High-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing and preparation method of high-strength and high-toughness CoCrMoW alloy

A high-toughness cobalt-chromium-molybdenum and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, can solve problems affecting the application of alloys, reduce stress concentration points, and reduce coarse, brittle, and hard. Phase, the effect of improving the yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

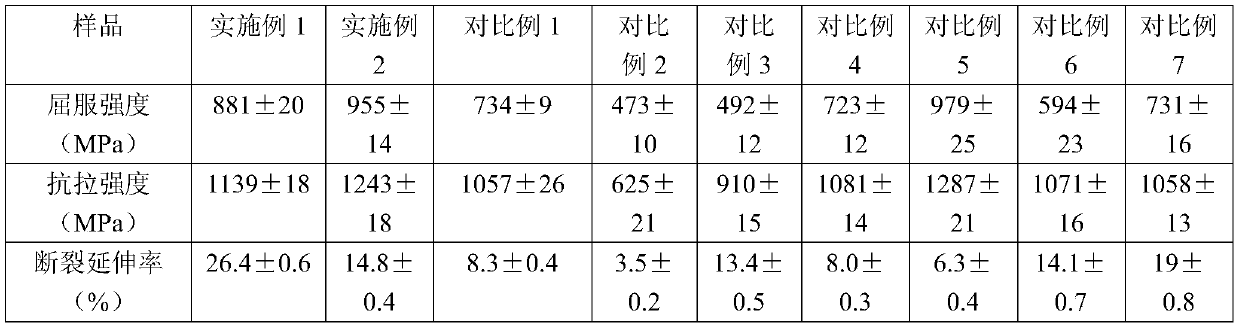

Examples

Embodiment 1

[0036] High-strength and high-toughness cobalt-chromium-molybdenum-tungsten alloy based on laser additive manufacturing, in terms of weight percentage, cobalt-chromium-molybdenum-tungsten alloy includes the following components:

[0037] Cr: 23-25%, Mo: 4-6%, W: 4-6%, Si: 0.5-1.5%, Mn: 0.4-0.6%, and the rest is Co.

[0038] The preparation method of the above-mentioned cobalt-chromium-molybdenum-tungsten bioalloy comprises the following steps:

[0039] 1) Gas atomization powder making: Accurately weigh according to the required formula ratio, mix the raw materials obtained by weighing and add them to a vacuum intermediate frequency induction furnace to smelt into a melt; use 1-6MPa high-pressure nitrogen to melt the melt Broken into fine droplets, solidified and cooled to obtain 20-65μm powder.

[0040] 2) Additive manufacturing molding: use software to build the model of the blank, slice and layer, and then import the data into the laser additive manufacturing equipment. Sp...

Embodiment 2

[0044] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0045] The molding blank obtained in step 2) is only subjected to strengthening and toughening heat treatment, and no plasticizing and toughening heat treatment is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com