Surface ion nitriding method for medical CoCrMo alloy

A technology of ion nitriding and alloying, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of inability to wear and prevent harmful ion release, limited thickness of nitrogen ion implantation, and poor penetration Difficult to meet the requirements and other problems, to achieve the effects of reducing the release of toxic ions, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

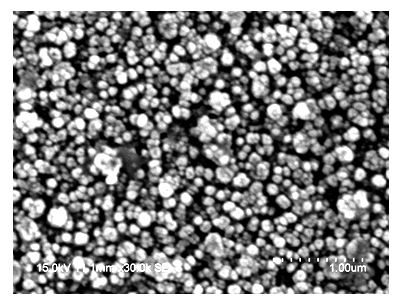

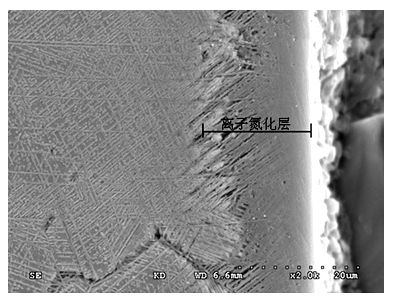

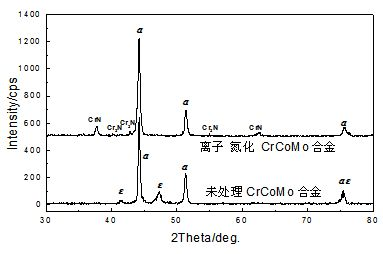

[0022] Embodiment one, with 180 # , 400 # , 800 # , 1200 # The surface of the medical CoCrMo (cobalt chromium molybdenum) alloy is polished in turn with water sandpaper, and then the surface roughness of the CoCrMo (cobalt chromium molybdenum) alloy is reduced to below 15nm by mechanical polishing. After polishing, the CoCrMo (cobalt chromium molybdenum) alloy is ultrasonically cleaned with alcohol solvent Alloy, cleaning time is 15 minutes to remove the dirt on the surface of the alloy, and then dry it in a drying furnace at 60°C for 10 hours, and set aside; the reaction of putting the dried medical CoCrMo (cobalt chromium molybdenum) alloy into the ion nitriding furnace In the chamber, vacuumize the reaction chamber (the air pressure of the reaction chamber is lower than 0.1Pa), and then pass argon gas into the reaction chamber to sputter and clean the alloy. When cleaning, the air pressure of the reaction chamber is 120Pa, and the discharge voltage is 500V. , Cleaning is...

Embodiment 2

[0024] Embodiment two, the medical CoCrMo (cobalt chromium molybdenum) alloy surface is coated with 180 # , 400 # , 800 # , 1200 # The water sandpaper is polished in sequence, and then the surface roughness of the CoCrMo (cobalt chromium molybdenum) alloy is reduced to below 15nm by mechanical polishing. After polishing, the CoCrMo (cobalt chromium molybdenum) alloy is immersed in an alcohol solvent and ultrasonically cleaned for 10 minutes to remove the surface roughness of the alloy surface. The dirt was dried in a drying oven at 60°C for 10 hours, and then set aside. Put the dried medical CoCrMo (cobalt chromium molybdenum) alloy into the reaction chamber of the ion nitriding furnace, and vacuumize the reaction chamber. When the pressure in the reaction chamber is lower than 0.1Pa, argon gas is introduced into the reaction chamber The alloy is sputtered and cleaned, and the cleaning is carried out simultaneously during the heating process of the reaction chamber. During ...

Embodiment 3

[0026] Embodiment three, the surface of the medical CoCrMo (cobalt chromium molybdenum) alloy is first coated with 180 # , 400 # , 800 # , 1200 # The surface roughness of the CoCrMo (cobalt chromium molybdenum) alloy is reduced to below 15nm by mechanical polishing. After polishing, the CoCrMo (cobalt chromium molybdenum) alloy is immersed in an alcohol solvent and ultrasonically cleaned for 20 minutes to remove the surface roughness of the alloy surface. Dirt, and then dried in a drying oven at 60°C for 10 hours, and set aside; put the dried medical CoCrMo (cobalt chromium molybdenum) alloy into the reaction chamber of the ion nitriding furnace, and vacuumize the reaction chamber. When the pressure in the reaction chamber is lower than 0.1Pa, argon gas is introduced into the reaction chamber to clean the alloy by sputtering. The cleaning is carried out synchronously during the heating process of the reaction chamber. When cleaning, the pressure in the reaction chamber is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com