Patents

Literature

30 results about "Cobalt chromium molybdenum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt Molybdenum Chromium Superalloy (T800) CT5200-2. CT5200-2 is a Cobalt Molybdenum Chromium superalloy which provides excellent wear resistance, corrosion resistance, high temperature resistance and oxidation resistance up to 1400° F. CT5200-2 is applied using the HVOF process to achieve very dense coatings that contain hard laves phases.

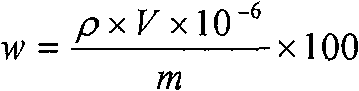

Method for measuring content of boron in cobalt-base alloy

ActiveCN101718688AAvoid interferenceImprove accuracyPreparing sample for investigationColor/spectral properties measurementsElement analysisMaterial resources

The invention belongs to a technique for analyzing trace elements of an alloy, and relates to a method for measuring the content of boron in a cobalt-base alloy. By adopting an inductively coupled plasma emission spectrometer and treating a sample of the cobalt-base alloy in particular a high-tungsten sample by using 20mL of hydrochloric acid, nitric acid and hydrofluoric acid, the method solves the puzzling problems that the past dissolved sample has large reagent dosage and high reagent blank and cannot be measured normally by an instrument; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the method has wide measuring ranges, the measuring lower limit is 0.002 percent, and the measuring upper limit is 0.20 percent and is 101 times of the measuring lower limit; and the method can perform measurement quickly, is simple and convenient to operate, and saves a large quantity of manpower and material resources.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

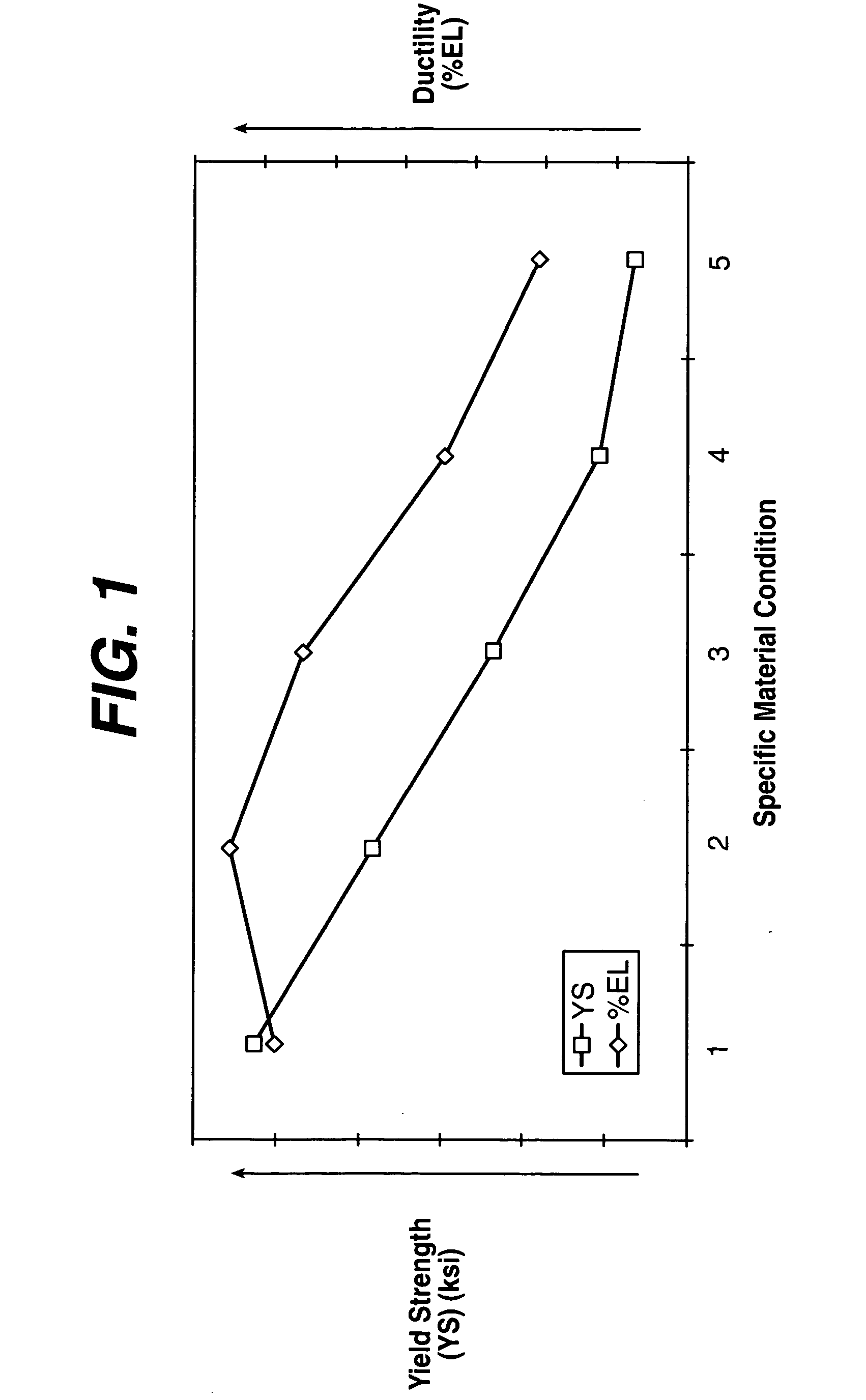

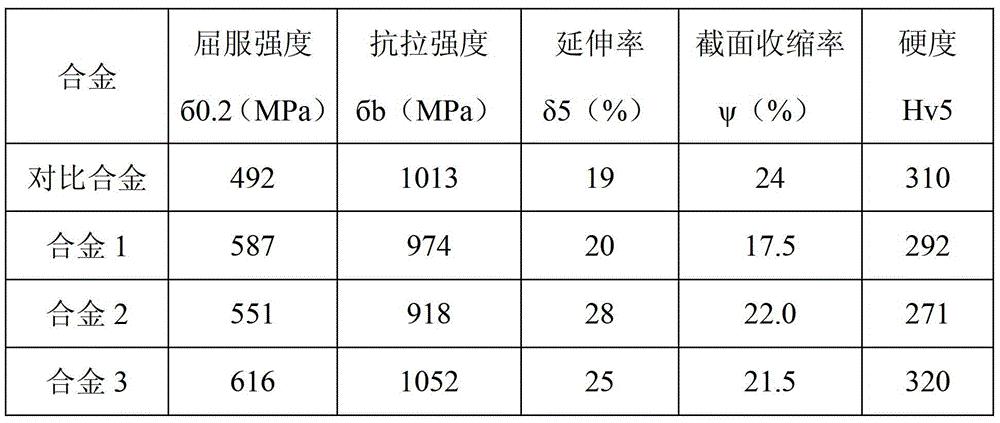

High-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing and preparation method of high-strength and high-toughness CoCrMoW alloy

InactiveCN111172432AReduce stress concentration pointsImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingUltimate tensile strength

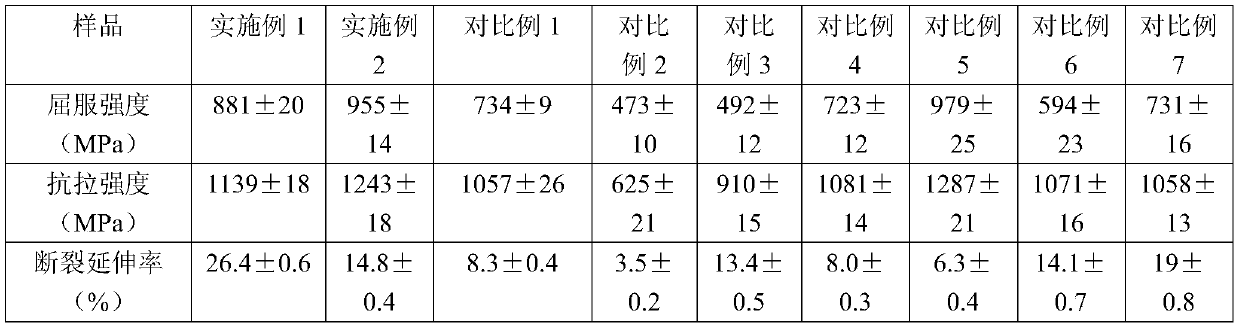

The invention discloses a high-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing and a preparation method of the high-strength and high-toughness CoCrMoW alloy. The preparation method comprises the following steps of (1) gas atomization powder preparing, wherein after CoCr alloy raw materials are molten together into melt, the melt is crushed by high-pressure inert gas into tiny liquid drops, and powder is formed after solidification and cooling; (2) blank additive manufacturing forming, wherein the powder is prepared into a formed blank through the laser additivemanufacturing technology; (3) strengthening and toughening heat treatment, wherein the formed blank is subjected to strengthening and toughening heat treatment to obtain the high-strength and high-toughness CoCrMoW alloy based on laser additive manufacturing, the yield strength of the alloy reaches up to 0.9 GPa or above, the tensile strength of the alloy reaches up to 1.2 GPa or above, and the ductility of the alloy reaches up to 14% or above; and (4) plastifying and toughening heat treatment, wherein the high-strength and high-toughness CoCrMoW biological alloy obtained in the step (3) canbe subjected to subsequent plastifying and toughening heat treatment, the plasticity of the high-strength and high-toughness CoCrMoW biological alloy based on laser additive manufacturing can be further improved, and the plasticity of the high-strength and high-toughness CoCrMoW biological alloy based on laser additive manufacturing can reach 26% or above on the premise of guaranteeing that the tensile strength is 1.1 GPa or above.

Owner:SICHUAN UNIV

Cobalt-chromium-molybdenum-tungsten alloy powder as well as preparation method and application thereof

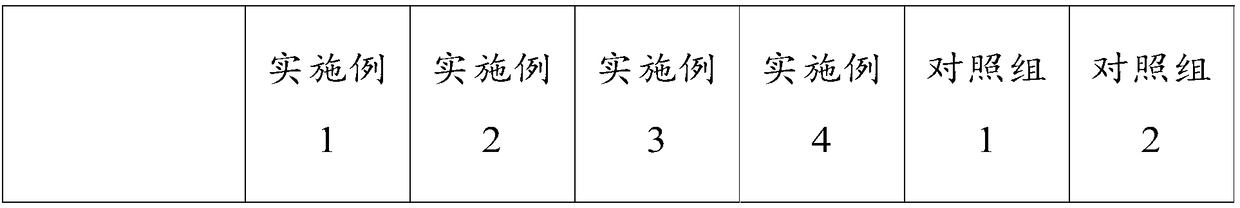

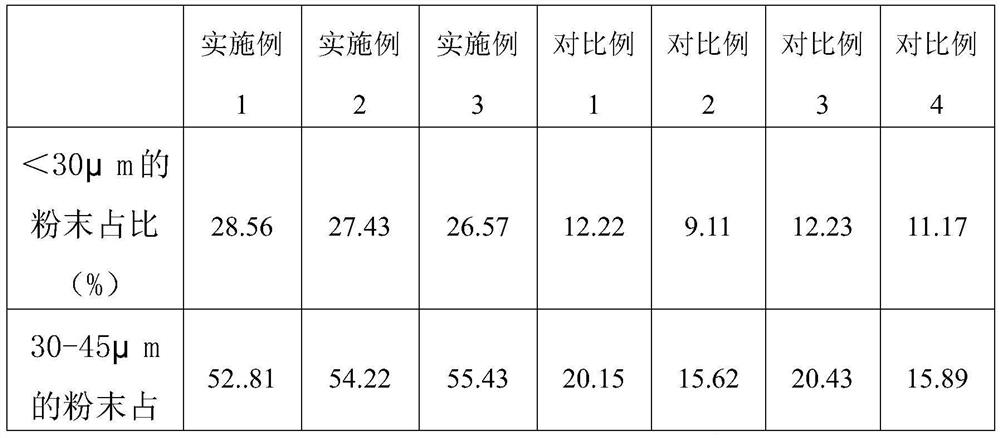

InactiveCN108705093AEasy to prepareImprove liquidityTransportation and packagingMetal-working apparatusSelective laser meltingApparent density

The invention relates to cobalt-chromium-molybdenum-tungsten alloy powder as well as a preparation method and application thereof, and belongs to the field of metal additive manufacturing. The preparation method comprises the following steps that smelting is carried out on a cobalt-chromium-molybdenum-tungsten raw material, atomizing is carried out, screening is carried out, and powder particles with the particle size of 15-53 micrometers are reserved to obtain the cobalt-chromium-molybdenum-tungsten alloy powder. The cobalt-chromium-molybdenum-tungsten raw material comprises the following components of, by weight, 58-70 wt% of Co, 23-27 wt% of Cr, 4-6 wt% of Mo, 4-6 wt% of W, less than 1.5 wt% of Si and the balance impurities. The preparation method is relatively simple, and therefore, the impurity content and satellite balls can be reduced, the fluidity of the powder can be improved, the yield of the powder can also be improved, and the industrial batch application is facilitated; and the obtained powder is small in particle size, narrow in particle size distribution, high in sphericity, good in mobility and high in apparent density, so that cobalt-chromium-molybdenum-tungsten alloy products with excellent performances can be conveniently obtained when the powder is used for the selective laser melting additive manufacturing.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Cobalt chromium molybdenum tungsten alloy fine spherical powder and preparation method thereof

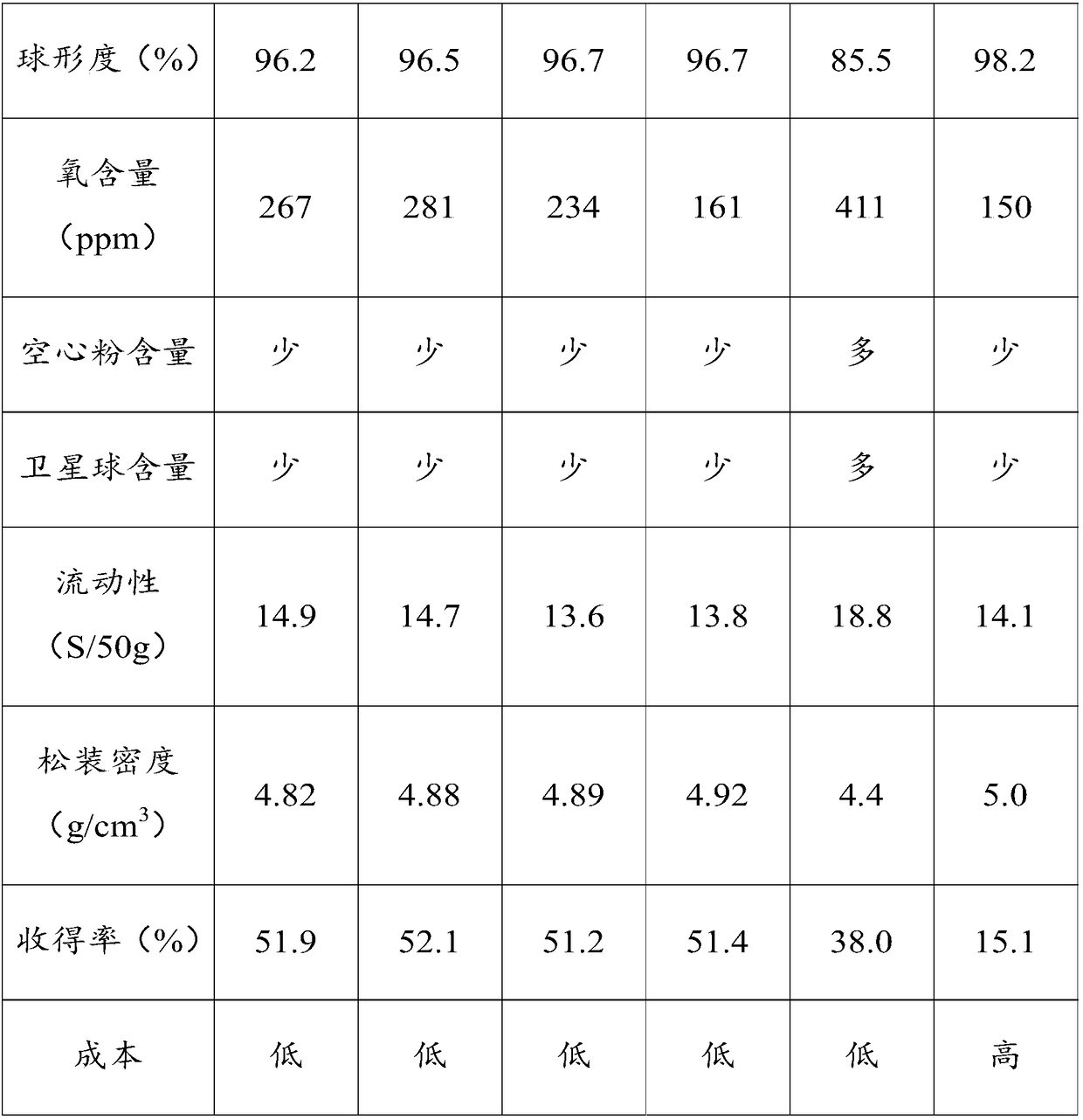

InactiveCN110090948AHigh densityGood mechanical propertiesAdditive manufacturing apparatusTransportation and packagingSpherical shapedCobalt

The invention discloses cobalt chromium molybdenum tungsten alloy fine spherical powder. The cobalt chromium molybdenum tungsten alloy fine spherical powder is characterized by comprising the following components in percentage by mass: 60-66% of cobalt, 24-27% of chromium, 5-6% of molybdenum, 5-6% of tungsten, 0-1.5% of silicon, and the balance of impurities. The preparation comprises the following steps: (S1) the precise weighing is performed according to the ratio of the needed formula; weighed raw materials are mixed in a medium-frequency induction furnace for smelting to obtain molten alloys; (S2) inert gas is heated by using a gas heating system; (S3) the molten alloys obtained in the step (S1) are poured in a tundish, and flow into an atomization nozzle through a liquid guide pipe; and the supersonic-speed gas atomization is performed on the molten metal by using hot air to obtain powder; and (S4) the obtained powder is screened to obtain the cobalt chromium molybdenum tungsten alloy fine spherical powder with the particle size of smaller than 30 microns. The cobalt chromium molybdenum tungsten alloy fine spherical powder achieves high relative density and excellent mechanical performances under the condition of relative lower cost, facilitates the popularization and the application of the SLM technology in the biomedical field, and achieves higher practicability.

