Preparation method for cobalt-chromium-molybdenum-tungsten-silicon alloy

A cobalt-chromium-molybdenum and tungsten-silicon technology, which is applied in the preparation of cobalt-chromium-molybdenum-tungsten-silicon alloys, can solve the problems of poor performance of 3D printing parts, lack of standardization and series of cobalt-chromium-molybdenum alloy powder particle size distribution, loose density, and fluidity. Standardization, affecting the promotion and application of dental medical field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

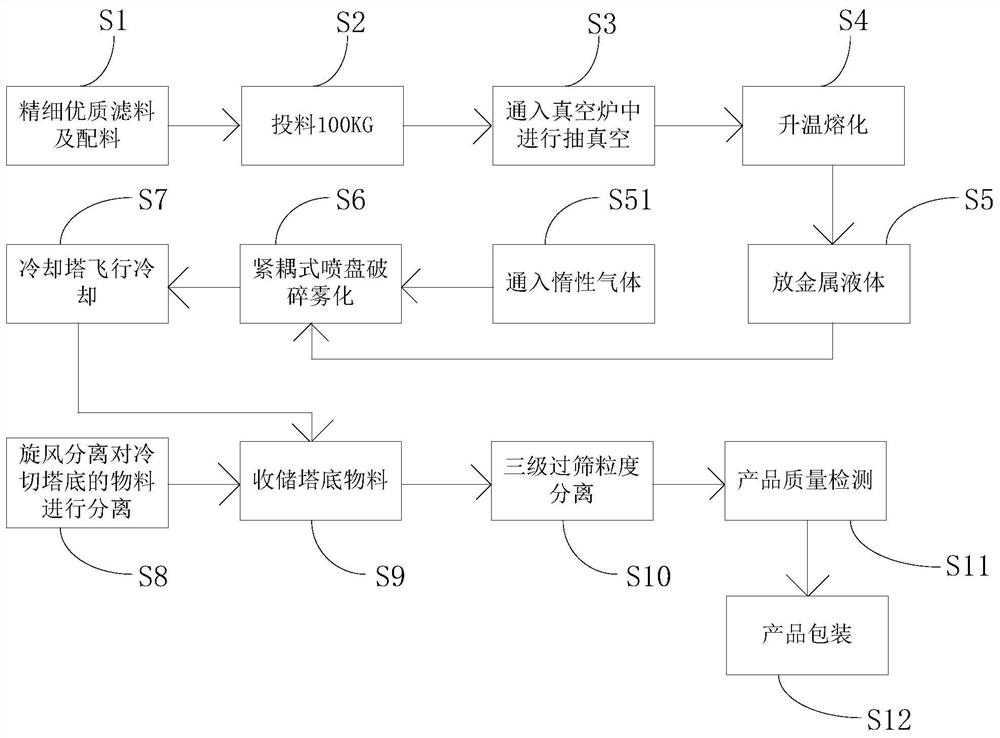

[0026] refer to figure 1 , the embodiment of the present invention provides a method for preparing a cobalt-chromium-molybdenum-tungsten-silicon alloy, comprising the following steps:

[0027] (1) vacuumize the elements of the cobalt-chromium-molybdenum-tungsten-silicon alloy formula in a vacuum furnace, then heat up and melt to obtain a metal liquid;

[0028] (2) Transport the metal liquid into the tight-coupled spray plate for crushing and atomization, and feed inert gas during the atomization process, and the flow rate of the inert gas is 2000-4000 cubic meters per hour;

[0029] (3) The material obtained after atomization enters the cooling tower for flight cooling;

[0030] (4) The cyclone separation device is used to separate the materials collected at the bottom of the cooling tower.

[0031] In this embodiment, the effect of vacuum hypoxia is achieved through the step of vacuuming in a vacuum furnace. In a further preferred embodiment, the vacuuming is divided into ...

Embodiment 1-3

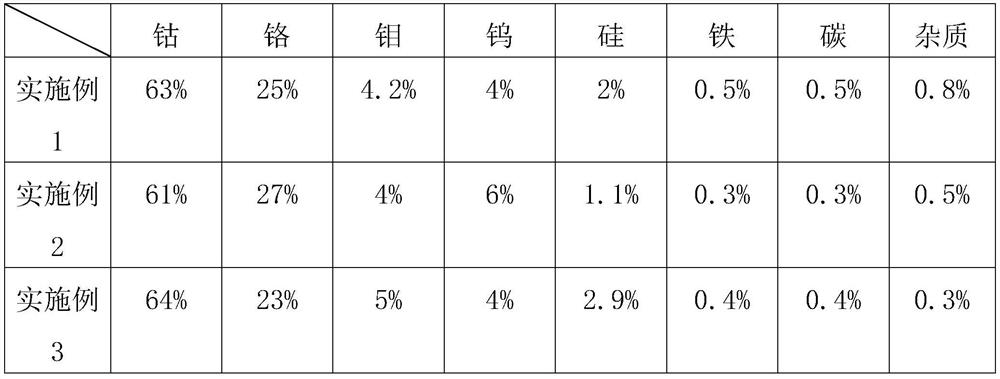

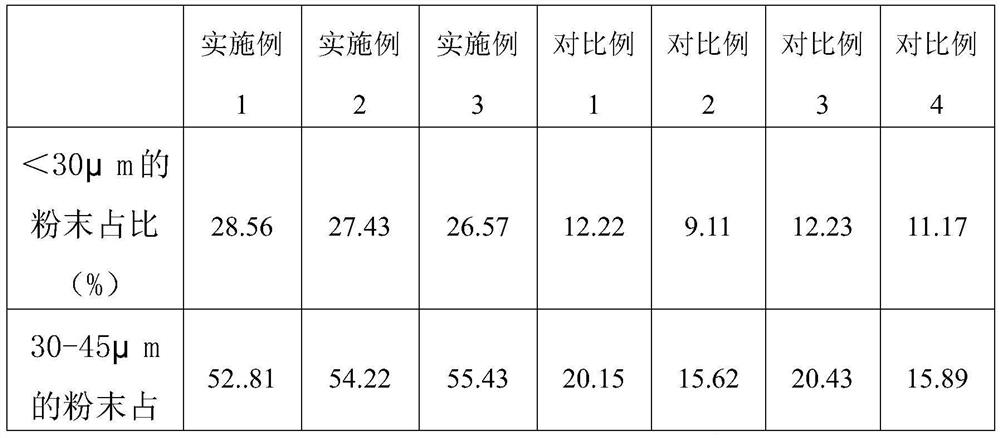

[0079] Dosing according to the formula in Table 1, feed 1000kg into the vacuum furnace, vacuumize with a pressure of 10Pa, and heat up and melt the vacuumized material in the melting furnace at a temperature of 1680°C to 1700°C to obtain a metal liquid. The metal liquid is passed into the close-coupled atomization spray plate device for crushing and atomization, and at the same time, an ultra-high-speed inert gas (nitrogen) is introduced into the close-coupled atomization spray plate. The flow rate of the ultra-high-speed inert gas is per 3000 cubic meters per hour. The atomized material is passed into the cooling tower for flight cooling. The tower diameter of the cooling tower is 1800mm and the tower height is 9000mm. A cyclone separation device is used to separate the materials collected at the bottom of the cooling tower to collect particles with smaller particle sizes, and then perform three-stage sieving particle size separation to obtain cobalt-chromium-molybdenum-tungs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com