Patents

Literature

67 results about "Cobalt Chromium Alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

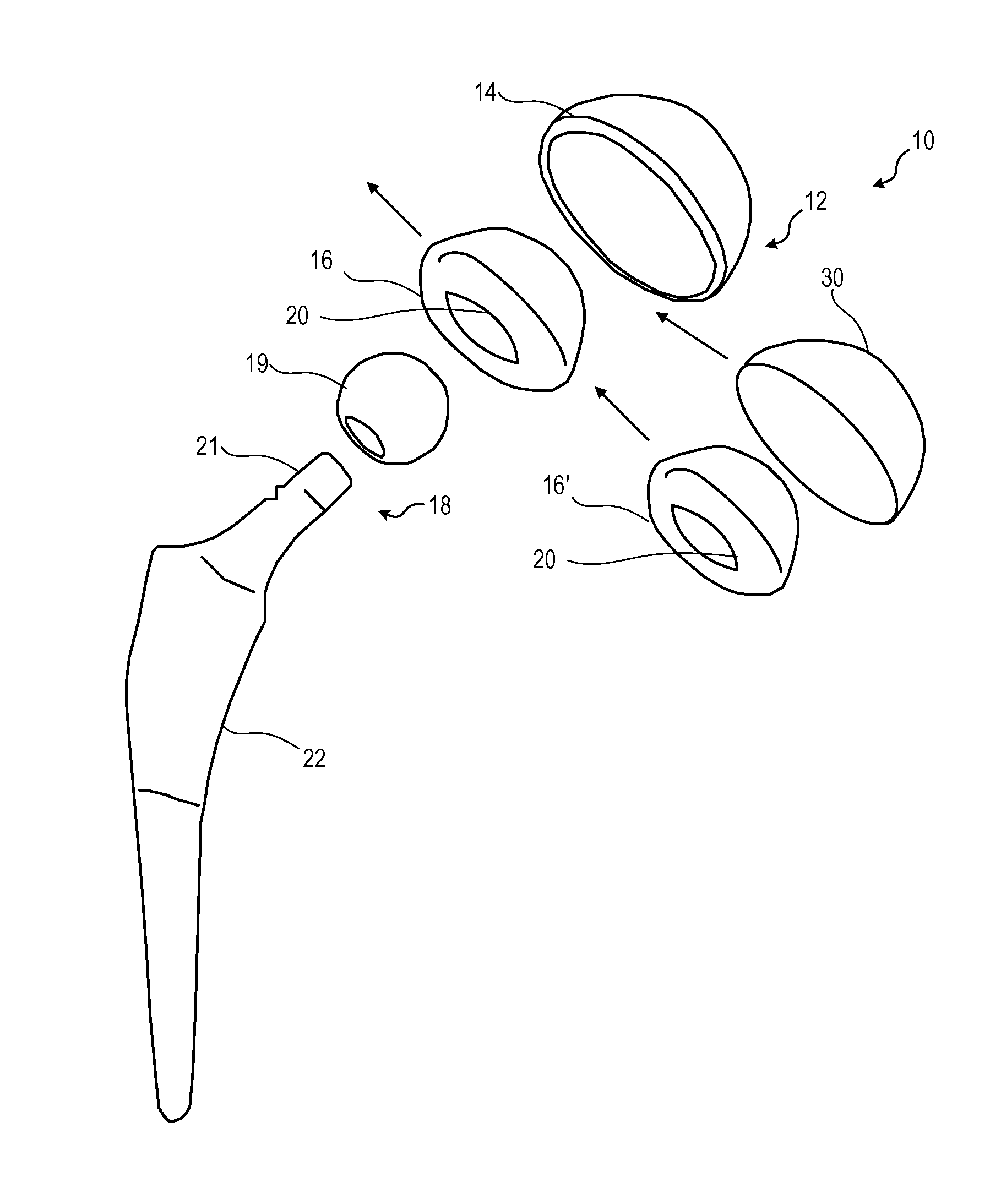

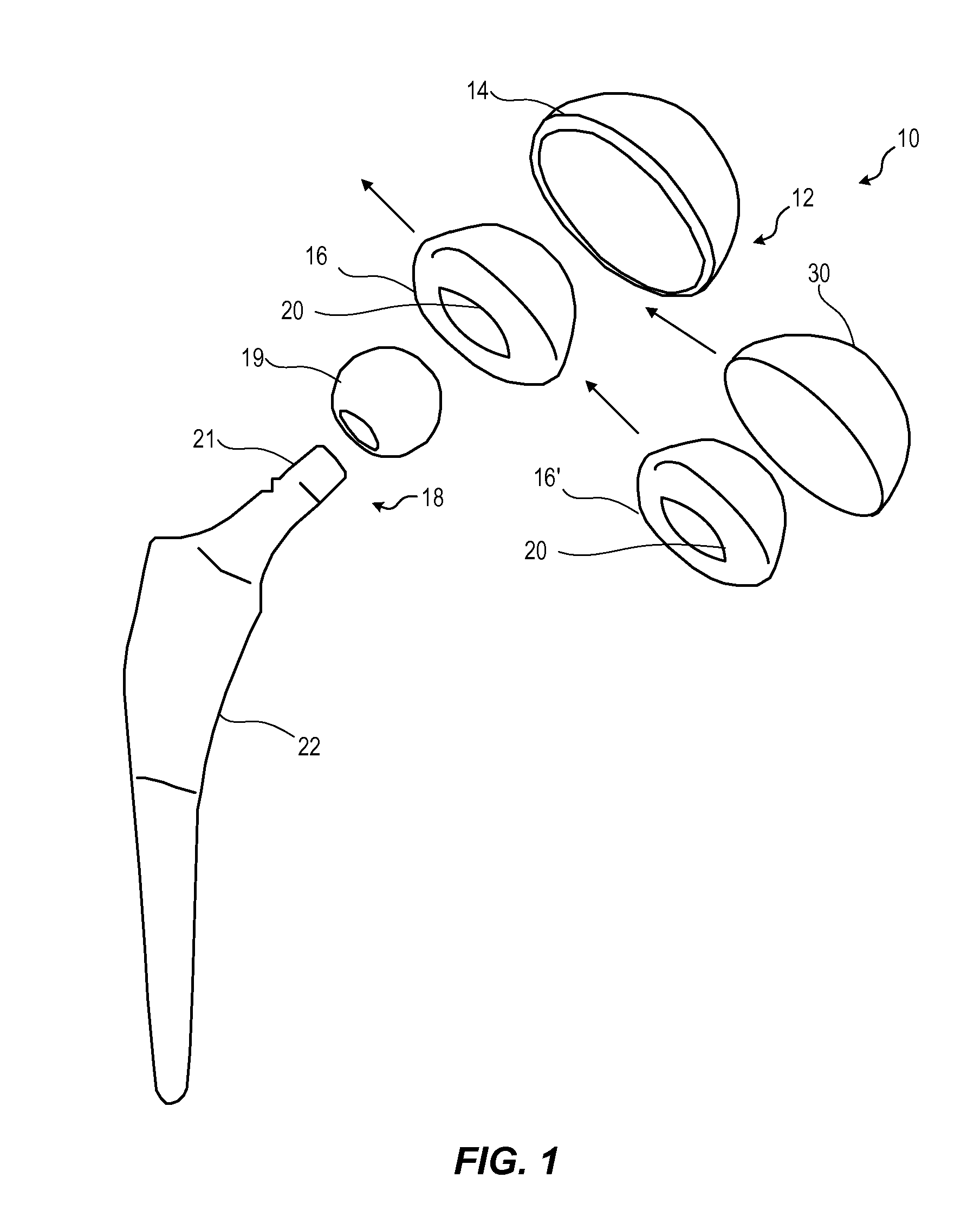

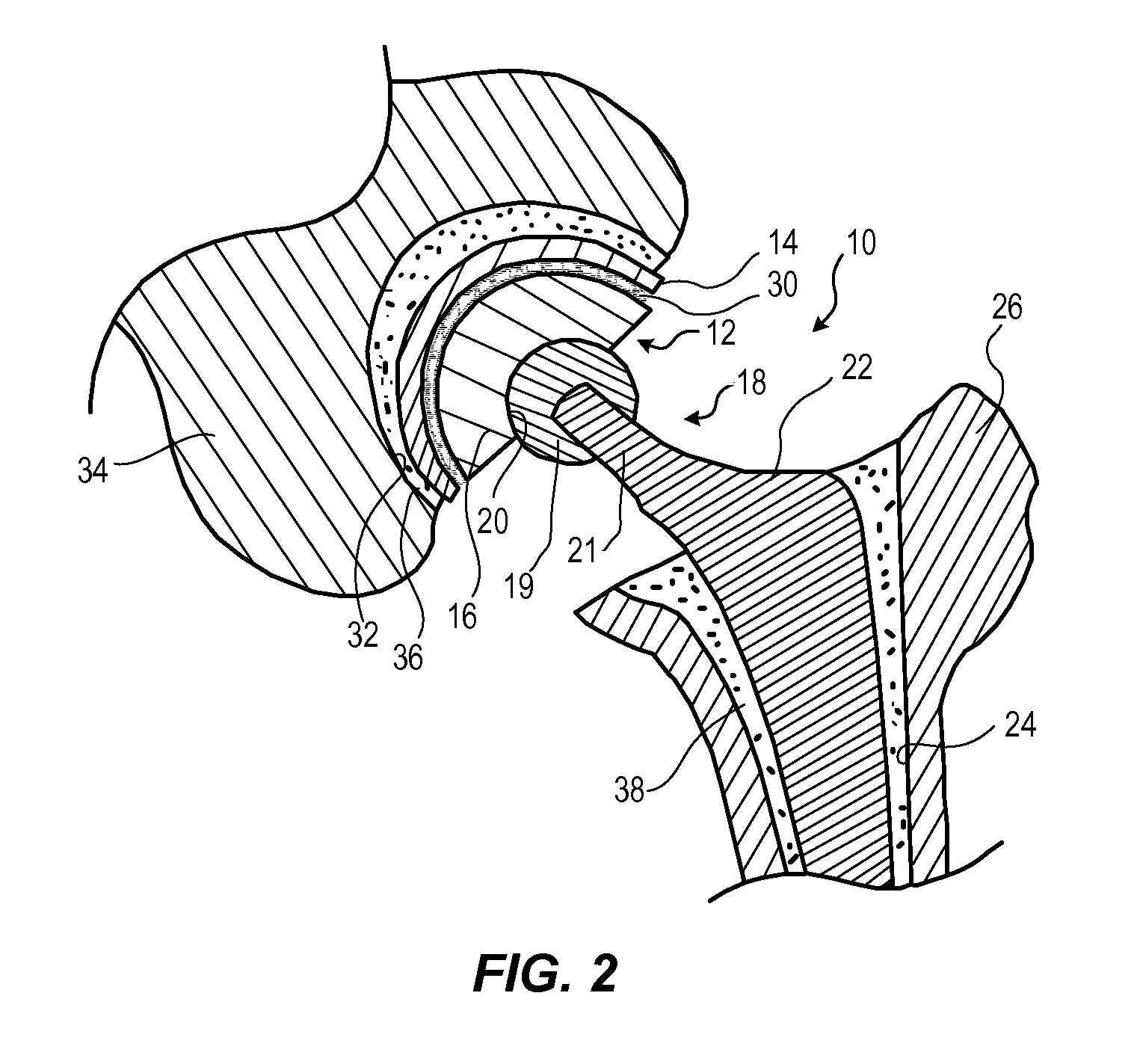

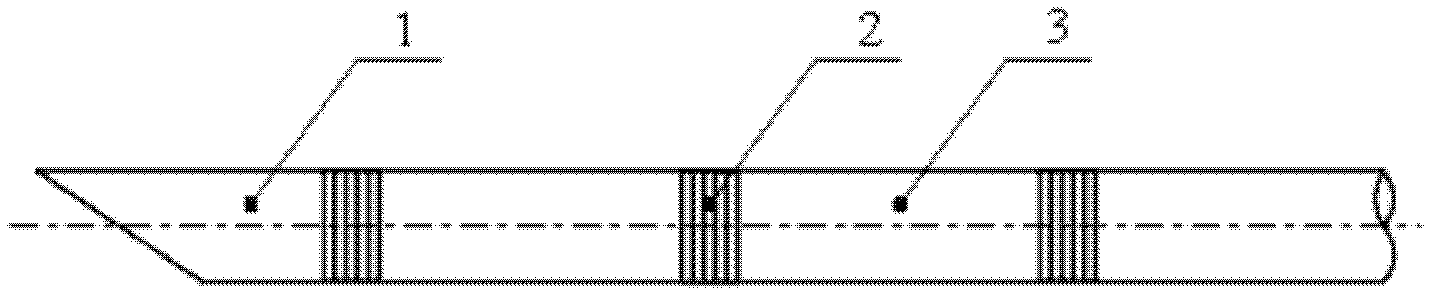

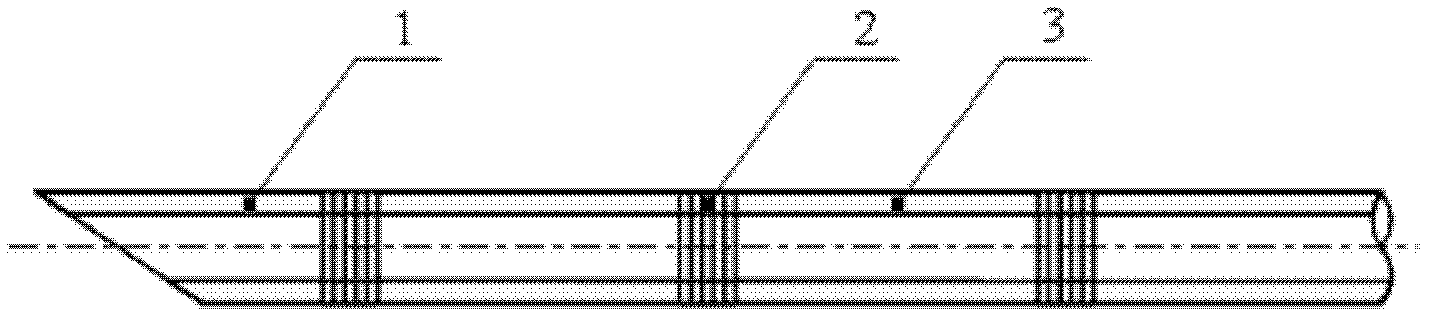

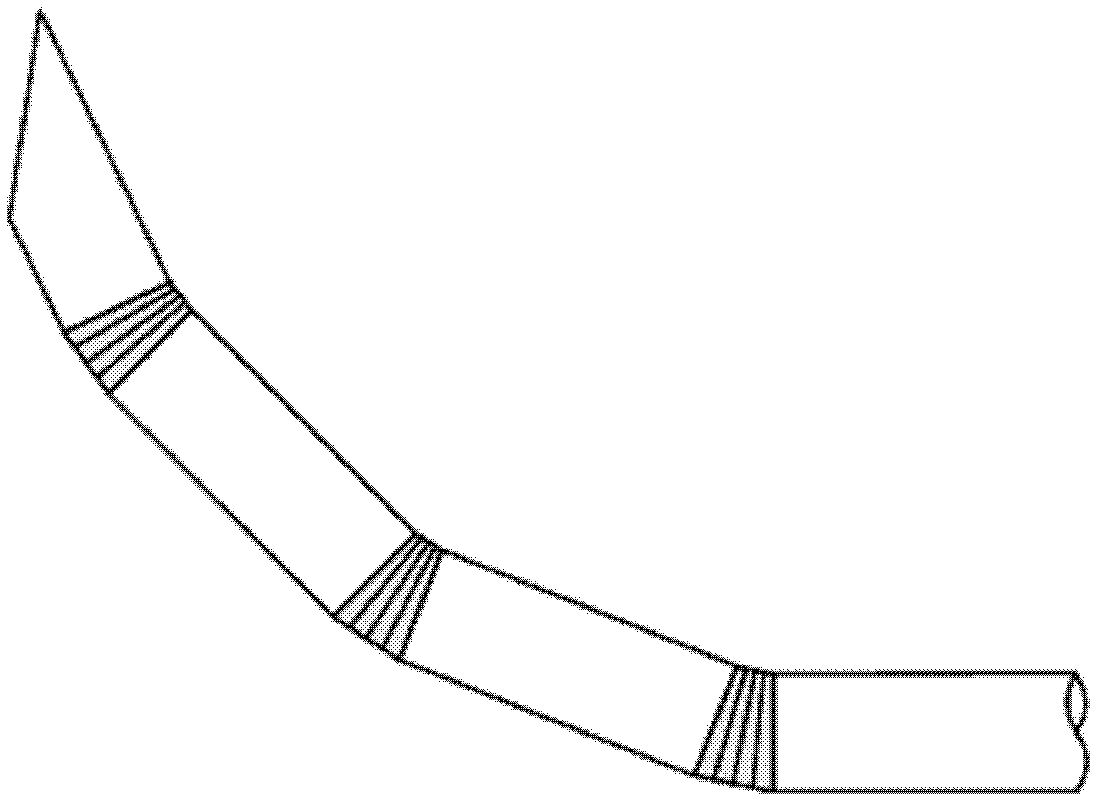

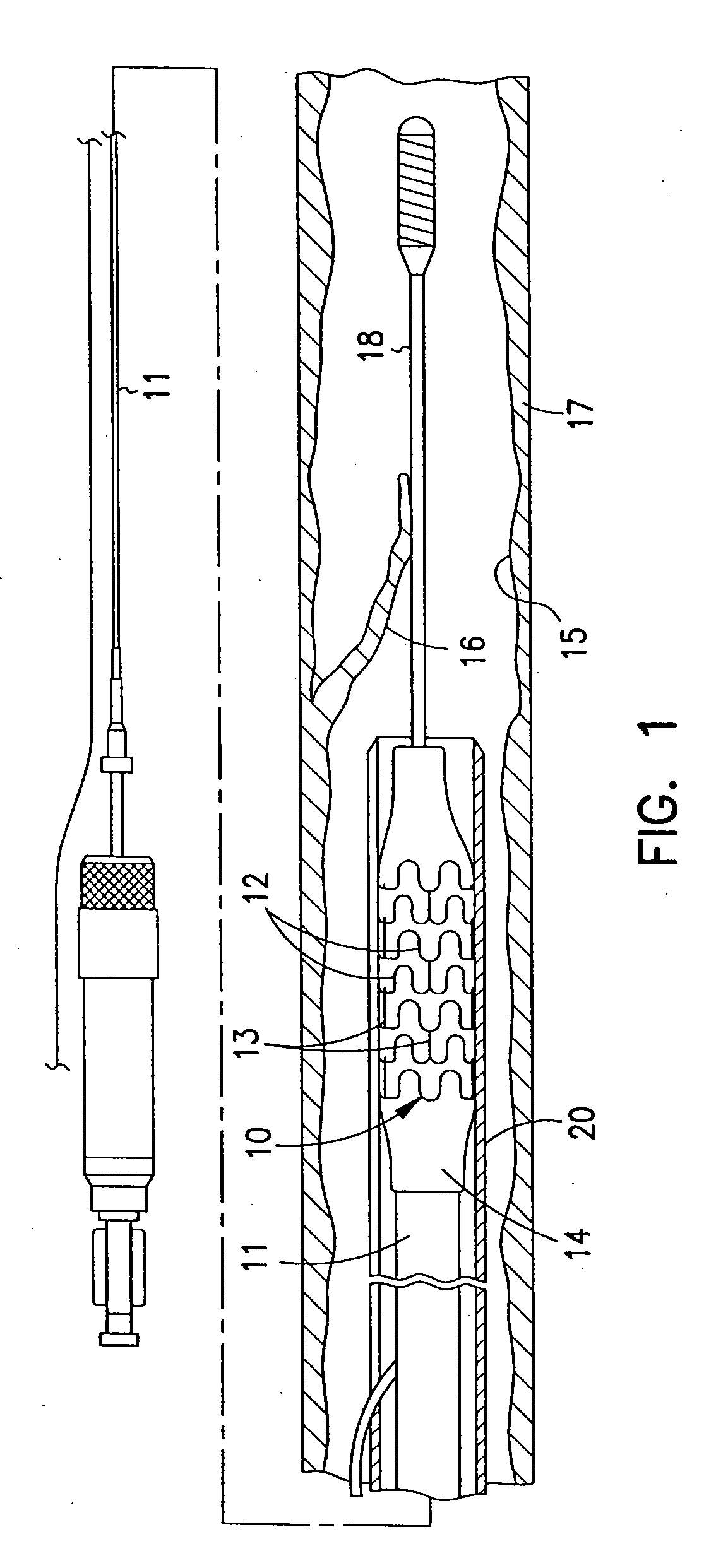

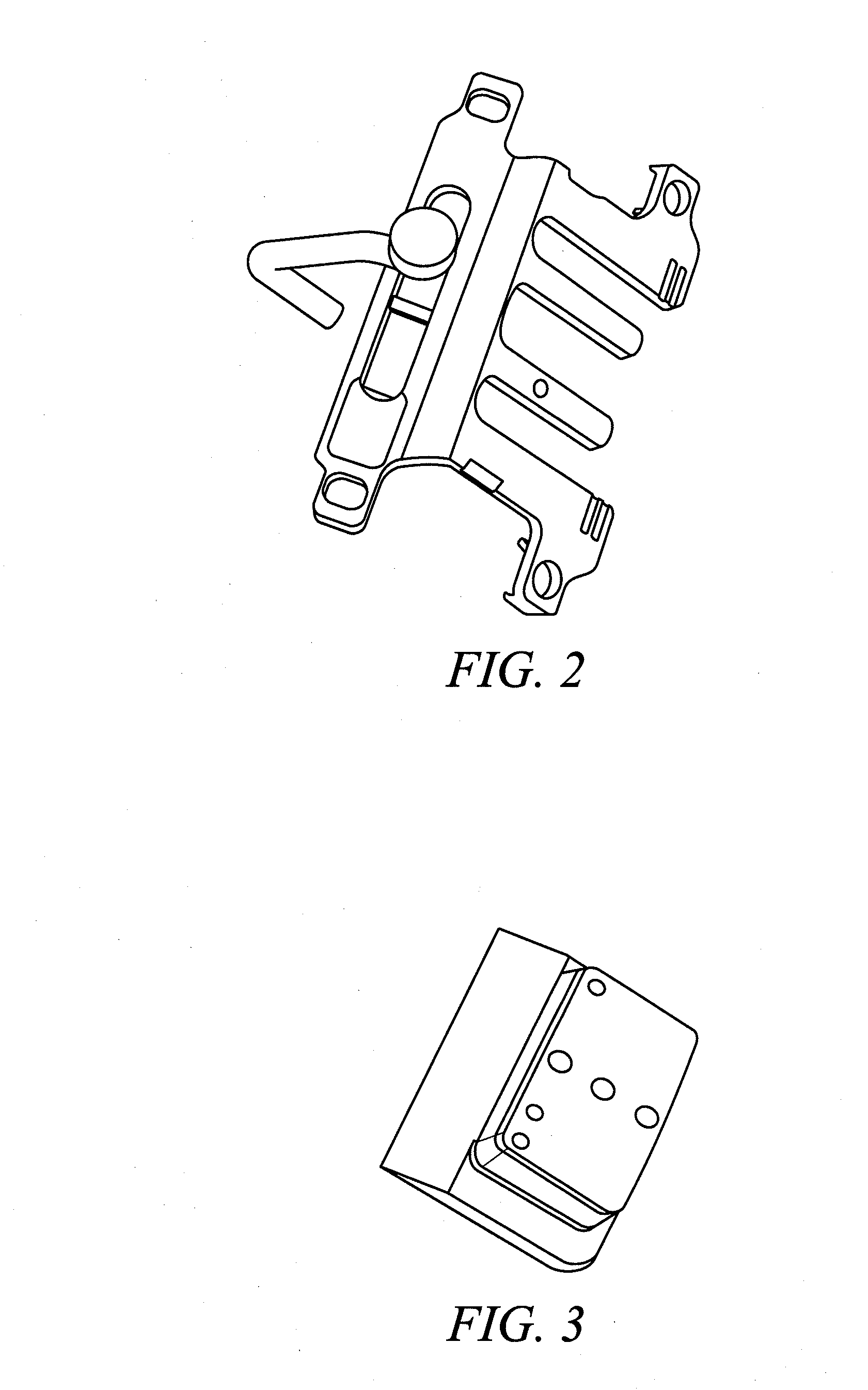

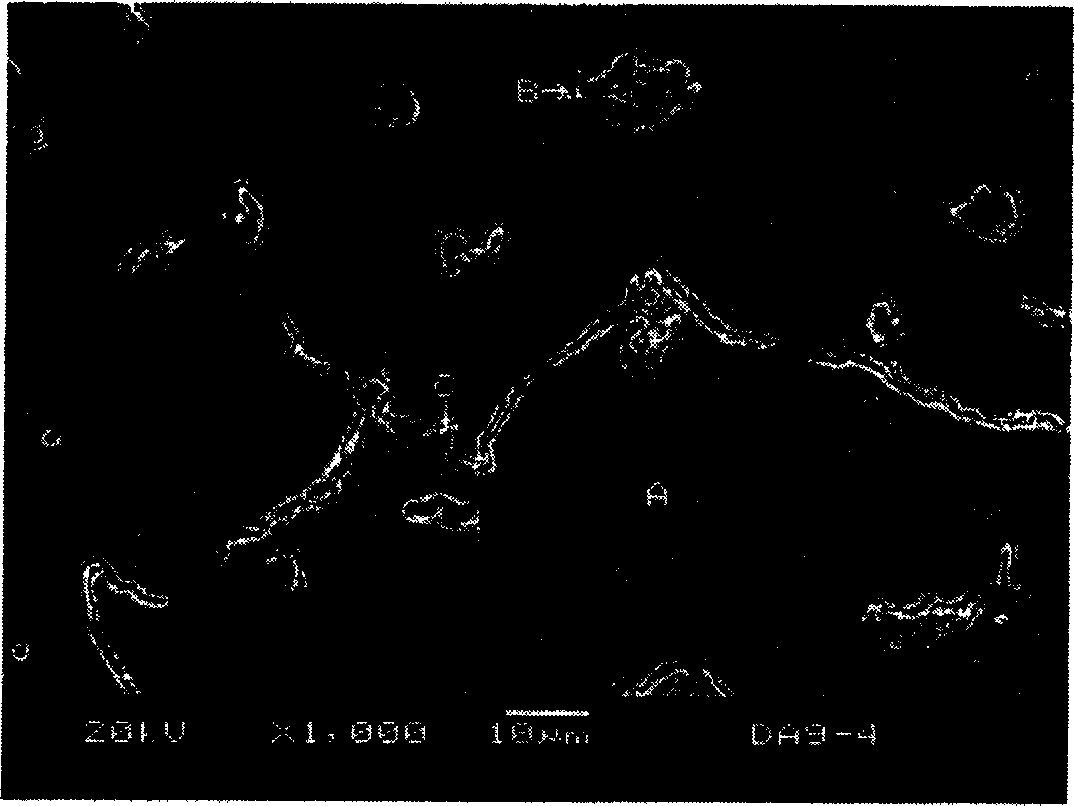

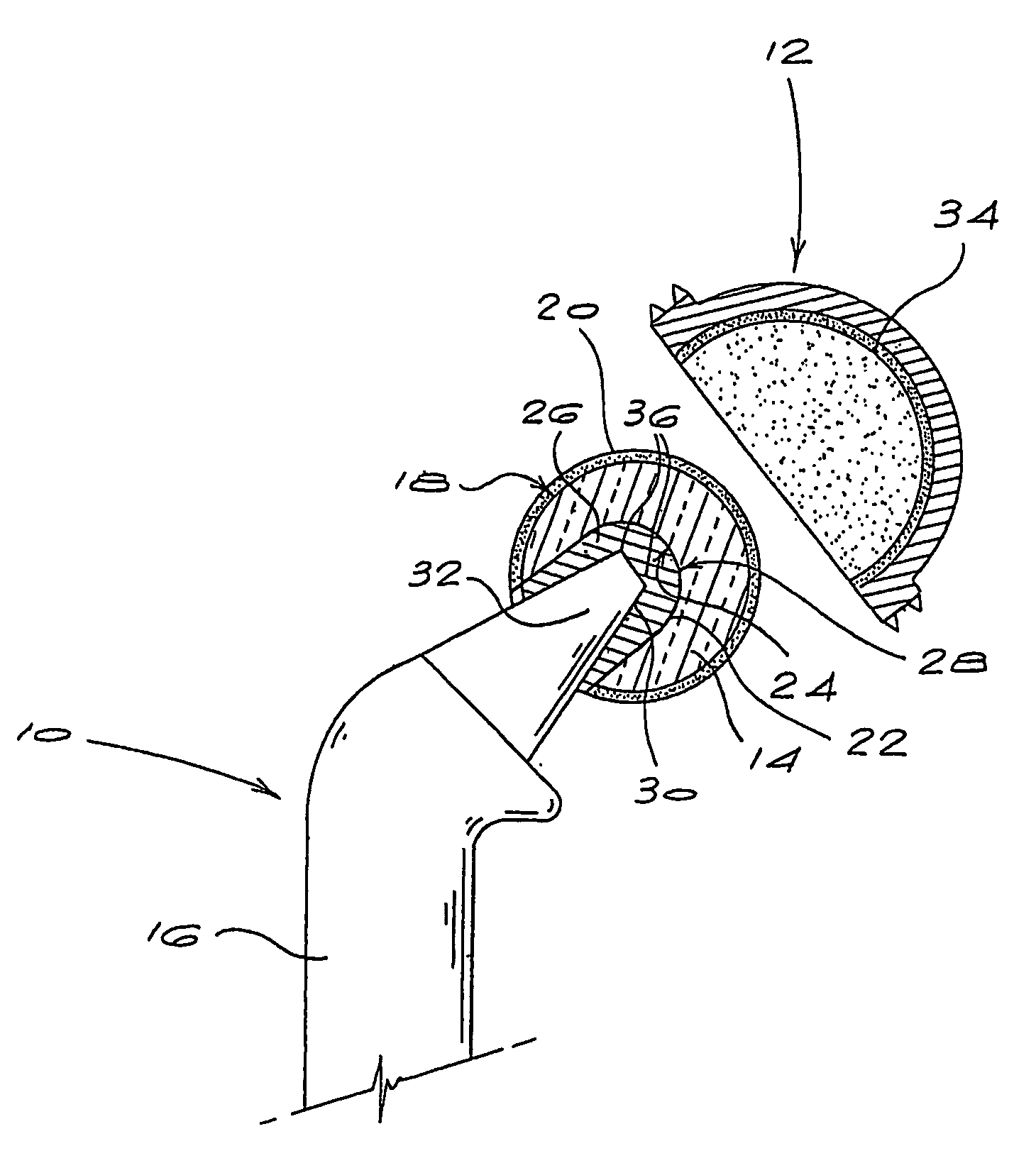

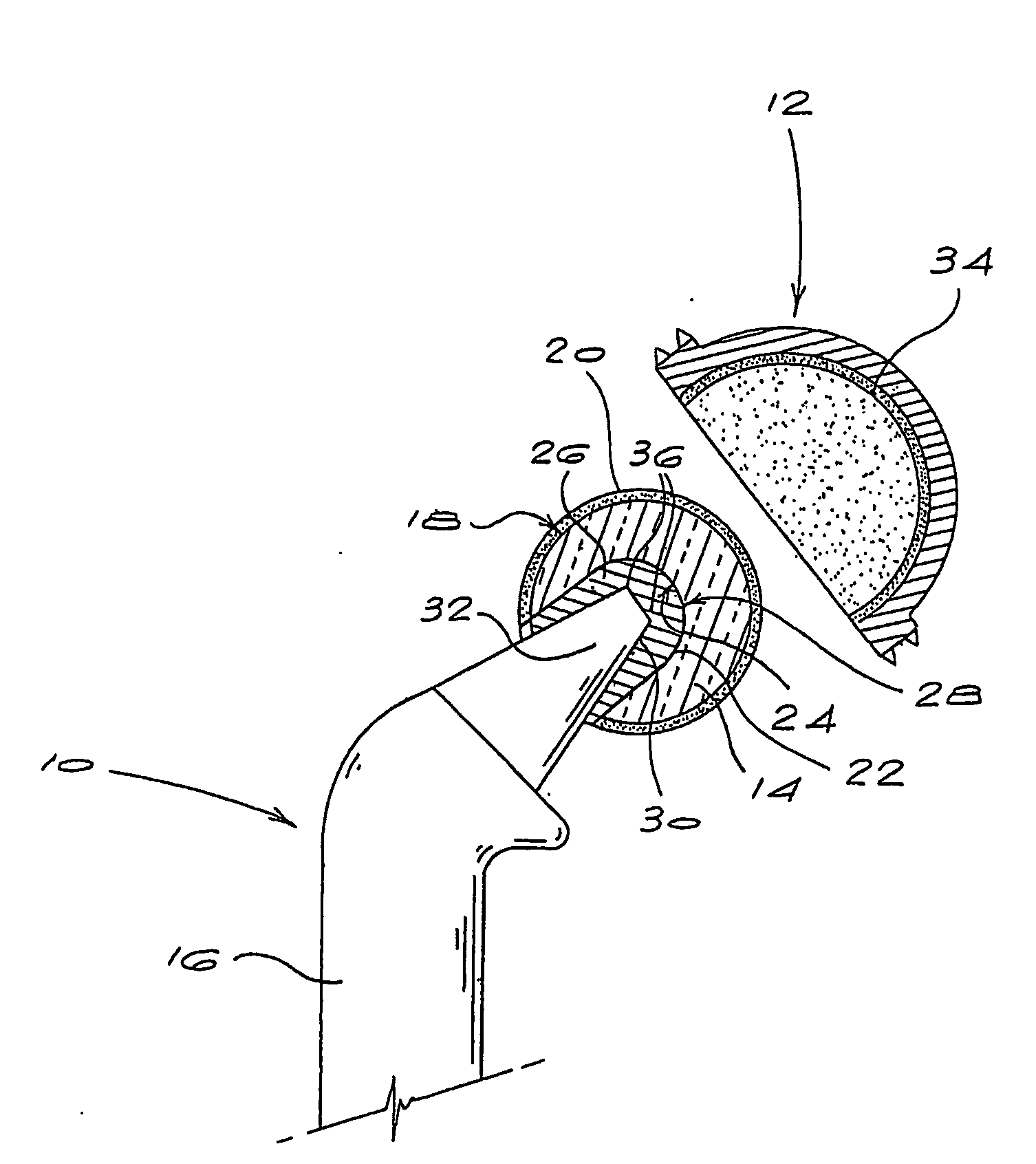

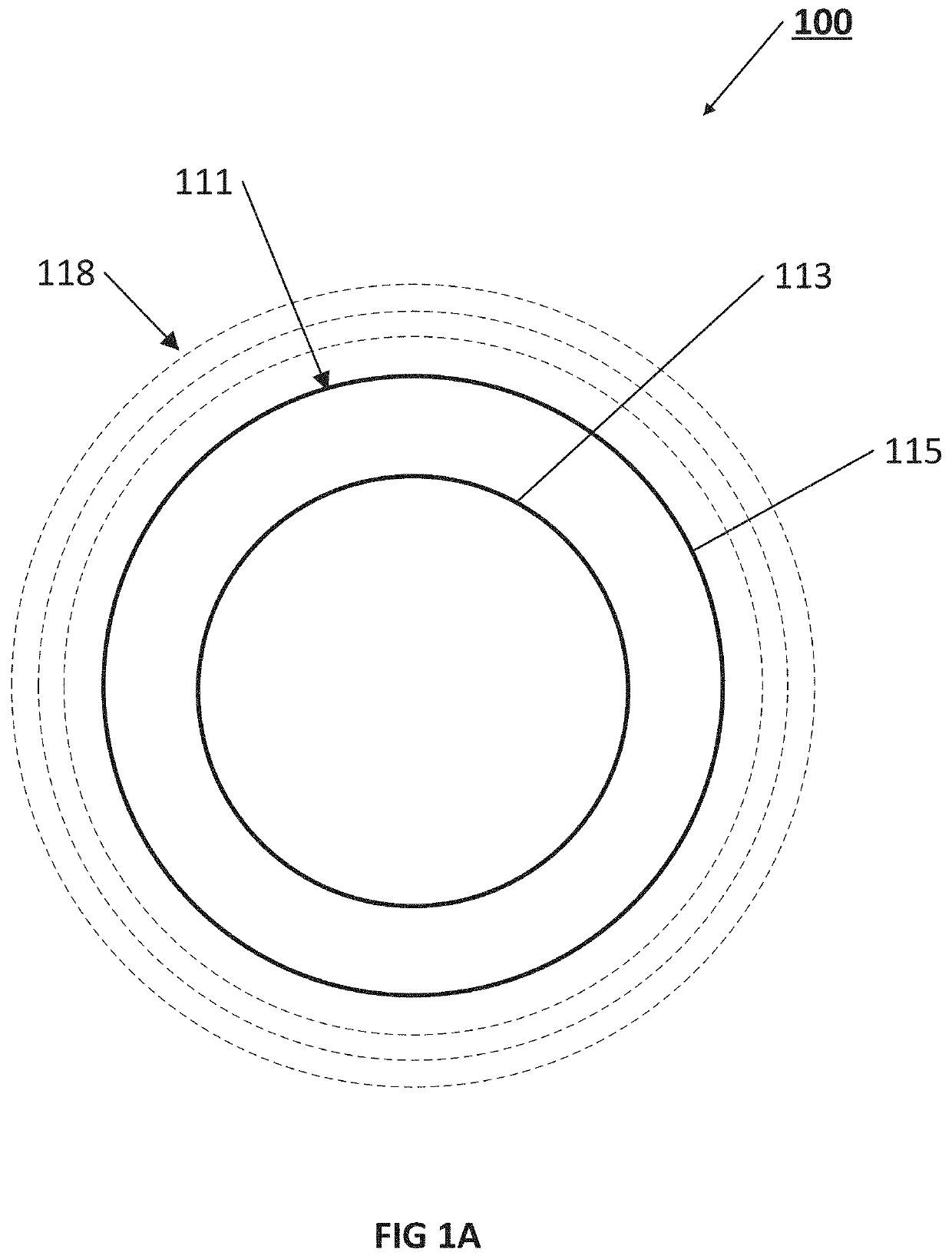

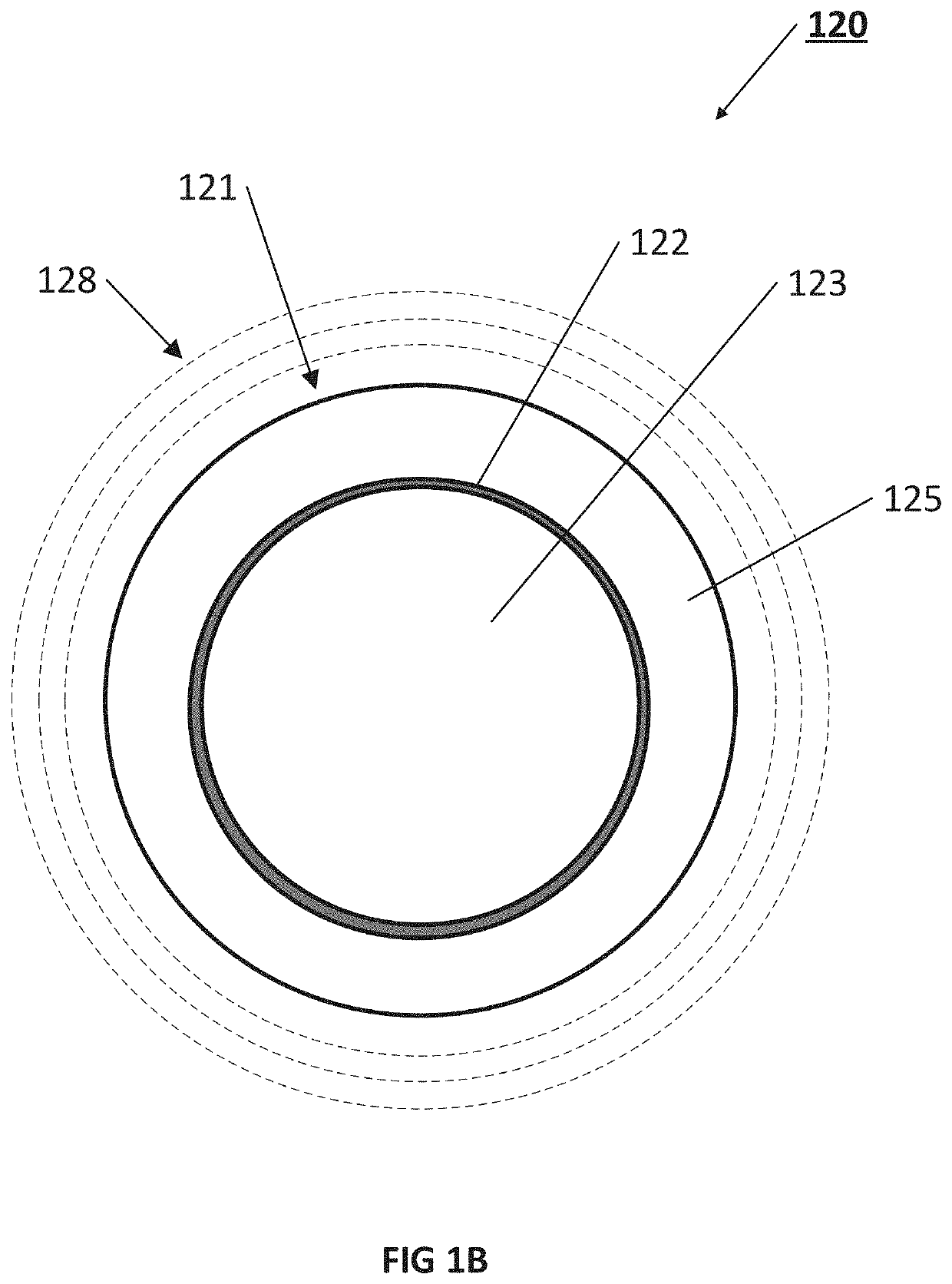

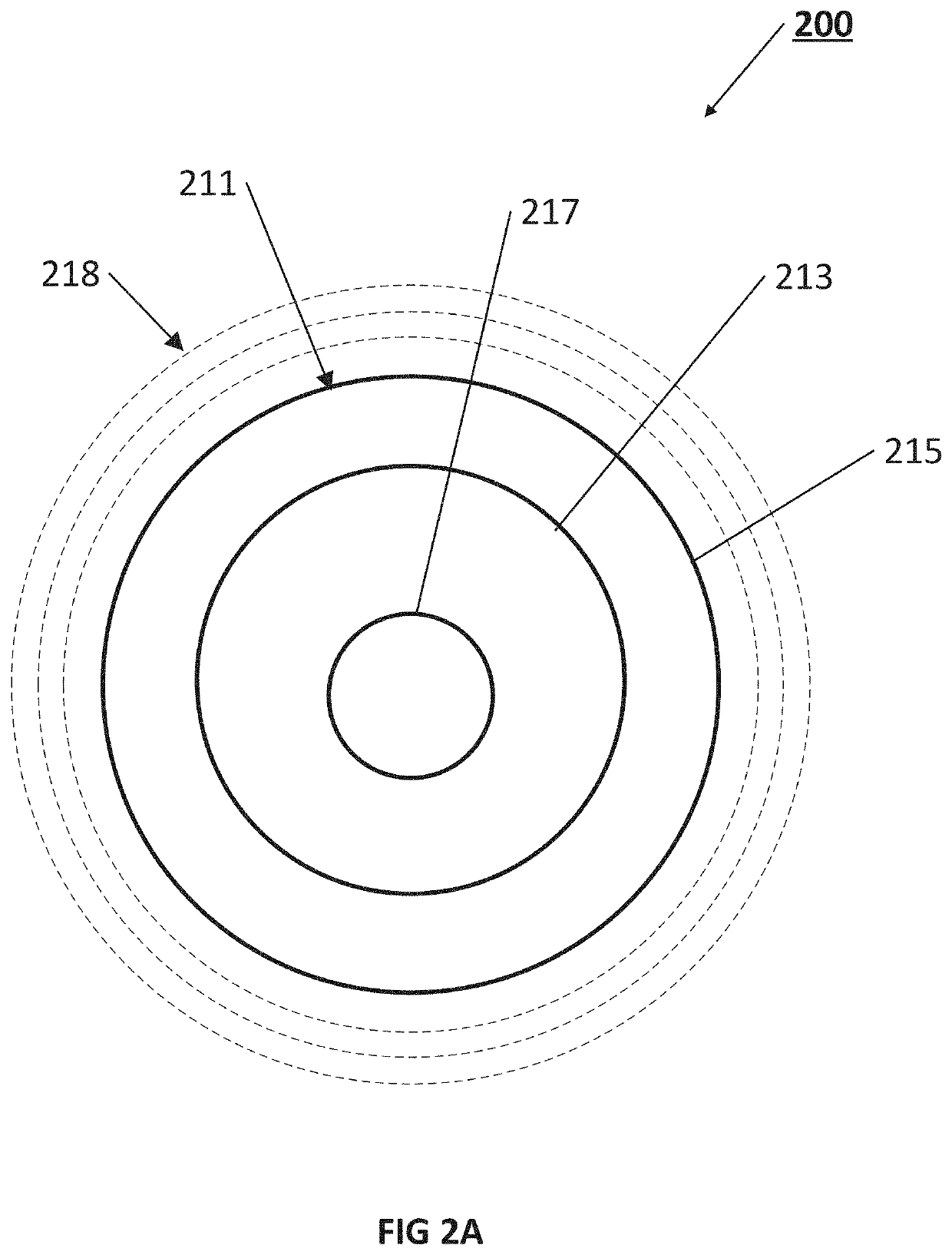

Inner acetabular liner for a dual mobility femoral head construct

A dual mobility femoral head construct has a secure acetabular shell received within an acetabular recess formed in a pelvis. An implantable prosthetic device is implantable after a failure of an originally installed articular head insert of an acetabular cup assembly. A hemispherical liner is formed from a cast cobalt-chromium alloy for thinness and elasticity. At least three spacers are annularly displaced about an outer diameter of the hemispherical liner to define a uniform cement thickness with the secure acetabular shell. Web shaped depressions are formed circumferentially in the outer diameter of the hemispherical liner to receive cement to resist lever out forces and to secure the cement bond with the secure acetabular shell. A replacement articular head insert is then received for dual mobility rotational movement in an inner diameter of the hemispherical liner. A femoral head implant is received for articulating movement in the articular head insert.

