Preparation method of nickel coated ceramic composite powder based on selective laser melting molding

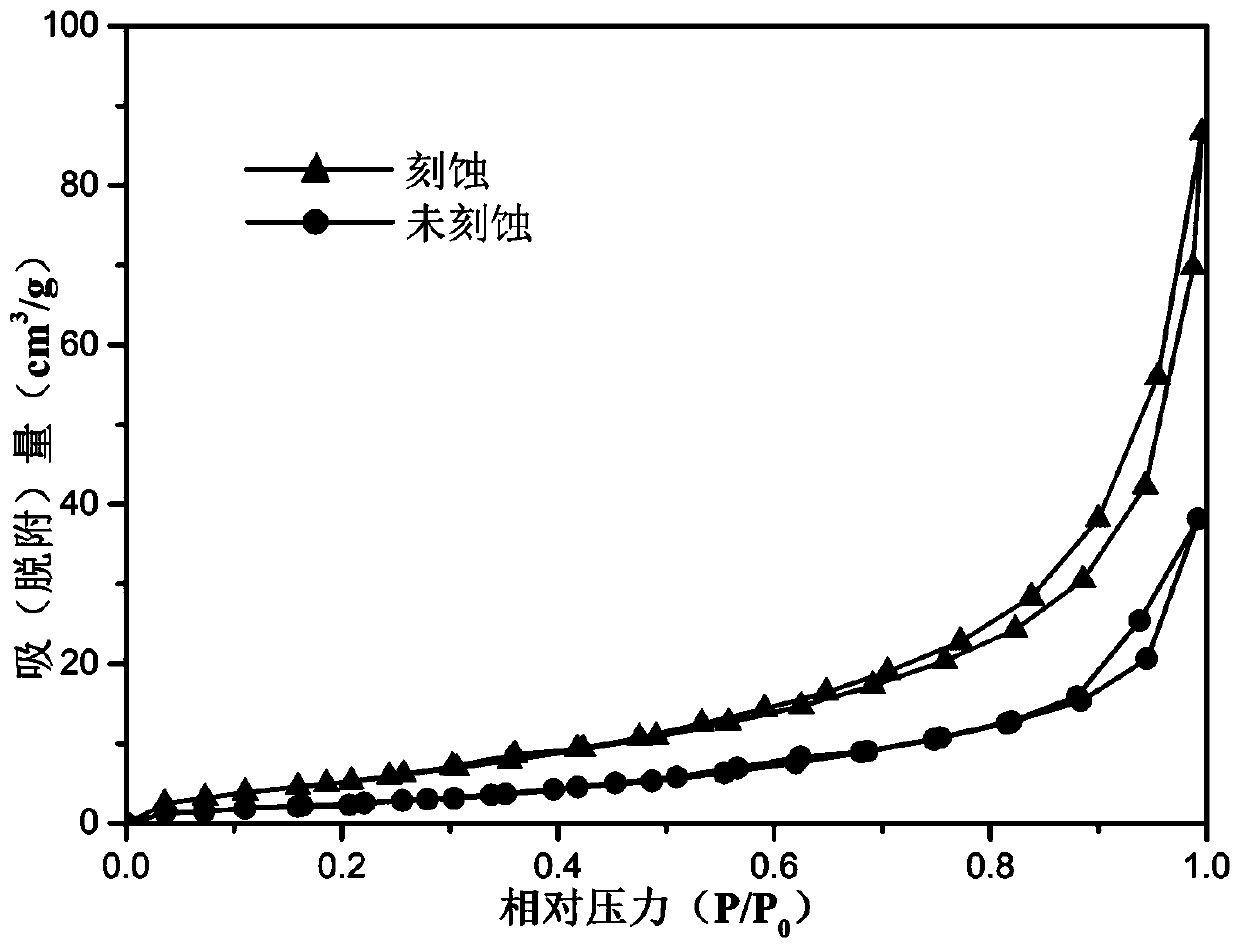

A selective laser melting and ceramic powder technology, which is applied in liquid chemical plating, transportation and packaging, metal processing equipment, etc., can solve the problem of affecting the yield of nickel-coated boron nitride, hexagonal boron nitride is easy to agglomerate, and the specific surface area is small To achieve the effect of improving the plating quality, speeding up the reaction speed and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Take 35ml of formic acid and 4ml of 30% hydrogen peroxide, and mix them evenly to obtain an etching solution.

