Cobalt chrome etching process

An etching, cobalt-chromium alloy technology, applied in the field of controlled etching compositions, can solve problems such as intergranular erosion of CoCr materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

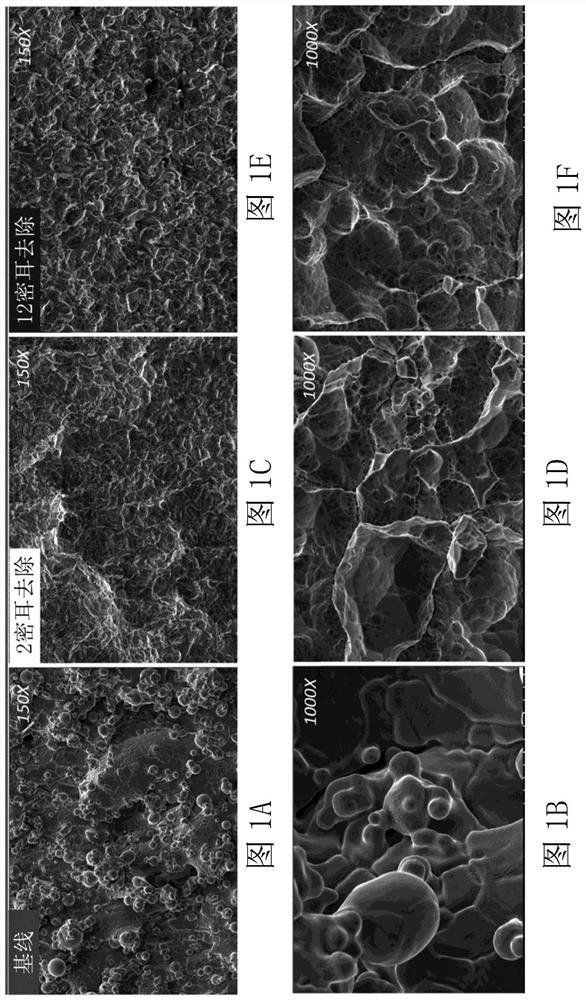

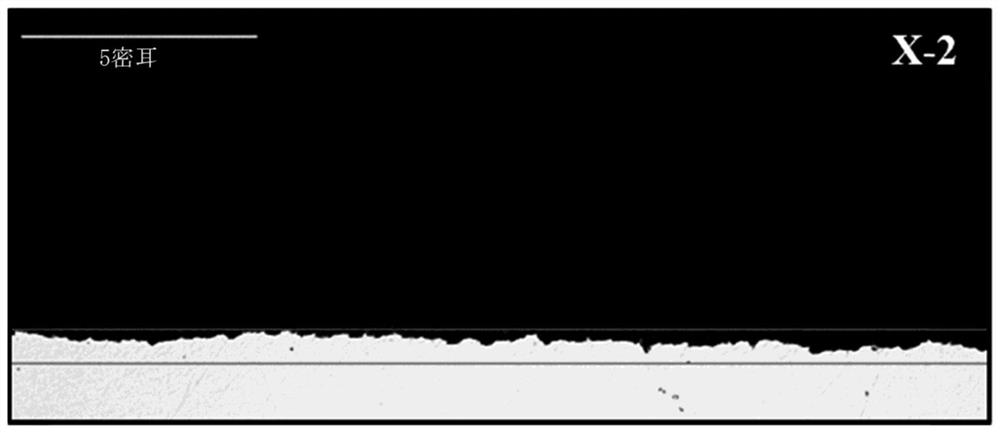

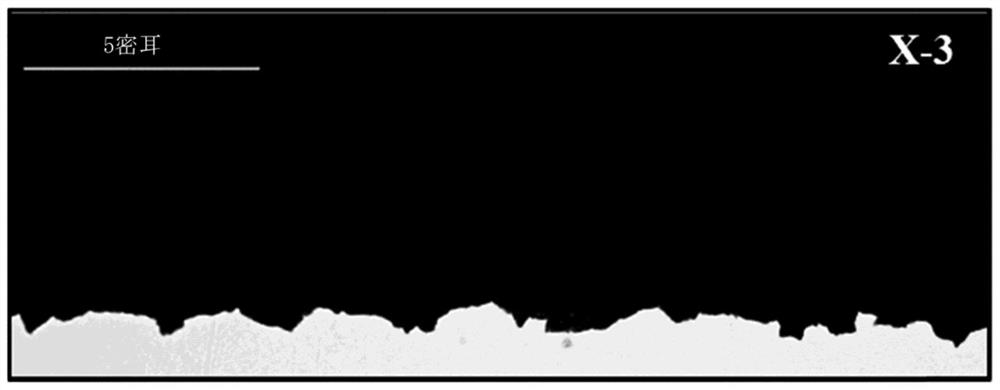

Image

Examples

no. 1 approach

[0046] Thus, according to the first disclosed embodiment of the present invention, the chemical etching composition may comprise at least two mineral acids, iron, and low to moderate concentrations of certain constituent metals of the alloy to be etched. For example, when the alloy to be etched is a cobalt-chromium-molybdenum alloy, the composition may contain any two or more inorganic acids listed herein, and 50-225 g / l iron (Fe), 1-10 g / l chromium ( Cr), 0.1 - 5 g / l molybdenum (Mo) and optionally cobalt (Co), eg 0 to 10 g / l cobalt (Co).

[0047] According to certain other aspects of the first embodiment, the chemical etching composition comprises at least 50 g / l iron (Fe), or at least 70 g / l, or at least 90 g / l, or at least 110 g / l, or at least 130 g / l, or At least 150 g / l, or at least 170 g / l, or at least 200 g / l. According to certain other aspects, the chemical etching composition comprises at most 225 g / l iron (Fe), such as at most 200 g / l, or at most 160 g / l, or at most...

no. 2 approach

[0051] According to a second embodiment of the present disclosure, the chemical etching composition may comprise at least two mineral acids and a high concentration of certain constituent metals of the alloy to be etched. For example, when the alloy to be etched is a cobalt-chromium-molybdenum alloy, the composition may contain any two or more of the mineral acids listed herein, and 7-355 g / l cobalt (Co), about 3-170 g / l chromium (Cr), and about 1–40 g / l molybdenum (Mo). The composition may be substantially free of iron or completely free of iron.

[0052]According to certain other aspects of the second embodiment, the chemical etching composition comprises at least 3 g / l chromium (Cr), or at least 10 g / l, or at least 20 g / l, or at least 30 g / l, or at least 40 g / l, or At least 50 g / l, or at least 70 g / l, or at least 90 g / l, or at least 110 g / l, or at least 130 g / l, or at least 150 g / l. According to certain other aspects, the chemical etching composition comprises at most 170...

Embodiment

[0103] The following examples provide formulations that can be used to etch various cobalt chromium alloys. The alloy material was activated prior to each chemical etching step listed in these examples. Exemplary activation steps that form part of the disclosed methods include exposing the alloy material to a mineral acid immediately prior to exposure to the chemical etching composition, such as immersing or spraying the alloy material with a mineral acid immediately prior to exposure to the chemical etching composition disclosed herein . For example, a workpiece can be dipped or sprayed with a 10% to 100% (v / v) aqueous solution of hydrochloric acid and exposed within a few minutes (e.g., less than 120 seconds, or even less than 30 seconds) to one of the chemical etching solutions, such as Details are given in Examples I-III below. While it is specifically stated herein that the activation solution comprises hydrochloric acid, other inorganic acids or mixtures thereof will p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com