Owner:佛山市岁之博新材料科技有限公司 +1

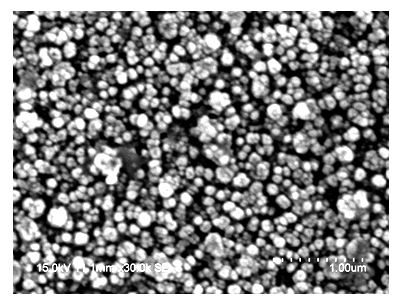

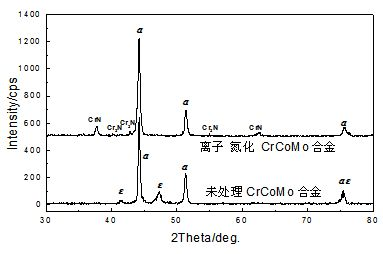

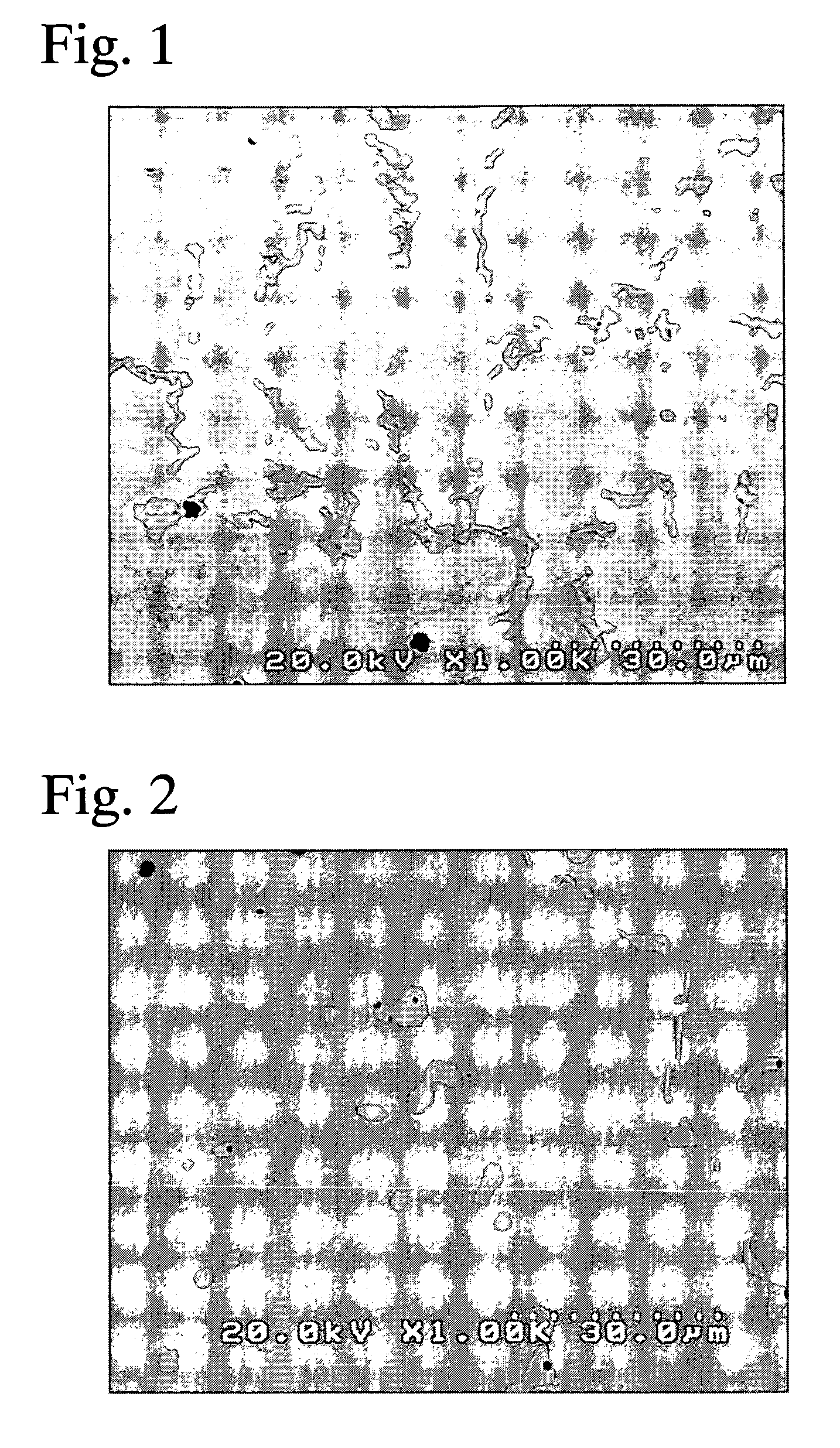

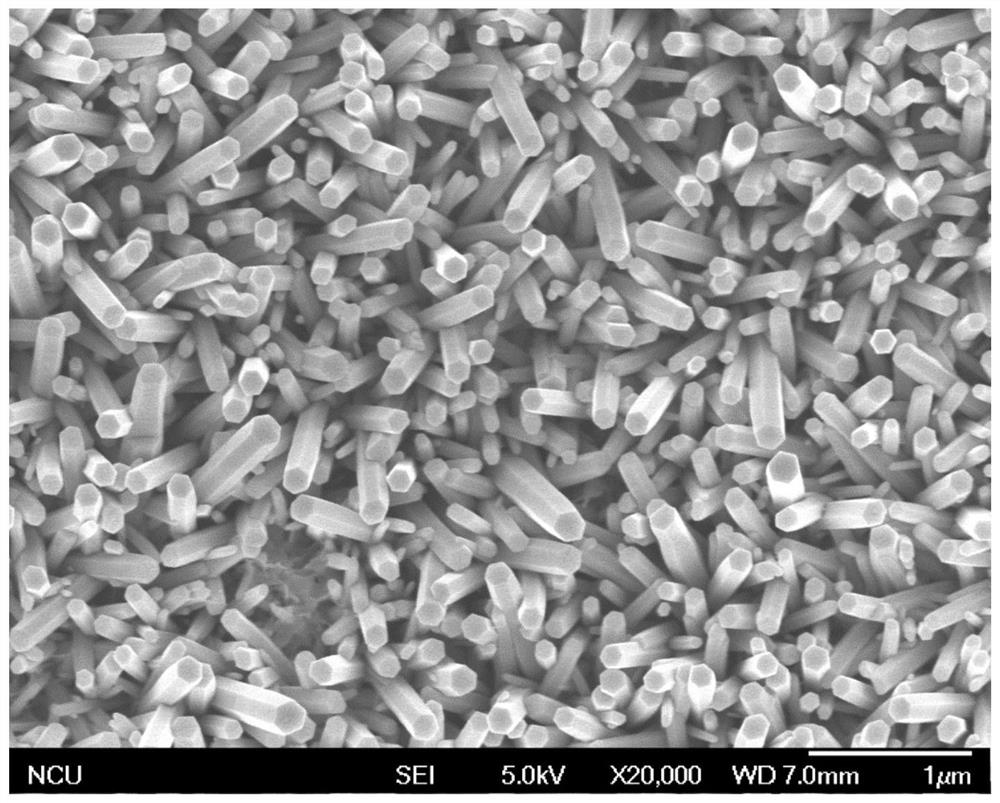

Surface ion nitriding method for medical CoCrMo alloy

InactiveCN102031482ATroubleshoot joint status issuesImprove carrying capacitySolid state diffusion coatingChromium nitrideNanostructure

The invention provides a surface ion nitriding method for a medical CoCrMo alloy. The method comprises the following steps of: firstly, polishing the surface of the CoCrMo alloy ground by waterproof abrasive paper, performing ultrasonic cleaning by using alcohol and deionized water, drying for later use; secondly, cleaning the CoCrMo alloy serving as a substrate with argon; and finally, forming a nitride ceramic layer on the surface of the CoCrMo alloy with pure NH3 (ammonia) serving as a gas source by ionic nitriding technology. The nitride layer consists of Cr2N (dichromium nitride) and CrN (chromium nitride) compounds with a compact nanostructure. The surface hardness of the CoCrMo alloy is improved to a certain degree. The nitride layer penetrates into the crystal boundary of the CoCrMo alloy and forms an interlaced net structure with the substrate. The method is simple in process and easy to popularize, effectively improves the wear resistance of the CoCrMo alloy, reduces the release of toxic Co (cobalt) and Cr (chromium) ions, solves the failure problem and has great application potential in the field of biomedicine and the like.

Owner:CHINA UNIV OF MINING & TECH

Forming method for cobalt-chromium-molybdenum superalloy bar

The invention relates to a forming method for a cobalt-chromium-molybdenum superalloy bar. Metal cobalt, metal chromium and metal molybdenum are adopted as raw materials, and the cobalt-chromium-molybdenum superalloy bar is finally prepared and obtained sequentially through vacuum smelting, electroslag remelting, homogenization treatment, finish forge cogging and rolling forming. The preparing method is simple, steps are easy to operate, cast ingot alloy components can be more uniform through the homogenization treatment in the preparing technology, during cogging, a finish forging device is used for cogging, the stress of the cast ingot alloy in the circumferential direction is uniform and consistent, deformation is uniform, and cracking of the alloy due to uneven stress or temperature difference is avoided; rolling is conducted after the blank surface is treated, the rolling time is short, the machining deformation rate is large, and efficiency is high; and meanwhile, the bar machined through the method is high in size precision and high in yield, grain is fine and uniform, and the mechanical performance is excellent.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Mold shell of investment casting cobalt chromium molybdenum artificial joint implant and manufacturing method of mold shell

InactiveCN108817309AImprove thermal conductivityIncreasing the thicknessFoundry mouldsFoundry coresSlurryHigh heat

The invention discloses a mold shell of an investment casting cobalt chromium molybdenum artificial joint implant and a manufacturing method of the mold shell and relates to the technical field of metal processing. A mold shell main body is provided with two layers of cobalt chromium molybdenum surface layers; each cobalt chromium molybdenum surface layer is prepared from silica sol, aluminum oxide powder, cobalt aluminate powder, a de-foaming agent, a wetting agent and latex, wherein the mass ratio of the aluminum oxide powder to the silica sol is 4.35 to 4.45 and the mass ratio of cobalt aluminate to the silica sol is 0.22 to 0.35; the mass ratio of the de-foaming agent to the silica sol is 6 to 8ml / Kg; the mass ratio of the wetting agent to the silica sol is 2 to 3ml / Kg and the mass ratio of the latex to the silica sol is 0.03 to 0.05; aluminum oxide slurry containing the cobalt aluminate and the aluminum oxide powder have very high heat conduction performance, a double-surface-layer manner ensures the thickness of a high-heat-conduction layer, the super-cooling degree of metal liquid is increased and the nucleation rate is improved, so that the aim of thinning crystal grains isfinally realized; a certain amount of the latex is added into surface-layer slurry and back-layer slurry and the latex is burnt after being baked, so that a lot of pores are formed in the mold shell,the air permeability of the mold shell is increased and the air pore rejection rate of castings is reduced.

Owner:无锡范尼韦尔工程有限公司

Composite powdered catalyst adn its preparing method

InactiveCN1470324AEasy to makeLow priceOrganic compound preparationAmino preparation by hydrogen substitutionPhosphorManganese

The invention refers to a kind of compound powder catalyst and the manufacturing method. The catalyst is made up of nickel, aluminium and other metal or nonmetal such as iron, copper, manganese, cobalt, chrome, molybdenum, boron, phosphor. The manufacturing method is: blends the nickel, aluminium and other metal or nonmetal powder and melts them, crushes into powder after cooled, then uses alkalito process them. The product has a low price, the process is simple.

Owner:侯金祥

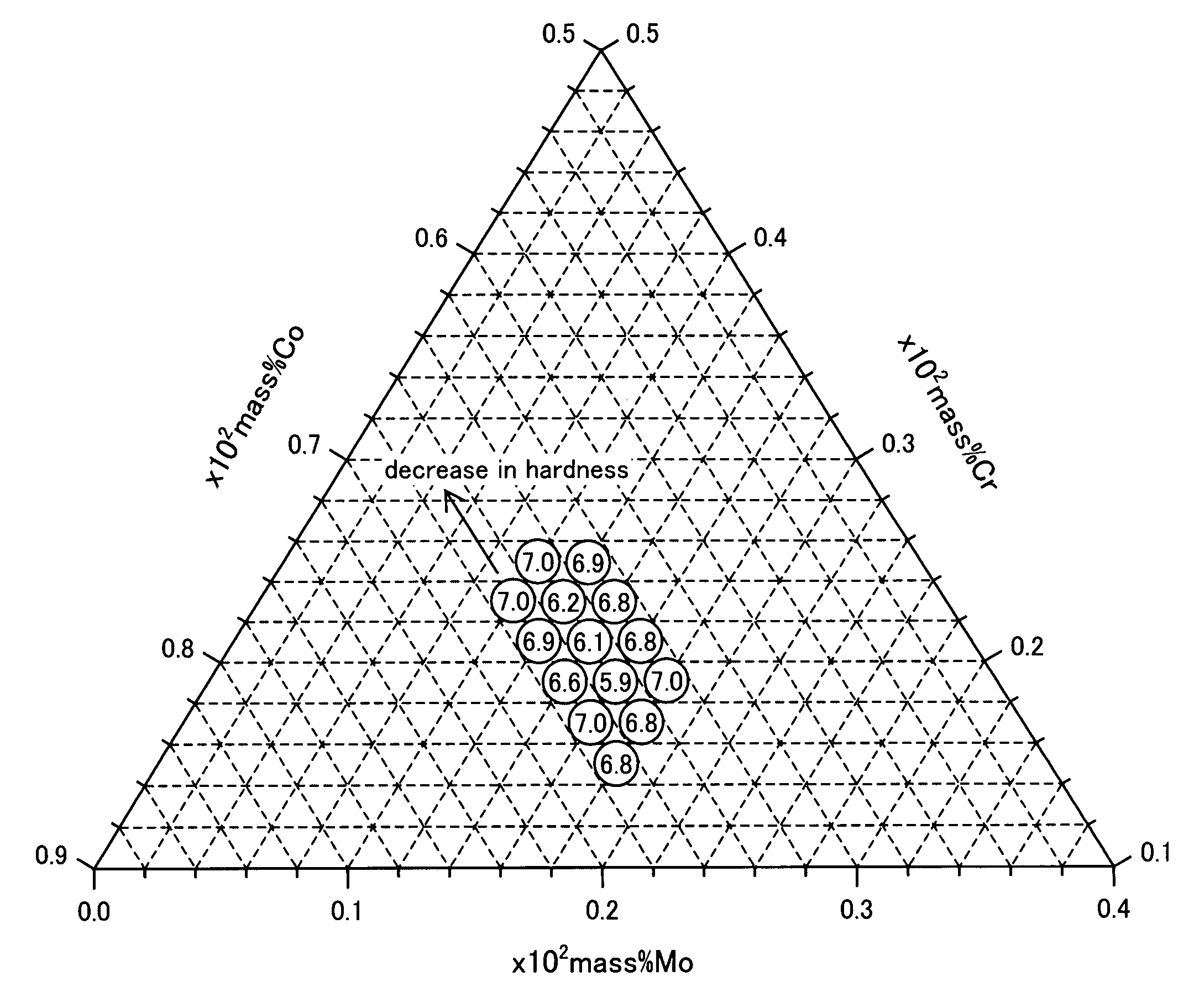

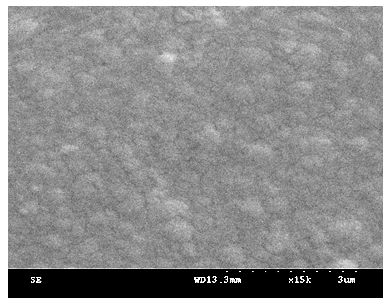

Co-Cr-Mo-based alloy and production method therefor

InactiveUS7569116B2Low magnetic susceptibilityReliable wear resistanceMagnetic materialsMagnetic susceptibilityRoom temperature

A Co—Cr—Mo-based alloy includes: 63 mass %≦Co<68 mass %; 15 mass %≦Cr<26 mass %; 10 mass %≦Mo<19 mass %; and the balance of inevitable impurities, wherein the total amount of Cr and Mo is from 32 mass % to 37%. The mass magnetic susceptibility of the alloy is 7×4π·10−9 m3 / kg or less at room temperature, and the Vickers hardness number (Hv) of the alloy is 400 or more.

