Die for rotary swaging machine and manufacturing method of die

A technology for rotary forging machines and molds, which is used in the manufacture of tools, forging/pressing/hammering machinery, forging/pressing/hammer devices, etc. It can solve the problems of unreasonable mold structure, high cost, low efficiency, etc. The effect of toughness and roughness, low production efficiency, and complete and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

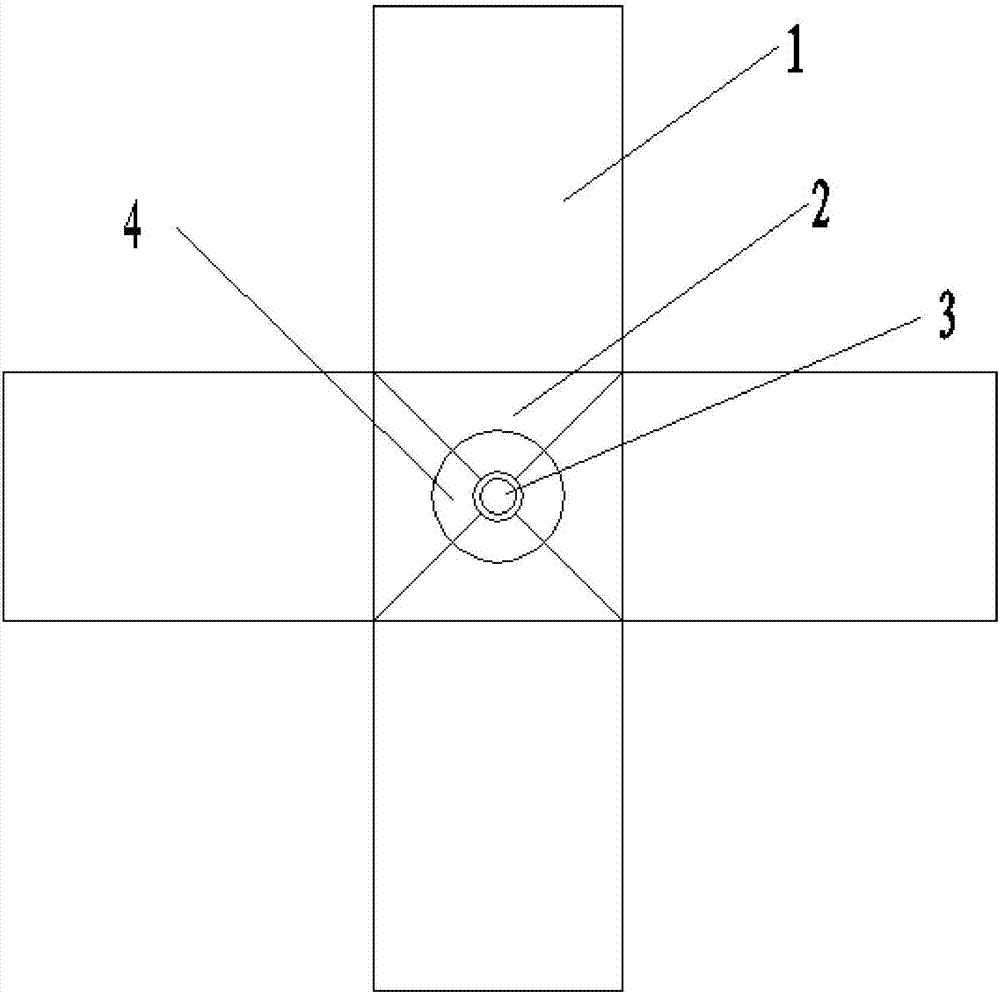

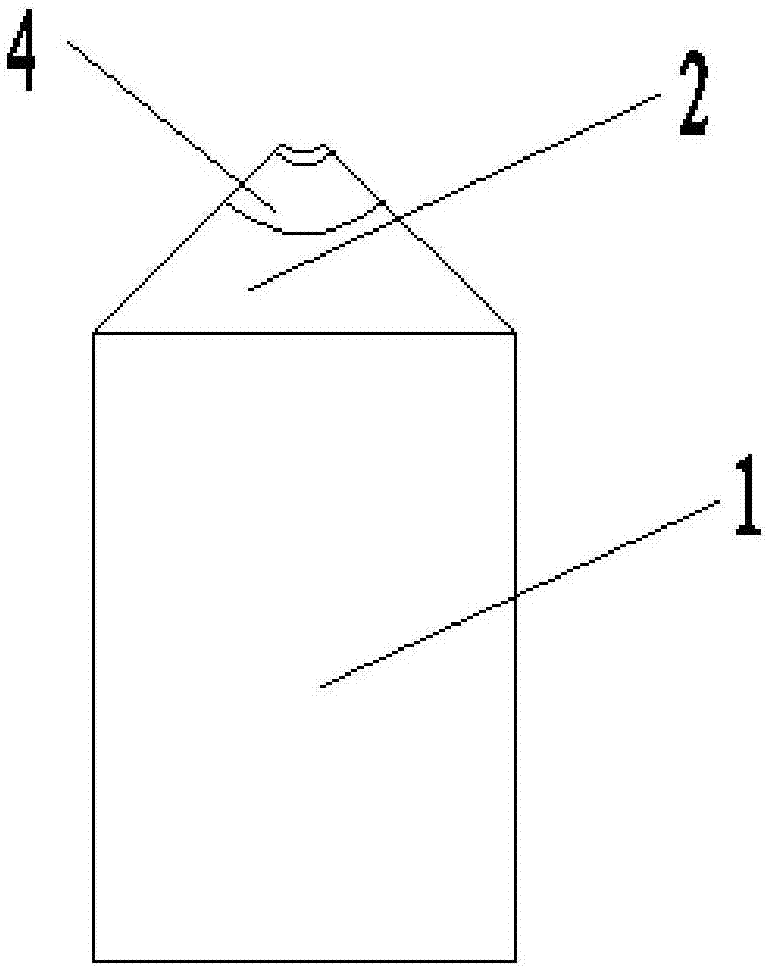

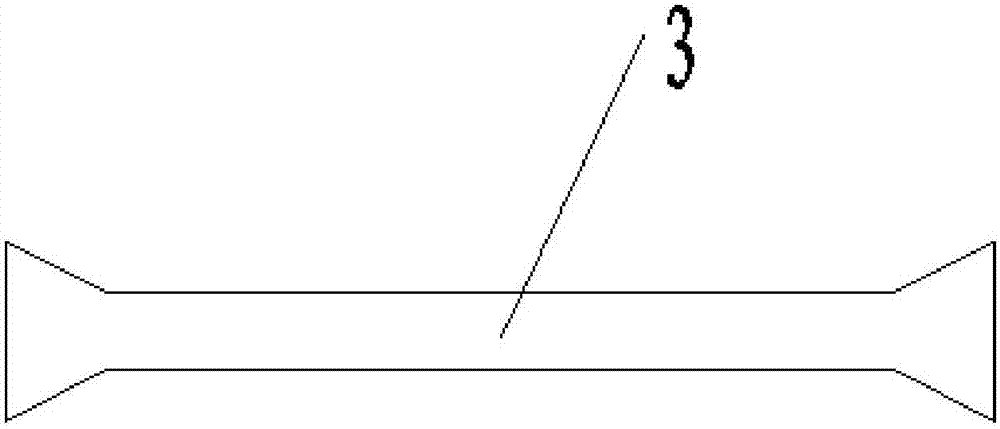

[0028] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes a mold main body, which is assembled sequentially by a plurality of mold blocks along the circumferential direction, and the mold blocks include a support body 1 and a working body 2, and the working body 2 of each mold block Assemble to form the working area of the mold main body, the center of the working area of the mold main body is provided with a mold hole 3, the inner wall of the mold hole 3 is provided with a surfacing layer 4, and the inner wall of the surfacing layer 4 The surface is the working surface of the swaging machine for swaging workpieces. The die hole 3 is a circular through hole. The problem that it is difficult to put the billet and tube billet into the mold hole improves the processing efficiency.

[0029] In this embodiment, the material of the working body 2 is cobalt-chromium-tungsten alloy or cobalt-chromium-molybdenum alloy; the material of the support body 1...

Embodiment 2

[0036] Such as figure 1 , figure 2 and image 3 As shown, taking four mold blocks assembled into a mold as an example, the manufacturing method of a mold for a rotary forging machine includes the following steps:

[0037] Step 1, mold blank processing: the mold steel is machined into the support body 1 and the working body 2 of the basic sample blank of the swaging mold, and then surfacing welding is formed on the support body 1 to form a surfacing layer 4; the cross section of the support body 1 is Rectangular, the section of the working body 2 is triangular, and the thickness of the support body 1 and the working body 2 is 30mm;

[0038] Step 2, preliminary processing: the surfacing layer 4 that obtains in step 2 is first through machining milling and grinding, and then assembled into the mold body of the unprocessed mold hole (such as Figure 4 shown);

[0039] Step 3, finishing: use wire cutting to cut out the mold hole 3 in the surfacing layer at the center of the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com