Co-Cr-Mo alloy with high wear resistance

A cobalt-chromium-molybdenum alloy, high wear-resistant technology, applied in the field of high-temperature alloys, can solve problems such as insufficient wear resistance of cobalt-chromium-molybdenum alloys, and achieve the effect of solving insufficient hardness and insufficient wear resistance and improving material hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

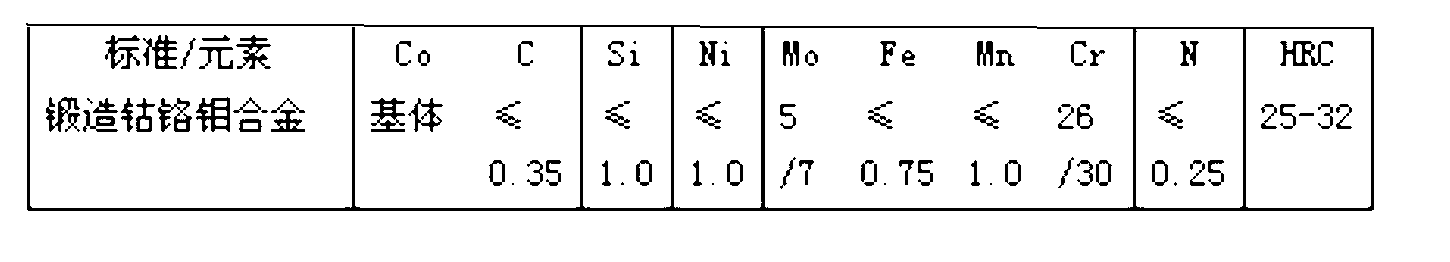

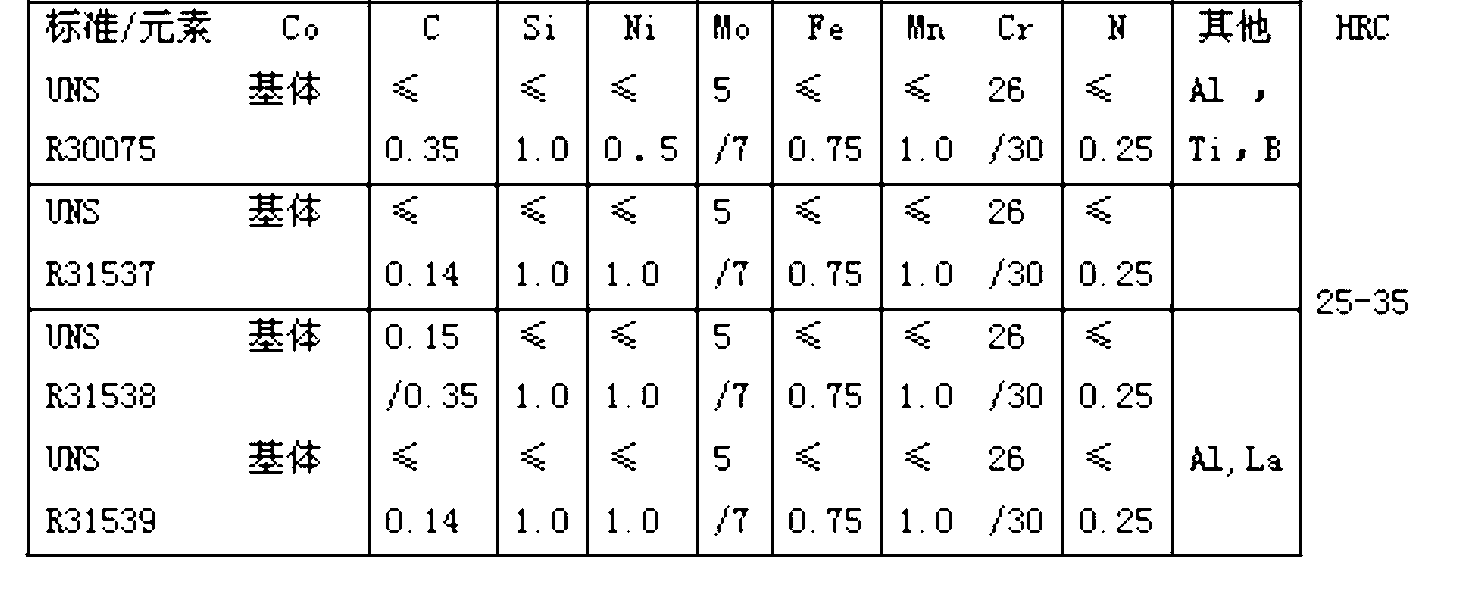

[0013] The hardness range of the above-mentioned cobalt-chromium-molybdenum alloy materials at home and abroad is between HRC25-35, and the wear resistance is obviously insufficient.

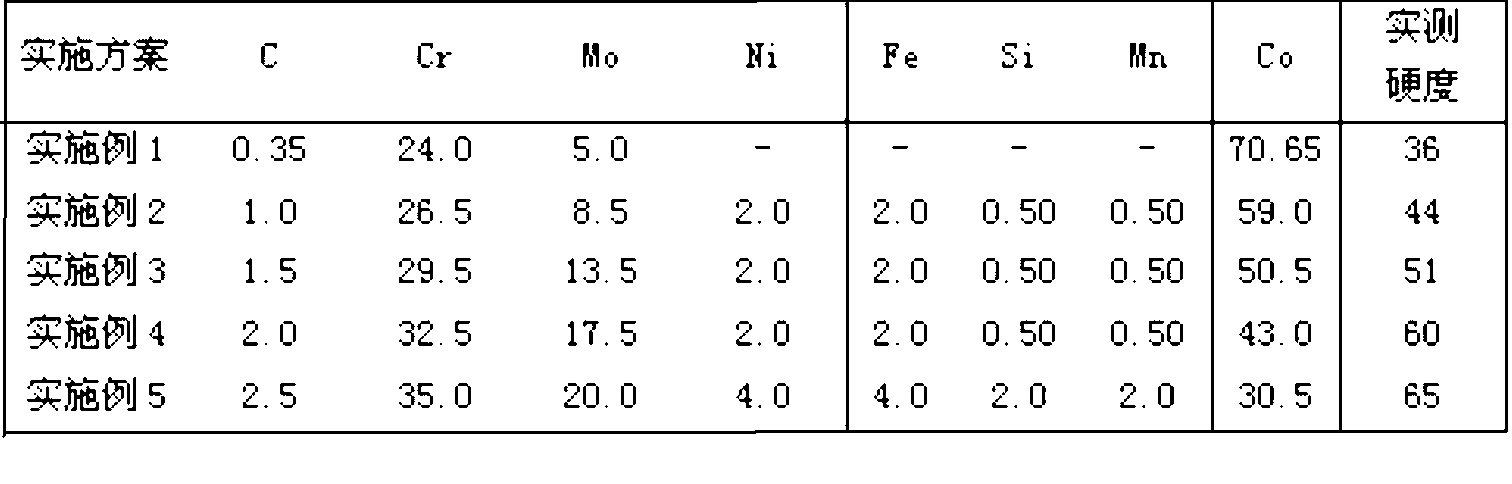

[0014] According to the following composition proportions, the ingots are produced by vacuum casting, and the hardness of the alloy is tested after production. The results are shown in Table 3:

[0015] Table 3 Wt%

[0016]

[0017] In summary, the high wear resistance cobalt-chromium-molybdenum alloy involved in the present invention has a hardness range of 36-65HRC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com