Owner:CHOUDHURY SAMBHU +3

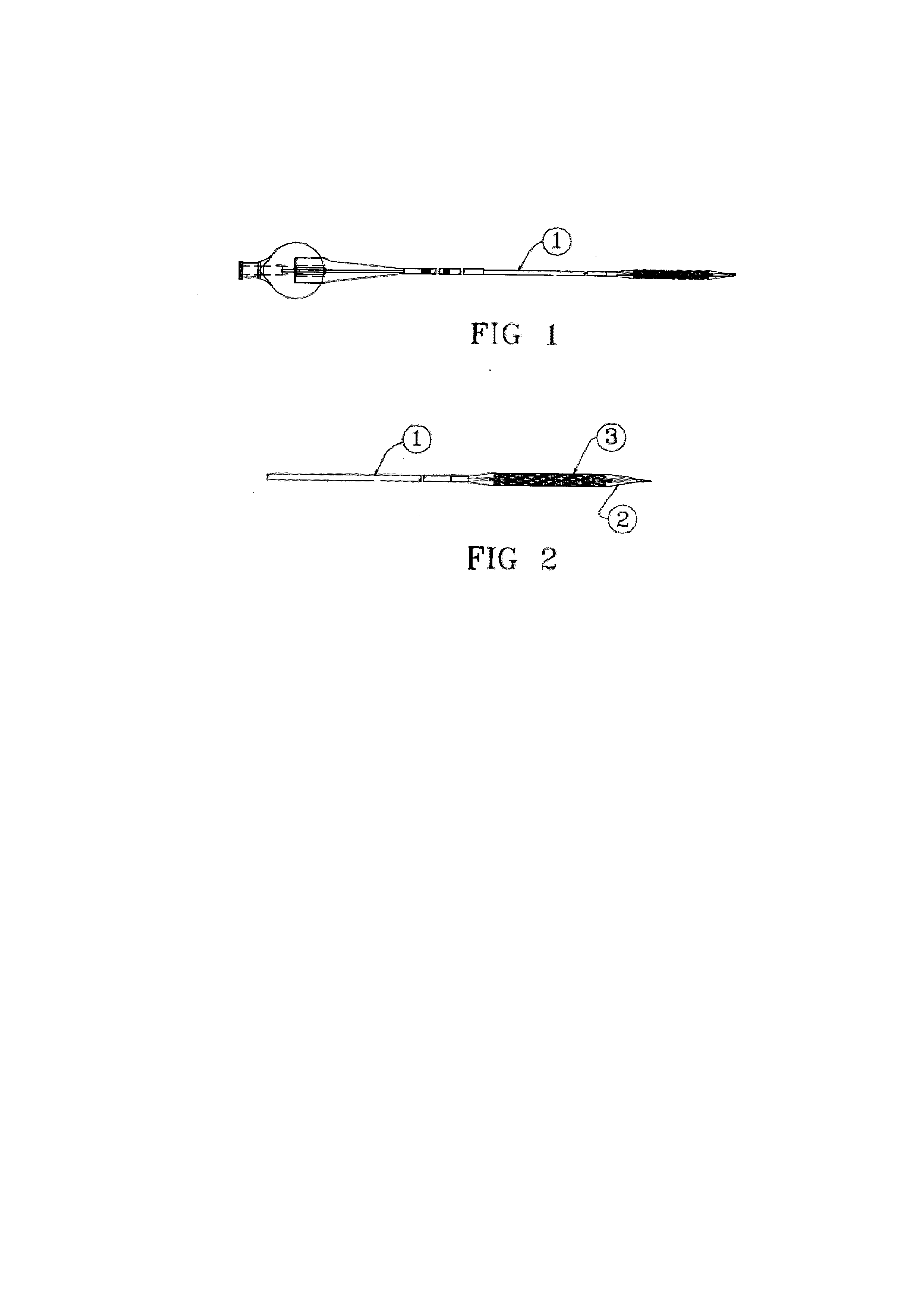

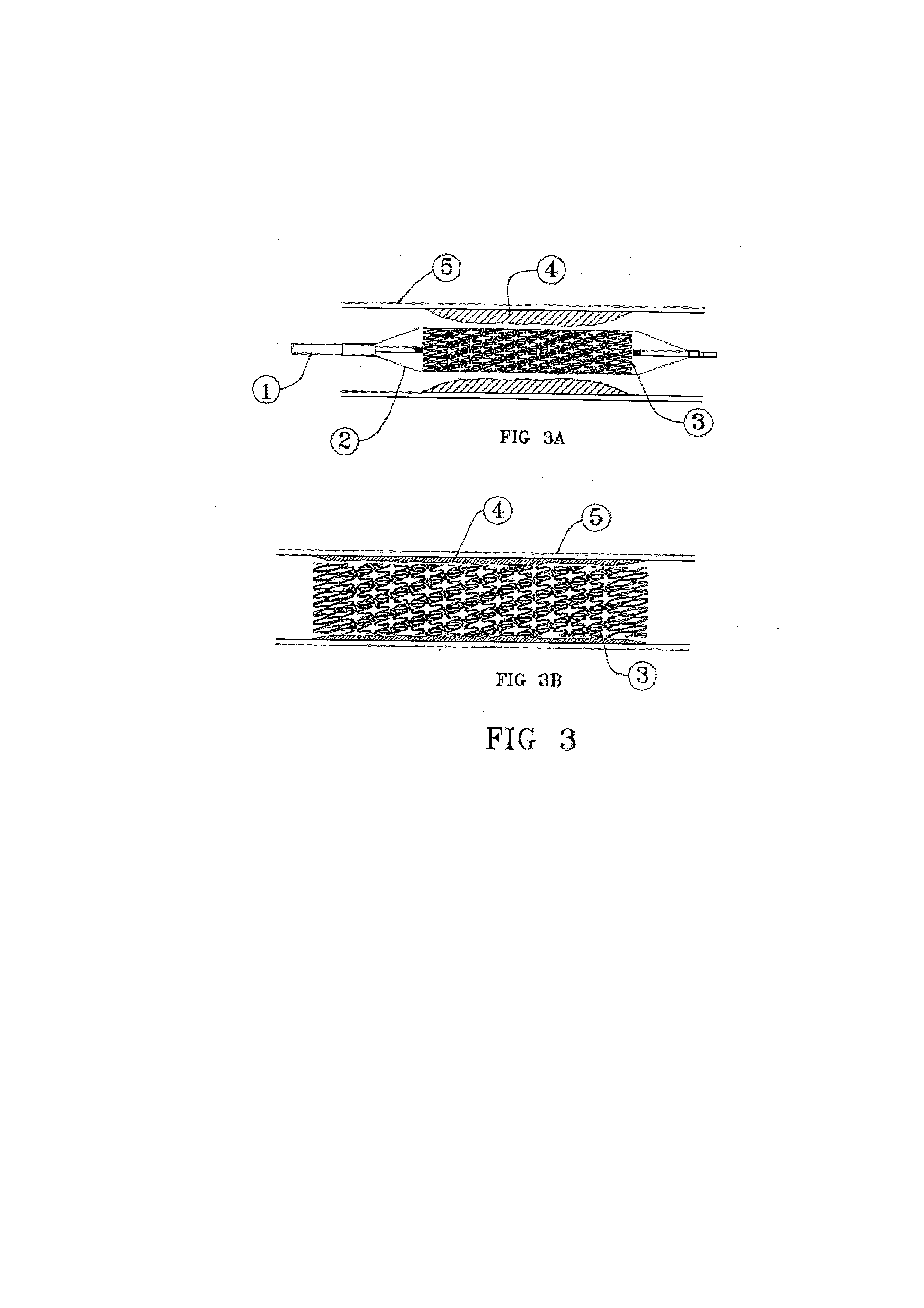

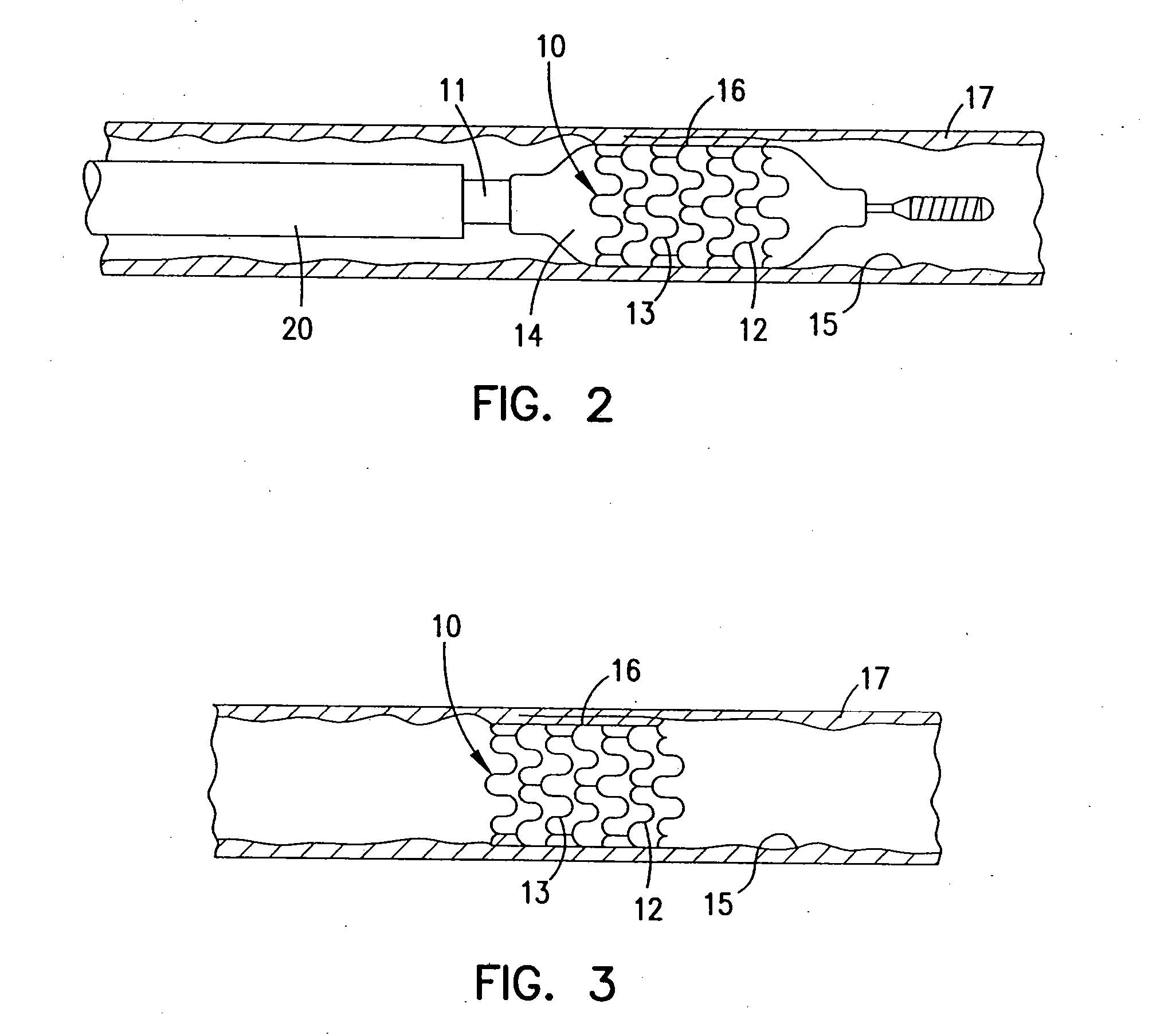

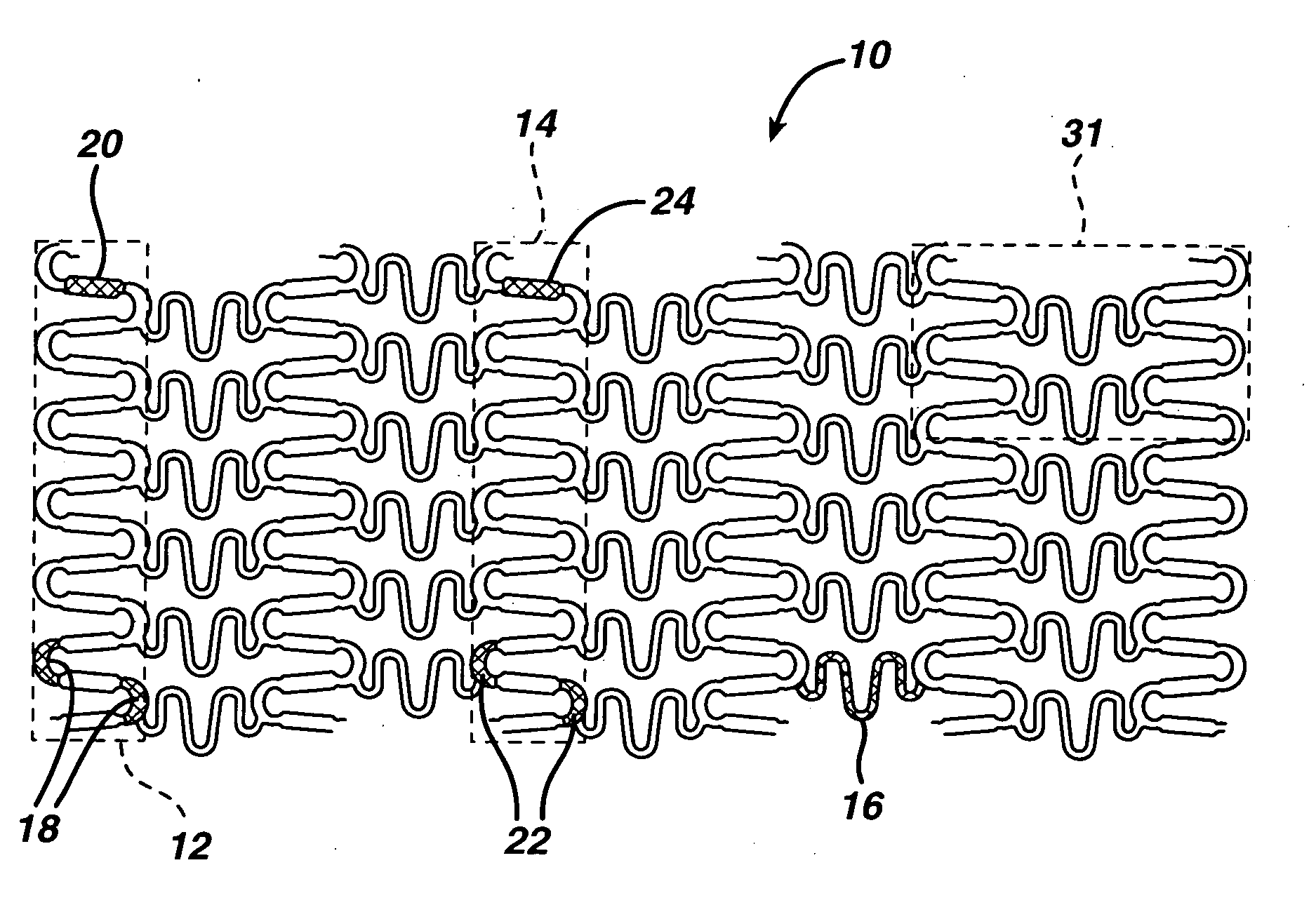

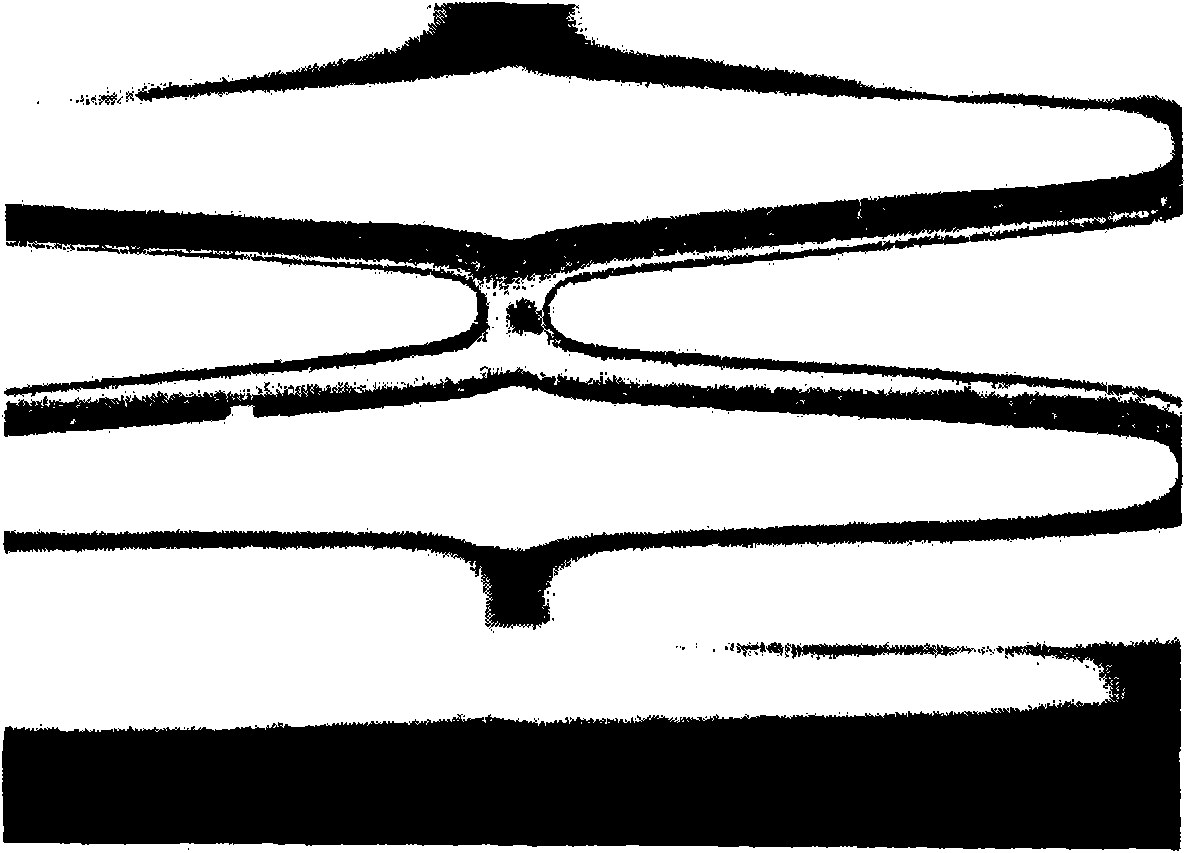

Stents with low strut thickness and variable strut geometry

InactiveUS20130178928A1Improve the immunityHigh mechanical strengthStentsBlood vesselsOpen cellClosed cell

The invention disclosed herein is a balloon expandable metallic stent with low and uniform strut thickness for implantation in a body lumen such as artery. The stent consists of variable geometry of scaffold structure consisting of cells with open and closed configuration across its axial length to impart differential mechanical strength to different parts. The closed cell configuration is stronger than the open cell configuration and hence offers more resistance to radial expansion than the open cell configuration. The stent is divided into distinct sections of rows of closed and open cells. By providing closed cells in the end portions and open cells in the central portion of a stent, the dog-boning effect can be eliminated. Other configurations can be created by making only one end section of the stent with closed cells. The thickness of the stent made from cobalt-chromium alloy L-605 could be reduced to as low as 35 microns with adequate radial strength as well as fatigue resistance. The stent with thinner struts and elimination of dog-boning effect are known to reduce arterial injury.