Owner:NHK SPRING CO LTD

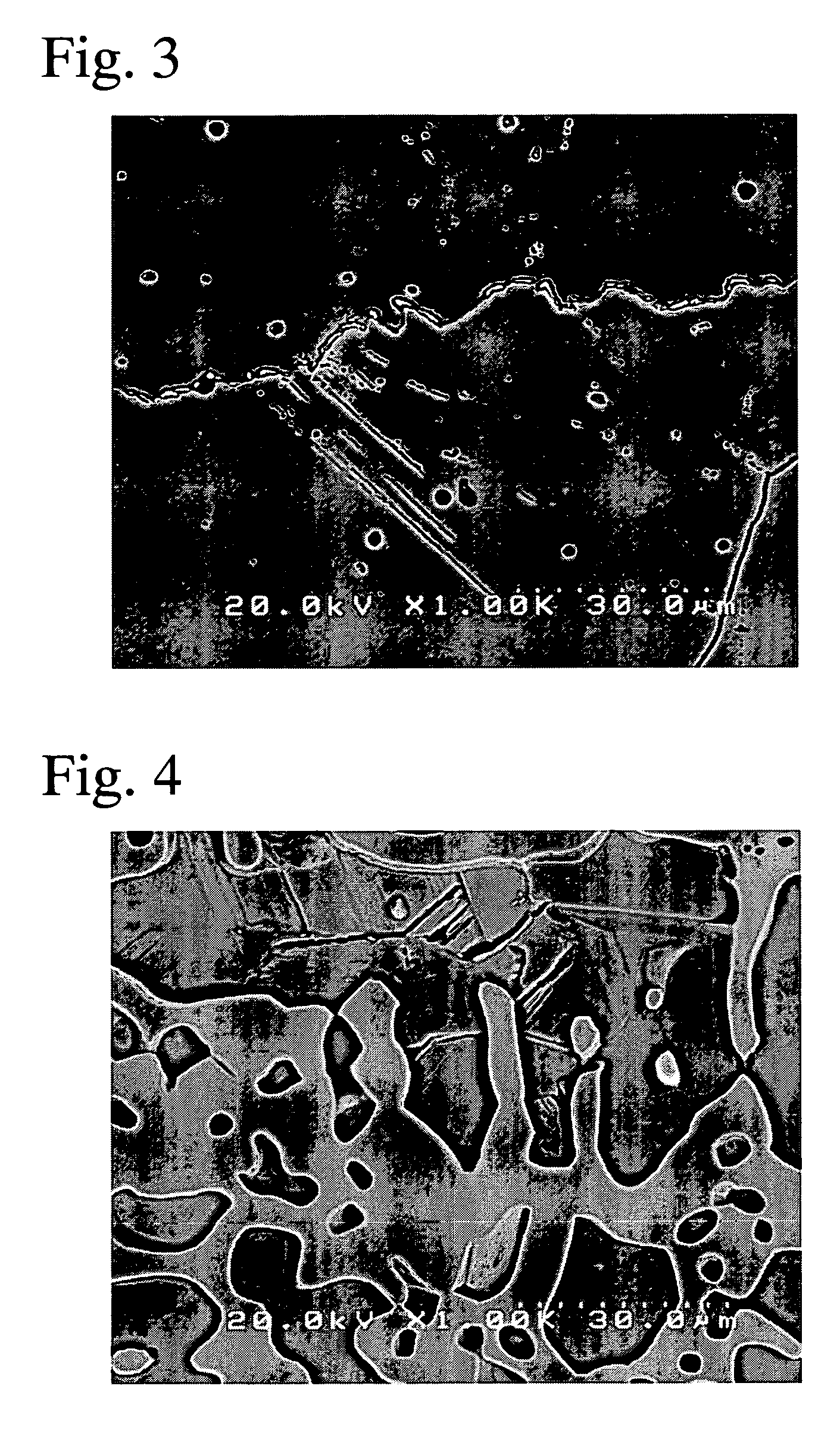

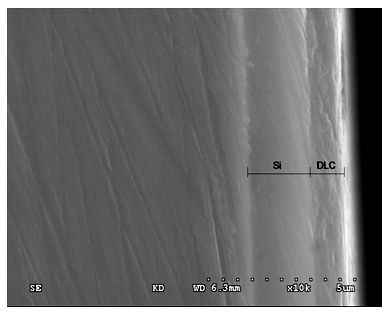

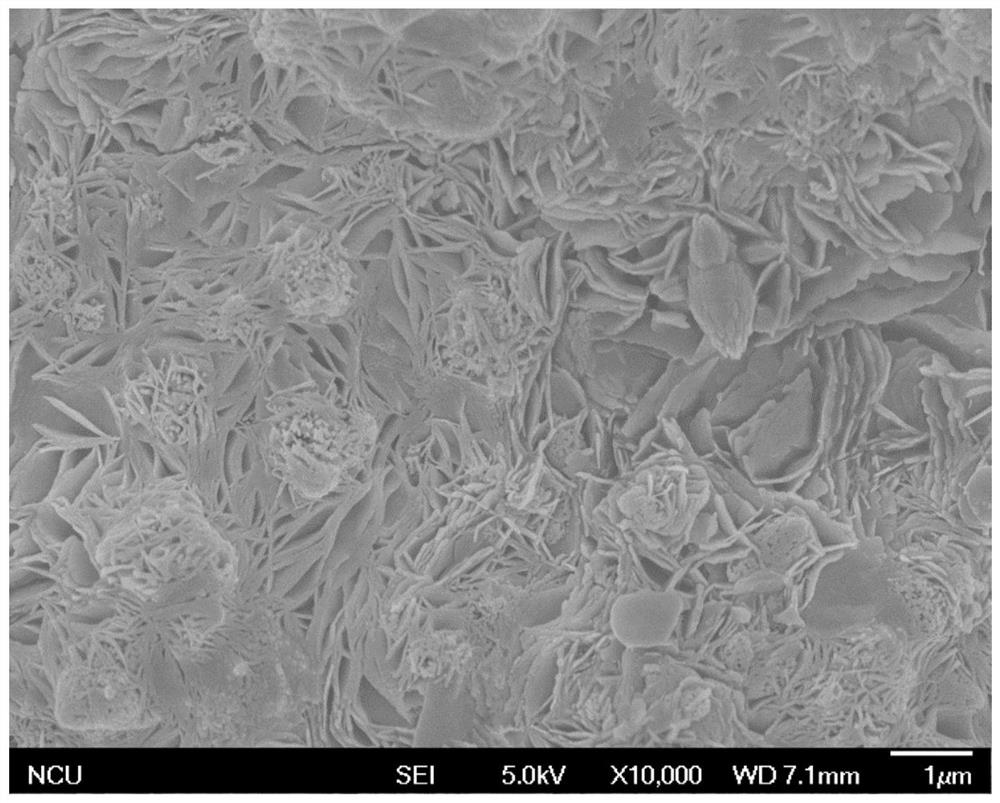

Method for preparing high-hardness diamond film on surface of medical CoCrMo alloy

InactiveCN101967626AHigh hardnessImprove stabilityChemical vapor deposition coatingSputter cleaningPolymer science

The invention discloses a method for preparing a high-hardness diamond film on the surface of medical cobalt-chrome-molybdenum (CoCrMo) alloy. The method comprises the following steps of: performing sputter-cleaning on polished and cleaned CoCrMo alloy by using hydrogen (H2) gas; depositing a silicon (Si) film transition layer on the surface of the CoCrMo alloy by taking silicane (SiH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition; and preparing a diamond like carbon (DLC) film on the Si film transition layer by taking methane (CH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition. Film bases prepared by the method are combined in a saw-toothed mode, good combination performance is represented between the film bases, and the defect of low boundary bearing capacity caused by low combination performance is overcome; meanwhile, the sp3C bond content of prepared DLC film is high, the DLC film with high hardness can be obtained and the wear resistance of the DLC film is effectively improved. In addition, the method has the advantages of simple process and low cost and has great application potential in the technical field of surface modification of a biomaterial.

Owner:CHINA UNIV OF MINING & TECH

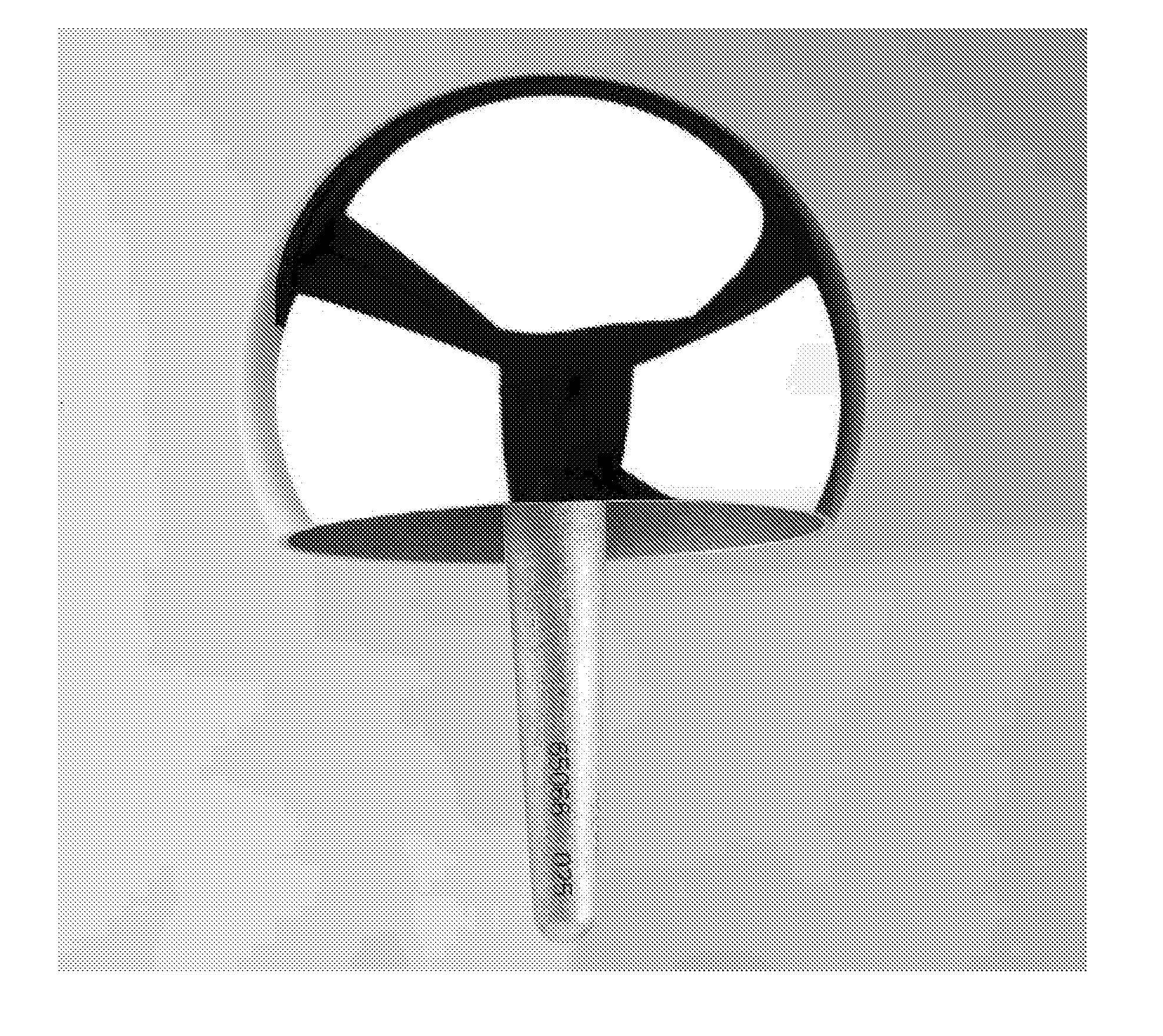

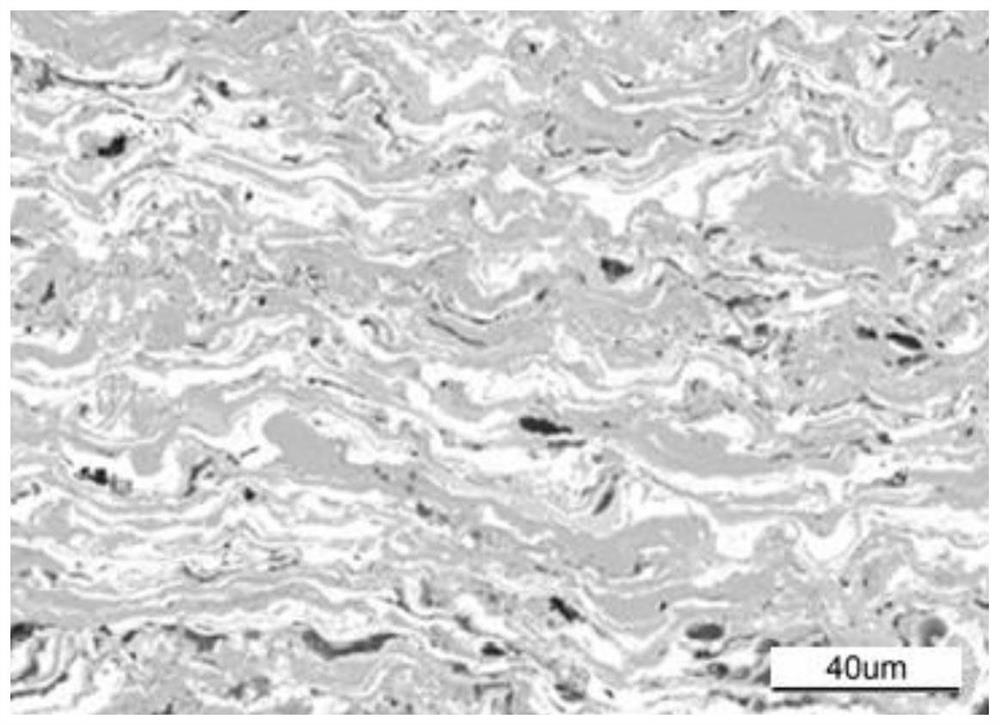

Surgical orthopedic implants made from wear-resistant cobalt-chromium-molybdenum alloys

A surgical implant component comprising an implant component body manufactured from an alloy comprising from about 23 to about 33 wt % Cr, from about 8 to about 20 wt % Mo, from about 0.05 to about 1.5 wt % Si, from about 0.35 to about 3.5 wt % C, from about 40 to about 60 wt % Co, and incidental impurities. The implant component alloy has an atomic % ratio of (Cr+Mo+Nb) / Co of at least 0.59, a matrix metallurgical microstructure comprising between about 45% and about 85% by volume face-centered cubic structure, and between about 15% and about 55% by volume hexagonal close-packed structure; and a Rockwell C hardness of greater than 35. A method for manufacturing a surgical implant component body for a surgical implant by a manufacturing method selected from the group consisting of casting, forging, and powder metallurgy pressing-plus-sintering from an alloy.

