Coupling expanding sleeve

An expansion sleeve and shaft coupling technology, applied in the field of coupling expansion sleeves, can solve the problems of increasing the volume of the coupling, cumbersome operation, and plastic deformation of the coupling components, so as to ensure dynamic balance, reduce the contact area, and reduce the pressing force. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

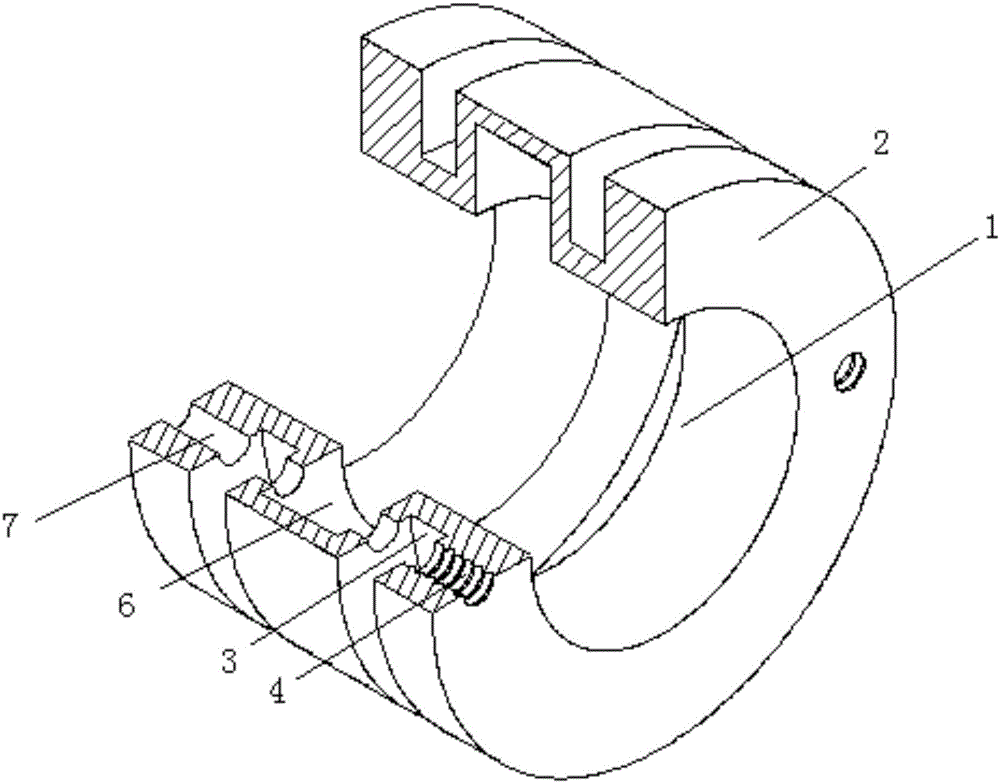

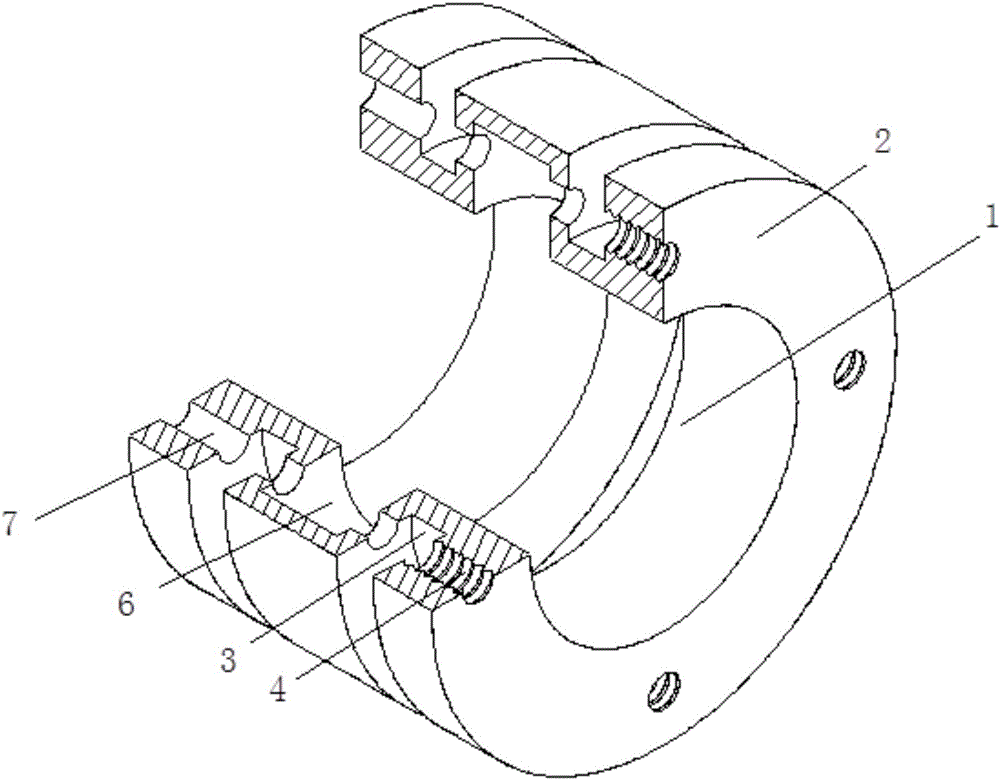

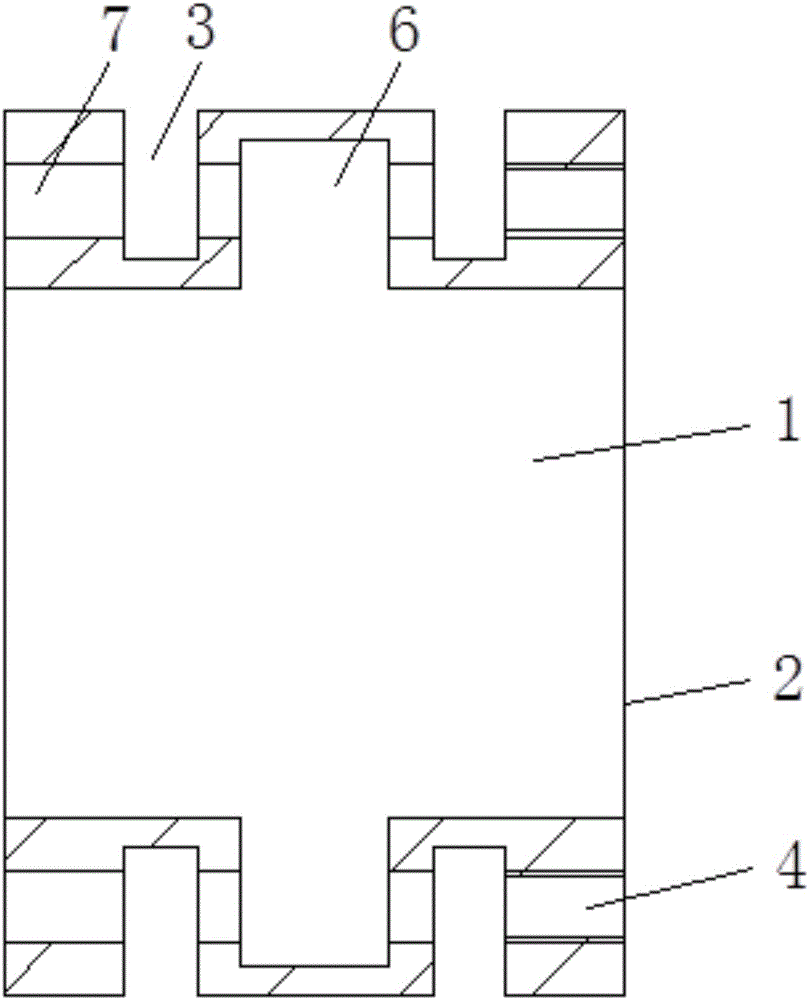

[0026] like Figure 1-5 As shown, a coupling expansion sleeve, the longitudinal section of the coupling expansion sleeve is in the shape of a square wave, including a cylinder 2 with a central shaft hole 1 and a screw 5, the cylinder 1 is provided with an outer annular groove 3, which is provided with an outer annular groove 3. The annular groove 3 is because to maintain a certain strength, the coupling expansion sleeve can be deformed, squeeze the driving shaft 111 and the driven shaft 112, so as to achieve the purpose of tightening transmission, the cylinder 2 is provided with a through hole in the axial direction. 7 and screw hole 6, the screw 5 is screwed into the screw hole 6 through the through hole 7, the diameter of the through hole 7 is larger than the diameter of the screw hole 6, the screw hole 6 is only located at the outer end of the outer annular groove 3, and the through hole 7 passes through In other parts of the cylinder 2, the arrangement of the through holes...

Embodiment 2

[0029] like Figure 1-5 As shown, a coupling expansion sleeve, the longitudinal section of the coupling expansion sleeve is a square wave shape, including a cylinder 2 with a central shaft hole 1, the cylinder 1 is provided with an outer annular groove 3, which is provided with an outer annular groove 3 It is because the coupling expansion sleeve can be deformed while maintaining a certain strength, and the driving shaft 111 and the driven shaft 112 can be squeezed, so as to achieve the purpose of tightening transmission. The cylinder 2 is axially provided with a through hole 7 and a screw. Hole 6, the screw 5 is screwed into the screw hole 6 through the through hole 7, the diameter of the through hole 7 is larger than the diameter of the screw hole 6, the screw hole 6 is only located at the outer end of the outer annular groove 3, and the through hole 7 passes through the cylinder 2 In other parts, the setting of the through hole 7 is convenient for tightening the screw 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com