Owner:MERIL LIFE SCI PVT

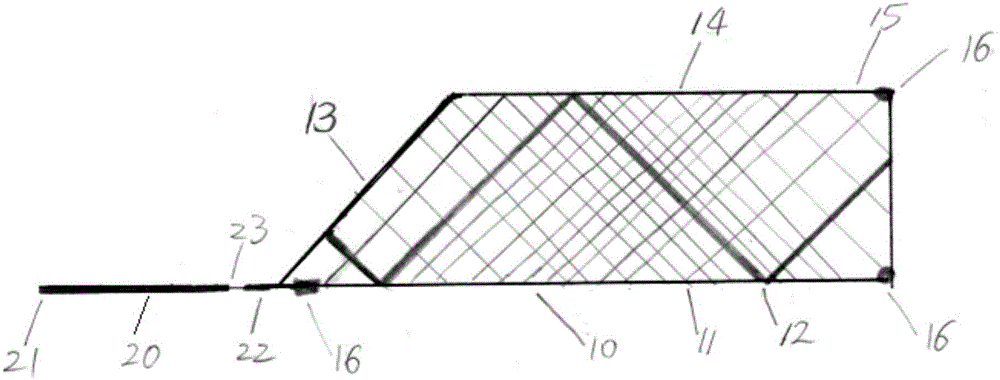

Intravascular stent of composite structure

The invention discloses an intravascular stent of a composite structure; the intravascular stent comprises a stent main body, wherein the distal end of the stent is restrained as an adducted form by virtue of a tightening wire, and the tightening wire is degradable magnesium alloy or degradable iron alloy; one or more auxiliary wires are woven on the stent main body; when the stent is applied to blood vessel of brain, the auxiliary wire is pure platinum or alloy thereof, pure gold or alloy thereof, pure tungsten or alloy thereof, or pure tantalum or alloy thereof; and when the stent is applied to peripheral blood vessel, the auxiliary wire is cobalt-chromium alloy or stainless steel or tungsten or tantalum. The stent, when serving as a thrombus removal system for treating cerebral apoplexy, not only can be used for removing thrombus effectively for several times but also can be used for catching small thrombus flowing to distal end so as to prevent distal blood vessels from getting blocked; and the stent can be used for dilating stenosis or blocked brain blood vessel or peripheral blood vessel, so as to take an effect of dredging and reconstructing a blood flow. The stent can be repositioned and released, with high controllability; and the stent can be used for reducing operation difficulty and greatly improving an operation success rate.

Owner:魏诗荣 +1

Method for the manufacture of dental prostheses

InactiveUS20080241788A1Good processing characteristicsMinimizing any tendencyAdditive manufacturingImpression capsRheniumManganese

The invention relates to the use of a cobalt-chromium alloy in the manufacture of a dental prosthesis. The alloy contains:43-68% by weight cobalt,12-30% by weight chromium,8-25% by weight tungsten,0-13% by weight iron,0-30% by weight manganese,0-10% by weight molybdenum,0-5% by weight of at least one of the elementsaluminum, tantalum, rhenium, titanium and less than 0.1% by weight carbon.A dental prosthesis with favorable workability and a low corrosion rate is obtained by manufacturing the dental prosthesis by means of a laser melting and / or sintering process.

Owner:DEGUDENT

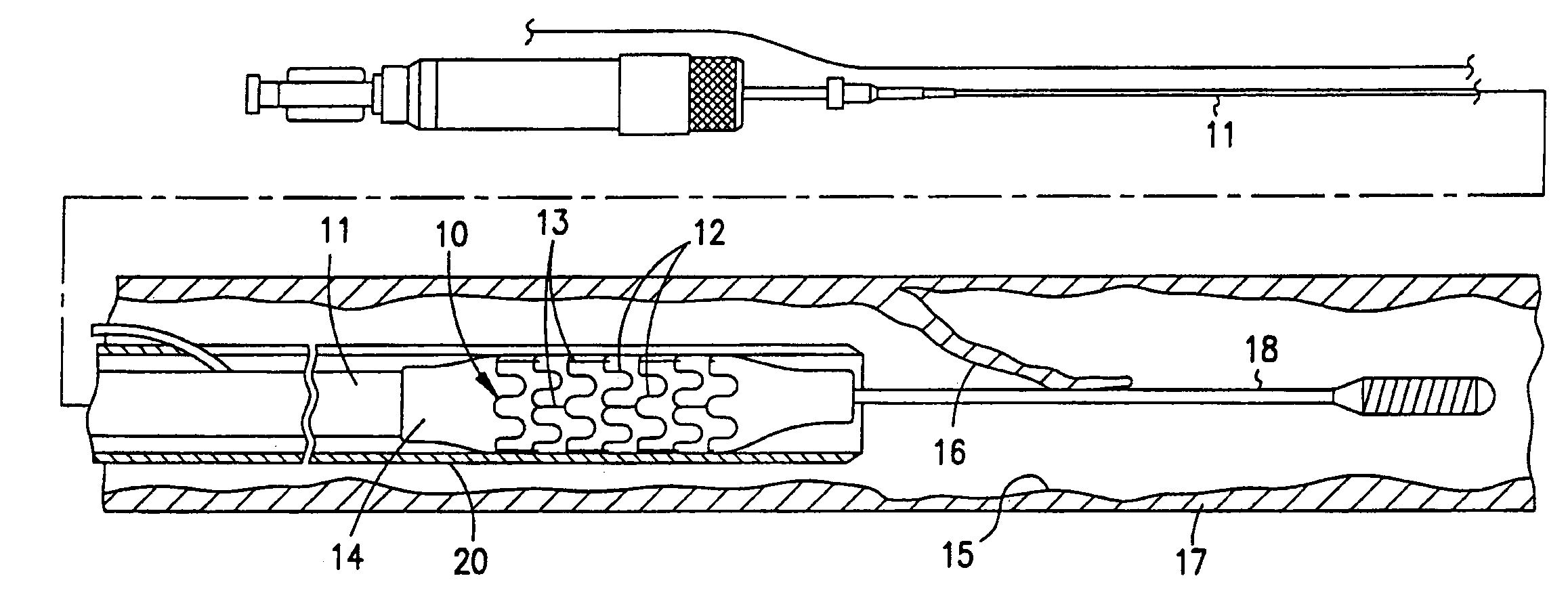

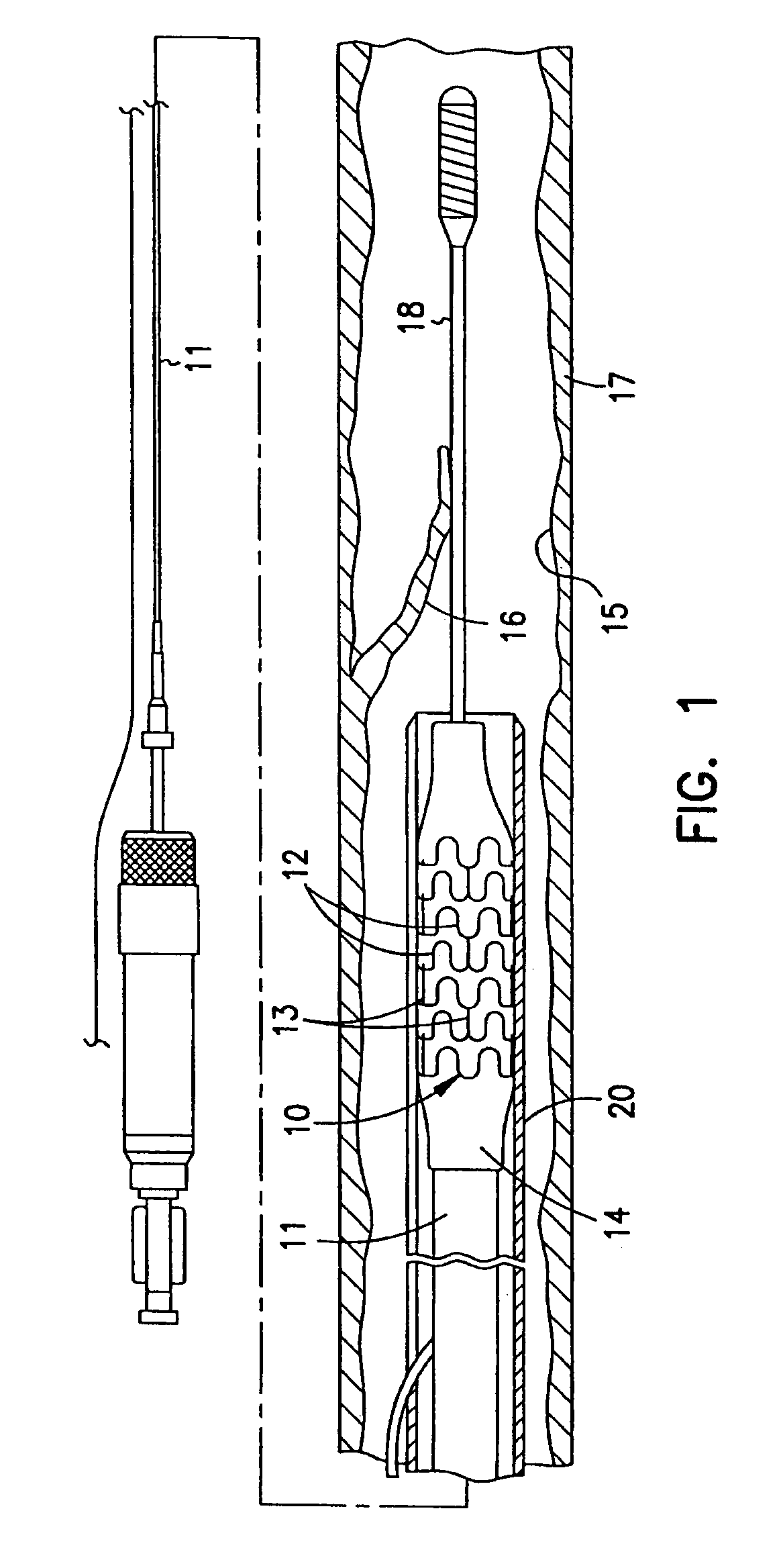

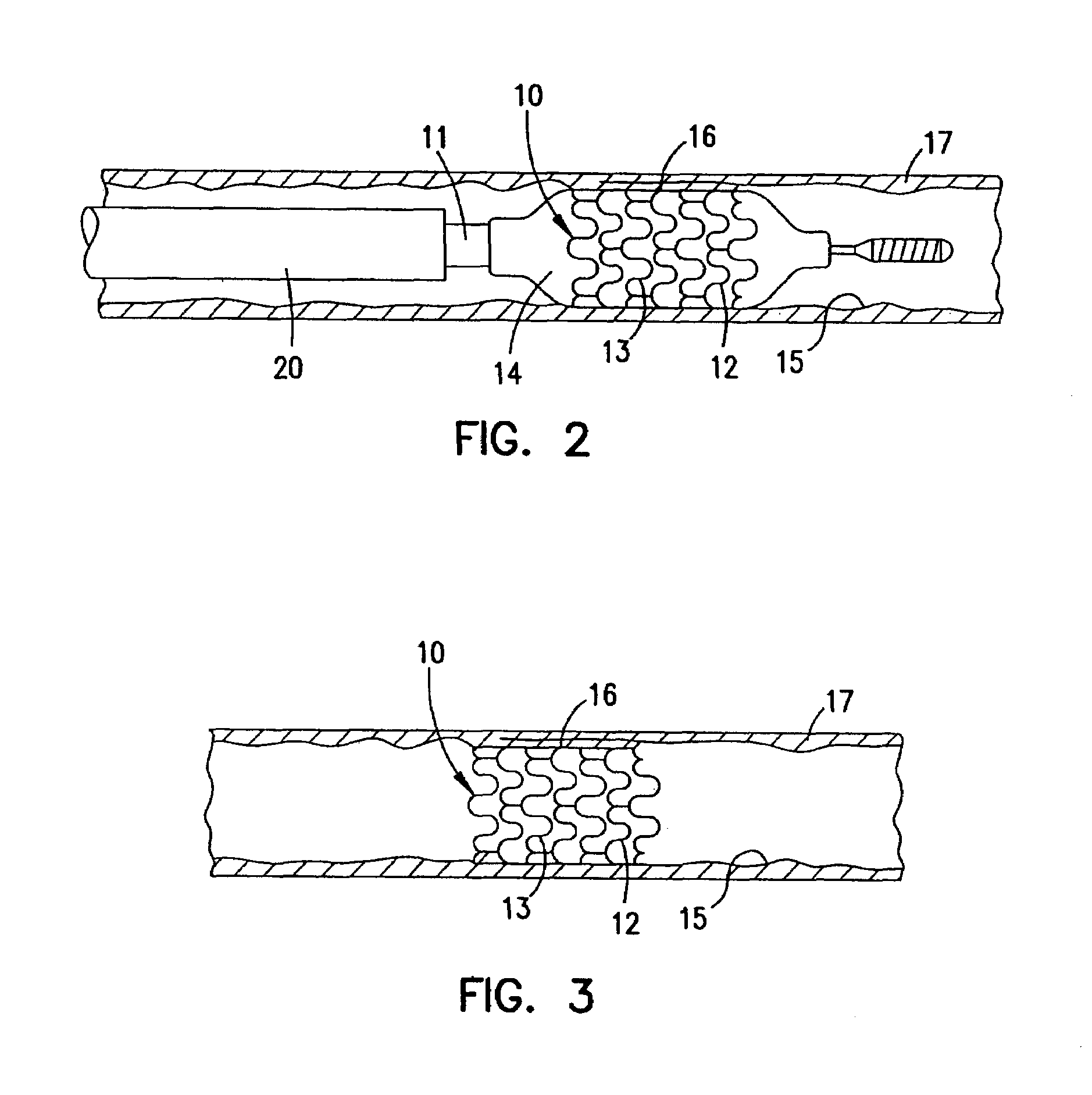

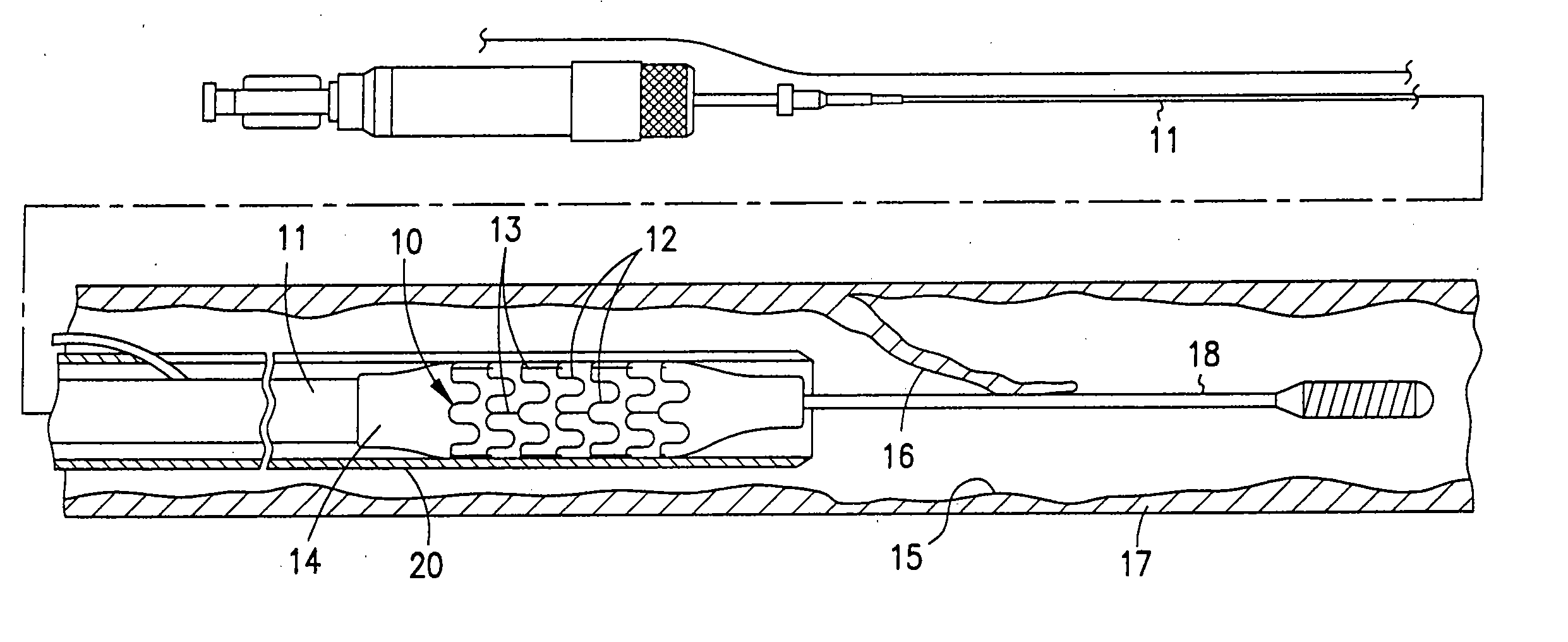

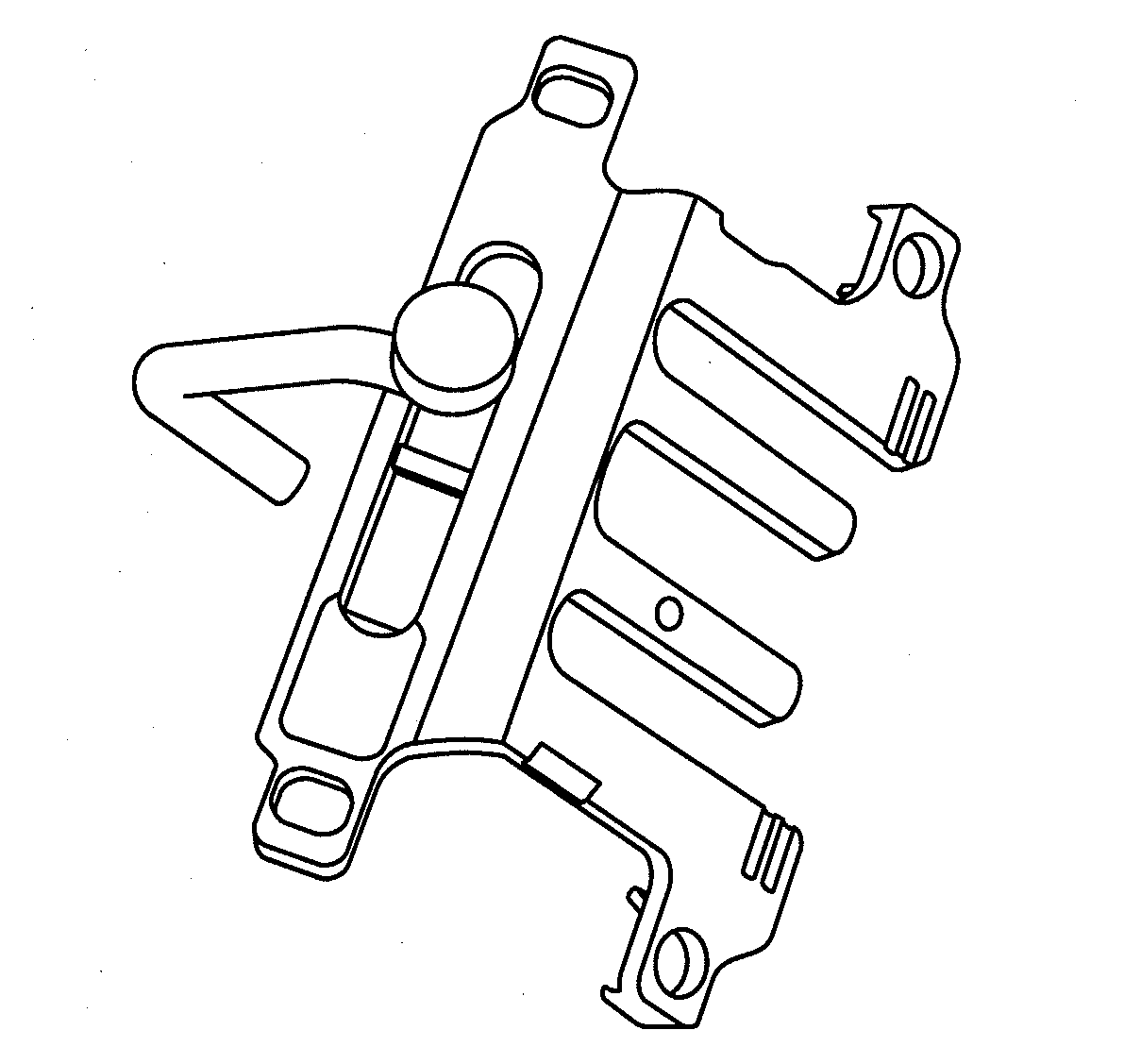

Magnetic-navigation joint type puncture needle

InactiveCN102500036AAchieve magnetic navigationPrecise NavigationGuide needlesSurgical needlesJoints typesNon magnetic

The invention relates to a magnetic-navigation joint type puncture needle which comprises a head section and needle sections, wherein, the head section is made of stainless steel material with high magnetic conductivity and is connected with the following needle sections coaxially mounted with the head section through a flexible joint; two needle sections are also coaxially connected with each other through a flexible joint; the needle sections are made of non-magnetic stainless steel material; the flexible joints adopts serpentine tubes formed by melting and engraving cobalt-chromium alloy through laser; and both the head section and the needle sections can be bent, but the flexibility of the head section and that of the needle sections are smaller than the flexibility of the flexible joints. According to the invention, an extra magnetic field force is used to cause the head section of the needle to deflect, so that the following purposes can be achieved that the insertion direction of the needle can be changed, and the other needle sections also deflect with the deflection of the head section; accurate navigation for and control over puncture path and puncture position when the puncture needle performs a non-direct channel puncture in a human body; the puncture needle provided by the invention can reach niduses which other types of puncture needles can not reach; the application scope of minimally invasive surgery is expanded; iatrogenic injuries can be reduced; and patients can be benefited.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for manufacturing a dental prosthesis

Owner:DENTSPLY SIRONA INC

Process for producing tools used in orthopedic surgeries

InactiveUS20100262149A1Ceramic shaping apparatusNon-surgical orthopedic devicesCobalt chromium alloyPlastic surgery

An orthopedic tool being made from an alloy in the group comprising stainless steel alloys, cobalt-chrome alloys, titanium alloys and alumina and zirconia ceramic alloys, and having a density less than 98% of a theoretical possible density for the alloy, the orthopedic tool being made by a metal injection moulding process.