Owner:KENNAMETAL INC

Cobalt-chromium ceramic-metal alloy disc for engraving fixed dentures and preparation method thereof

InactiveCN110819851AHigh strengthImprove creep resistanceImpression capsDentistry preparationsCeriumWire cutting

The invention relates to oral medical materials, in particular to a cobalt-chromium ceramic-metal alloy disc for engraving fixed dentures. The cobalt-chromium ceramic-metal alloy disc is prepared fromthe following raw materials in percentage by weight: 50%-65% of cobalt, 20%-35% of chromium, 3%-6% of molybdenum, 1%-3% of titanium, 5%-7% of tungsten, 0.08%-0.3% of lanthanum, 0.1%-0.5% of cerium, 0.09%-0.3% of yttrium and 0.06%-0.2% of strontium. The preparation method comprises the following steps that 1, after the tungsten is firstly melt in a high-frequency high-temperature furnace, the cobalt, the chromium and the molybdenum are added in sequence; 2, the metals are introduced into a vacuum smelting furnace after melting, and then the cerium, the lanthanum, the titanium, the yttrium andthe strontium are added for vacuum melting; 3, a smelted and molten metal solution is introduced into a rectangular parallelepiped mold, and is cooled after being formed in a vacuum; and 4, for a cooled alloy metal ingot, residues in an alloy are cut off and separated from the alloy by a material reducing method, the remaining materials are machined by wire cutting and lathe turning, and the cobalt-chromium ceramic-metal alloy disc with the diameter being 98mm and the thickness being 10mm-25mm is machined. Compared with existing products, the cobalt-chromium ceramic-metal alloy disc is high inengraving machining yield and stable in quality, and is suitable for promotion and use.

Owner:南通今日高科技新材料股份有限公司

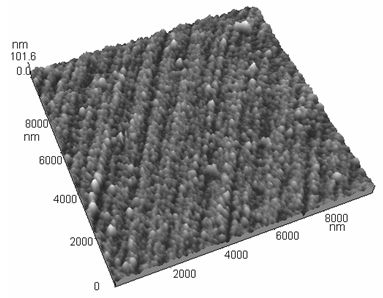

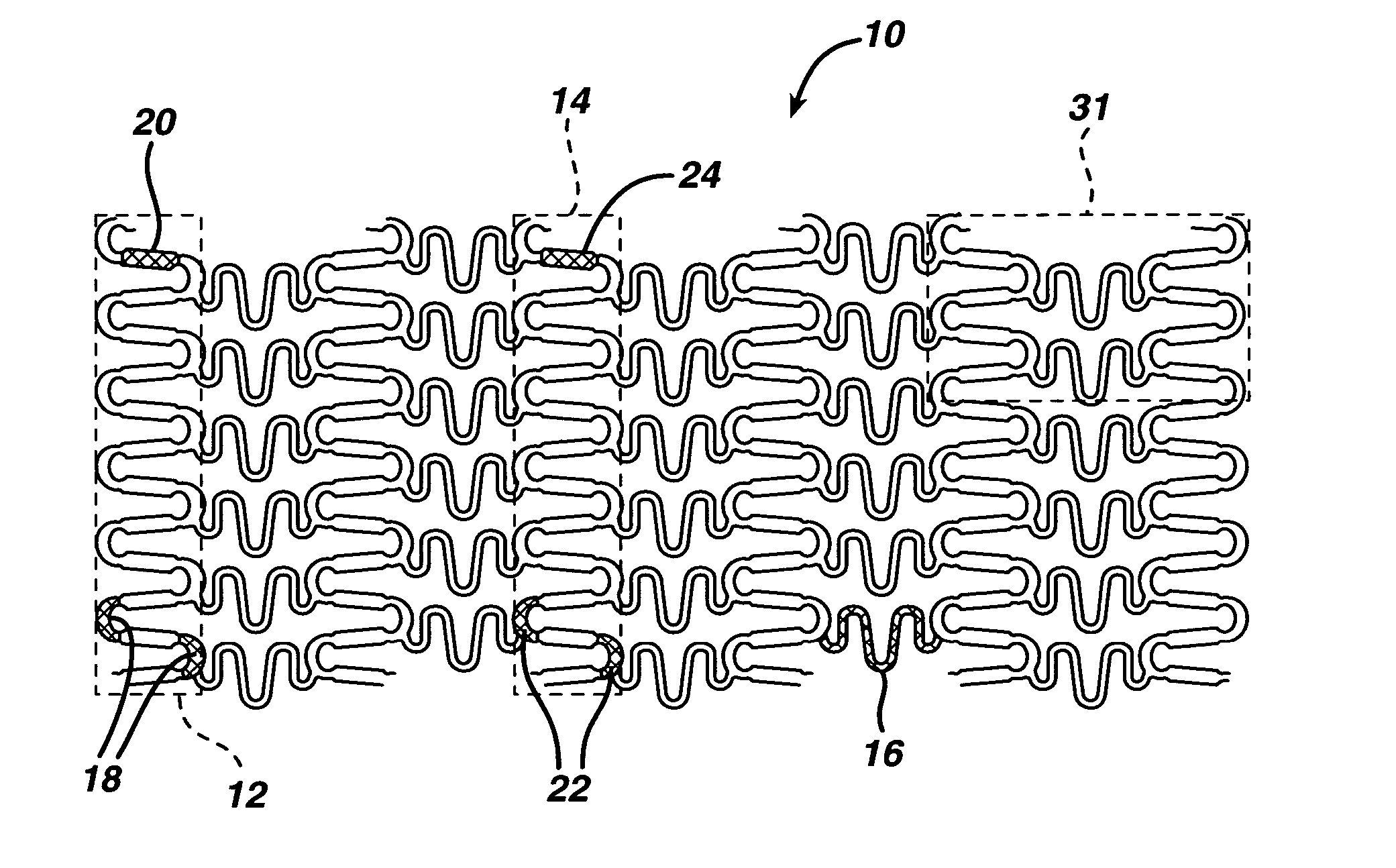

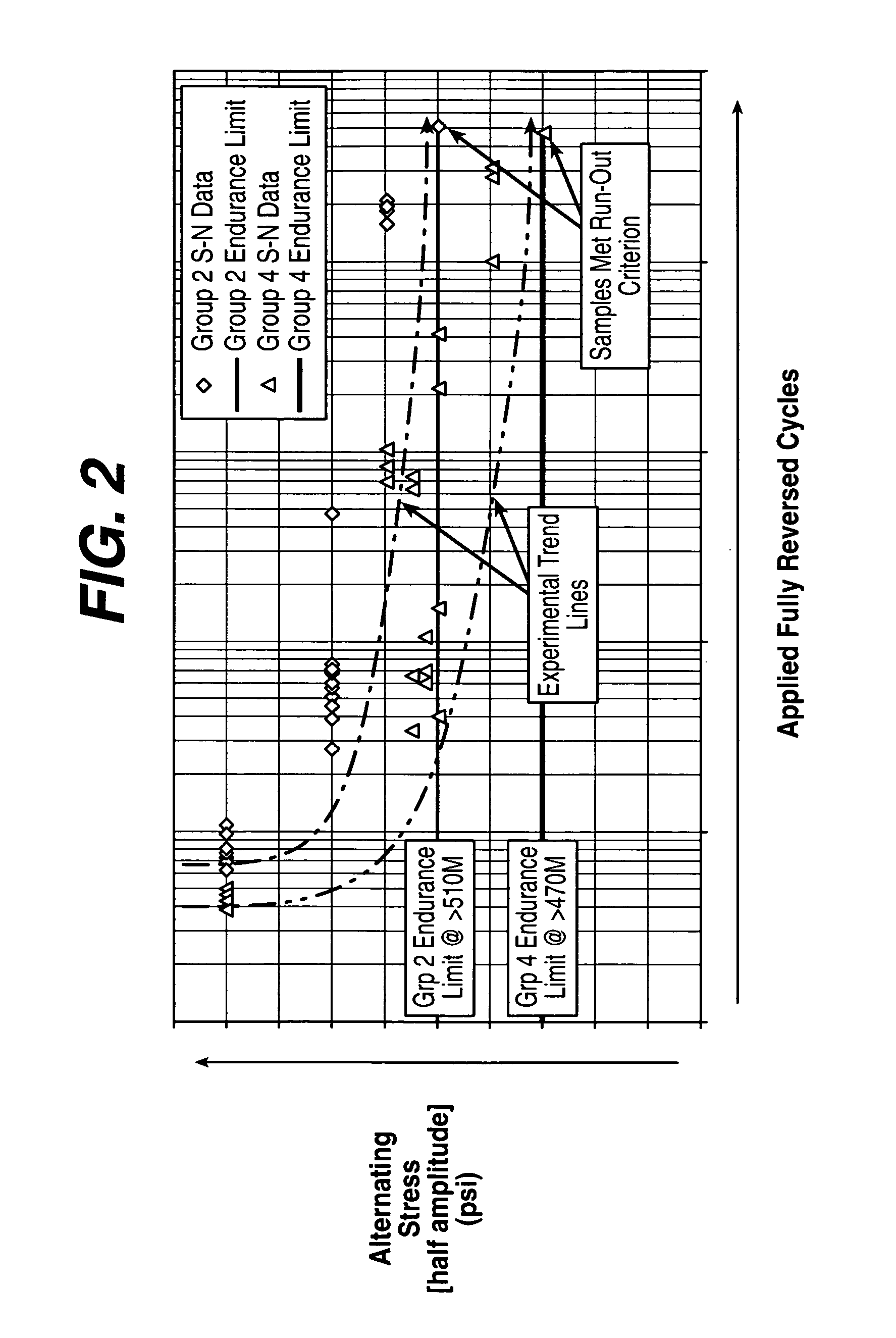

Cobalt-chromium-molybdenum fatigue resistant alloy for intravascular medical devices

InactiveUS20060100692A1Improve fatigue durabilityImprove compatibilityStentsSurgeryMetallic materialsSolid solution

A solid-solution alloy may be formed into any number of implantable medical devices such as intraluminal scaffolds. The biocompatible, solid-solution alloy comprises a combination of elements in specific ratios that improve its fatigue resistance while retaining the characteristics required for intraluminal scaffolds. The biocompatible, solid-solution alloy is an essentially carbon free cobalt-chromium-molydenum metallic material.

Owner:CORDIS CORP

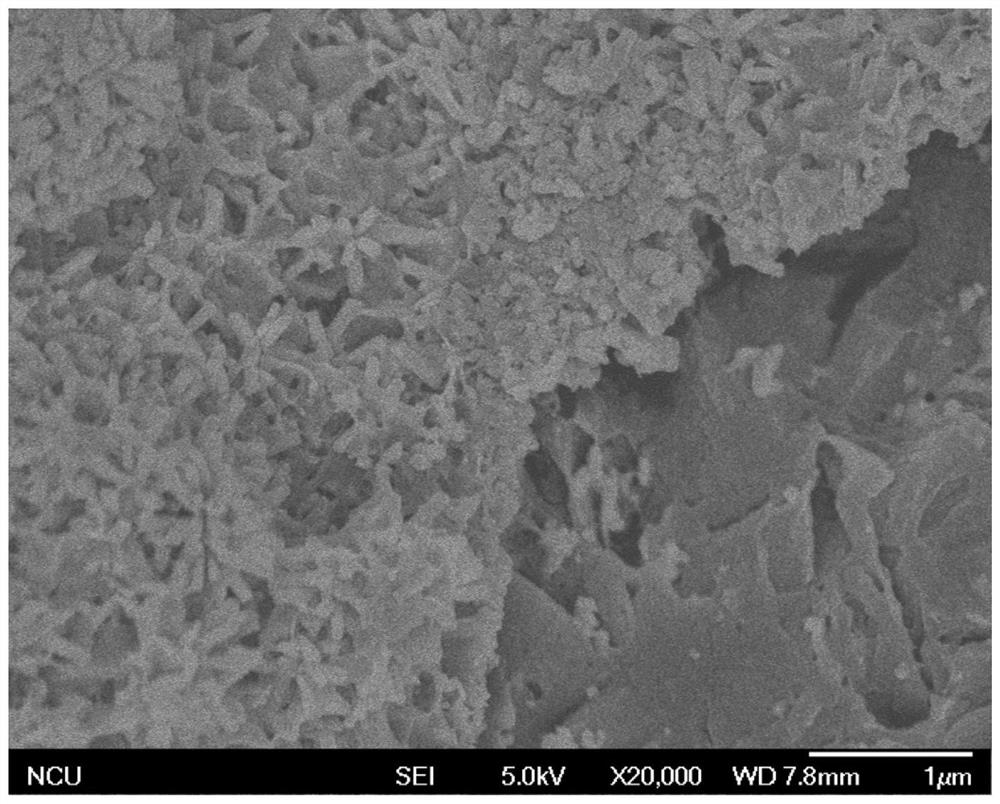

High-temperature-oxidation-resistant and corrosion-resistant coating and preparation method thereof

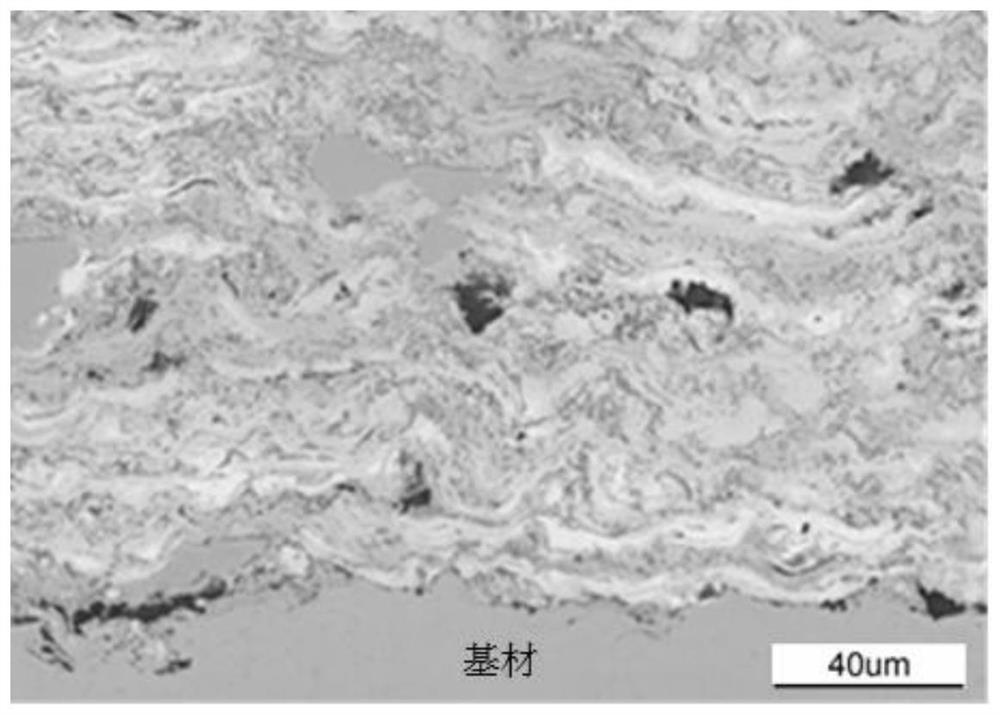

PendingCN112626442AImprove surface roughnessGood adhesionMolten spray coatingOxidation resistantSS - Stainless steel

The invention relates to a high-temperature-oxidation-resistant and corrosion-resistant coating and a preparation method thereof. The preparation method comprises the following steps of, mixing 35-50 wt% of cobalt, 15-35 wt% of chromium, 15-30 wt% of molybdenum and 2-10 wt% of silicon in proportion to prepare alloy powder for later use; cleaning and drying substrate to be machined, and then carrying out roughening treatment on the surface of the base material for later use; spraying the alloy powder to the surface of the substrate through hypersonic flame to obtain the high-temperature-oxidation-resistant and corrosion-resistant coating; and carrying out heat treatment at 800-1150 DEG C for 60 min after the coating is obtained. The coating prepared by the method has good resistance to various corrosive media and high-temperature oxidation resistance up to 900 DEG C in severe environments such as normal temperature and even high-temperature corrosion, and can ensure that metal substrates such as high-strength stainless steel and the like can keep a stable and good use state for a long time in the severe environments.

