Method of determining range of exposure dose in mask aligner image quality detection technology

A technology of exposure dose and lithography machine, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, electrical components, etc., which can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to better understand the present invention, a specific embodiment is now given in conjunction with the accompanying drawings.

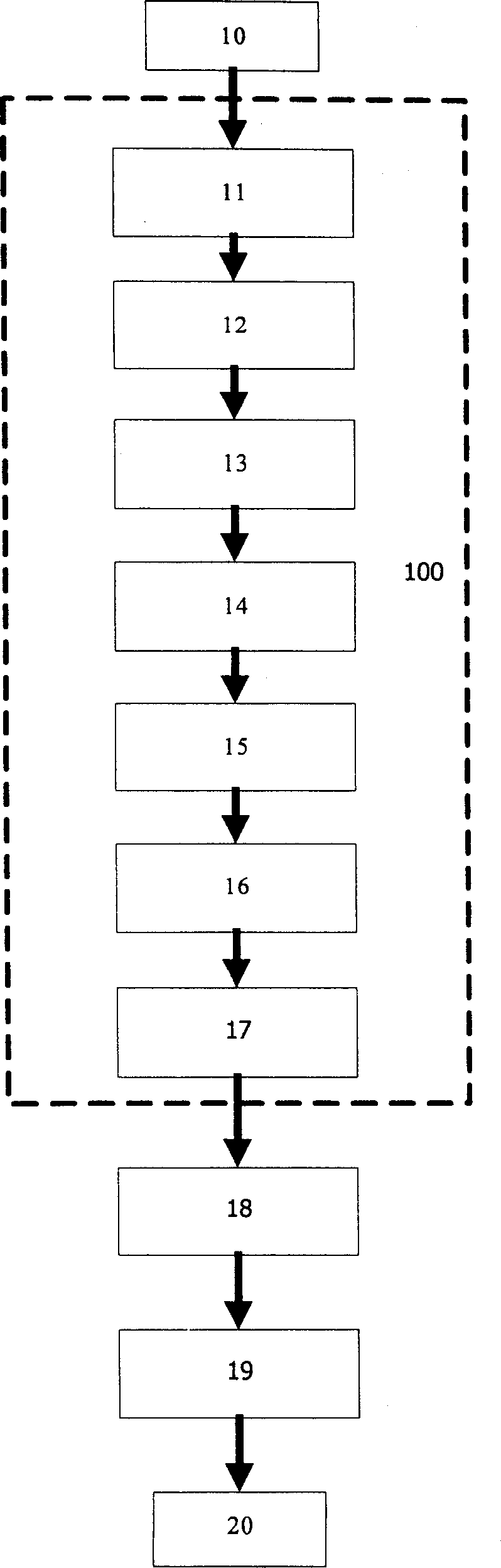

[0059] figure 2 This is the basic step of the method for determining the FOCAL exposure dose range proposed by the present invention.

