Dental opaque baked porcelain powder and particle size distribution method

A ceramic powder, particle size technology, applied in dentistry, dental prosthesis, pharmaceutical formulations, etc., can solve the problems of unfavorable body porcelain pushing and filling operation, difficult body porcelain material stacking and shaping, weakening of mechanical fitting effect, etc. The effect of overcoming unreliable factors, saving inspection costs and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: see Figure 1-4 ;

[0038] The present embodiment provides a particle size grading method for dental opaque porcelain powder;

[0039](1) Preparation of opaque porcelain powder

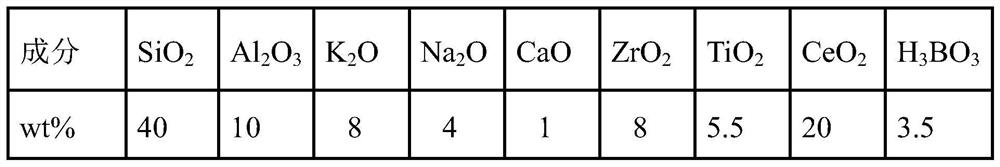

[0040] chemical composition (see figure 1 ):

[0041] Preparation process:

[0042] According to the chemical composition of the frit, the ingredients are weighed and mixed. The uniformly mixed raw materials are added to the high-temperature muffle furnace for melting. The molten material is directly quenched by water and then fully dried, then ball milled and sieved, and heat treated and cooled again to obtain a block. Opaque Porcelain Powder.

[0043] (2) Crushing ball milling of opaque porcelain powder

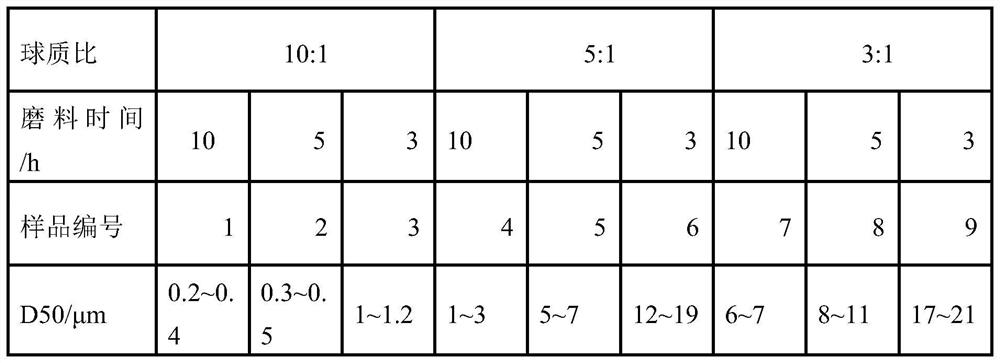

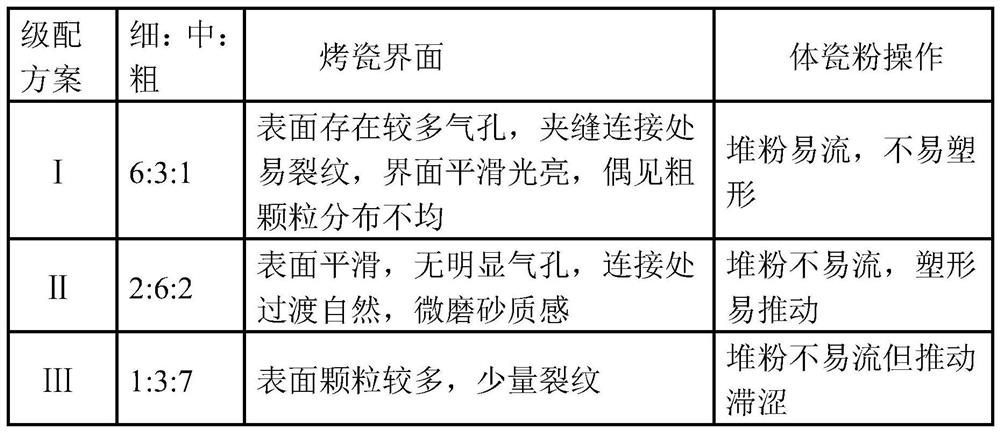

[0044] After the massive ceramic powder prepared in 1.1 is rapidly crushed, the grinding balls and materials are filled into the ball mill according to the spheroid ratio of 10:1, 5:1 and 3:1, respectively, and the three spheroid ratios are set separately Three kinds of abr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com