Owner:中机凯博表面技术江苏有限公司

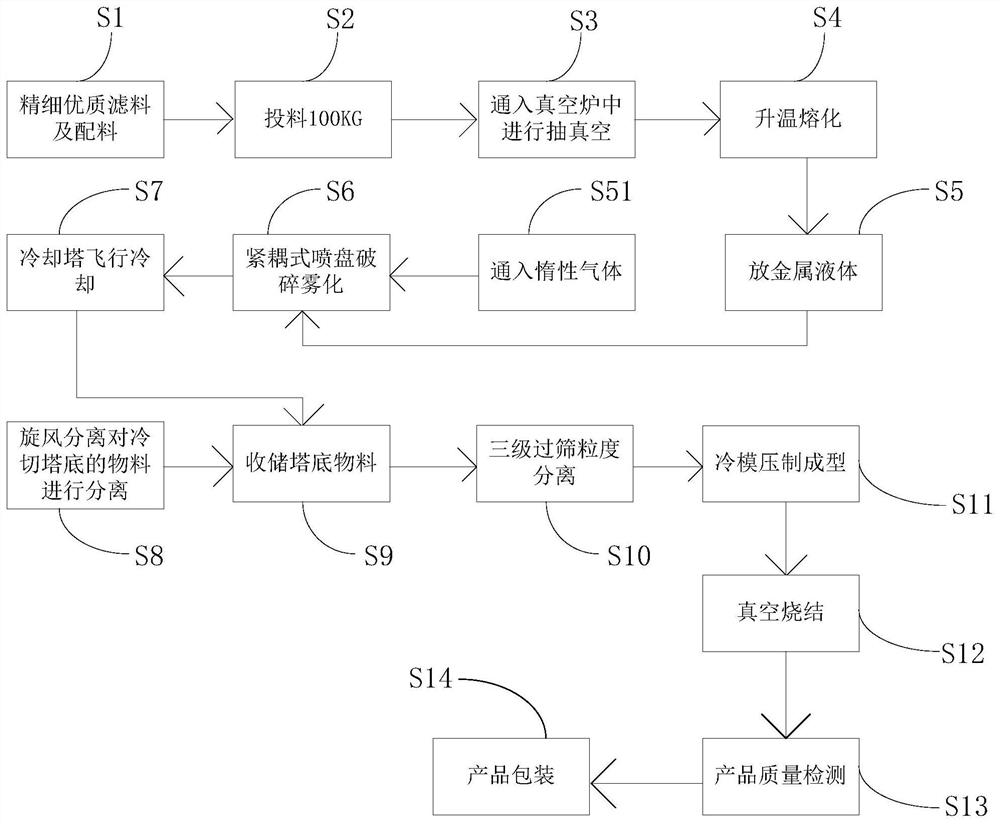

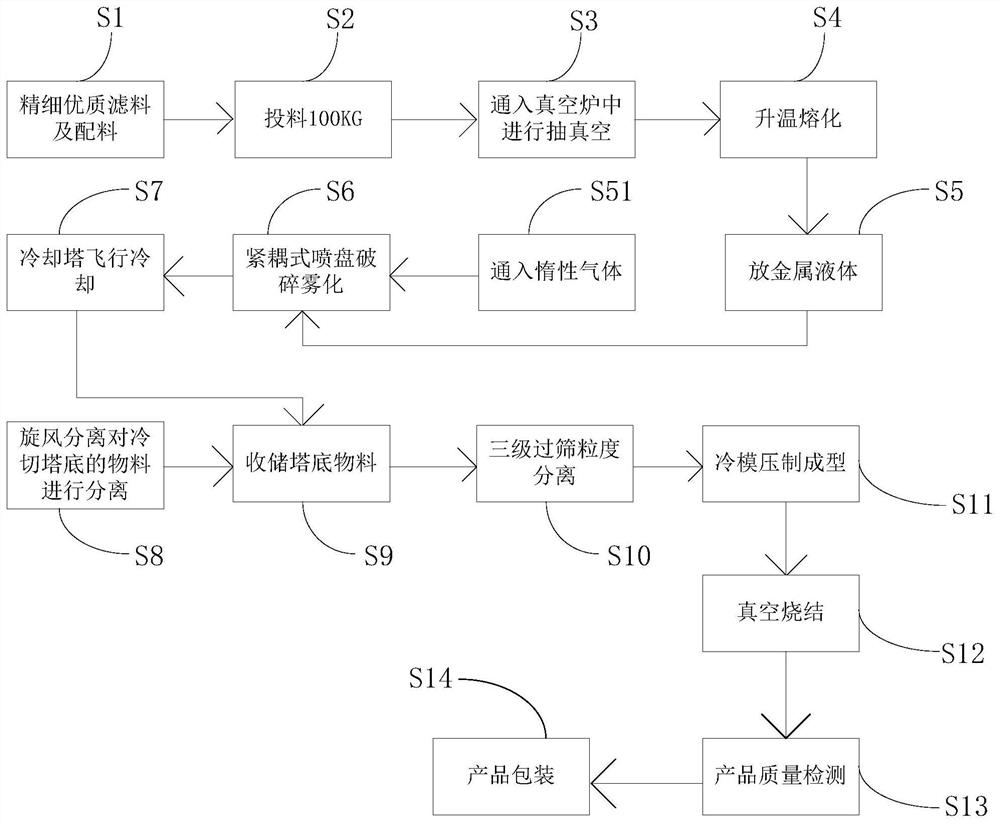

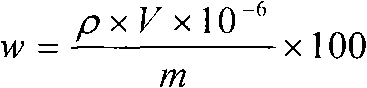

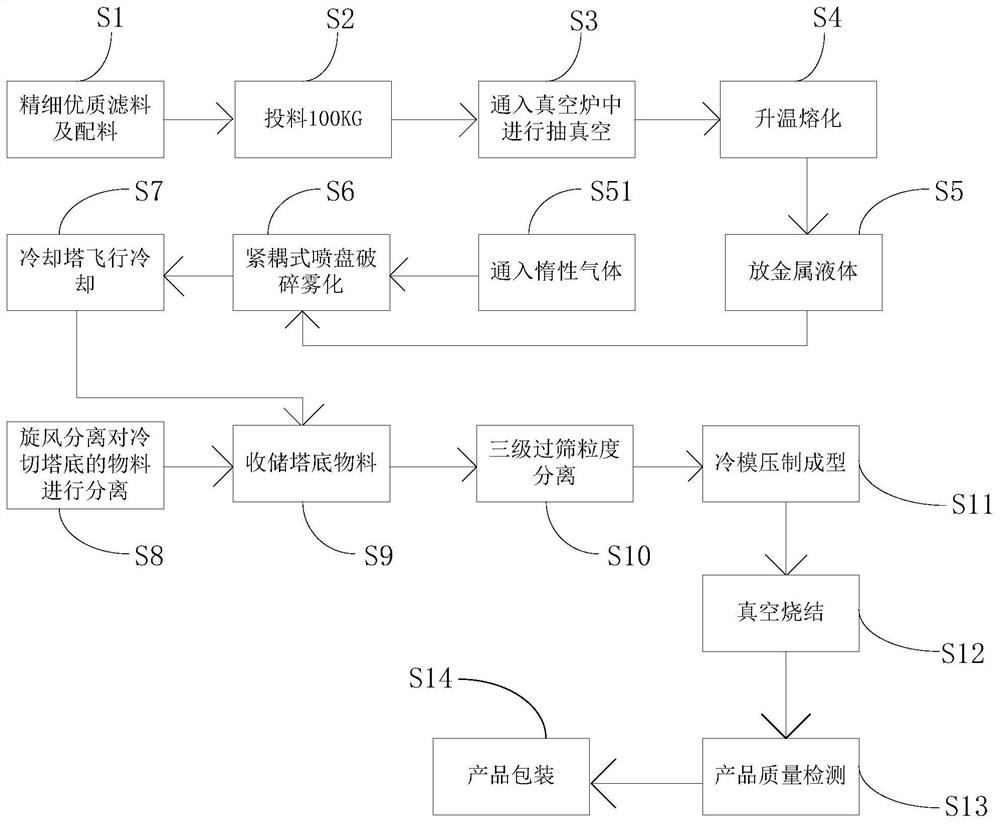

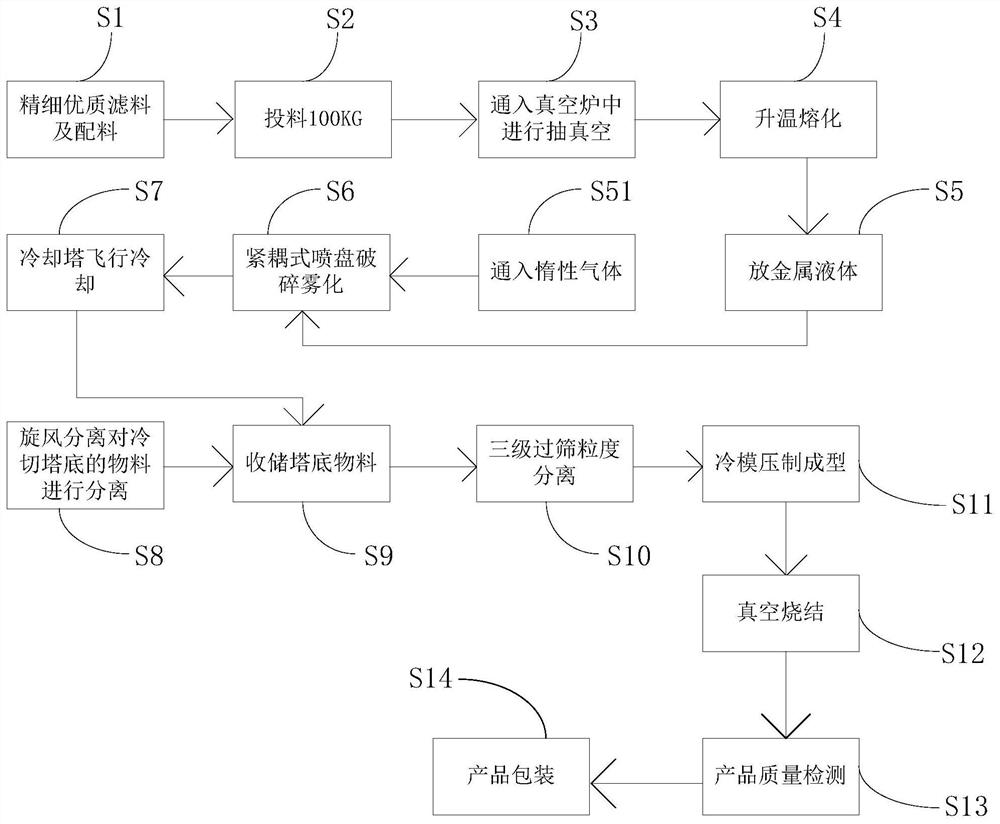

Preparation method for cobalt-chromium-molybdenum-tungsten-silicon alloy

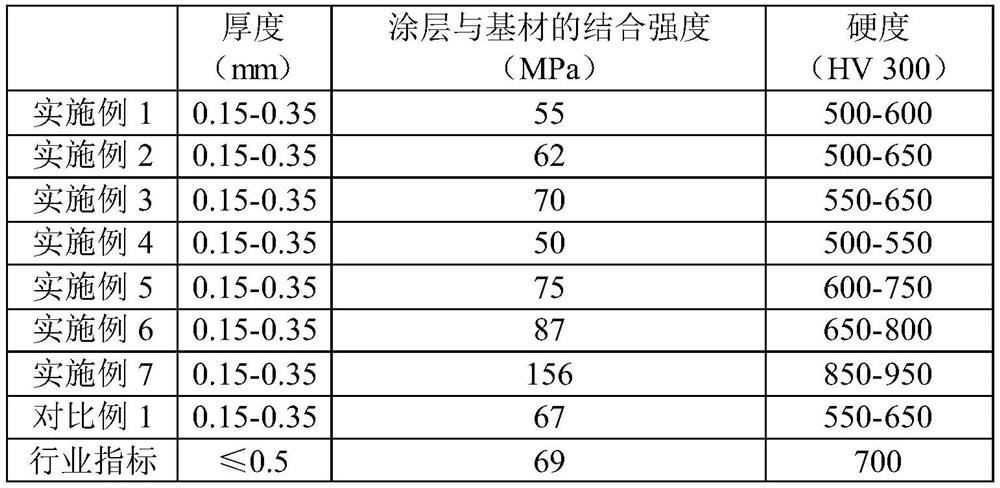

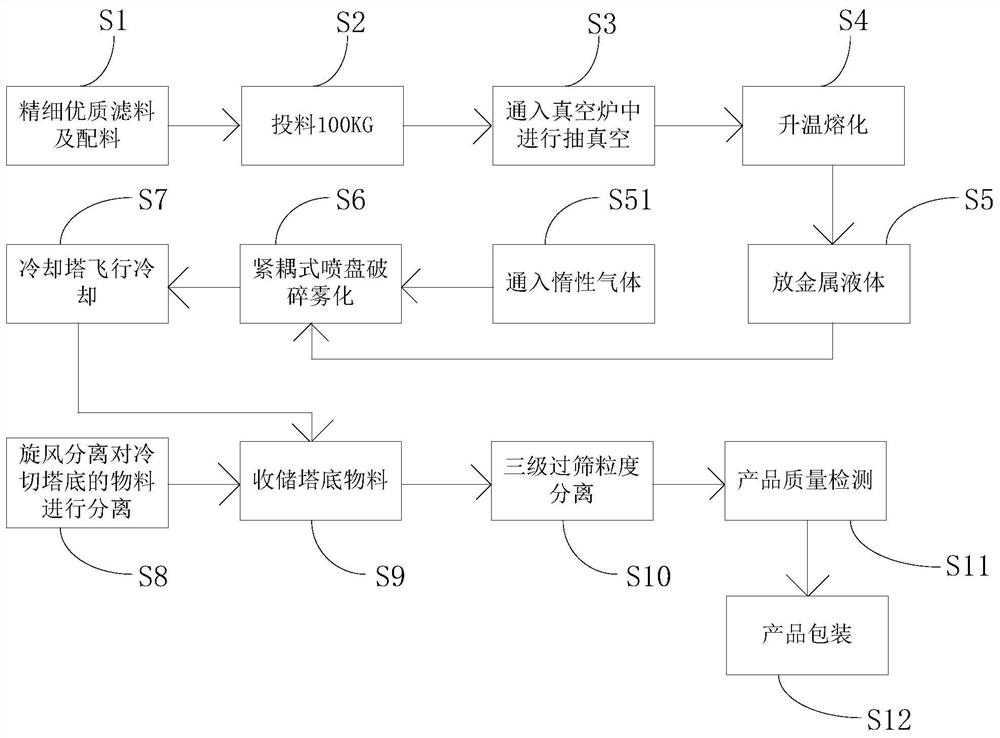

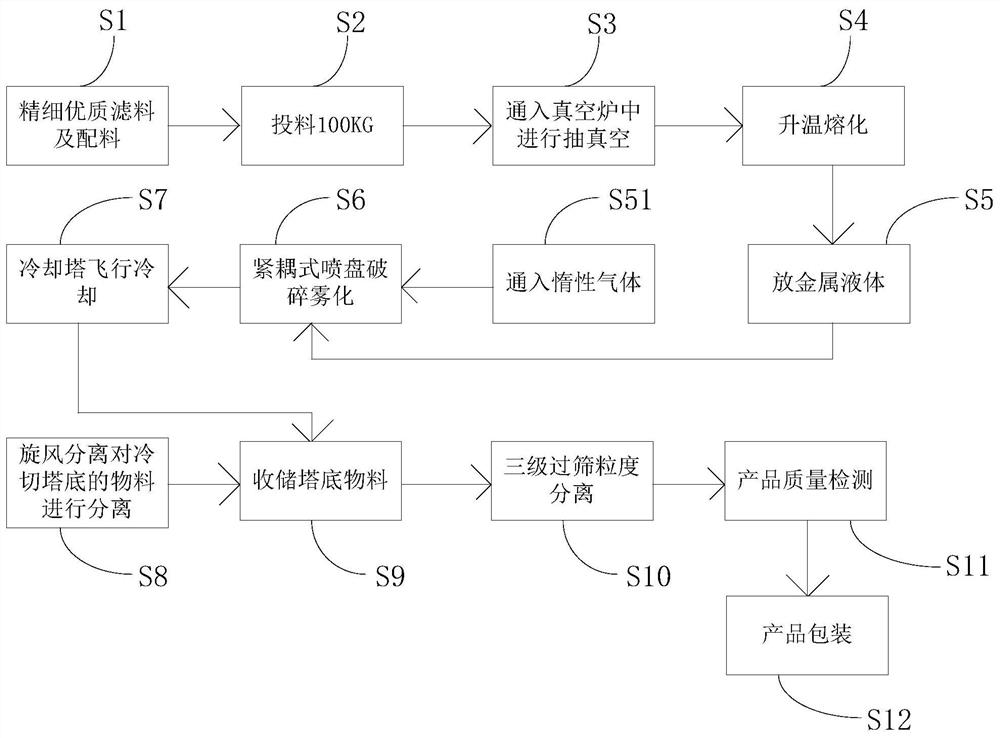

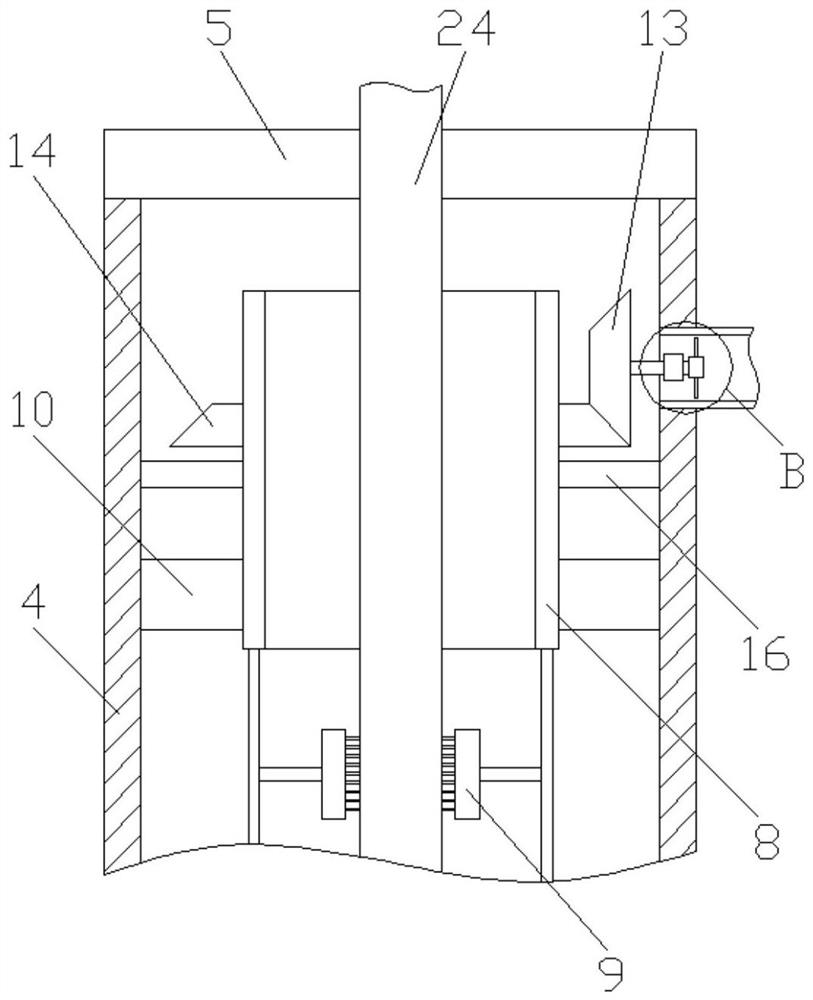

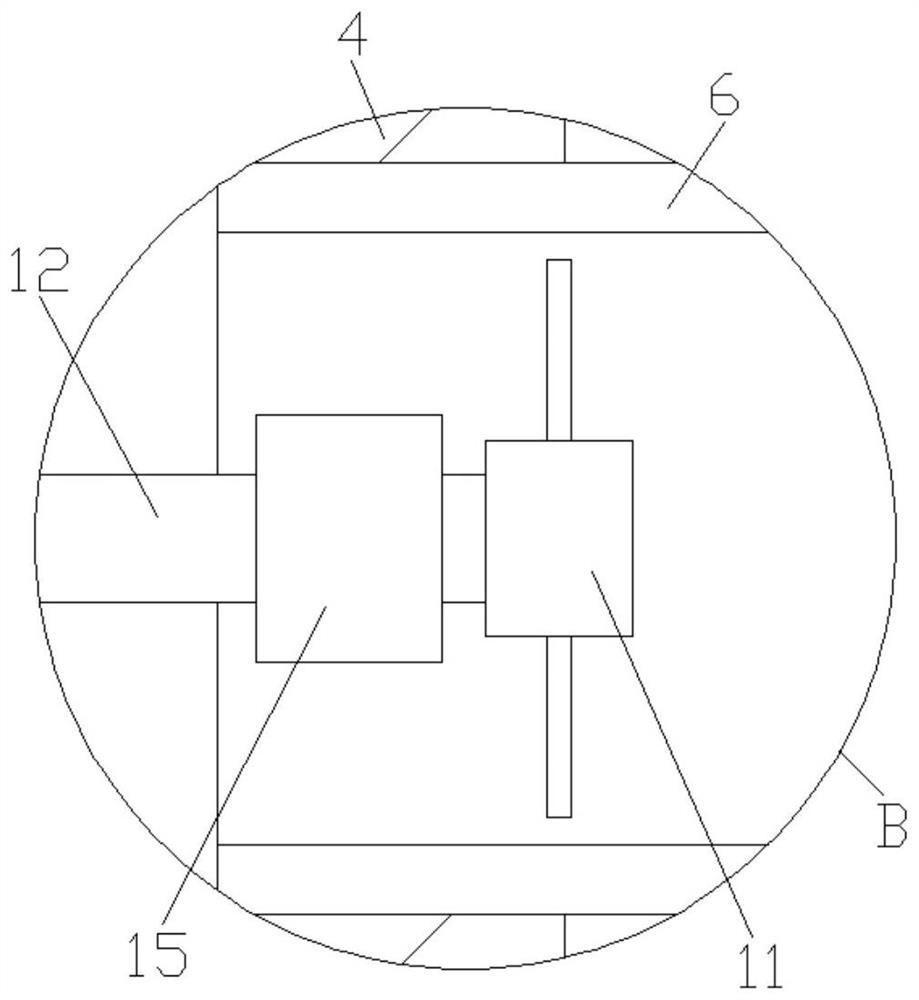

InactiveCN112809011AGood metal-ceramic bonding performanceTurbinesOther manufacturing equipments/toolsCooling towerSilicon alloy

The invention provides a preparation method for a cobalt-chromium-molybdenum-tungsten-silicon alloy. The preparation method is characterized by comprising the following steps that (1) elements of a cobalt-chromium-molybdenum-tungsten-silicon alloy formula is vacuumized in a vacuum furnace, and then heating and melting are carried out to obtain a metal liquid; (2) the metal liquid is conveyed into a tight coupling type spraying disc to be crushed and atomized, and inert gas is introduced in the atomization process, wherein the flow of the inert gas is 2000-4000 cubic meters per hour; (3) an atomized material enters a cooling tower for flying cooling; and (4) the material collected at the bottom of the cooling tower is separated by adopting a cyclone separation device. A dental product prepared from alloy powder obtained through the preparation method for the cobalt-chromium-molybdenum-tungsten-silicon alloy is good in gold-porcelain bonding performance.

