Novel cobalt-base alloy for surgical implant and application thereof

A technology of surgical implantation and cobalt-based alloys, which is applied in the field of alloys, can solve problems such as sensitization, carcinogenicity, and side effects, and achieve the effects of avoiding sensitization, avoiding the hazards of nickel, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

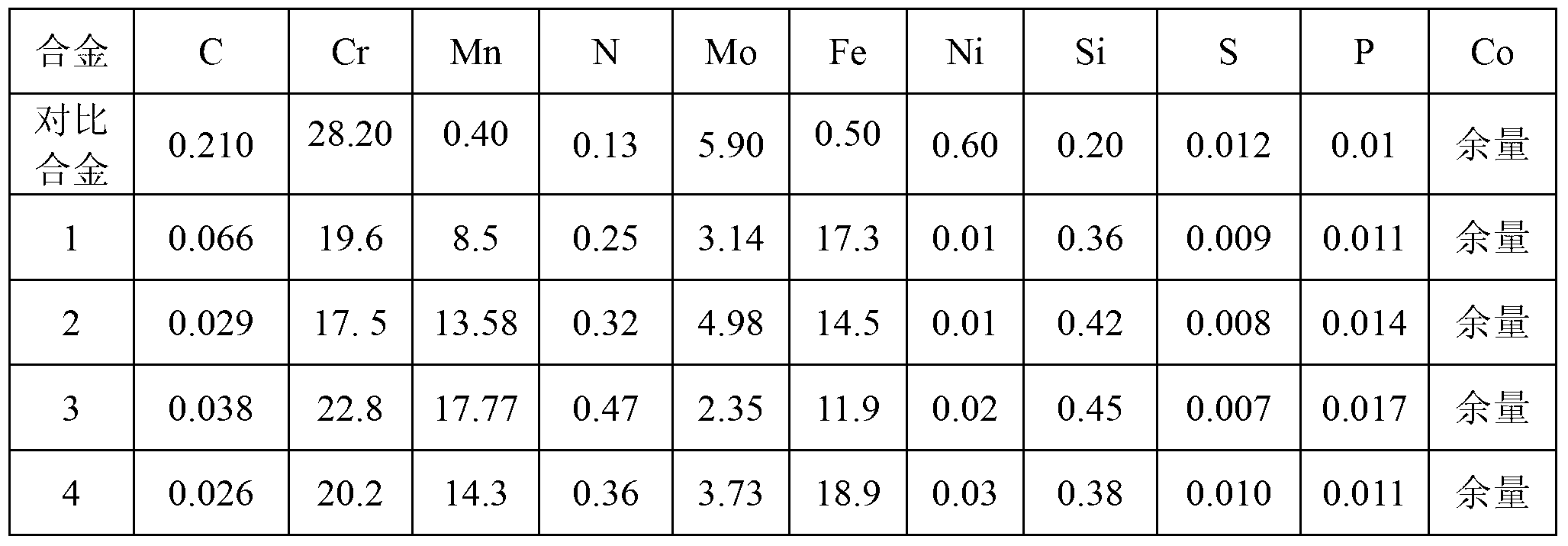

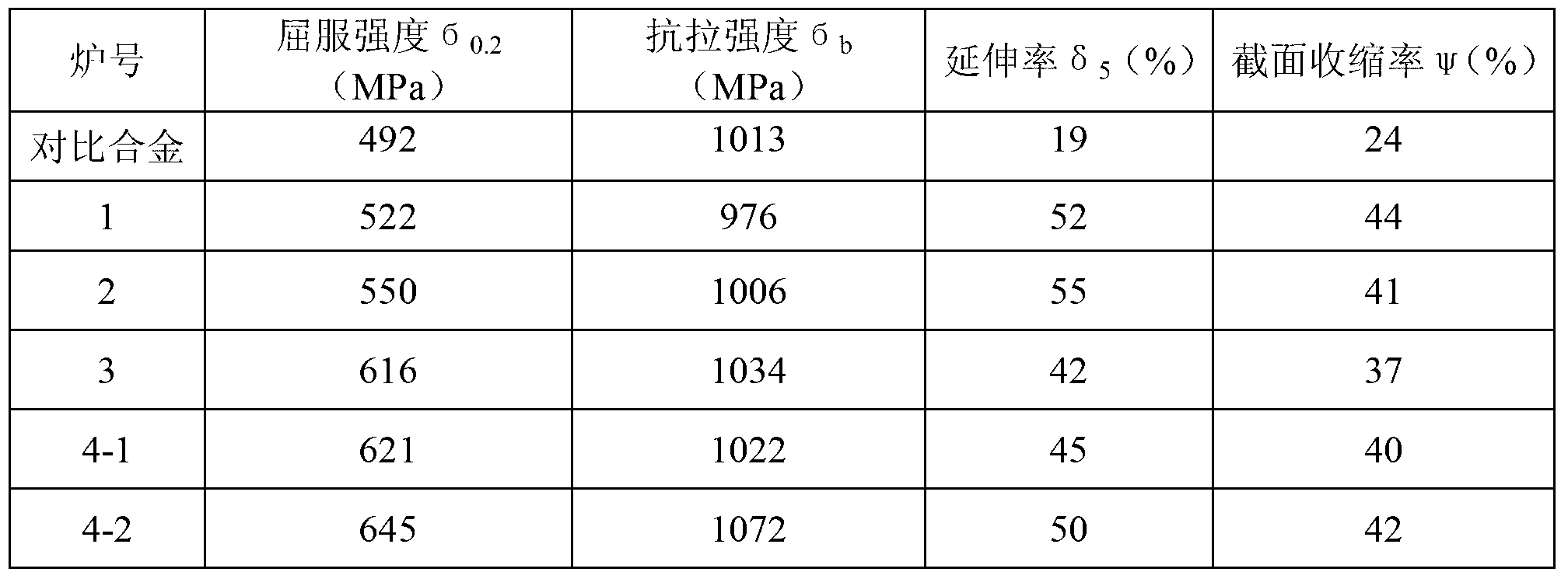

[0026] According to the chemical composition range set by the cobalt-based alloy of the present invention, the cobalt-based alloy for surgical implantation of the present invention adopts a 15 kg vacuum induction furnace to smelt 4 furnaces of alloys (respectively numbered 1-4) and 1 furnace of comparative cobalt-chromium-molybdenum alloys. 10 kg, the protective nitrogen pressure is 0.05-0.07MPa, and the nitrided alloy is MnN with a nitrogen content of 6% (wt%). These 5 furnace alloys are respectively poured into a φ80×150 ingot, and processed and heat treated as follows Process specifications for processing.

[0027] The forging process is as follows: the alloy ingot is homogenized and heat-treated at 1150°C±15°C for 2 hours to open the billet, and is forged in three fires to form a preliminary rolling billet, and the final forging temperature is 900°C.

[0028] The hot-rolling process is as follows: the first-rolled billet is kept at a temperature of 1150°C±15°C for 2 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com