Owner:MAETTA SCI

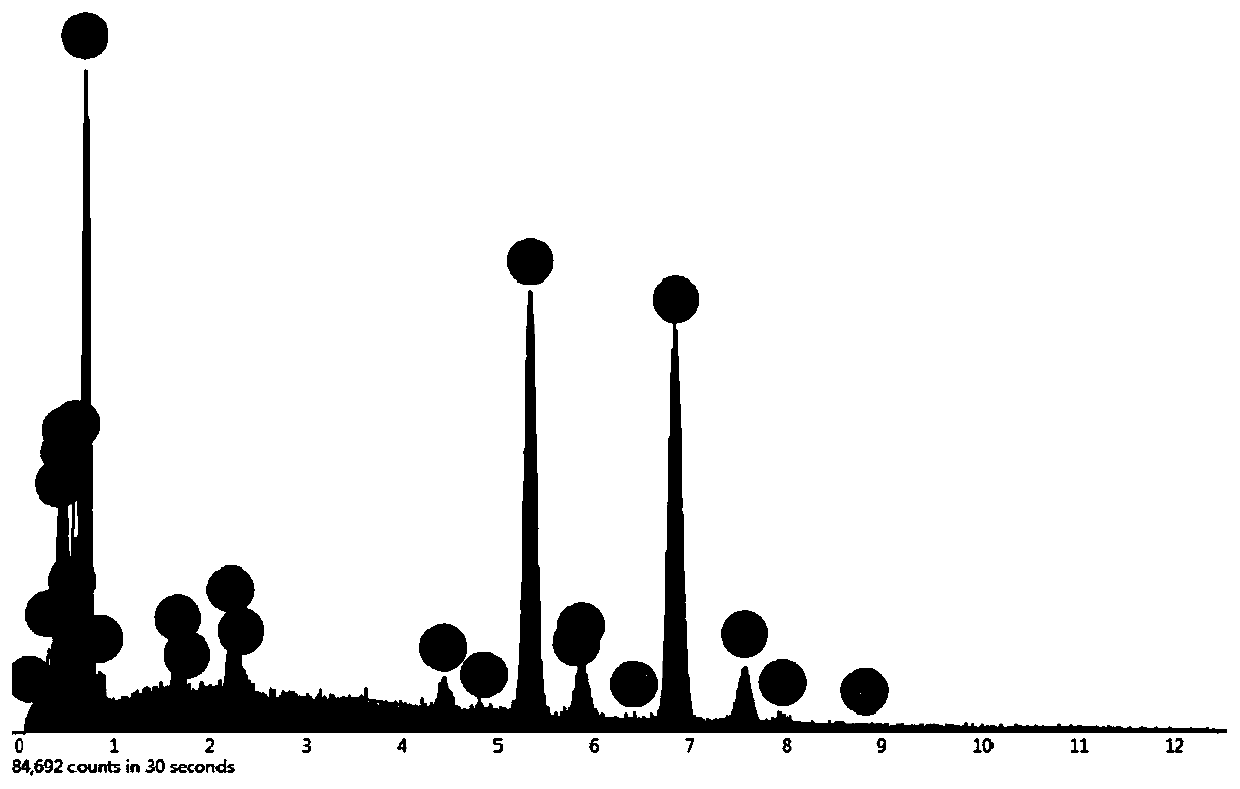

Cobalt chrome alloy containing rare earth La for dental ceramic stent

InactiveCN1827814AHigh wearing safetyHigh strengthImpression capsDentistry preparationsCobaltInduction furnace

The invention relates the stove enamel support cobalt chromium alloy containing rare earth La used for teeth. The method uses the electrolysis Co, metal Cr, metal Mo, metal La, metal W, electrolysis Mn, and crystal Si as raw materials, getting the cast ingot by melting them in electric induction furnace. The chemical compositions are following: Cr 15.0-30.0wt%,Mo 4.0-9.0wt%, La 0.03-0.30wt%, Mn 0-2.0wt%, Si 0-3.0wt%, W 0-10.0wt%,C 0-0.2wt% and Co. The alloy can be made with the casting machine, stove enamel furnace, and porcelain. The alloy binding ability is improved because of the rare earth La. The test indicates: alloy bonding strength is 75MPa, strength for extension (ªÊb ) is 800MPa, yield strength (ªÊ0.2) is 680MPa, elongation (ª€5) is 18%, diamond pyramid hardness (HV) is 300-400, coefficient of thermal expansion (ª‡RT-500Deg.C) is 13.4-14.5ª–m / m / Deg.C, and casting shrinkage is 1.8-2.1%. The binding ring and bar, which are cast by cobalt chromium alloy, has the advantages of high intensity and good rebound elasticity. The invention is the ideal material.

Owner:SICHUAN UNIV

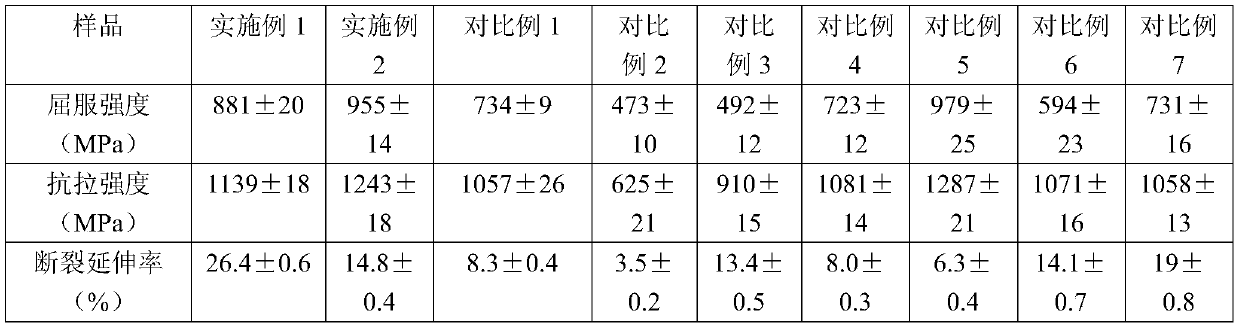

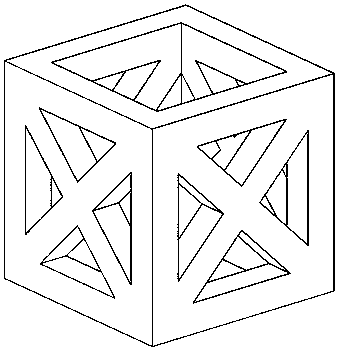

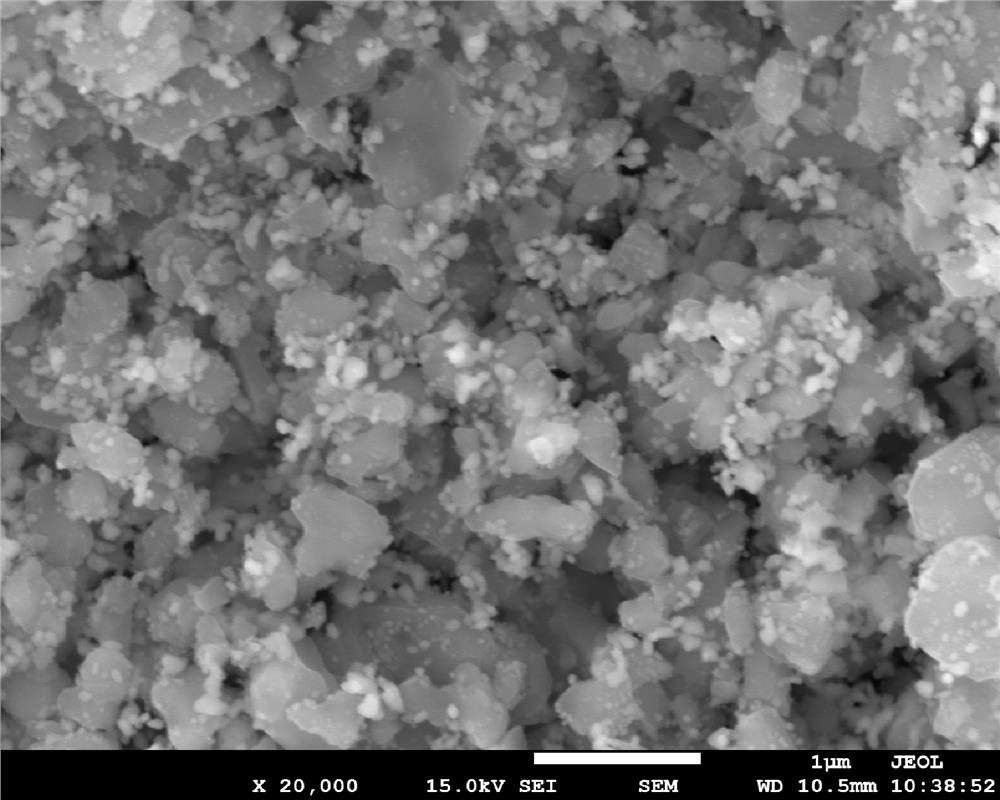

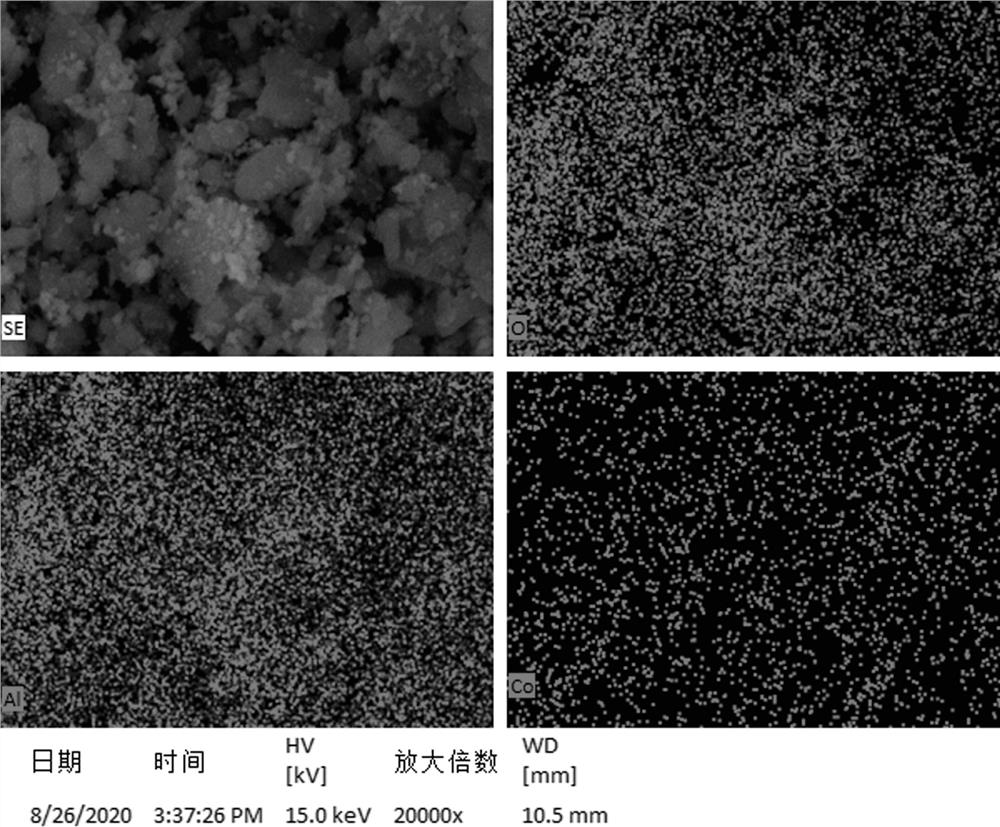

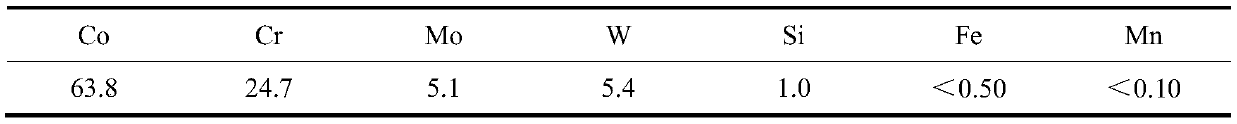

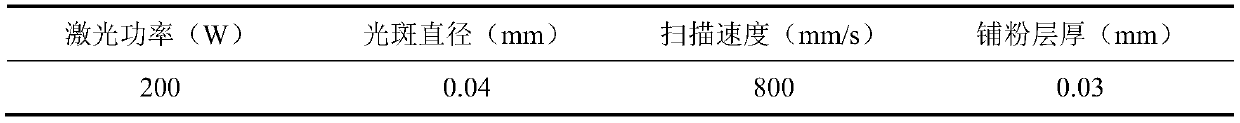

High-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing and preparation method of high-strength and high-toughness CoCrMoW alloy

InactiveCN111172432AReduce stress concentration pointsImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingUltimate tensile strength

The invention discloses a high-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing and a preparation method of the high-strength and high-toughness CoCrMoW alloy. The preparation method comprises the following steps of (1) gas atomization powder preparing, wherein after CoCr alloy raw materials are molten together into melt, the melt is crushed by high-pressure inert gas into tiny liquid drops, and powder is formed after solidification and cooling; (2) blank additive manufacturing forming, wherein the powder is prepared into a formed blank through the laser additivemanufacturing technology; (3) strengthening and toughening heat treatment, wherein the formed blank is subjected to strengthening and toughening heat treatment to obtain the high-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing, the yield strength of the alloy reaches up to 0.9 GPa or above, the tensile strength of the alloy reaches up to 1.2 GPa or above, and the ductility of the alloy reaches up to 14% or above; and (4) plastifying and toughening heat treatment, wherein the high-strength and high-toughness CoCrMoW biological alloy obtained in the step (3) canbe subjected to subsequent plastifying and toughening heat treatment, the plasticity of the high-strength and high-toughness CoCrMoW biological alloy based on laser additive manufacturing can be further improved, and the plasticity of the high-strength and high-toughness CoCrMoW biological alloy based on laser additive manufacturing can reach 26% or above on the premise of guaranteeing that the tensile strength is 1.1 GPa or above.

Owner:SICHUAN UNIV

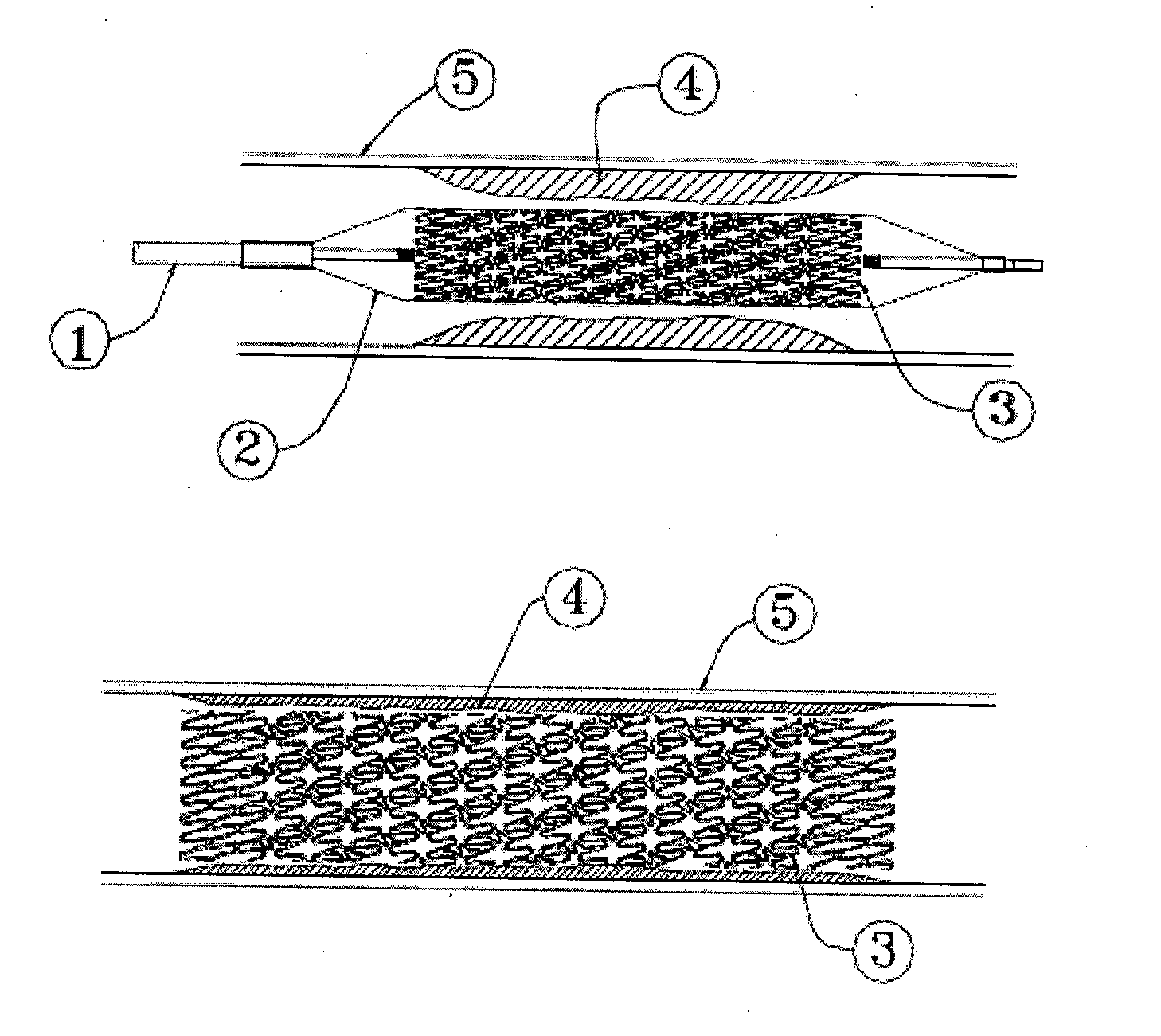

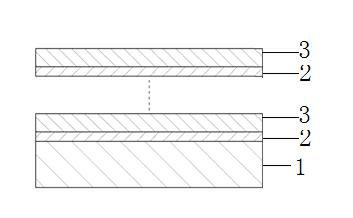

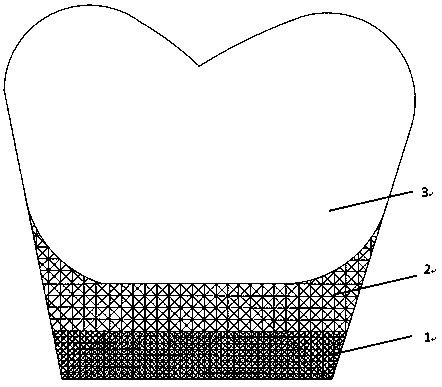

Antifriction and toughening metal/ceramic bionic multilayer-film artificial joint

InactiveCN102580154AVacuum evaporation coatingSputtering coatingMultilayer membraneShape-memory alloy

The invention discloses an antifriction and toughening metal / ceramic bionic multilayer-film artificial joint, comprising an artificial joint matrix (1). The artificial joint matrix is made of materials such as stainless steel, nickel-titanium shape memory alloy, medical titanium alloy or cobalt-chromium alloy. The artificial joint is characterized in that a bionic multilayer film grows on the surface of the artificial joint matrix (1) and is formed in the way that soft metal film layers (2) and hard ceramic film layers (3) grow alternatively to each other, and the thickness of the bionic multilayer film ranges from 50nm to 30mum. According to the invention, the soft metal film layers (2) and the hard ceramic film layers (3) are sequentially deposited on the surface of the artificial joint matrix (1) by an ultrahigh vacuum magnetron sputtering method, thus forming the bionic multilayer film which is ordered and is controllable in thickness. The bionic multilayer film is small in layer friction factor, good in bioactivity and strong in fluid corrosion resistance, can effectively buffer damage on a coating by instantaneous impact, remarkably improves biocompatibility and tribology performance of the artificial joint, and reduces tissue reactivity and aseptic loosening of the artificial joint.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Biocompatible alloy for implantable medical devices

A biocompatible solid-solution alloy may be formed into any number of implantable medical devices. The solid-solution alloy comprises a combination of elements in specific ratios that make it magnetic resonance imaging compatible while retaining the characteristics required for implantable medical devices. The biocompatible solid-solution alloy is a Cobalt-Chromium alloy having substantially reduced Iron, Silicon, Phosphorous and Sulfur content.