Owner:广州湘龙高新材料科技股份有限公司

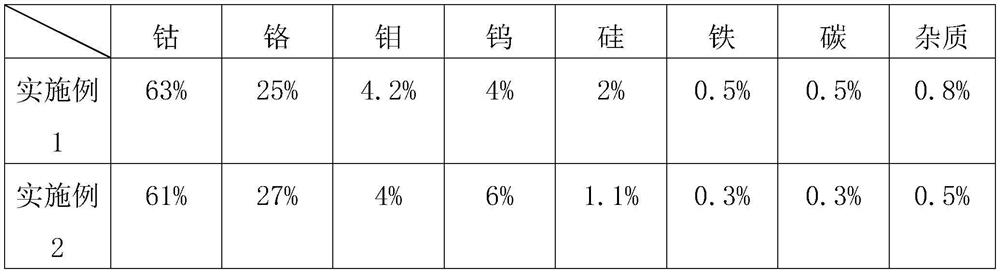

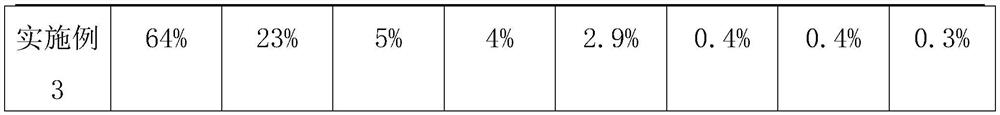

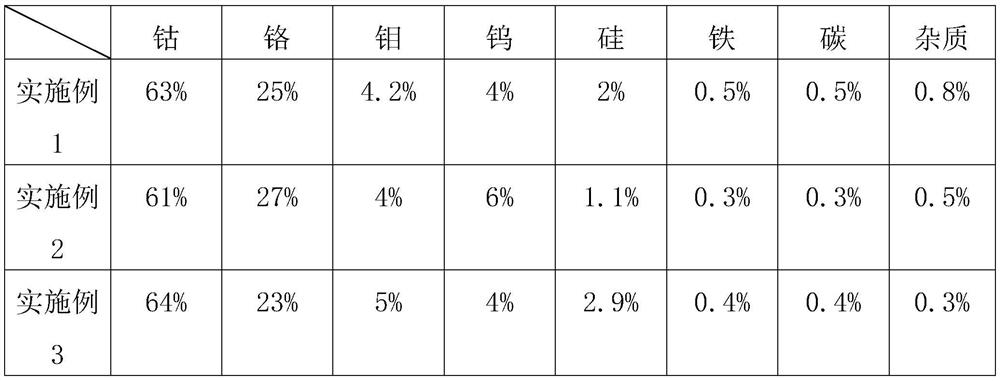

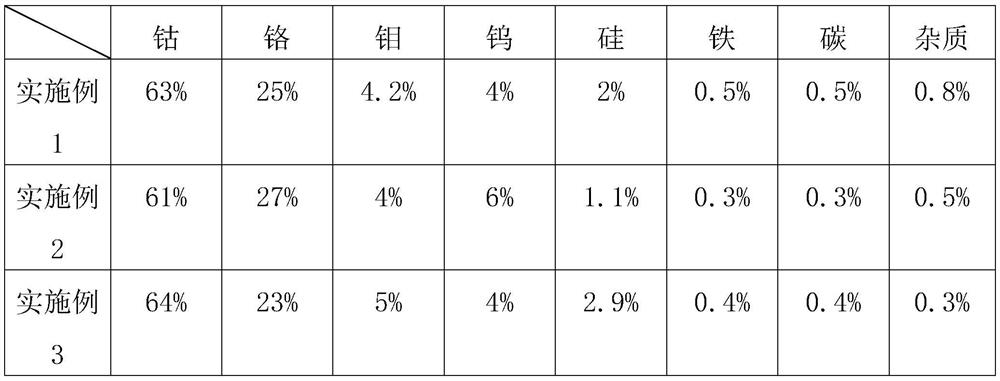

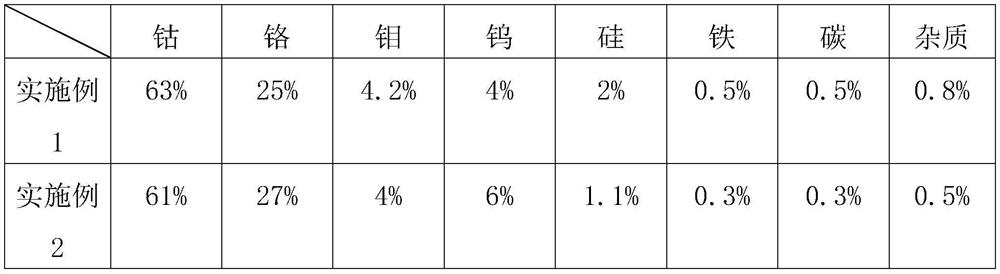

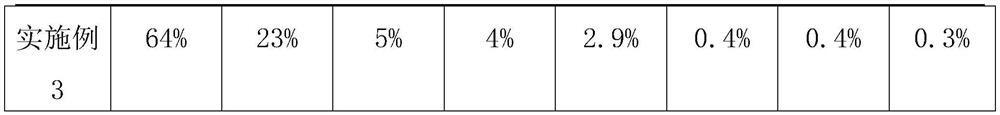

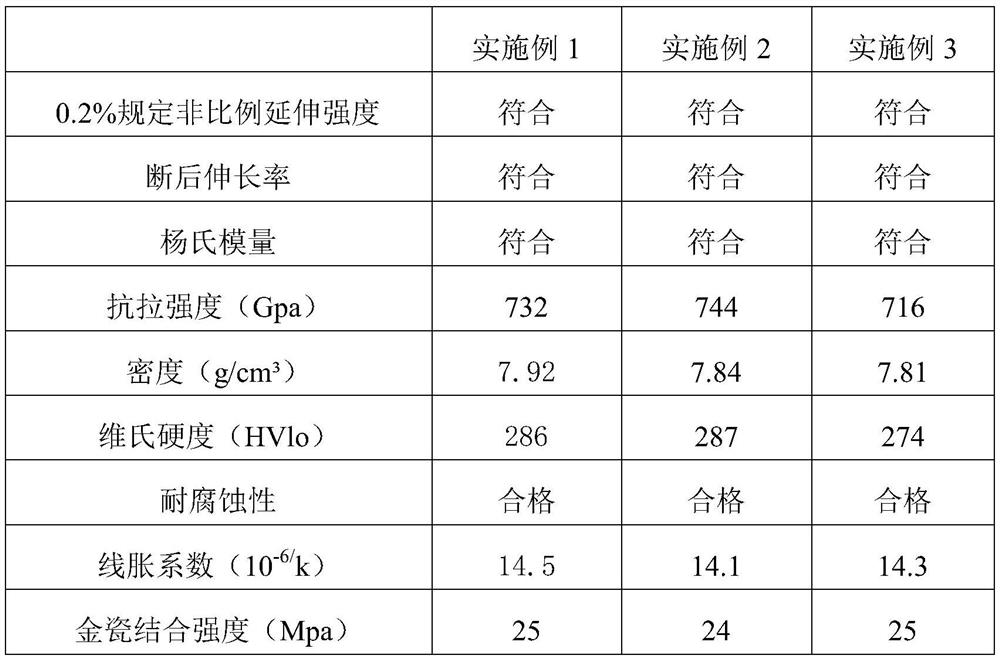

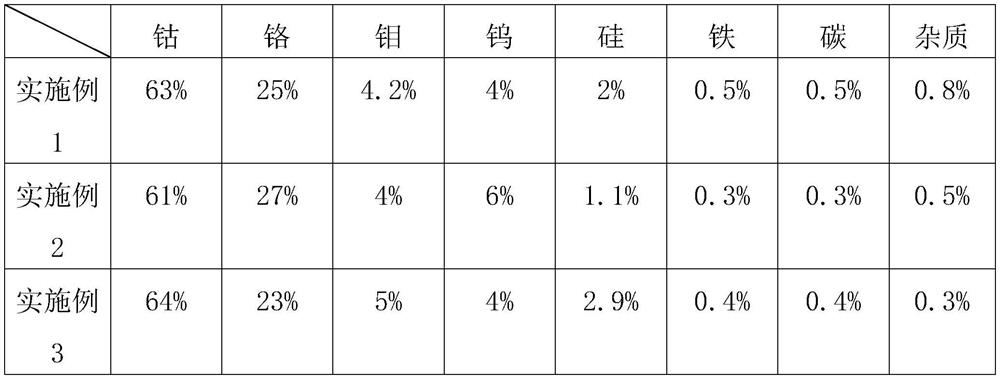

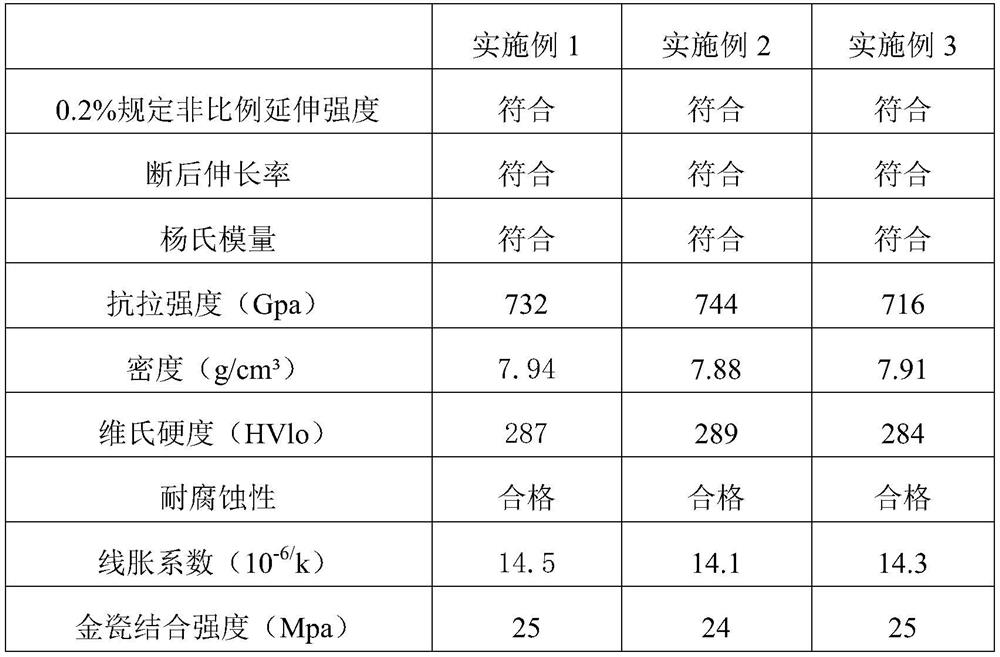

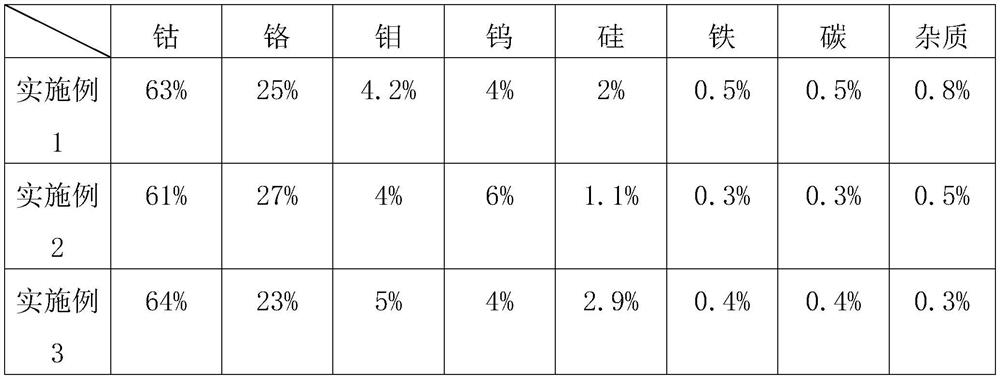

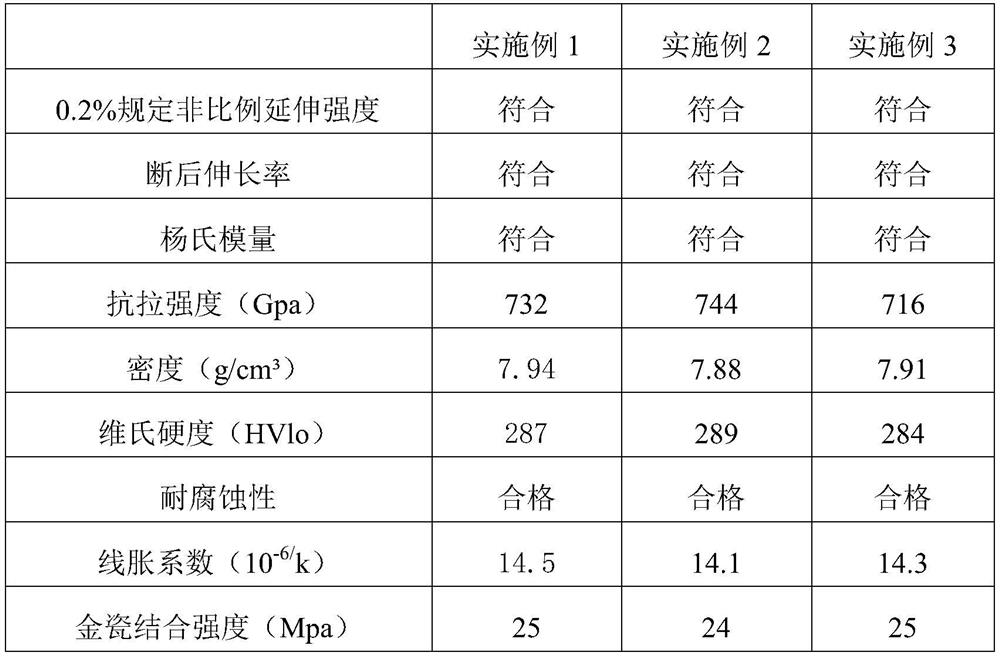

Cobalt-chromium-molybdenum-tungsten-silicon alloy powder

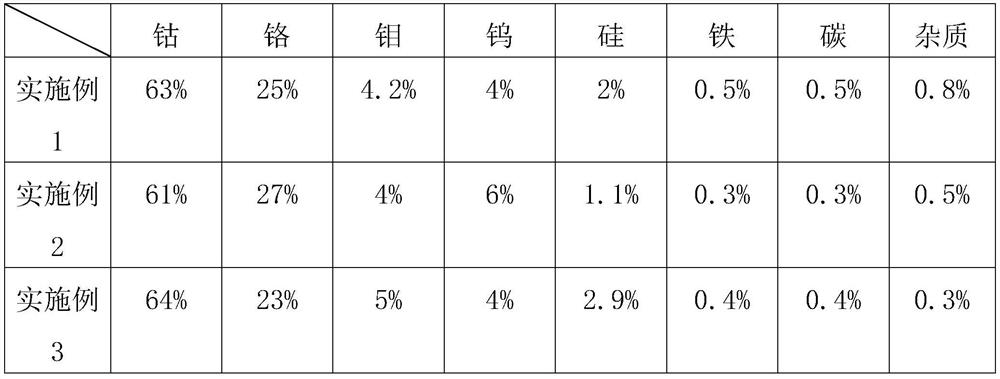

ActiveCN112795815AGood metal-ceramic bonding performanceAdditive manufacturing apparatusTransportation and packagingSilicon alloyFerrosilicon

The invention provides cobalt-chromium-molybdenum-tungsten-silicon alloy powder. The cobalt-chromium-molybdenum-tungsten-silicon alloy powder comprises the following components in percentages by weight: 60%-66% of cobalt, 20%-30% of chromium, 3%-7% of molybdenum, 3%-7% of tungsten, 0.5%-5% of silicon, less than 0.8% of iron, less than 0.8% of carbon and less than 2% of impurities, wherein the sum of the weight percentages of all the components is 100%, and the average particle size of the