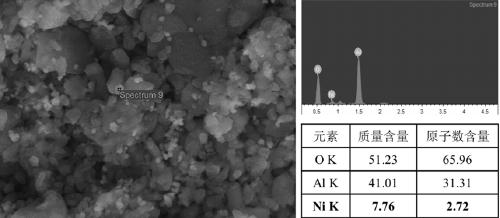

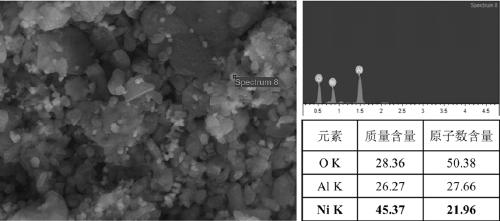

[0044] Add 2g Al to the etchant 2 o 3 powder, magnetically stirred for 30 minutes, filtered, washed twice with deionized water and once with absolute ethanol, and dried in an oven at 65°C for 2 hours to obtain etched Al 2 o 3 powder.

[0045] Weigh 1g of stannous chloride dihydrate, dissolve it in 2ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain a sensitization solution.

[0046] Weigh 0.025g of palladium chloride, dissolve it in 0.5ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain an activation solution.

[0047] The above etched Al 2 o 3 The powder was placed in the sensitizing solution, stirred magnetically for 30 minutes, centrifuged, washed twice with deionized water and once with absolute ethanol to obtain sensitized Al 2 o 3 powder.

[0048] Finally, the sensitized Al ...

Embodiment 2

[0067] Take 30ml of formic acid and 4ml of 30% hydrogen peroxide, and mix them evenly to obtain an etching solution.

[0068] Add 1.5g ZrO to the etchant 2 powder, magnetically stirred for 60 minutes, filtered, washed three times with deionized water, washed twice with absolute ethanol, and dried in an oven at 70°C for 1 hour to obtain etched ZrO 2 powder.

[0069] Weigh 0.5g of stannous chloride dihydrate, dissolve it in 1ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain a sensitization solution.

[0070] Weigh 0.02g of palladium chloride, dissolve it in 0.3ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain an activation solution.

[0071] The above etched ZrO 2 The powder was placed in the sensitizing solution, stirred by magnetic force for 40 minutes, centrifuged, washed 3 times with deionized water and 2 times with absolute ethanol to obtain sensitized ZrO 2 powder.

[0072] Finally, the sensit...

Embodiment 3

[0086] Take 40ml of formic acid and 4ml of 30% hydrogen peroxide, and mix them evenly to obtain an etching solution.

[0087] Add 2.5g of SiC powder into the etching solution, stir magnetically for 60min, filter, wash with deionized water 4 times, wash with absolute ethanol 3 times, and dry in an oven at 80°C for 0.5h to obtain etched SiC powder.

[0088] Weigh 2g of stannous chloride dihydrate, dissolve it in 3ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain a sensitization solution.

[0089] Weigh 0.05g of palladium chloride, dissolve in 0.75ml of concentrated hydrochloric acid, and dilute to 50ml with deionized water to obtain an activation solution.

[0090] The above-mentioned etched SiC powder was placed in a sensitization solution, magnetically stirred for 50 min, centrifuged, washed 4 times with deionized water and 3 times with absolute ethanol to obtain a sensitized SiC powder.

[0091] Finally, the sensitized SiC powder was pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com