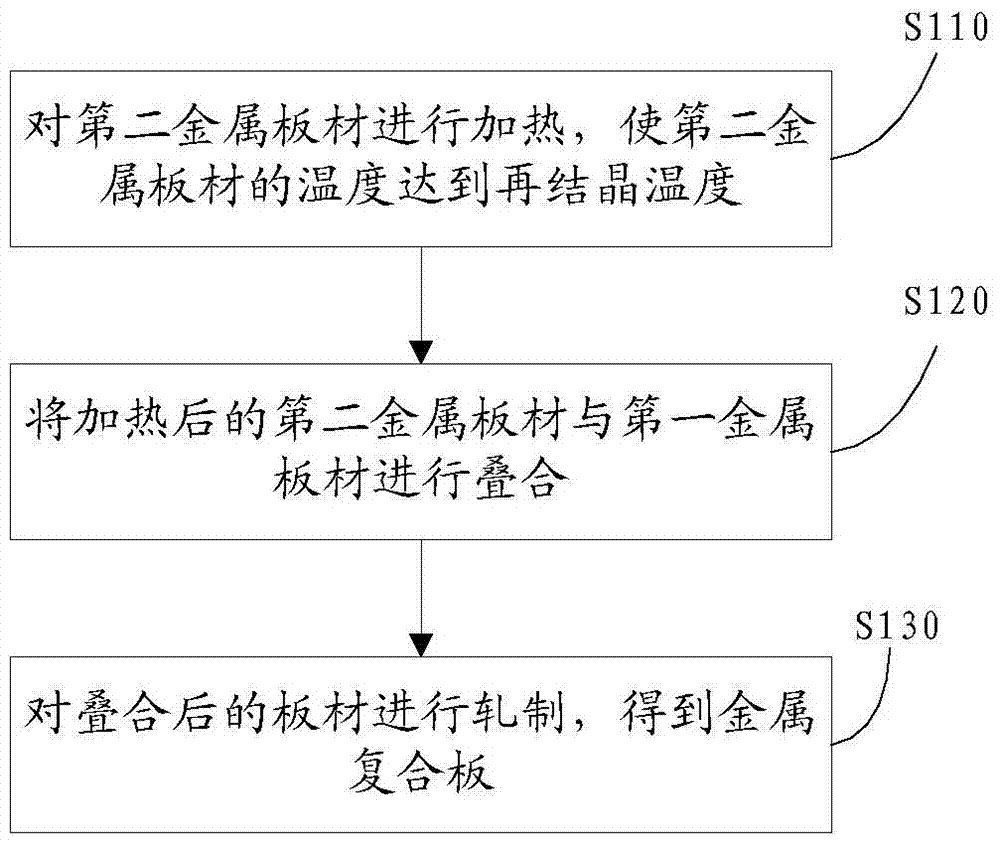

[0031] see figure 1 , the preparation method for the metal composite panel provided by the embodiment of the present invention includes:

[0032] Step S110: heating the second metal plate, so that the temperature of the second metal plate reaches the recrystallization temperature;

[0033] In this embodiment, the heating temperature for heating the second metal plate is 850-1300°C.

[0034] To illustrate this step, the second metal sheet may be sent to a heating furnace for heating.

[0035] Step S120: stacking the heated second metal plate with the first metal plate; wherein, the melting point of the first metal plate is lower than the recrystallization temperature of the second metal plate;

[0036] To illustrate this step, step S120 specifically includes:

[0037] The first metal plate is placed on the surface of the heated second metal plate, and the first metal plate and the second metal plate are pressed together.

[0038] Specifically, the first metal sheet is stack...

Embodiment 2

[0053] The process of preparing aluminum-carbon steel single-sided composite panels by this method includes:

[0054] 1. Processing and heating of steel slabs: the base material is made of Q235, and the size is 40mm×900mm×6000mm. After the upper and lower surfaces of the steel plate are machined, they are cleaned with alcohol to make the surface clean and free of oil. After completion, the steel slab is sent to a heating furnace to be heated to 900°C.

[0055] 2. Aluminum plate processing: The cladding material is made of pure aluminum plate with a thickness of 8mm and a width of 900mm. Uncoil the aluminum coil, and then remove the oxide layer on the upper and lower surfaces with a wire brush, and use an air blower to remove dust to keep the board surface clean.

[0056] 3. Lamination: The aluminum plate is stacked on the surface of the high-temperature steel slab by the guide roller, and pressed by the pinch roller.

[0057] 4. Rolling: Roll the pressed slab to 10mm in 6 pa...

Embodiment 3

[0060] The process of preparing aluminum-carbon steel-aluminum double-sided composite panels by this method includes:

[0061] 1. Processing and heating of steel slabs: the base material is made of 304 stainless steel, and the size is 20mm×800mm×6000mm. After the upper and lower surfaces of the stainless steel plate are machined, they are cleaned with alcohol to make the surface clean and free of oil. After completion, the stainless steel plate is sent to the heating furnace to be heated to 1000°C.

[0062] 2. Aluminum plate processing: The cladding material is prepared from two volumes of pure aluminum plates with a thickness of 6mm and a width of 800mm. Uncoil the aluminum coil, and then remove the oxide layer on the upper and lower surfaces with a wire brush, and use an air blower to remove dust to keep the board surface clean.

[0063] 3. Lamination: The aluminum plate is stacked on the upper and lower surfaces of the high-temperature stainless steel plate through the gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com