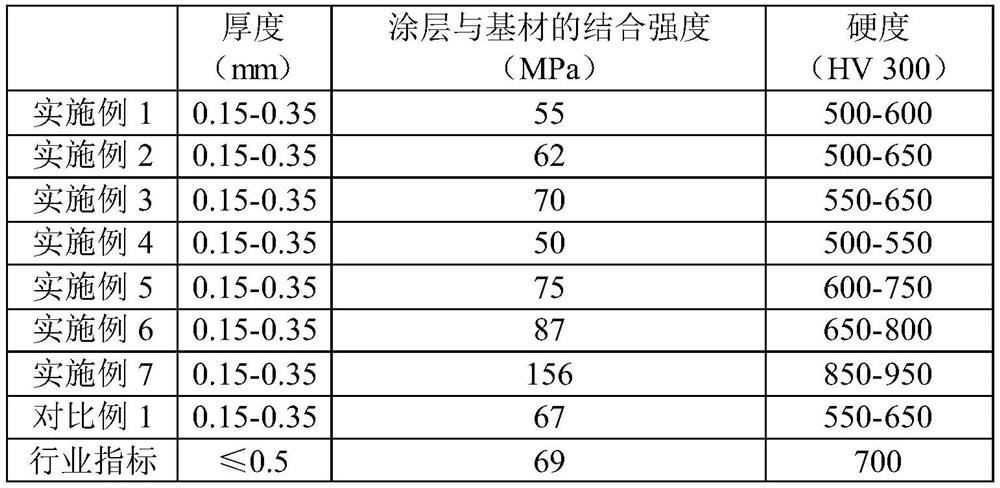

High-temperature-oxidation-resistant and corrosion-resistant coating and preparation method thereof

A high-temperature oxidation-resistant and corrosion-resistant technology, used in coatings, metal material coating processes, melt spraying, etc., can solve the problems of large environmental pollution and low production efficiency, and achieve uniform and dense coating structure, good resistance to various Corrosion-like medium performance, the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-temperature oxidation-resistant and corrosion-resistant coating, comprising the steps of:

[0035] (1) Mix the raw materials of 35wt% cobalt, 30wt% chromium, 30wt% molybdenum and 5wt% silicon according to the ratio, and then use the water atomization method to make spherical particles of alloy powder, with a particle size of 5 μm to 30 μm and a bulk density of The density is 5.5g / cm 3 ~6g / cm 3 stand-by;

[0036](2) The stainless steel substrate to be processed is manually wiped clean with alcohol and dried at 50°C, and then the surface of the substrate is subjected to sand blowing treatment, and the sand blowing treatment uses compressed air as power, and utilizes high-speed sand flow The impact effect of the material is used to roughen the surface of the substrate. The material of the sand blasting sand is white corundum, the sand blowing pressure is 0.6MPa, and the sand blowing distance is 100mm, which is ready for use;

[0037] (3) Th...

Embodiment 2

[0039] A method for preparing a high-temperature oxidation-resistant and corrosion-resistant coating, comprising the steps of:

[0040] (1) Mix the raw materials of 40wt% cobalt, 30wt% chromium, 20wt% molybdenum and 10wt% silicon according to the ratio, and then use the water atomization method to make spherical particles of alloy powder, with a particle size of 40 μm to 60 μm and a bulk density of The density is 4.8g / cm 3 ~5g / cm 3 stand-by;

[0041] (2) Clean the stainless steel base material to be processed by ultrasonic cleaning with acetone and dry it at 80°C, then perform sand blowing treatment on the surface of the base material, the sand blowing process uses compressed air as the power, and utilizes high-speed sand flow The impact effect is used to achieve the roughening of the surface of the substrate. The material of the sand blasting sand is white corundum, the sand blowing pressure is 0.4MPa, and the sand blowing distance is 80mm, which is ready for use;

[0042]...

Embodiment 3

[0044] A method for preparing a high-temperature oxidation-resistant and corrosion-resistant coating, comprising the steps of:

[0045] (1) Mix the raw materials of 45wt% cobalt, 30wt% chromium, 23wt% molybdenum and 2wt% silicon according to the ratio, and then use the water atomization method to make alloy powder spherical particles with a particle size of 15 μm to 45 μm and a bulk density of The density is 5.2g / cm 3 ~5.8g / cm 3 stand-by;

[0046] (2) Clean the stainless steel base material to be processed by ultrasonic cleaning with acetone and dry it at 80°C, then perform sand blowing treatment on the surface of the base material, the sand blowing process uses compressed air as the power, and utilizes high-speed sand flow The impact effect of the material is used to roughen the surface of the substrate. The material of the sand blasting sand is white corundum, the sand blowing pressure is 0.5MPa, and the sand blowing distance is 120mm, which is ready for use;

[0047] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com