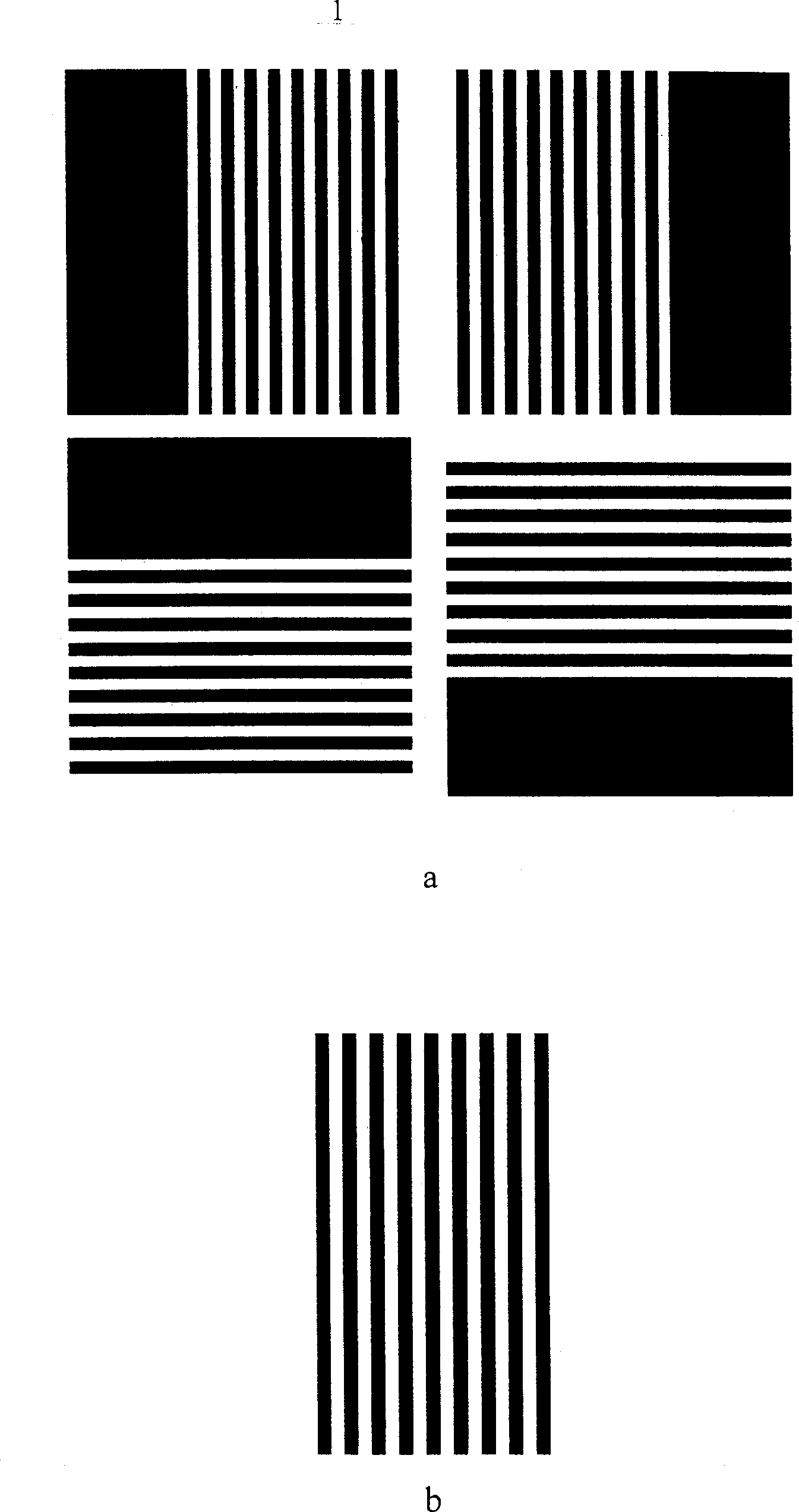

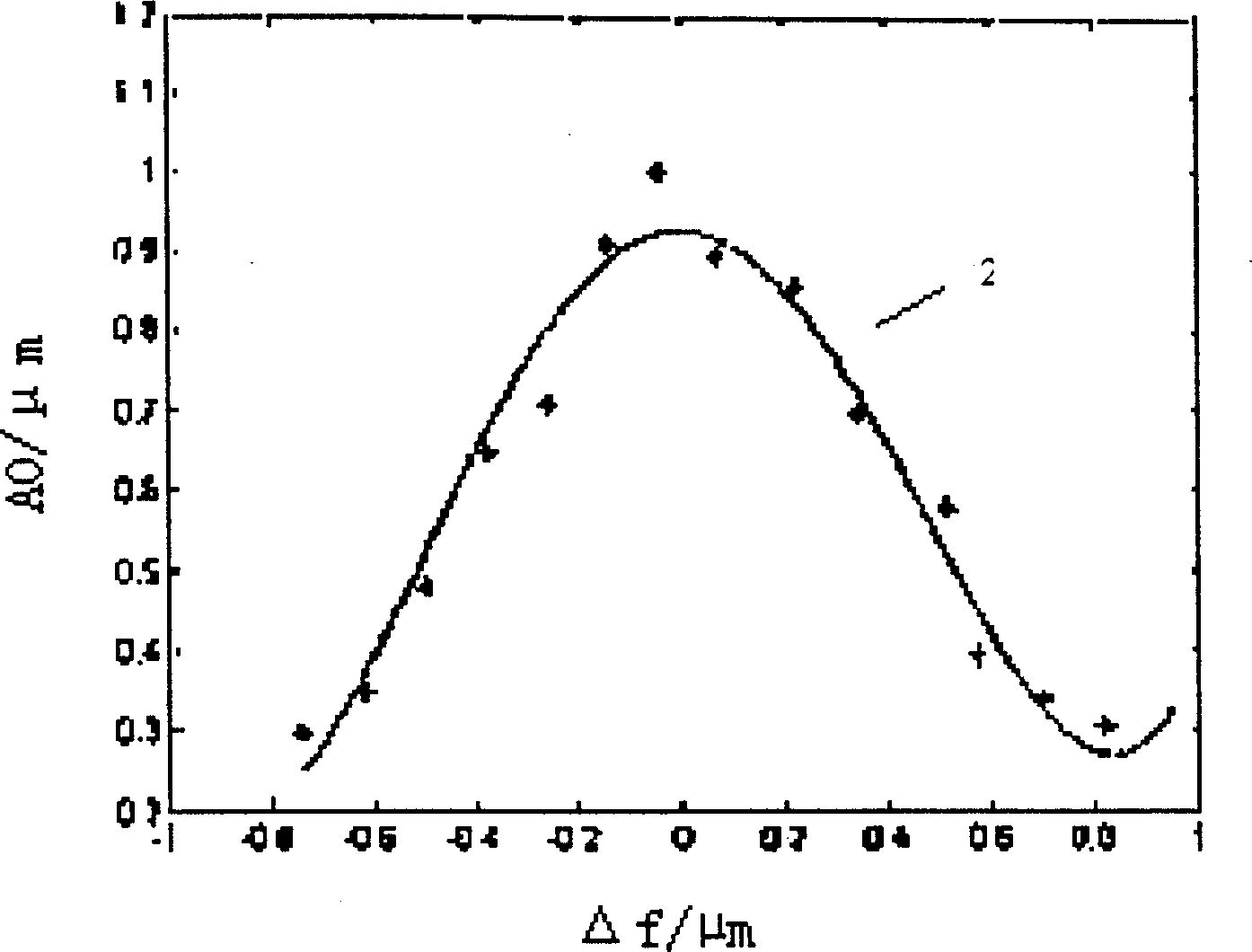

[0060] The lighting conditions of the FOCAL test in this embodiment are: traditional lighting, NA is 0.57, partial coherence factor is 0.7; process conditions are: JSR AR165J photoresist, glue thickness is 1000nm, post-bake temperature is 115°, post-bake time is 60s , Development time is 60s; the above are the parameters required for stage 11. The pattern of the simulated mask is a dense line with a duty ratio of 1:1, and the line width is 250 nm, which is a parameter required for stage 12. According to the relevant parameters of the FOCAL test process, the defocus range of the simulation process is -900nm~900nm, and the defocus step is 120nm, which is the parameter required for stage 13. The minimum dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com