cobalt-chromium-molybdenum-tungsten-silicon alloy powder is 10-55 microns. The metal-porcelain bonding performance of dental products prepared from the cobalt-chromium-molybdenum-tungsten-silicon alloy powder is good.

Owner:广州湘龙高新材料科技股份有限公司

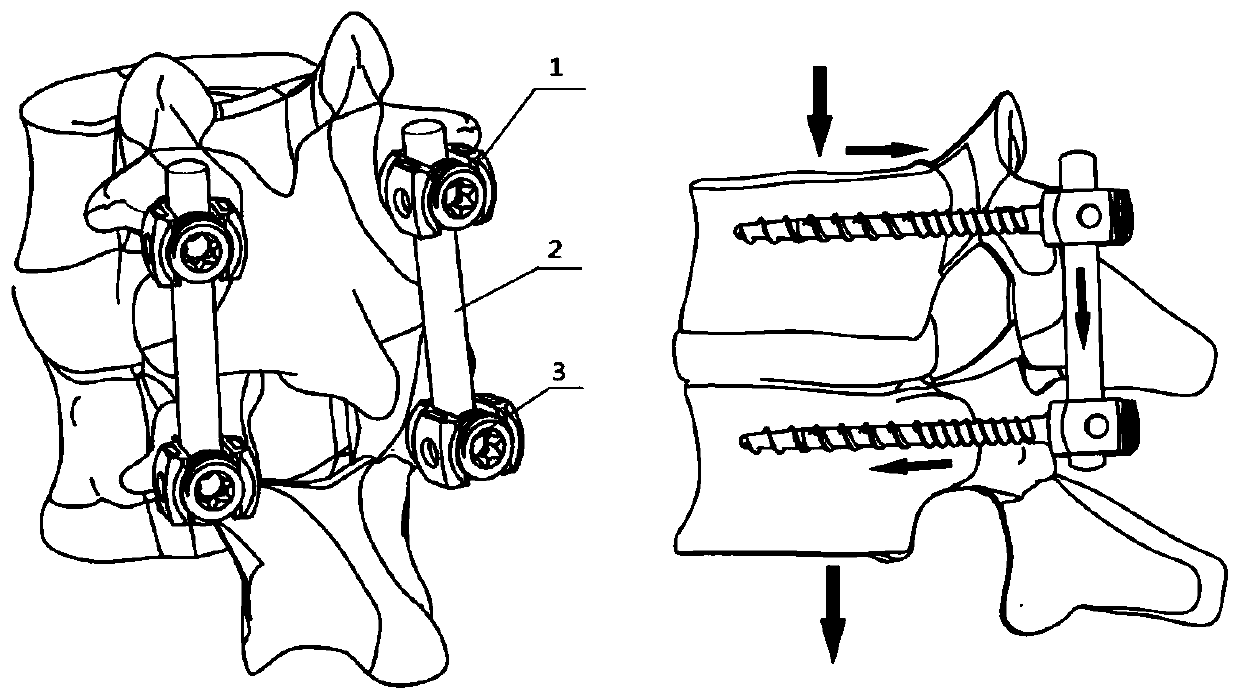

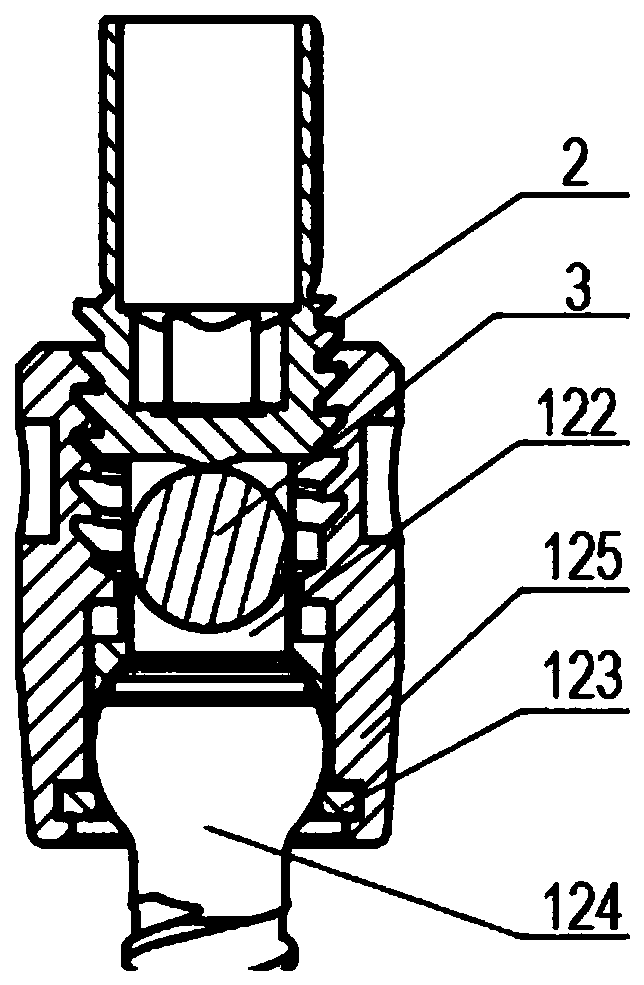

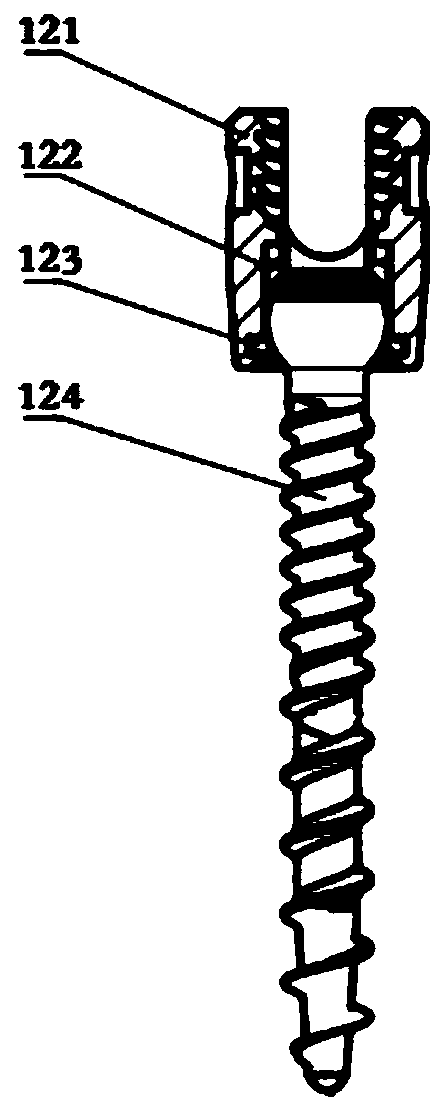

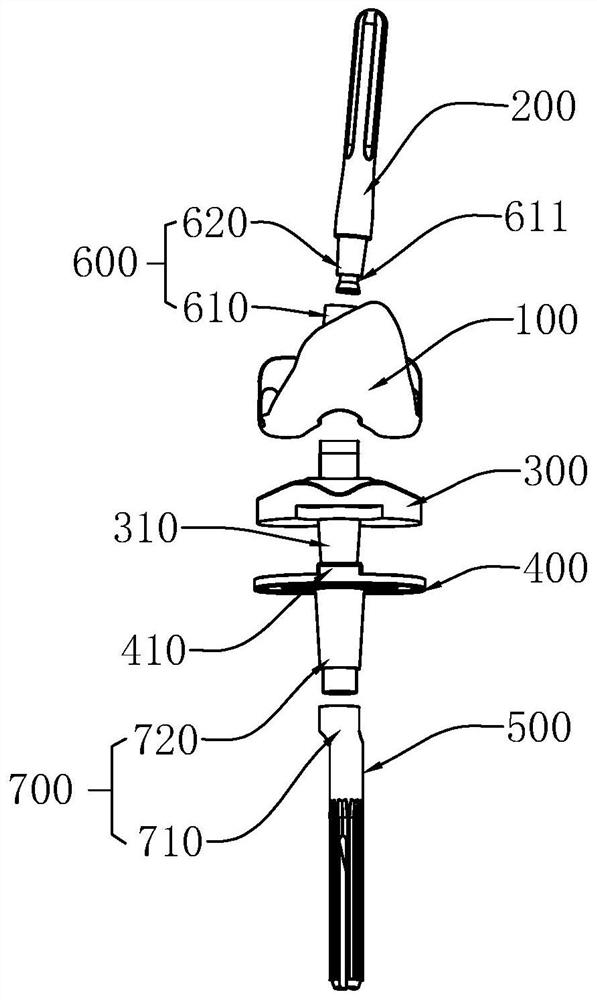

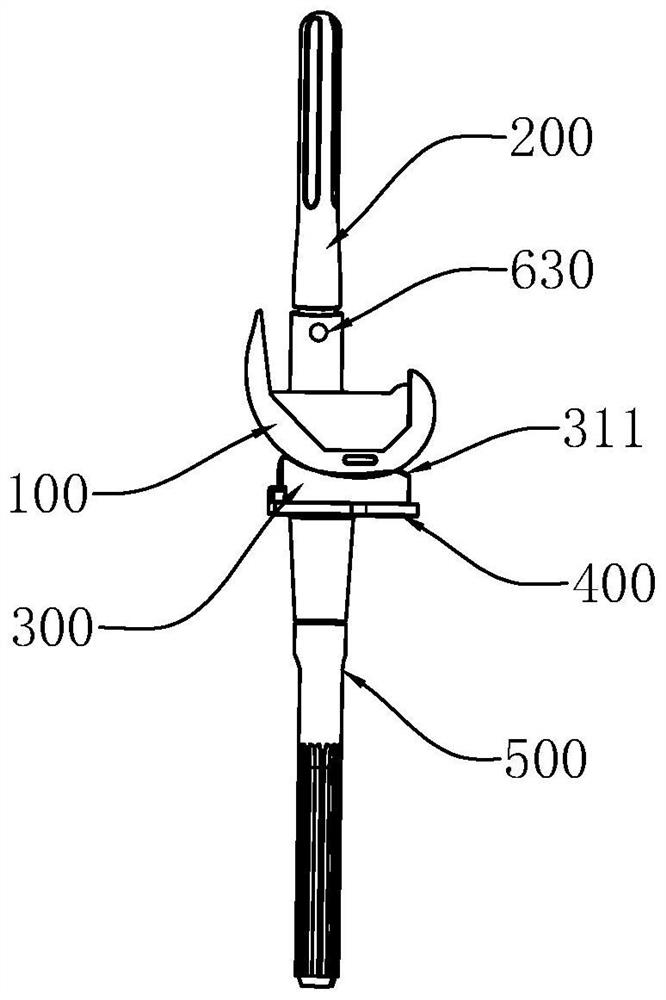

A cobalt-chromium-molybdenum thoracolumbar posterior screw-rod system

The invention discloses a cobalt-chromiun-molybdenum thoracolumbar posterior screw-rod system. The cobalt-chromiun-molybdenum thoracolumbar posterior screw-rod system comprises pedicle screws, rectangular rods and plug screws. Different parts are prepared from a cobalt-chromiun-molybdenum material, a titanium alloy material and a pure titanium material, under the condition that the stress intensity required by the system is ensured, the sizes of the parts in the system are reduced, and the harm to the human body is reduced. Meanwhile, through the design of matching structures of concrete structures, the combination of the system and the spine is more stable, and the use effect is improved.

