Preparation method for medical cobalt chromium molybdenum alloy powder for laser 3D printing

A cobalt-chromium-molybdenum alloy, 3D printing technology, applied in additive processing and other directions, can solve the problems of difficult preparation of fine-grained powder, high content of oxygen and other impurities, and low powder yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

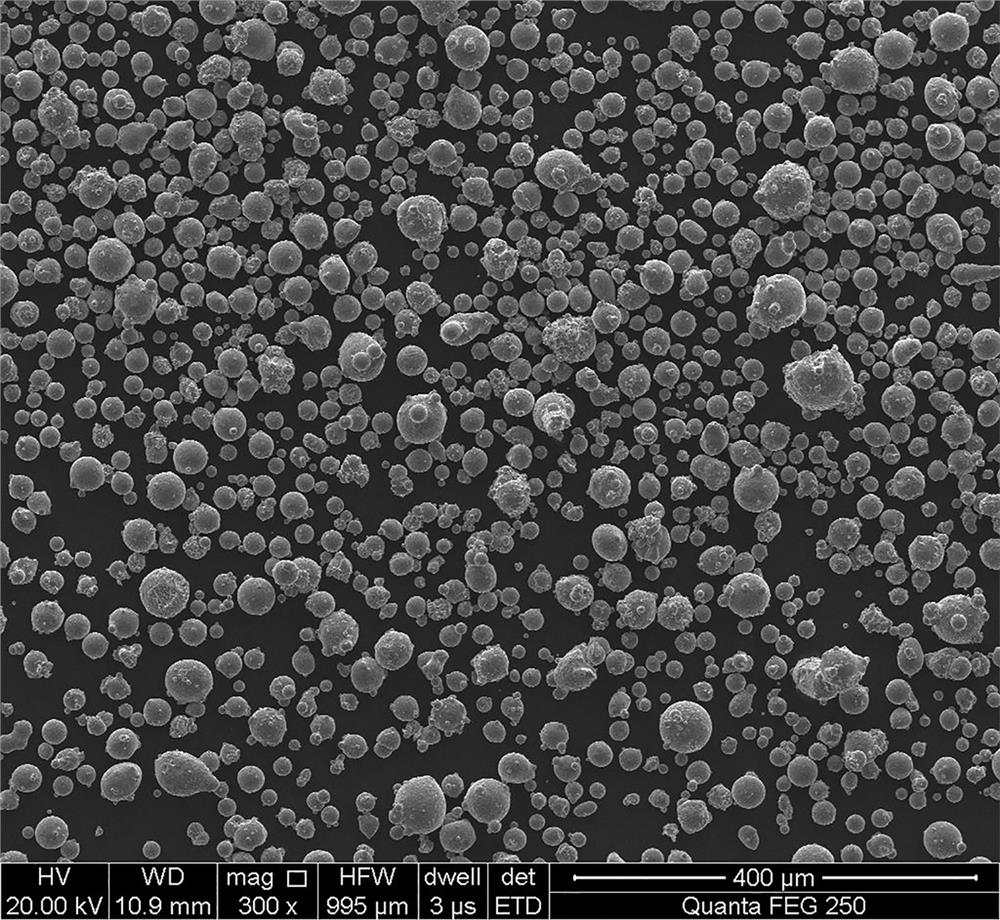

Image

Examples

preparation example Construction

[0024] A preparation method for medical cobalt-chromium-molybdenum alloy powder for laser 3D printing, comprising the following steps:

[0025] Step 1. Put the cobalt-chromium-molybdenum alloy chemical raw material into a vacuum induction furnace for melting according to the ratio of GB 17100-1997. The melting temperature is controlled at 1300-1500°C. After melting, cast under vacuum to obtain a cobalt-chromium-molybdenum alloy rod;

[0026] Step 2. Using machining equipment, peel off the cobalt-chromium-molybdenum alloy bar stock obtained in step 1, and remove defective parts such as the head and tail at the same time to obtain an alloy bar stock of Ø90mm×(200-220)mm;

[0027] Step 3. Put the cobalt-chromium-molybdenum alloy rod obtained in step 2 into the argon atomization melting chamber, and then vacuumize the melting chamber to 5×10 -2 Below Pa, fill in high-purity argon to keep the pressure in the smelting chamber at 0.001-0.01MPa;

[0028] Step 4, heating the cobalt-ch...

Embodiment 1

[0033] Step 1, carry out batching according to the cobalt-chromium-molybdenum alloy chemical composition that GB 17100-1997 stipulates, by weight percentage, C: 0.28%, Cr: 27.6%, Mo: 5.5%, Ni: 0.80%, Fe: 0.55%, Mn: 0.75%, Si: 0.83%, Co: 63.69%, put the raw materials into the vacuum induction furnace for smelting, the smelting temperature is controlled at 1450°C, and after smelting, cast under vacuum to obtain cobalt-chromium-molybdenum alloy rods.

[0034] Step 2. Using machining equipment, peel off the cobalt-chromium-molybdenum alloy bar stock obtained in step 1, and remove defective parts such as head and tail at the same time to obtain an alloy bar stock of Ø90mm×200mm;

[0035] Step 3. Put the cobalt-chromium-molybdenum alloy rod obtained in step 2 into the argon atomization melting chamber, and vacuumize the melting chamber to 5×10 -2 Below Pa, refill high-purity argon to keep the pressure in the smelting chamber at 0.008MPa;

[0036] Step 4. Heating the cobalt-chromium...

Embodiment 2

[0043]Step 1, carry out batching according to the cobalt chromium molybdenum alloy chemical composition that GB 17100-1997 stipulates, by weight percentage, C: 0.25%, Cr: 28.6%, Mo: 5.3%, Ni: 0.75%, Fe: 0.68%, Mn: 0.77%, Si: 0.79%, Co: 62.86%, put the cobalt-chromium-molybdenum alloy chemical raw material into the vacuum induction furnace for smelting, the melting temperature is controlled at 1300°C, and the cobalt-chromium-molybdenum alloy bar is obtained by casting under vacuum after smelting;

[0044] Step 2. Using machining equipment, peel off the cobalt-chromium-molybdenum alloy bar stock obtained in step 1, and remove defective parts such as head and tail at the same time to obtain an alloy bar stock of Ø90mm×200mm;

[0045] Step 3. Put the cobalt-chromium-molybdenum alloy rod obtained in step 2 into the argon atomization melting chamber, and vacuumize the melting chamber to 5×10 -2 Below Pa, refill high-purity argon to keep the pressure in the smelting chamber at 0.001M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com