Owner:CORDIS CORP

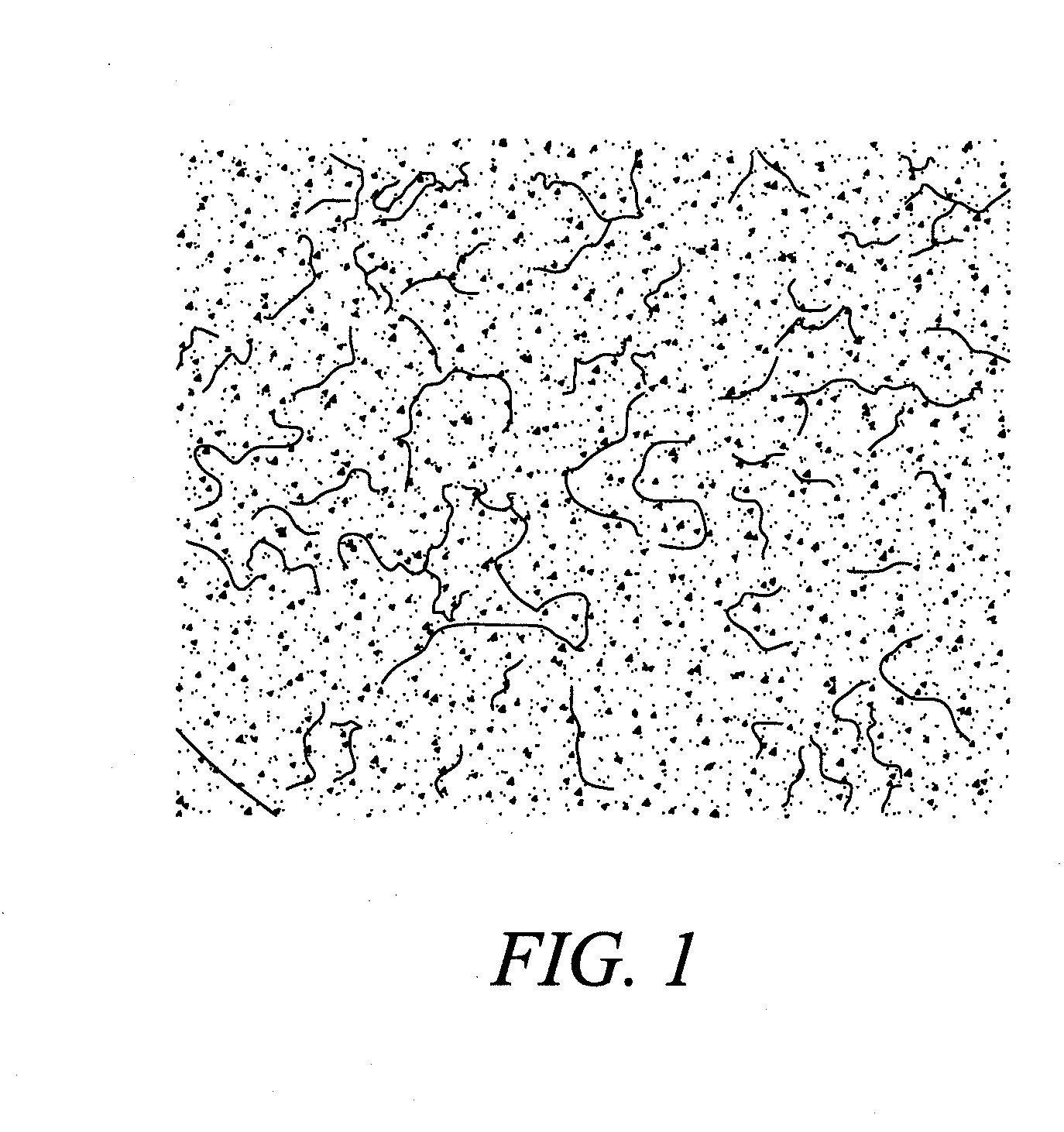

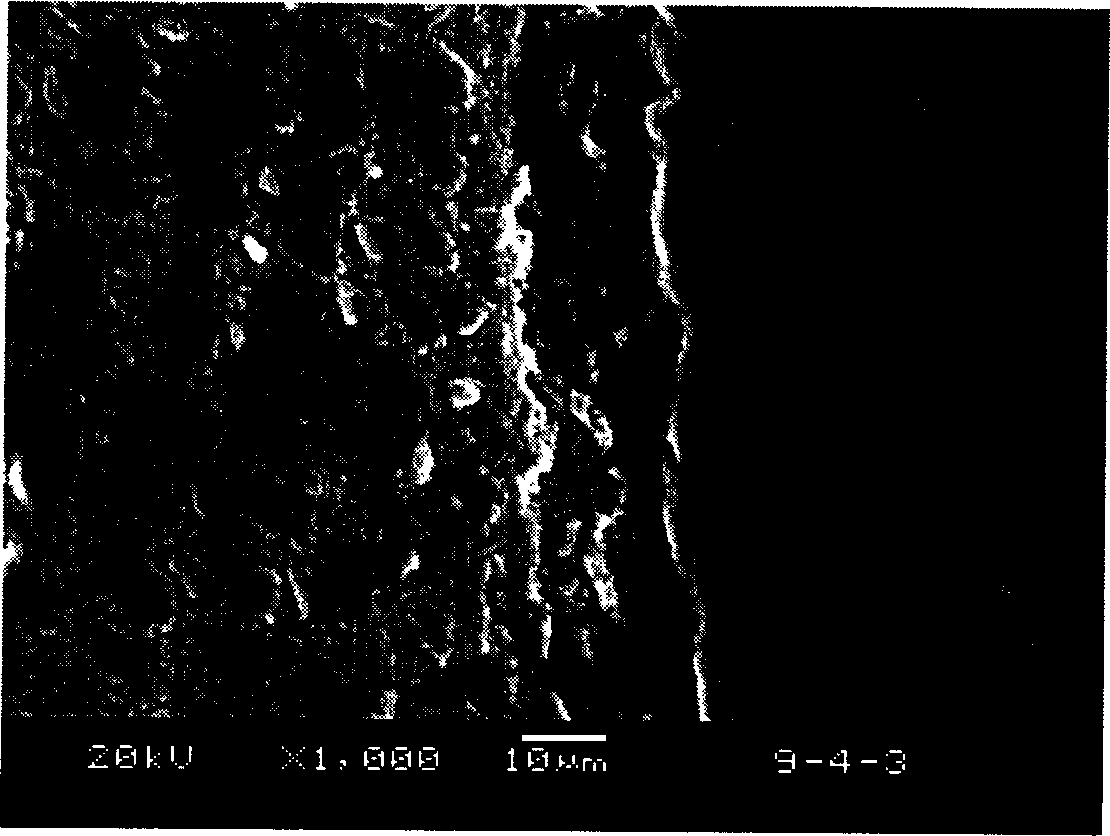

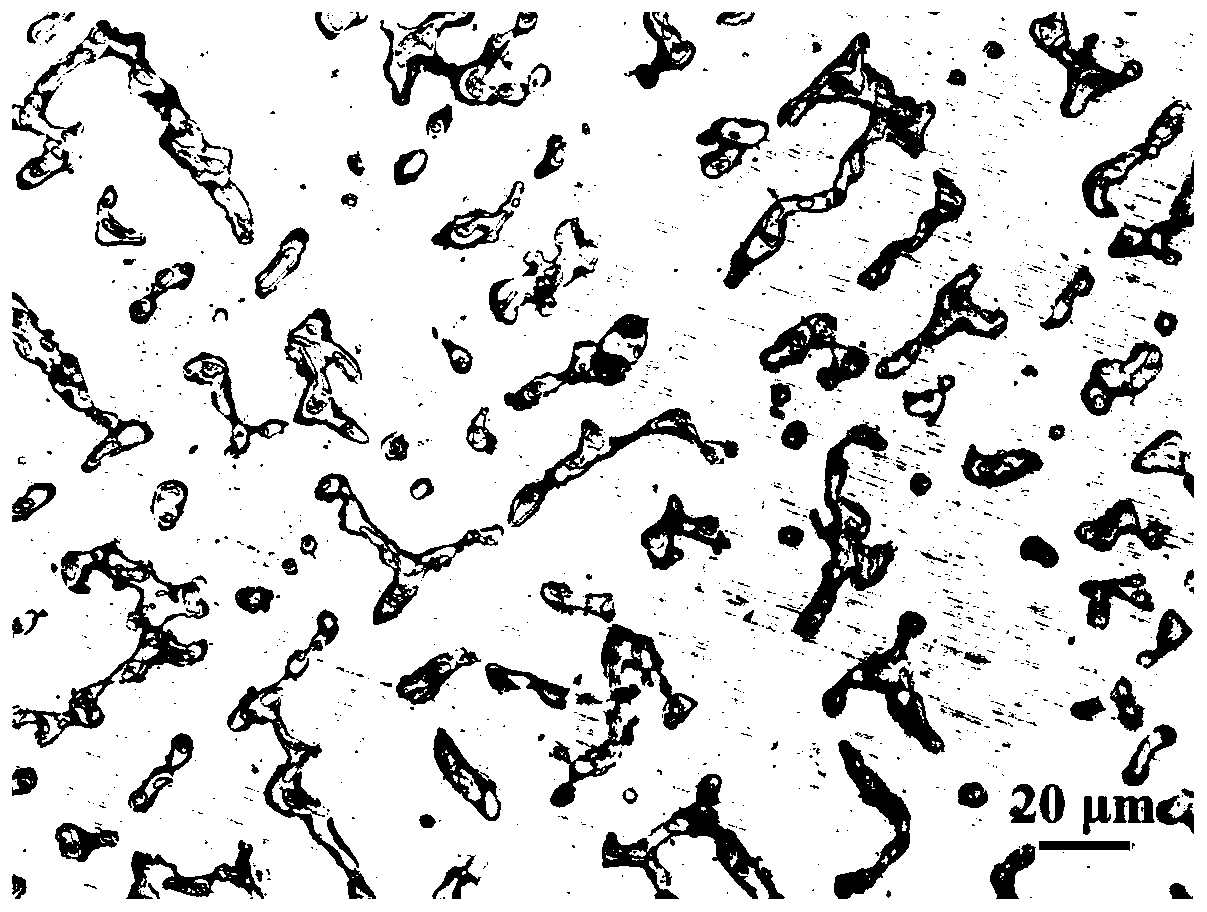

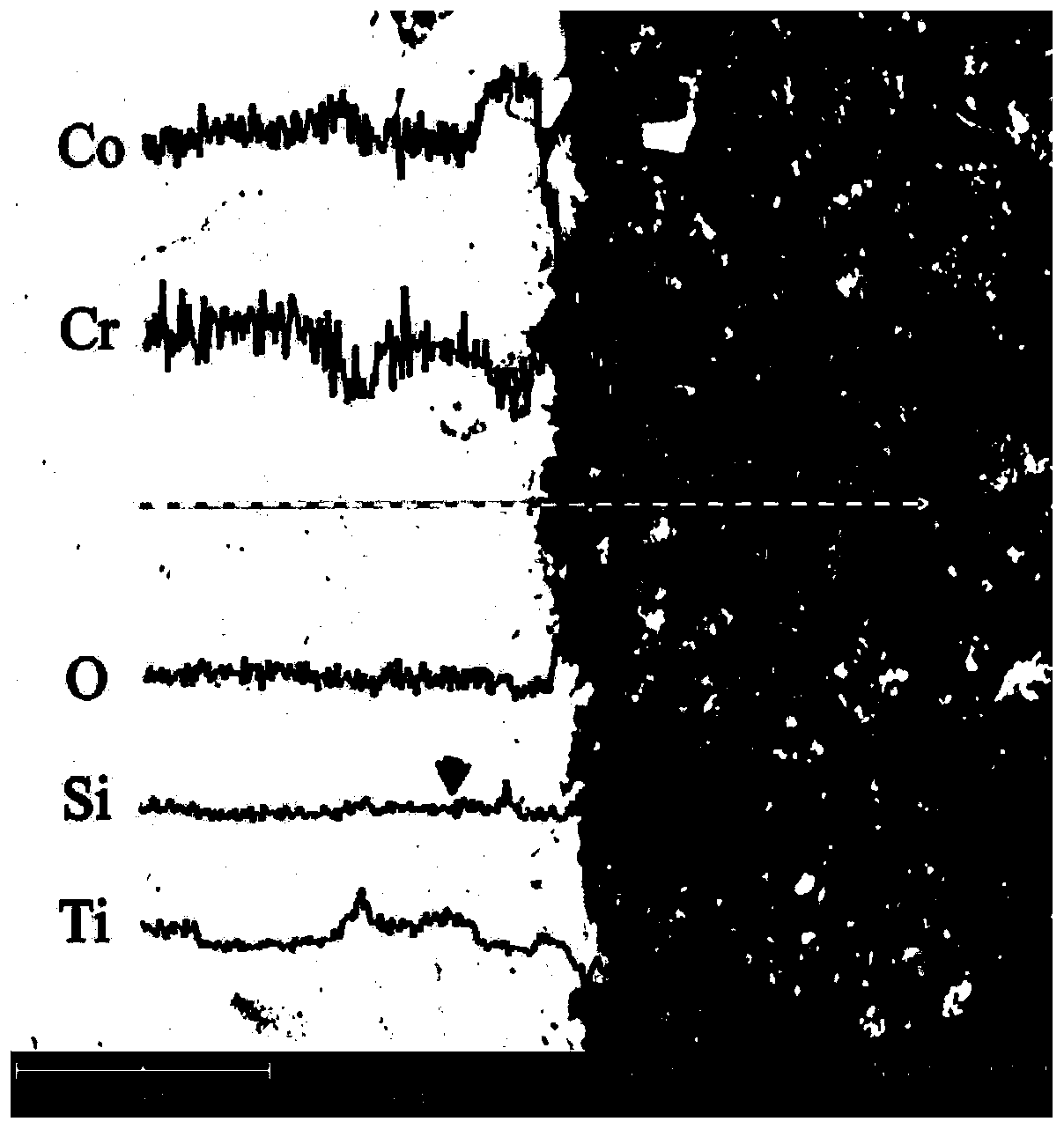

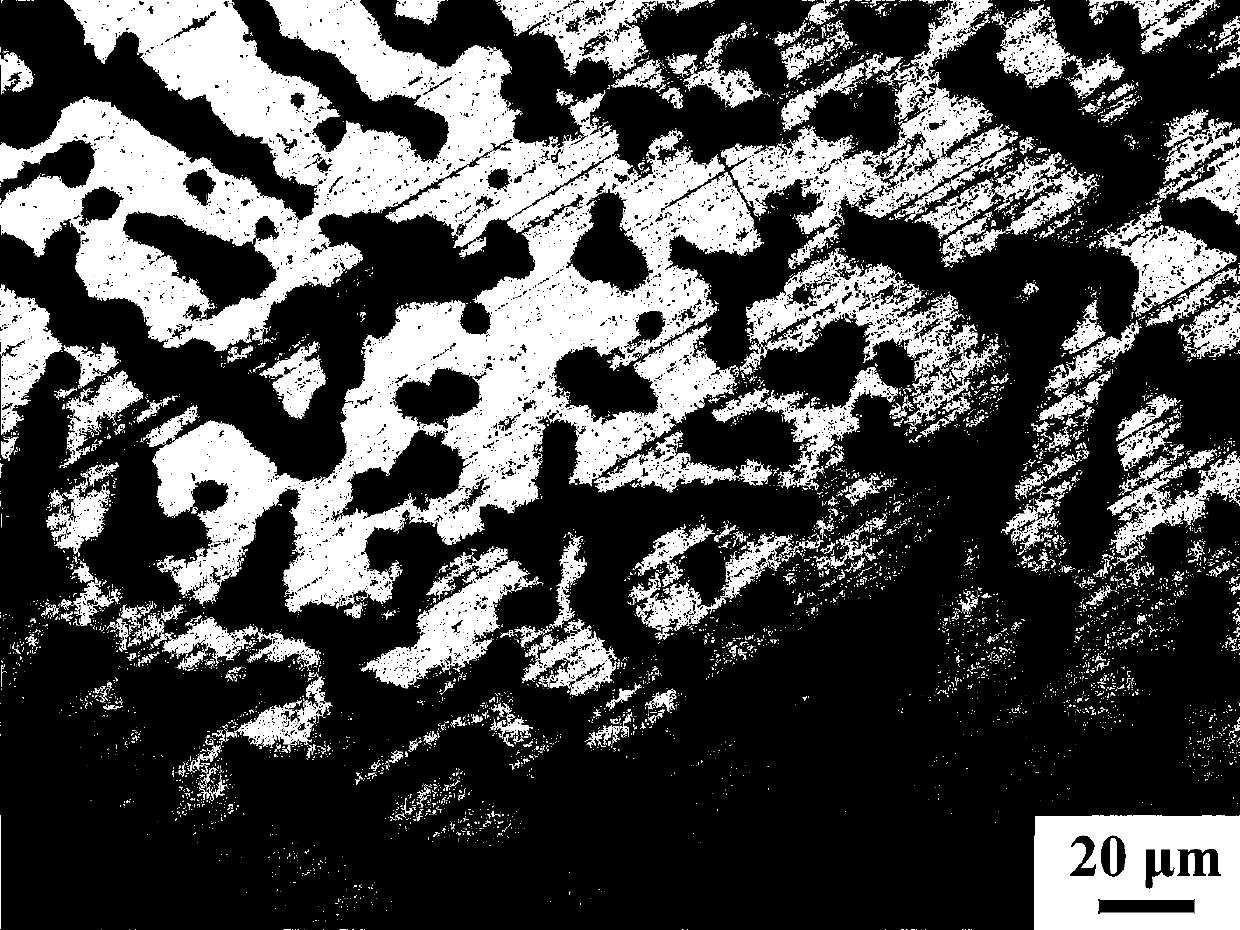

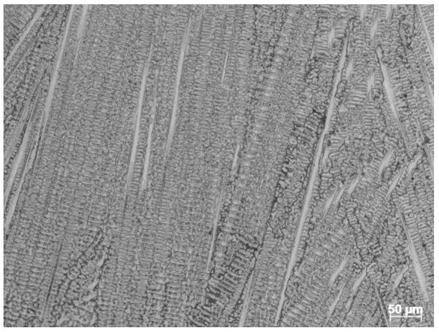

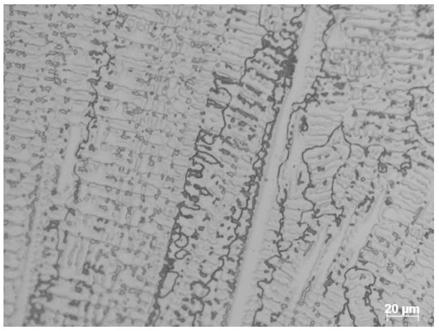

Metallographic erosion method for displaying cobalt-chromium alloy structure

InactiveCN102980794AErosion effect is goodDisplay clearPreparing sample for investigationCobaltAqua regia

The present invention describes a metallographic erosion method for displaying a cobalt-chromium alloy structure, including: preparing aqua regia; placing the aqua regia at a certain temperature for a specified time to make the aqua regia reach the chroma meet the requirements; dipping in the aqua regia with a flexible material to wipe a sample, wherein the wiping time is 30-90 seconds; removing the surface aqua regia; and drying to get a etched sample surface. The method of the present invention is clearly, completely and accurately displays the metallographic structure of the cobalt-chromium alloy. The good erosion effect of the reagent is reflected by a test of a cobalt-chromium alloy human body implantable material. According to the present invention, the cobalt-chromium alloy etchant is prepared by a conventional metallographic etchant, good erosion effect of cobalt-chromium alloy is achieved by using that the erosion abilities of the etchant during different periods are different, thus a clear, complete and accurate metallographic structure is displayed.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Prosthetic joint

A prosthetic joint ball is receivable in a prosthetic joint socket to form a prosthetic joint. The ball is generally spherical and is mounted on a stem. The outer rounded surface of the ball is provided with a layer of CVD diamond, prepared by mechanical polishing to present a surface with an RA of 20 nm or less. The ball is formed of a silicon carbide or similar substrate and includes a rounded recess. Mounted in the recess is a metal insert formed of a cobalt-chromium alloy or titanium alloy. The metal insert includes a socket shaped and sized to receive, in use, the tapered end of the stem.

Owner:WORT CHRISTOPHER JOHN HOWARD

Flexible alloy and preparation method thereof

The invention discloses a flexible alloy. The flexible alloy is made by melting the following ingredients in parts by weight: 20-30 parts of cobalt-chromium alloy, 4-6 parts of gold alloy, 30-35 parts of aluminum-manganese alloy, 40-50 parts of nickel-chrome alloy, 12-18 parts of PVC / ABS blend resin. A preparation method of the flexible alloy is also provided. The invention has the benefits that: according to the flexible alloy and preparation method thereof provided by the invention, the impact of ambient temperature changes on the alloy body of the prepared flexible alloy can be effectively reduced, the toughness of the alloy is increased, and the flexible alloy is applicable to the aerospace field. The factory experiments show that the rate of toughness change of the flexible alloy is less than or equal to 5% under high- / low-temperature conditions.

Owner:WUXI YANGGONG MACHINERY MFG

Calcium phosphate coated stents comprising cobalt chromium alloy

Disclosed herein are medical devices, such as stents, coated with calcium phosphate and processes for making the same. The stent can comprise a cobalt chromium alloy that has been treated to improve surface adhesion to the calcium phosphate and / or improve surface finish properties. A pharmaceutically active agent can be present in the calcium phosphate coating.