Owner:浙江德康医疗器械有限公司

Nickel-cobalt alloy stainless steel wire and production process thereof

PendingCN114700383AImprove antioxidant capacityAchieve coolingDrawing diesCleaning using toolsHigh humidityOxidation resistant

The invention relates to a nickel-cobalt alloy stainless steel wire which comprises, by weight, 0.001%-1.25% of Fe, 1.22%-1.25% of Co, 10%-20% of Cr, 1%-5% of Mo, 4%-6% of Nb + Ta, 0.001%-3% of Al, 0.001%-2% of Ti, 0.001%-0.1% of C, 0.01%-0.03% of P, 0.001%-0.01% of Mg, 0.001%-0.02% of B, 0.001%-0.1% of Zr, 3%-8% of Si and the balance Ni. According to the nickel-cobalt alloy stainless steel wire and a production process thereof, the oxidation resistance of the nickel-cobalt alloy stainless steel wire in severe environments such as high humidity and high temperature is improved, and the service life of the nickel-cobalt alloy stainless steel wire is prolonged. Through the drawing cooling device, cooling of the nickel-cobalt alloy stainless steel wire after drawing is completed is achieved, the situation that the nickel-cobalt alloy stainless steel wire is shrunk and broken or scratched in the rolling process is prevented, and meanwhile the functions of cleaning and lubricating the nickel-cobalt alloy stainless steel wire are achieved.

Owner:江阴泰坦高压电气有限公司

Preparation method for cobalt-chromium-molybdenum-tungsten-silicon alloy bar

ActiveCN112809006AGood metal-ceramic bonding performanceTurbinesOther manufacturing equipments/toolsCompression moldingSilicon alloy

The invention provides a preparation method for a cobalt-chromium-molybdenum-tungsten-silicon alloy bar. The preparation method comprises the following steps that (1) cobalt-chromium-molybdenum-tungsten-silicon alloy powder is prepared; (2) cold mold compression molding is carried out on the powder obtained in the step (1); and (3) vacuum sintering is carried out, and then the alloy bar is obtained. A dental product prepared from an alloy material obtained through the preparation method for the cobalt-chromium-molybdenum-tungsten-silicon alloy bar is good in gold-porcelain bonding performance.

Owner:广州湘龙高新材料科技股份有限公司

A kind of preparation method of cobalt-chromium-molybdenum-tungsten-silicon alloy rod

ActiveCN112809006BGood metal-ceramic bonding performanceTurbinesOther manufacturing equipments/toolsMetallurgySilicon alloy

The invention provides a method for preparing a cobalt-chromium-molybdenum-tungsten-silicon alloy bar, comprising the following steps: (1) preparing cobalt-chromium-molybdenum-tungsten-silicon alloy powder; (2) cold-molding the powder obtained in step (1) forming; (3) and then vacuum sintering to obtain alloy rods. The alloy material prepared by the preparation method of the cobalt-chromium-molybdenum-tungsten-silicon alloy rod provided by the invention has better metal-ceramic bonding performance in dental products.

Owner:广州湘龙高新材料科技股份有限公司

Method for measuring content of boron in cobalt-base alloy

ActiveCN101718688BAvoid interferenceImprove accuracyPreparing sample for investigationColor/spectral properties measurementsElemental analysisMaterials science

The present invention belongs to a technique for analyzing trace elements of an alloy, and relates to a method for measuring the content of boron in a cobalt-base alloy. By adopting an inductively coupled plasma emission spectrometer and treating a sample of the cobalt-base alloy in particular a high-tungsten sample by using 20mL of hydrochloric acid, nitric acid and hydrofluoric acid, the method solves the puzzling problems that the past dissolved sample has large reagent dosage and high reagent blank and cannot be measured normally by an instrument; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the method has wide measuring ranges, the measuring lower limit is 0.002 percent, and the measuring upper limit is 0.20 percent and is 101 times of the measuring lower limit; and the method provided by the present invention can perform measurement quickly, is simple and convenient to operate, and saves a large quantity of manpower and material resources.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A kind of cobalt chromium molybdenum tungsten silicon alloy powder

ActiveCN112795815BGood metal-ceramic bonding performanceAdditive manufacturing apparatusTransportation and packagingSilicon alloyFerrosilicon

The invention provides a cobalt-chromium-molybdenum-tungsten-silicon alloy powder, which comprises 60%-66% cobalt; 20%-30% chromium; 3%-7% molybdenum; 3%-7% tungsten; 0.5% silicon ‑5%; iron<0.8%; carbon<0.8%, impurity<2%, wherein, the sum of the weight percentages of the above-mentioned components is 100%, and the average particle size of the cobalt-chromium-molybdenum-tungsten-silicon alloy powder is 10‑55 Microns. Dental products prepared from the cobalt-chromium-molybdenum-tungsten-silicon alloy powder provided by the invention have better metal-ceramic bonding performance.

Owner:广州湘龙高新材料科技股份有限公司

A kind of forming method of cobalt-chromium-molybdenum superalloy bar

The invention relates to a forming method for a cobalt-chromium-molybdenum superalloy bar. Metal cobalt, metal chromium and metal molybdenum are adopted as raw materials, and the cobalt-chromium-molybdenum superalloy bar is finally prepared and obtained sequentially through vacuum smelting, electroslag remelting, homogenization treatment, finish forge cogging and rolling forming. The preparing method is simple, steps are easy to operate, cast ingot alloy components can be more uniform through the homogenization treatment in the preparing technology, during cogging, a finish forging device is used for cogging, the stress of the cast ingot alloy in the circumferential direction is uniform and consistent, deformation is uniform, and cracking of the alloy due to uneven stress or temperature difference is avoided; rolling is conducted after the blank surface is treated, the rolling time is short, the machining deformation rate is large, and efficiency is high; and meanwhile, the bar machined through the method is high in size precision and high in yield, grain is fine and uniform, and the mechanical performance is excellent.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

A method for antibacterial modification of the surface of an implant material

The invention discloses an antibacterial modification method for a surface of an implant material. According to the invention, solid zinc oxide is taken as a raw material, the solid zinc oxide is modified on the surface of a metal implant material (titanium, tantalum, cobalt, chromium and molybdenum) and a high-molecular implant material (silica gel, polyurethane, polyether-ether-ketone and polylactic acid) by taking a cardiac pacemaker as a representative through simple steps. The method has the following obvious advantages that 1) a two-step system is firstly provided for preparing a solid zinc oxide coating which is different with a traditional single-layer material surface coating, the solid zinc oxide coating has excellent permanent antibacterial property, and realizes the long-actingantibiosis; and 2) the preparation method is simple, and can be widely used for clinical application.

Owner:NANCHANG UNIV

A kind of cobalt-chromium-molybdenum-tungsten-silicon alloy rod and preparation method thereof

The invention provides a cobalt-chromium-molybdenum-tungsten-silicon alloy bar, which comprises 60%-66% of cobalt; 20%-30% of chromium; 3%-7% of molybdenum; 3%-7% of tungsten; %-5%; iron<0.8%; carbon<0.8%, impurity<2%, wherein, the sum of the weight percentages of the above components is 100%, and the appearance of the alloy rod is cylindrical. Dental products prepared from the cobalt-chromium-molybdenum-tungsten-silicon alloy bar provided by the invention have better metal-ceramic bonding performance.

Owner:广州湘龙高新材料科技股份有限公司

A dental cobalt-chromium-molybdenum-copper antibacterial ceramic alloy and heat treatment method thereof

ActiveCN103215474BImprove corrosion resistanceHigh hardnessImpression capsDentistry preparationsRare-earth elementMedical equipment

The purpose of the invention is to provide a dental cobalt-chromium-molybdenum-copper antibacterial baked porcelain alloy which is mainly used for crowns, bridges and the like of baked porcelain teeth. The dental cobalt-chromium-molybdenum-copper antibacterial baked porcelain alloy comprises the following specific chemical components (wt%): less than or equal to 0.08% of C, 16-26% of Cr, 4-10% of Mo, 0.5-2% of W, 0.1-0.5% of Re, less than or equal to 0.1% of Ni, 1-6% of Cu and the balance of Co, wherein RE is a rare earth element. The cobalt-based baked porcelain alloy provided by the invention is added with appropriate copper element and rich copper precipitated phase is evenly dispersed and distributed through special heat treatment so that the alloy is enabled to have broad-spectrum antibacterialfunction. The alloy provided by the invention contains no toxic element and has excellent resistance to oxidation and corrosion, and can be well matched with the existing porcelain powder in use. In addition to being used as the baked porcelain alloy, the dental cobalt-chromium-molybdenum-copper antibacterial baked porcelain alloy also can be used in the fields of implants for surgery, medical equipment, food catering equipment, jewelry and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

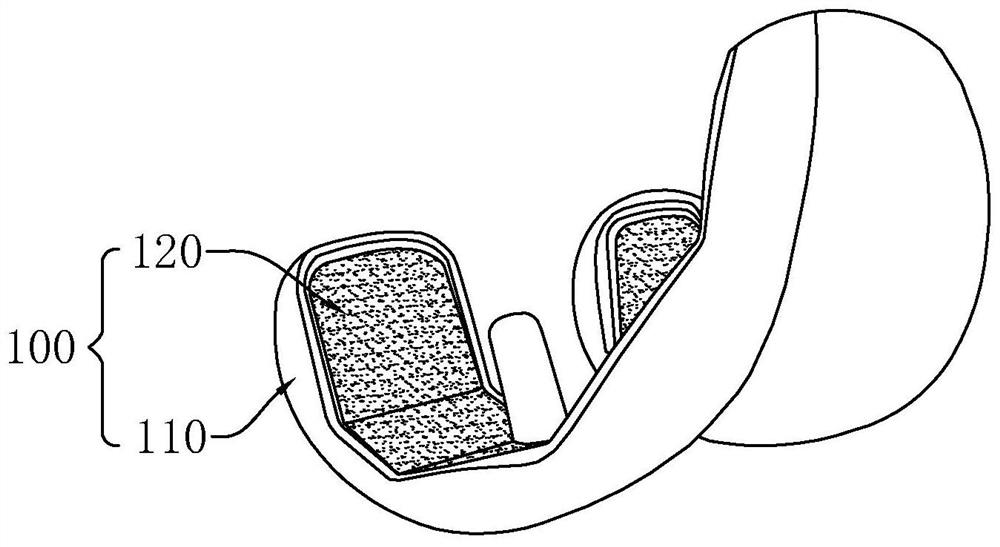

Tantalum metal bone trabecula femoral condyle prosthesis and knee joint replacement body

The invention relates to a tantalum metal bone trabecula femoral condyle prosthesis and a knee joint replacement body. The femoral condyle prosthesis comprises a cobalt-chromium-molybdenum substrate and a porous tantalum metal bone trabecula inner shell welded into the cobalt-chromium-molybdenum substrate, the knee joint prosthesis comprises the femoral condyle prosthesis and further comprises a femoral marrow needle, a tibial plateau pad, a tibial plateau support and a tibial marrow needle, the femoral marrow needle and the femoral condyle prosthesis are connected through a first taper locking mechanism, the tibial marrow needle and the tibial plateau support are connected through a second taper locking mechanism, the upper end face of the tibial plateau support and the lower end face of the tibial plateau pad are both planes, and a rotary limiting hole is formed in the upper end face of the tibial plateau support; and the lower end face of the tibial plateau pad is provided with a rotary limiting column corresponding to the rotary limiting hole, and the rotary limiting column is arranged in the rotary limiting hole. The femoral condyle prosthesis has the beneficial effects that a wide bone ingrowth space can be provided, stress shielding can be reduced, chemical erosion can be resisted, and the risk of prosthesis loosening and dislocation can be effectively reduced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Marking system of cobalt-chromium-molybdenum thoracolumbar posterior approach screw-rod system

InactiveCN106971209AEnsure safetyEasy to useKey distribution for secure communicationUser identity/authority verificationPosterior approachComputer science

The present invention relates to a marking system for a cobalt-chromium-molybdenum thoracolumbar posterior approach screw-rod system. The marking system is applied to the cobalt-chromium-molybdenum thoracolumbar posterior approach screw-rod system so as to trace the information of implantable objects in the cobalt-chromium-molybdenum thoracolumbar posterior approach screw-rod system at any time; each implantable object is configured with a marking plate which records the production information of the implantable objects; and the marking system comprises the marking plates, a reading and writing control device, a state storage device and a system use memory. The external marking system applied to the cobalt-chromium-molybdenum thoracolumbar posterior approach screw-rod system is used for tracing implants; the corresponding marking plates are configured for each implant product; and the marking plates and the products are integrated. The marking system is convenient to use and makes the tracing of the products more convenient; and the reading and writing control device matched with the marking plates is utilized to perform scanning so as to obtain all required related information of the product, and the safety of communication in this process is ensured.

Owner:浙江德康医疗器械有限公司

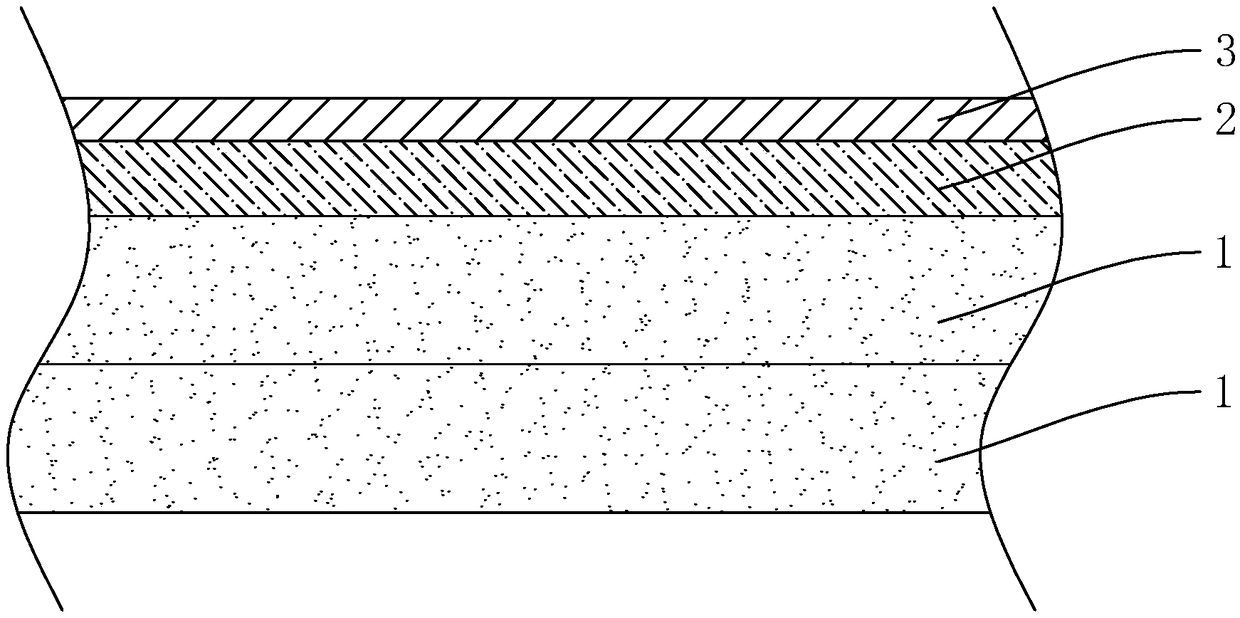

A kind of reinforced seamless steel pipe piercing plug and its preparation method

ActiveCN110205561BAvoid crackingHigh bonding strengthMandrelsMetallic material coating processesNiobiumNichrome

The invention discloses a reinforced seamless steel pipe perforated plug, comprising a plug base, a transition layer and a strengthening layer are sequentially arranged on the outer surface of the plug base from the inside to the outside, and the transition layer includes the following components in parts by weight: iron : 61.0-79.0%; Co: 5.0-10.0%; Chromium: 10.0-15.0%; Mo: 5.0-10.0%; Nickel: 1.0-4.0%; The additive with a fraction of 4% is composed of two parts, and the main material includes the following components by weight: cobalt: 20.0-30.0%; nickel: 20.0-30.0%; chromium: 15.0-20.0%; niobium: 5.0-5.5% ; silicon: 1.0-2.5%; tungsten: 1.0-2.0%; carbon: 1.0-1.8%; boron: 3.5-5.0%; rare earth: 0.5-0.9%; iron: 2.3-30.7%, the present invention has good strength and In addition to the hardness, it also has high temperature resistance, which can also reduce the friction between the plug and the steel pipe, and improve the quality of the inner wall of the steel pipe, thereby reducing the workload of the subsequent processing of the steel pipe, which is also conducive to reducing the sticking of steel on the surface of the plug, and also reduces the workmanship. workload.

Owner:芜湖点金机电科技有限公司

Cobalt-chromium-molybdenum-tungsten-silicon alloy bar

Owner:广州湘龙高新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com