Nitriding CoCrMo alloy and smelting process thereof

An alloy and process technology, which is applied in the field of CoCrMo alloy and its smelting process, can solve the problems of limited nitrogen ion implantation thickness, difficulty in meeting the requirements of the permeated layer, and high cost of surface nitriding, so as to improve the surface hardness and wear resistance. Low, wear resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] This embodiment provides a nitrogen-increased CoCrMo alloy and its melting process, which is composed of the following components in weight percentage: C: 0.3%, Cr: 29%, Mo: 6%, Si: 0.9%, Mn: 0.4% , N: 0.25%, Co: 63.15%.

[0024] The above-mentioned CoCrMo alloy is prepared through the following process steps:

[0025] S1: After measuring C, Co, Mo, Si, Mn, and CrN according to the above weight percentages, add them into the crucible of the vacuum melting furnace in layers, and sandwich C in the middle;

[0026] S2: Vacuumize the vacuum melting furnace, stop the pump and fill nitrogen to 20000pa when the vacuum degree reaches 20pa;

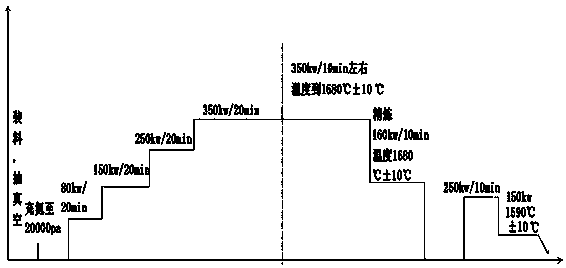

[0027] S3: Adjust the power of the vacuum melting furnace to 80kw to heat the mixed raw materials for 20mim, then increase the power to 150kw to heat the mixed raw materials for 20mim, then increase the power to 250kw to heat the mixed raw materials for 20mim; finally increase the power Up to 350kw to heat the mixed raw materials for 20mi...

Embodiment approach 2

[0034] This embodiment provides a nitrogen-increased CoCrMo alloy and its melting process, which is composed of the following components in weight percentage: C: 0.27%, Cr: 28%, Mo: 5%, Si: 0.8%, Mn: 0.35% , N: 0.2%, Co: 65.38%.

[0035] The preparation process of the above-mentioned CoCrMo alloy is completely the same as that of Embodiment 1, and will not be repeated here.

Embodiment approach 3

[0037]This embodiment provides a nitrogen-increased CoCrMo alloy and its melting process, which is composed of the following components in weight percentage: C: 0.25%, Cr: 30%, Mo: 7%, Si: 0.85%, Mn: 0.3% , N: 0.19%, Co: 61.41%.

[0038] The preparation process of the above-mentioned CoCrM alloy is completely the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com