Owner:MIV SCI HLDG

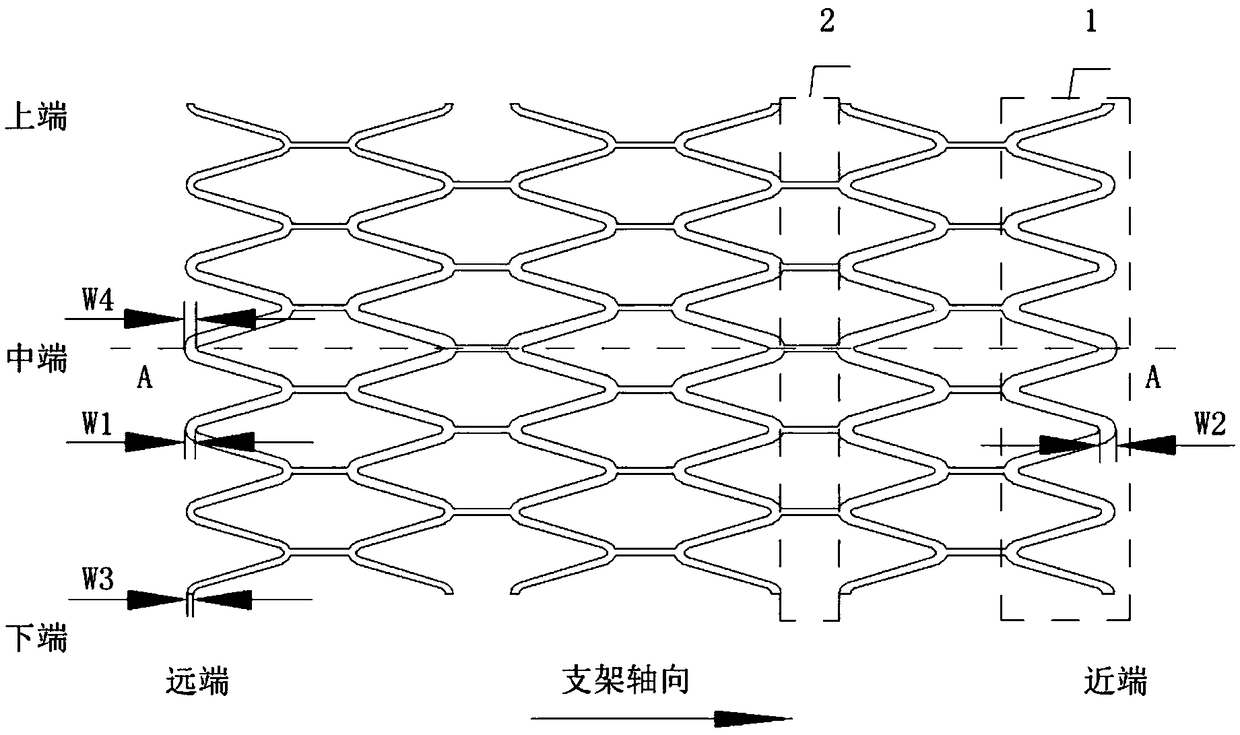

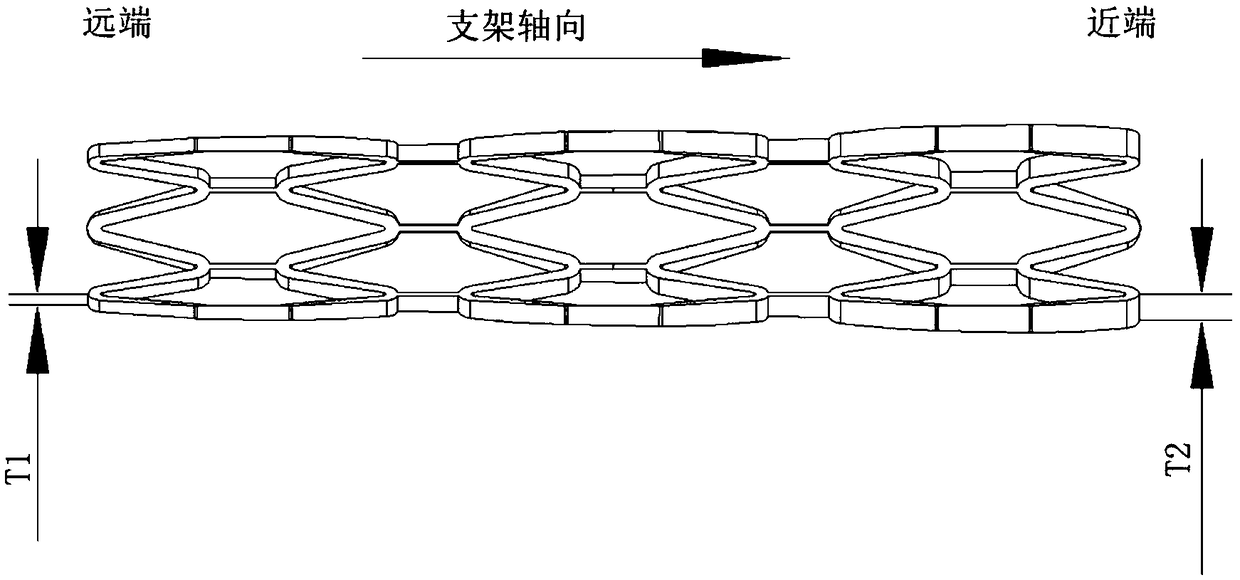

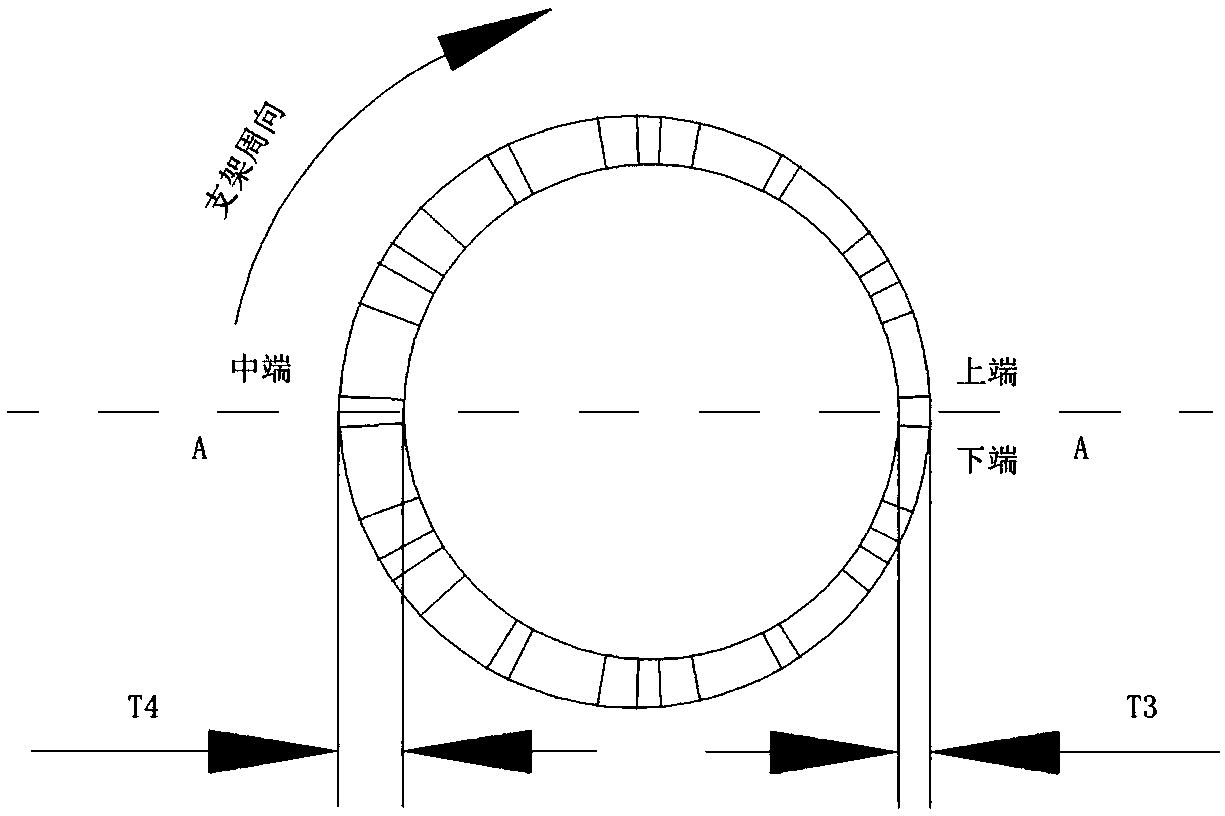

Asymmetric intravascular stent

The invention provides an asymmetric intravascular stent. The asymmetric intravascular stent comprises a plurality of annular supports and connecting ribs, wherein every two annular supports are connected through the corresponding connecting rib. The annular supports are arranged in the longitudinal direction of an intravascular stent body in sequence, and each annular support comprises a plurality of sinusoidal unit waves which are arranged in the circumferential direction of the intravascular stent body in sequence; the widths of the connecting ribs keep constant, the rib widths of the annular supports are regularly changed, that is, the rib widths of the annular supports are gradually increased from the upper ends and the lower ends to the middle ends at the same time, and in the axialdirection of the stent body, the rib widths of the annular supports are gradually increased from the far end to the near end. In the asymmetric intravascular stent, the characteristics that the circumferential thicknesses of the blood vessel are different and the axial thicknesses of the blood vessel are different are comprehensively considered, the adherence of the stent is improved, and the vascular stress and strain are reduced. Besides, a functionally graded material is adopted, while good supporting performance is ensured, the dog bone effects of a cobalt-chromium alloy stent and a stainless steel stent are greatly reduced, and the long-time curative effect of the stent is improved.

Owner:JIANGSU UNIV

Method for 3D printing of rapidly renewable cobalt-chromium alloy coated tooth

PendingCN109464205AFast preparationHigh precisionImpression capsArtificial teethCarbon nanotubeBiocompatibility Testing

The invention discloses a method for 3D printing of a rapidly renewable cobalt-chromium alloy coated tooth. Laser scanning is adopted to assist manufacturing of an individual false tooth model, by using a 3D printing technique, zirconium dioxide powder is mixed with a small amount of graphene and carbon nanotube powder to make a false tooth main body, cobalt-chromium alloy powder is mixed with a small amount of the graphene and the carbon nanotube powder to make a false tooth base which is small and large gradually, and coating treatment is carried out on the false tooth base. The problems that a pure metal material is not attractive in appearance, a pure ceramic material is too crispy and long in recovery period after implanting can be overcome, people can feel that a false tooth and gingiva grow together, and an individual false tooth which is high in precision, good in wearing resistance, good in acid-alkali resistance, high in mechanical strength and good in biocompatibility can befinally manufactured.

Owner:SHANDONG JIANZHU UNIV

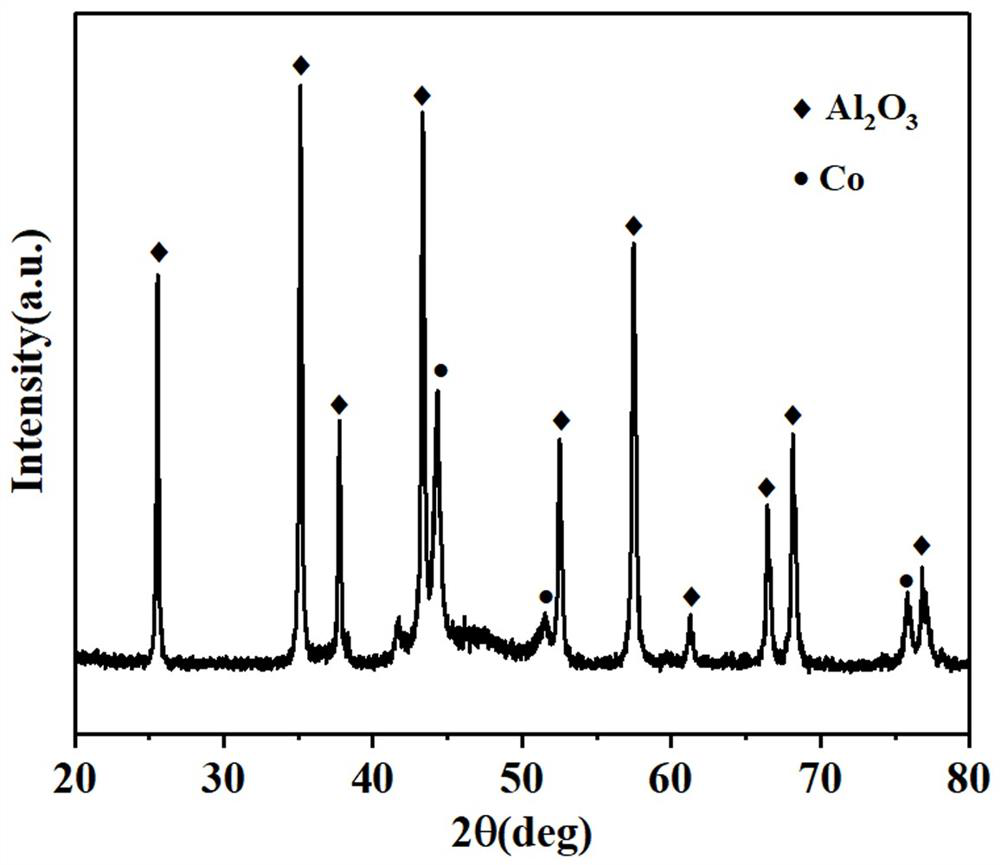

Cobalt-coated ceramic composite powder and preparation method and application thereof

PendingCN112548096AEvenly dispersedImprove interfacial wettabilityAdditive manufacturing apparatusTransportation and packagingThermal dilatationSelective laser melting

Owner:ZHONGBEI UNIV

Titanium-containing cobalt-chromium alloy, preparation method and application thereof

InactiveCN111057909ALow priceGood biocompatibilityTooth crownsArtificial teethThermal dilatationShrinkage rate

The invention relates to the technical field of alloys, in particular to a titanium-containing cobalt-chromium alloy, a preparation method and application thereof. The titanium-containing cobalt-chromium alloy comprises the following components according to the weight percentage: 23.0-30.0% of Cr, 5.0-8.0% of Mo, 1.5-3.5% of Ti, 0-1.0% of Mn, 0-2.0% of Si, 2.0-4.0% of Cu, and the balance being Co.The titanium-containing cobalt-chromium alloy has the tensile strength of 828 MPa, the yield strength of 632 MPa, the elongation percentage of 8%-15%, the Vickers hardness of HV 270-330, and the casting shrinkage ratio of 1.5%-2.0 %, and has a suitable coefficient of thermal expansion with earthenware, can be used for making a denture movable repairing bracket, a porcelain base crown and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

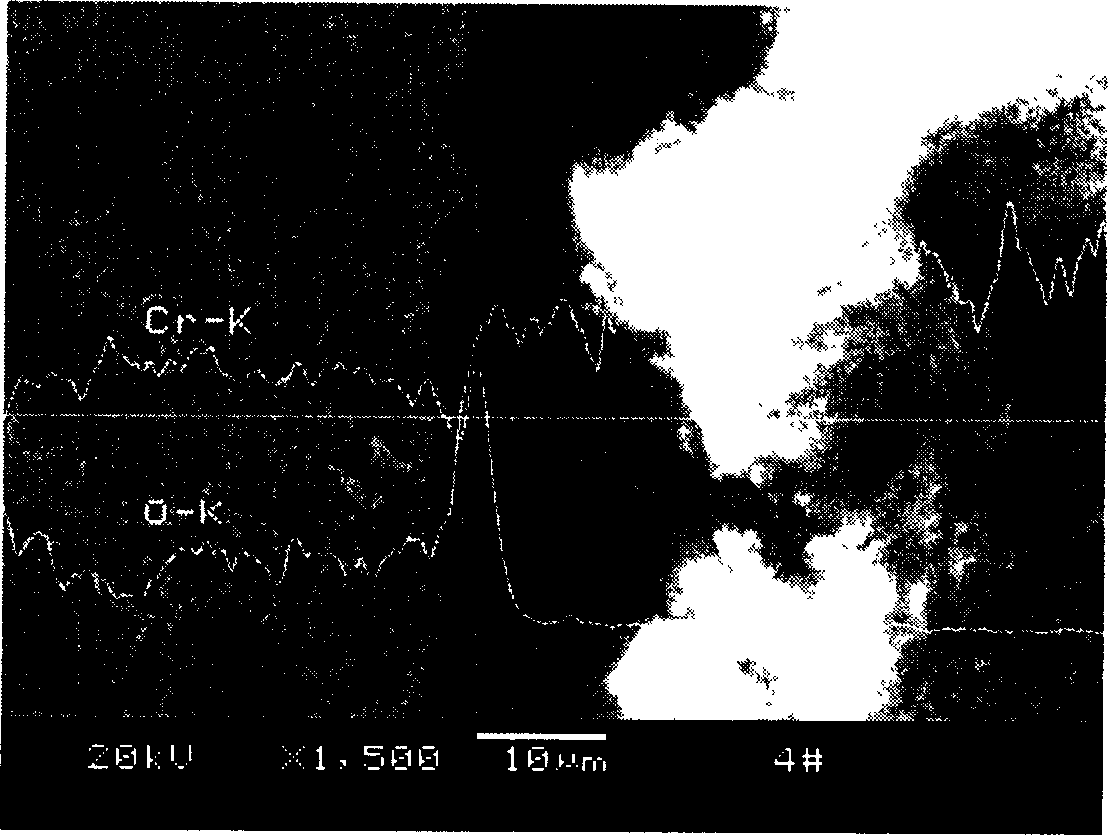

Etching agent for cobalt-chromium alloy and method using etching agent to acquire metallographic structure

ActiveCN107643204AReduced corrosion resistanceThe outline of the grain boundary is clear and completePreparing sample for investigationHydrofluoric acidPotassium ferricyanide

The invention relates to an etching agent for cobalt-chromium alloy and a method using the etching agent to acquire a metallographic structure. The etching agent comprises an acid etching agent and analkaline etching agent which are used independently, wherein the acid etching agent is an acid solution mixed by 40wt% hydrofluoric acid and 65-68wt% nitric acid according to the volume ratio of 1:(50-100), and the alkaline etching agent is an aqueous solution dissolved with 5-10wt% potassium ferricyanide and 5-10wt% sodium hydroxide. A cobalt-chromium alloy sample is soaked in the acid etching agent for not less than 5 hours and then soaked in the alkaline etching agent for not less than 0.5 hour, a prepared cobalt-chromium alloy metallographic sample is evident in microstructure and clear and complete in metallographic structure grain boundary contour, the clear cobalt-chromium alloy metallographic structure can be acquired fast, and the accuracy of the observation and analysis of the metallographic structure is increased.

Owner:ZHONGBEI UNIV

Working wire for a biological sensor

A working wire for a biological sensor is disclosed. The working wire includes a substrate comprising cobalt-chromium (Co—Cr) alloy or Nitinol alloy, a platinum layer comprising platinum on the substrate, and a membrane layer comprising a biological membrane applied over the platinum layer.

Owner:ZENSE LIFE INC

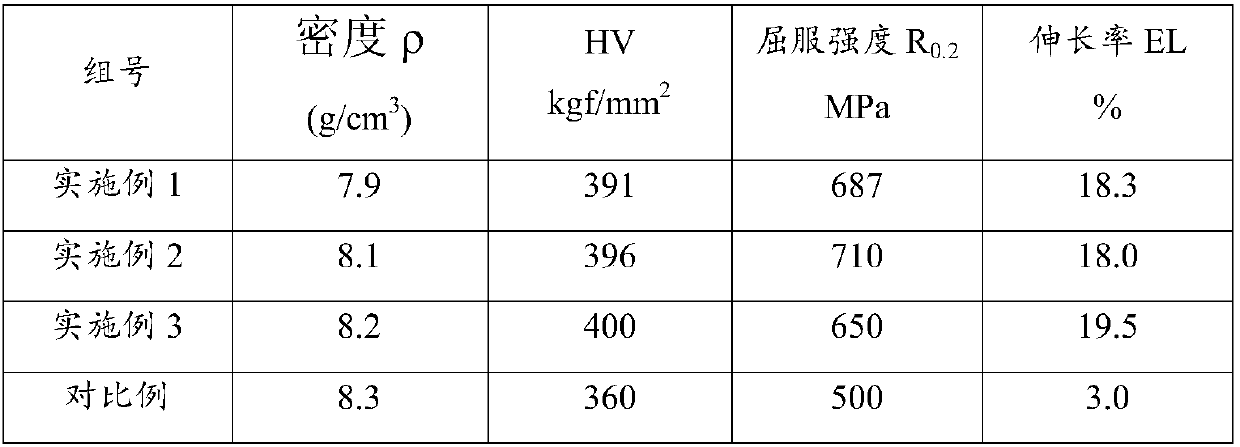

Medical high-toughness cobalt-chromium alloy

ActiveCN109536782AImprove toughnessHigh strengthImpression capsDentistry preparationsCobalt-chromeCobalt chromium alloy

The invention belongs to the field of precise alloy functional materials, and particularly relates to a medical high-toughness cobalt-chromium alloy. The alloy can be used as an orthopedic casting alloy, and comprises a dental baking porcelain alloy, a baking porcelain bracket restoring body and the like. The medical high-toughness cobalt-chromium alloy comprises, by mass, 24.0%-29.0% of Cr, 4.0%-8.0% of Mo, 1.3%-2.0% of Fe, 0.2%-0.8% of Ti, 0.1%-0.5% of Mn, less than or equal to 0.010% of P, less than or equal to 0.010% of S and the balance Co. According to the cobalt-chromium alloy, the density is 8.2g / cm3; the yield strength is greater than or equal to 650 MPa, the maximum yield strength can exceed 700 MPa; the Vickers hardness is greater than or equal to 390kgf / mm2; and the elongationis larger than or equal to 18%. Compared with a domestic traditional roasted porcelain casting alloy, the strength is nearly 6 times higher; and meanwhile, the processing performance is good, and thealloy can be widely applied to the field of biomedicine.

Owner:CENT IRON & STEEL RES INST

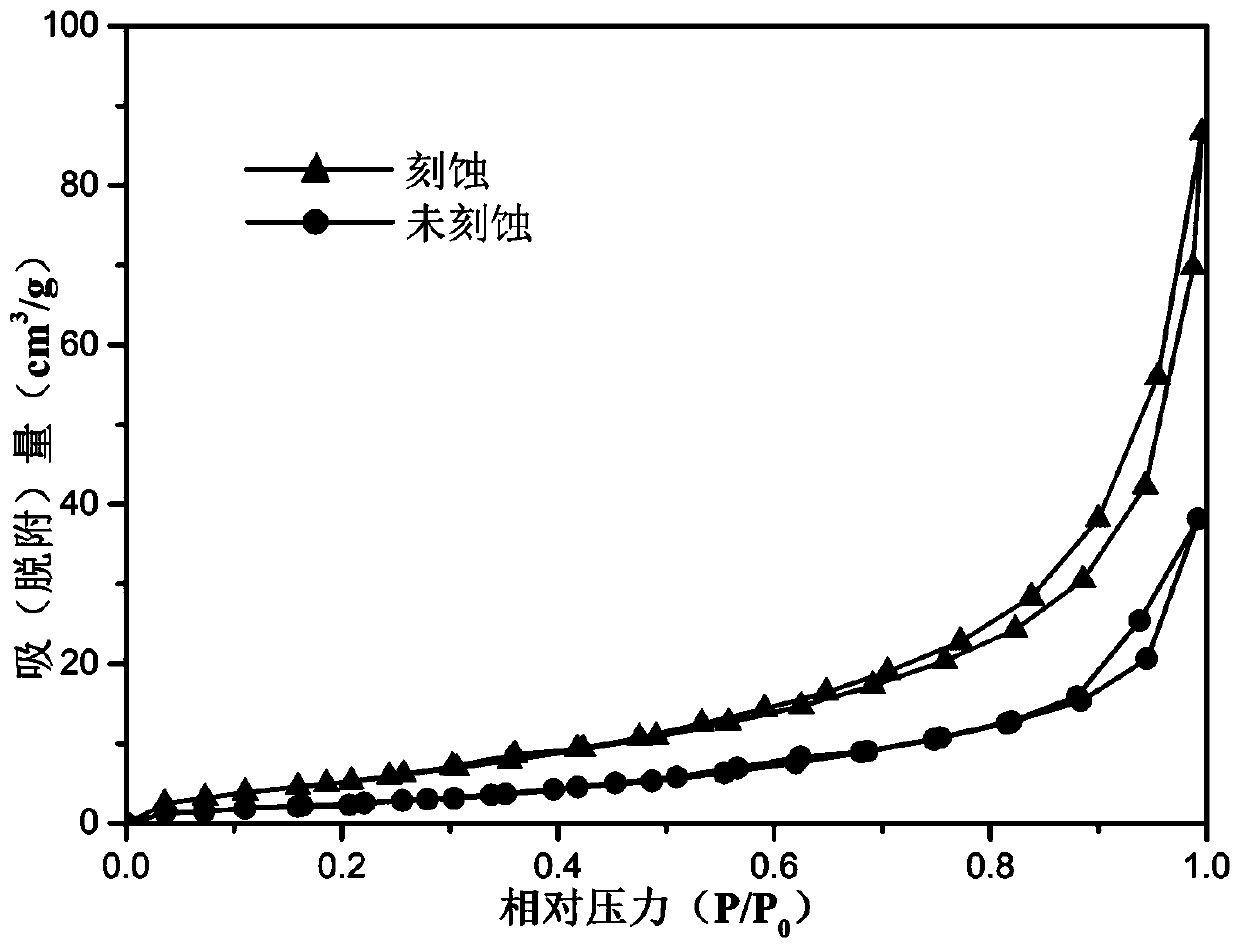

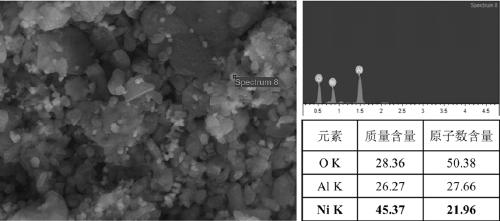

Preparation method of nickel coated ceramic composite powder based on selective laser melting molding

ActiveCN111185594AReduce wear rateStrong oxidation abilityAdditive manufacturing apparatusTransportation and packagingSelective laser meltingCeramic composite

The invention discloses a preparation method of nickel coated ceramic composite powder based on selective laser melting molding. The preparation method comprises the following steps of etching ceramicpowder by an etching liquid composed of formic acid and hydrogen peroxide; then sensitizing and activating the etched ceramic powder by a conventional method; and putting the ceramic powder in a chemical nickel-plating solution to react to obtain uniformly coated nickel coated ceramic composite powder. The nickel coated ceramic composite powder prepared by the invention is uniform in size distribution and high in quality of a nickel plate. A cobalt-chromium alloy is modified by the nickel coated ceramic composite powder. A cobalt-chromium alloy part is prepared by selective laser melting molding. The wear rate of the cobalt-chromium alloy part is lower than that of a common cobalt-chromium alloy, and the hardness and tensile strength of the cobalt-chromium alloy part are superior to thoseof the common cobalt-chromium alloy, so that the cobalt-chromium alloy part is suitable for being used as an orthopaedic implant, in particular artificial hip joint prosthesis.

