Mold shell of investment casting cobalt chromium molybdenum artificial joint implant and manufacturing method of mold shell

A technology for artificial joints and investment casting, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of uneven fine grains, insufficient pouring of thin-walled parts, and a large number of pores in castings, so as to achieve uniform fine grains, The effect of improving the nucleation rate and reducing the scrap rate of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

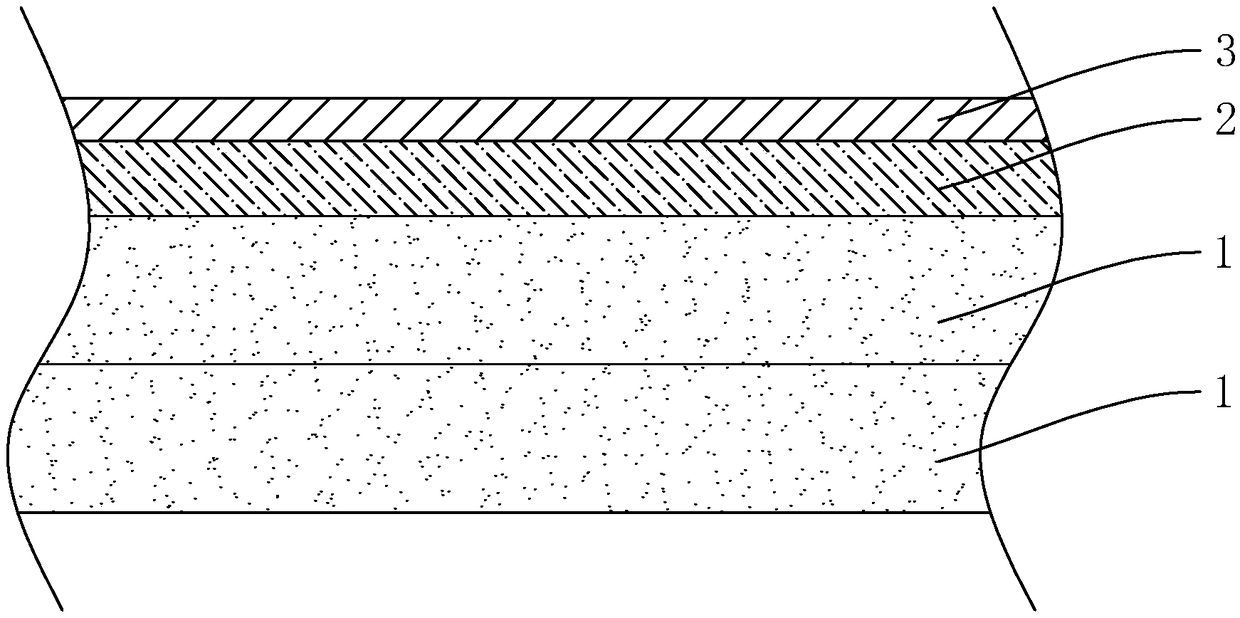

[0028] Embodiment 1: The formwork of an investment casting cobalt-chromium-molybdenum artificial joint implant provided by this embodiment includes a main body of the formwork, and the main body of the formwork includes two layers of cobalt aluminate surface layer 1, Back layer 2 and sealing layer 3, cobalt aluminate surface layer 1 includes silica sol, alumina powder, cobalt aluminate powder, defoamer, wetting agent, latex, wherein the mass ratio of alumina powder to silica sol is 4.35 , the mass ratio of cobalt aluminate to silica sol is 0.22, the mass ratio of defoamer to silica sol is 6ml / Kg, the mass ratio of wetting agent to silica sol is 2ml / Kg, and the mass ratio of latex to silica sol is 0.03 , wherein the active ingredient content of the cobalt aluminate powder is 35%, the mesh number of the alumina powder is 320 mesh, and the defoamer is set as an aliphatic amide defoamer, and the wetting agent is set as a polyoxyethylene wetting agent.

[0029] The back layer 2 inc...

Embodiment 2

[0038] Embodiment 2: The formwork of an investment casting cobalt-chromium-molybdenum artificial joint implant provided by this embodiment includes a main body of the formwork, and the main body of the formwork includes two layers of cobalt aluminate surface layer 1, Back layer 2 and sealing layer 3, cobalt aluminate surface layer 1 includes silica sol, alumina powder, cobalt aluminate powder, defoamer, wetting agent, latex, wherein the mass ratio of alumina powder to silica sol is 4.40 , the mass ratio of cobalt aluminate to silica sol is 0.28, the mass ratio of defoamer to silica sol is 7ml / Kg, the mass ratio of wetting agent to silica sol is 2.5ml / Kg, and the mass ratio of latex to silica sol is 0.04, wherein the active ingredient content of the cobalt aluminate powder is 35%, and the mesh number of the alumina powder is 320 mesh.

[0039] The back layer 2 includes silica sol, fused silica powder, zirconium powder, defoamer, latex, distilled water, wherein the mass ratio of...

Embodiment 3

[0048] Embodiment 3: The formwork of an investment casting cobalt-chromium-molybdenum artificial joint implant provided in this embodiment includes a main body of the formwork, and the main body of the formwork includes two layers of cobalt aluminate surface layer 1, Back layer 2 and sealing layer 3, cobalt aluminate surface layer 1 includes silica sol, alumina powder, cobalt aluminate powder, defoamer, wetting agent, latex, wherein the mass ratio of alumina powder to silica sol is 4.45 , the mass ratio of cobalt aluminate to silica sol is 0.35, the mass ratio of defoamer to silica sol is 8ml / Kg, the mass ratio of wetting agent to silica sol is 3ml / Kg, and the mass ratio of latex to silica sol is 0.05 , wherein the active ingredient content of the cobalt aluminate powder is 35%, and the mesh number of the alumina powder is 320 mesh.

[0049] The back layer 2 includes silica sol, fused silica powder, zirconium powder, defoamer, latex, distilled water, wherein the mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com