Owner:ZHONGBEI UNIV

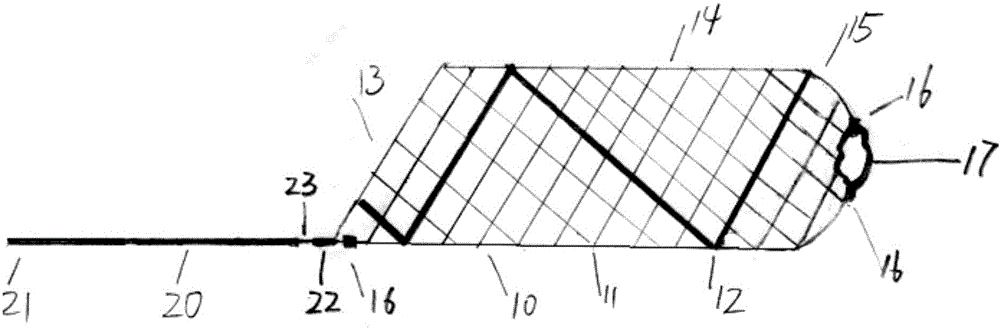

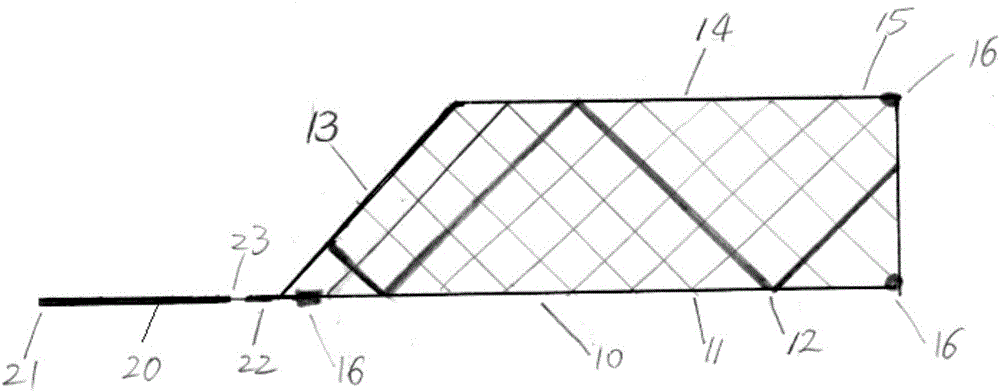

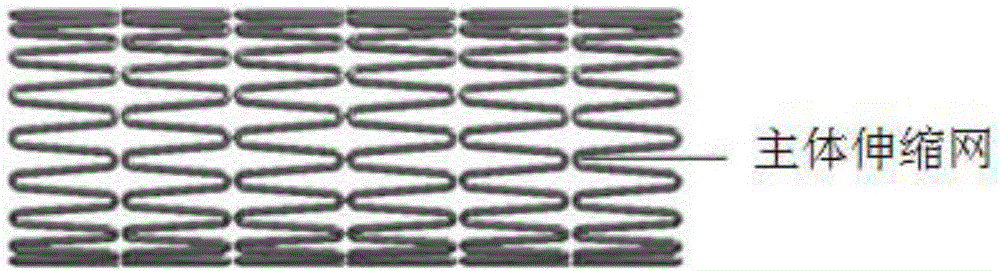

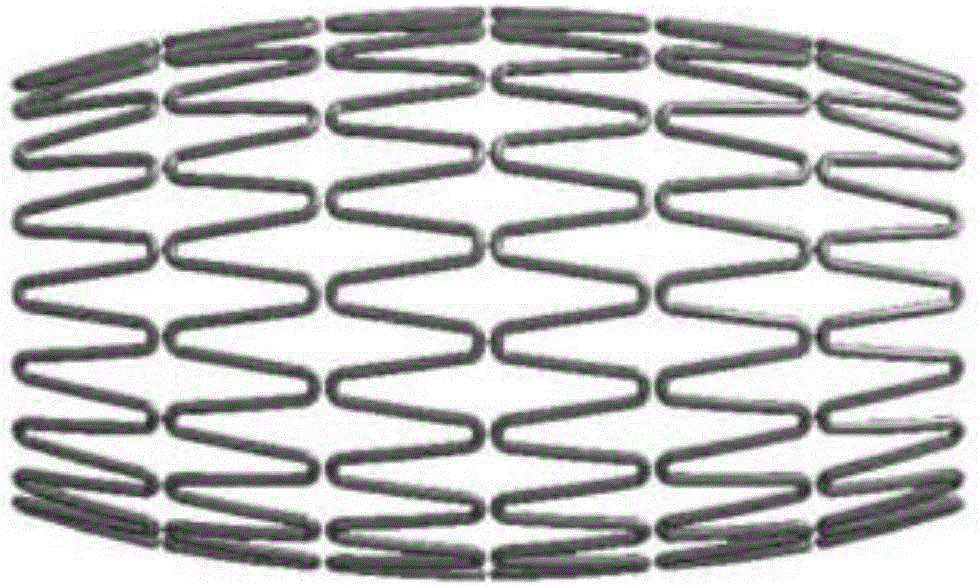

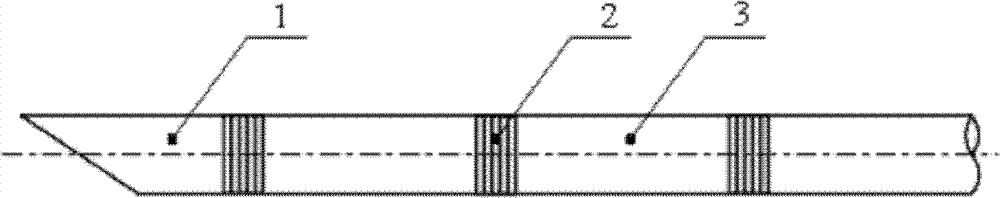

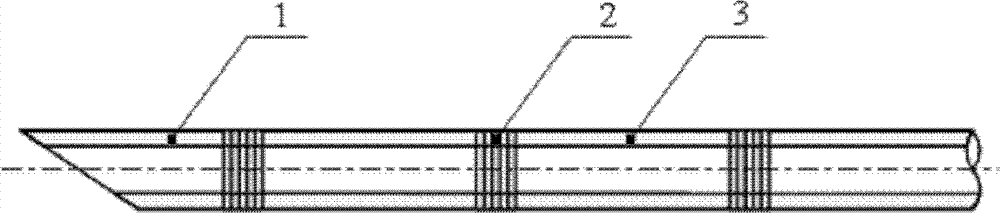

Transforaminal nanometer-bioglass-coating minimally-invasive fusing device

The invention discloses a transforaminal nanometer-bioglass-coating minimally-invasive fusing device. The minimally-invasive fusing device comprises a body stretching net, and the surface of the body stretching net is coated with an ordered nanometer-mesoporous biological activity glass coating. The body stretching net is formed by cobalt-chromium alloy wires. A nanometer biological glass coating material is prepared from SiO2 sol, CaO sol and P2O5 sol, attachment of osteoblast and growing of blood vessels can be achieved through the biological glass coating, and bone fusion between centrums is promoted. The minimally-invasive fusing device can be applied to the lumbar vertebra fusing technology conducted under a foramen intervertebrale mirror. The transforaminal nanometer-bioglass-coating minimally-invasive fusing device has the advantage of being extensible in minimally invasive technology, is used in cooperation with a saccule, the saccule and the net-shaped fusing device with which the surface of the saccule is covered are expanded at the same time, intervertebral space with narrow reset is opened, extension of the net-shaped fusing device along the outline of an end plate reaches the estimated height, then the elliptic-cylinder-like shape is shown, the obtained the net-shaped fusing device and the outline of an end plate are completely matched, the saccule is pulled out, the fusing device is reserved in the intervertebral space, the intervertebral space is supported, and the transforaminal nanometer-bioglass-coating minimally-invasive fusing device can be applied to the lumbar vertebra fusing technology conducted under the foramen intervertebrale mirror for curing lumbar spine instability.

Owner:NANJING FIRST HOSPITAL

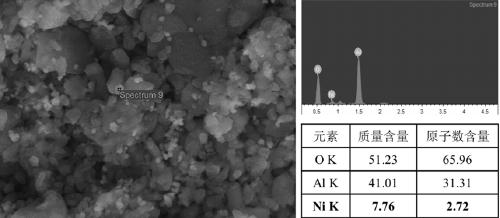

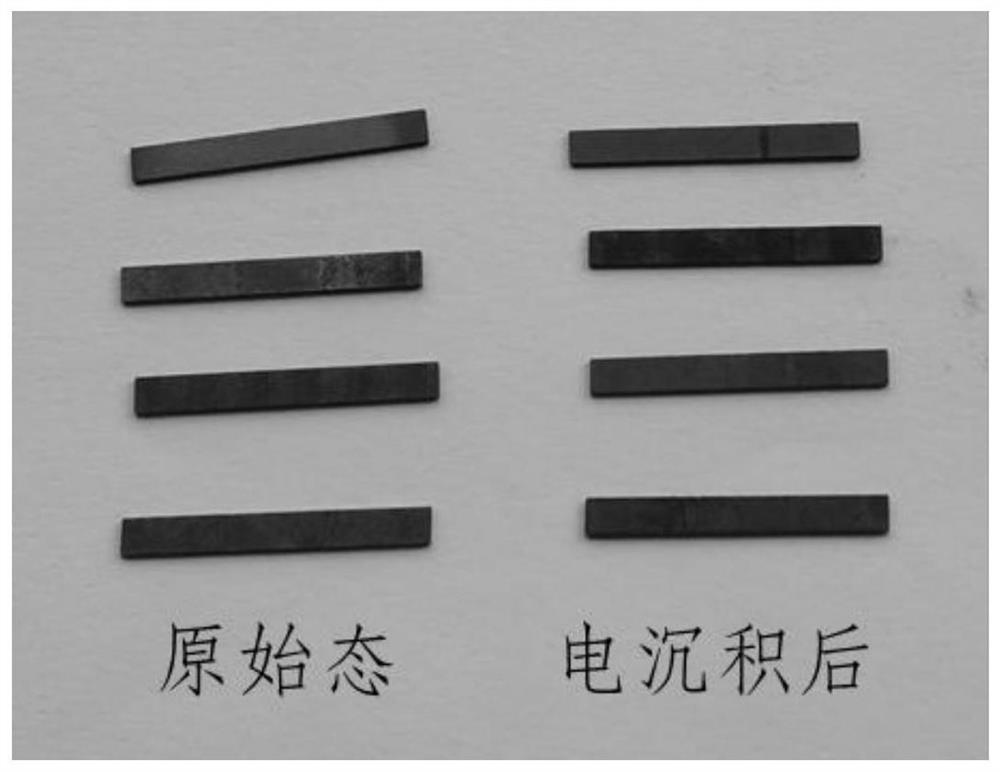

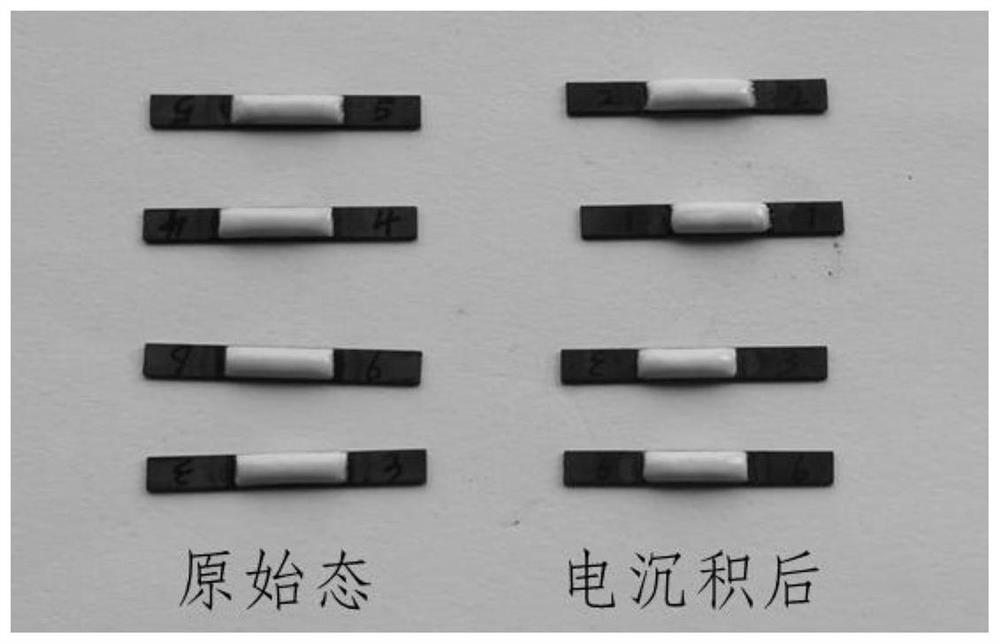

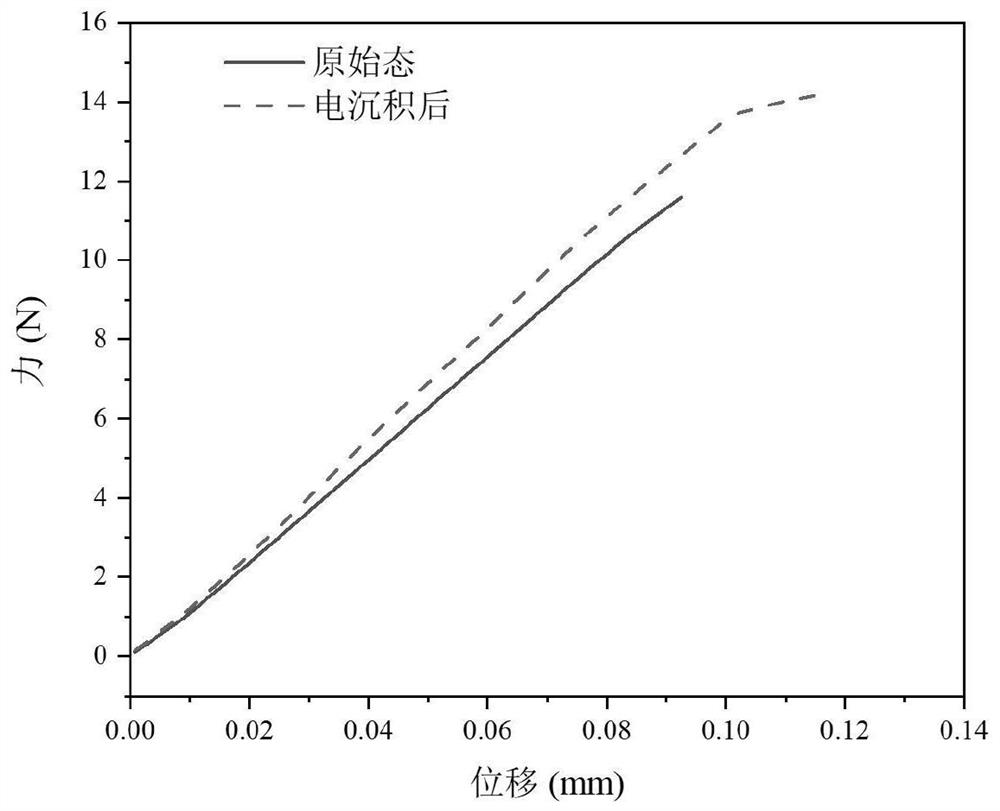

Surface-modified selective laser cladding cobalt-chromium alloy and preparation method and application thereof

ActiveCN113322462AIncreasing the thicknessIncrease roughnessMetallic material coating processesCobaltCobalt Chromium Alloys

The invention provides a surface-modified selective laser cladding cobalt-chromium alloy and a preparation method and application thereof, and relates to the technical field of biological alloys. The surface-modified selective laser cladding cobalt-chromium alloy comprises a selective laser cladding cobalt-chromium alloy and a cobalt-chromium-nickel-tungsten coating deposited on the surface of the selective laser cladding cobalt-chromium alloy, and the cobalt-chromium-nickel-tungsten coating comprises the following chemical components in percentage by mass: 35%-50% of cobalt, 15%-25% of chromium, 5%-15% of nickel and 5%-25% of tungsten. According to the surface-modified selective laser cladding cobalt-chromium alloy and the preparation method and application thereof, the thickness of a diffusion layer and an oxide layer on the surface of the selective laser cladding cobalt-chromium alloy can be increased through the cobalt-chromium-nickel-tungsten coating, the roughness of the surface of the selective laser cladding cobalt-chromium alloy is improved, meanwhile, the nickel element and the tungsten element are added into the cobalt-chromium-nickel-tungsten coating, combination of the cobalt-chromium alloy and ceramic can be more compact, and then the gold-ceramic bonding strength is improved.

Owner:CHENGDU KENINGDA MATERIALS

Magnetic-navigation joint type puncture needle

InactiveCN102500036BAchieve magnetic navigationPrecise NavigationSurgical needlesTrocarEngineeringJoints types

Owner:TIANJIN UNIV OF SCI & TECH

Production method of cobalt-chromium-alloy-based spherical niobium carbide powder

InactiveCN109702189AImprove liquiditySimple and fast operationMolten spray coatingThermal sprayingCobalt-chrome

The invention discloses a production method of cobalt-chromium-alloy-based spherical niobium carbide powder. The production method comprises the steps of 1, drying cobalt-chromium alloy with the grainsize ranging from 45 microns to 150 microns and spherical niobium carbide with the grain size ranging from 45 microns to 150 microns for 2-4 hours at the temperature of 110-130 DEG C, wherein the spherical niobium carbide is prepared through a plasma method, and the content of niobium carbide is greater than 99%; 2, adding, by weight percentage, 50%-80% of the cobalt-chromium alloy and 20%-50% ofthe spherical niobium carbide into a three-dimensional powder mixer, wherein the rotating speed of the three-dimensional powder mixer is 15-20 r / min, and the time is 90-120 min; and 3, collecting thecobalt-chromium-alloy-based spherical niobium carbide powder. According to the production method of the cobalt-chromium-alloy-based spherical niobium carbide powder, operation is easy and convenientto conduct, the production cost is low, and industrialization is easy to achieve; the obtained cobalt-chromium-alloy-based spherical niobium carbide powder is good in flowability and suitable for massproduction; when the cobalt-chromium-alloy-based spherical niobium carbide powder is used as a coating, the problem that cracking is caused due to segregation is not likely to be generated; and the cobalt-chromium-alloy-based spherical niobium carbide powder is resistant to high temperature, corrosion and abrasion and can be applied to a plasma transferred arc surfacing process or a thermal spraying process, and the good commercial value is achieved.

Owner:SHANGHAI MARITIME UNIVERSITY

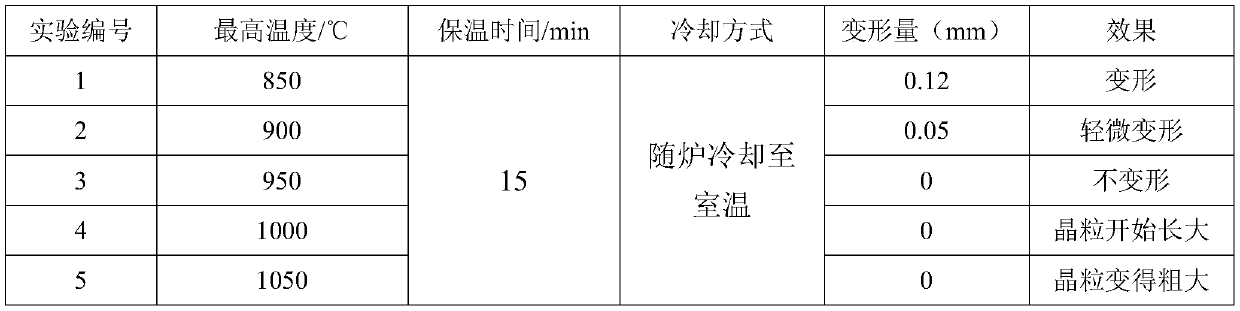

Laser selective melting cobalt chromium alloy false tooth infrared heating annealing heat treatment method

ActiveCN111172484AHigh strengthImprove toughnessAdditive manufacturingIncreasing energy efficiencyThermal insulationHeat conservation

The invention discloses a laser selective melting cobalt chromium alloy false tooth infrared heating annealing heat treatment method, and belongs to the technical field of heat treatment. The method comprises the following steps that a cobalt chromium alloy false tooth formed through laser selective melting is placed in a tubular infrared heating furnace, the cobalt chromium alloy false tooth is subjected to annealing heat treatment by adopting infrared heating, a thermal insulation temperature of infrared heating annealing heat treatment is 850-1050 DEG C, thermal insulation time of the infrared heating annealing heat treatment is 5-25 min, furnace cooling is firstly conducted to 300 DEG C, and then the tooth is taken out to be subjected to air cooling to a room temperature. Compared withthe mode that a resistance wire is used to heat the cobalt chromium alloy false tooth through convective heat transfer, the method has the advantages that due to the fact that infrared heating conducts heat transfer through radiation, a heating speed is high, the thermal insulation time is short, and the heat treatment efficiency is high.

Owner:无锡德润堂贸易有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com