Nickel-cobalt alloy stainless steel wire and production process thereof

A technology of stainless steel wire and nickel-cobalt alloy, which is applied to wire drawing dies, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as shortening service life and oxidation, and achieve the effect of preventing snapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

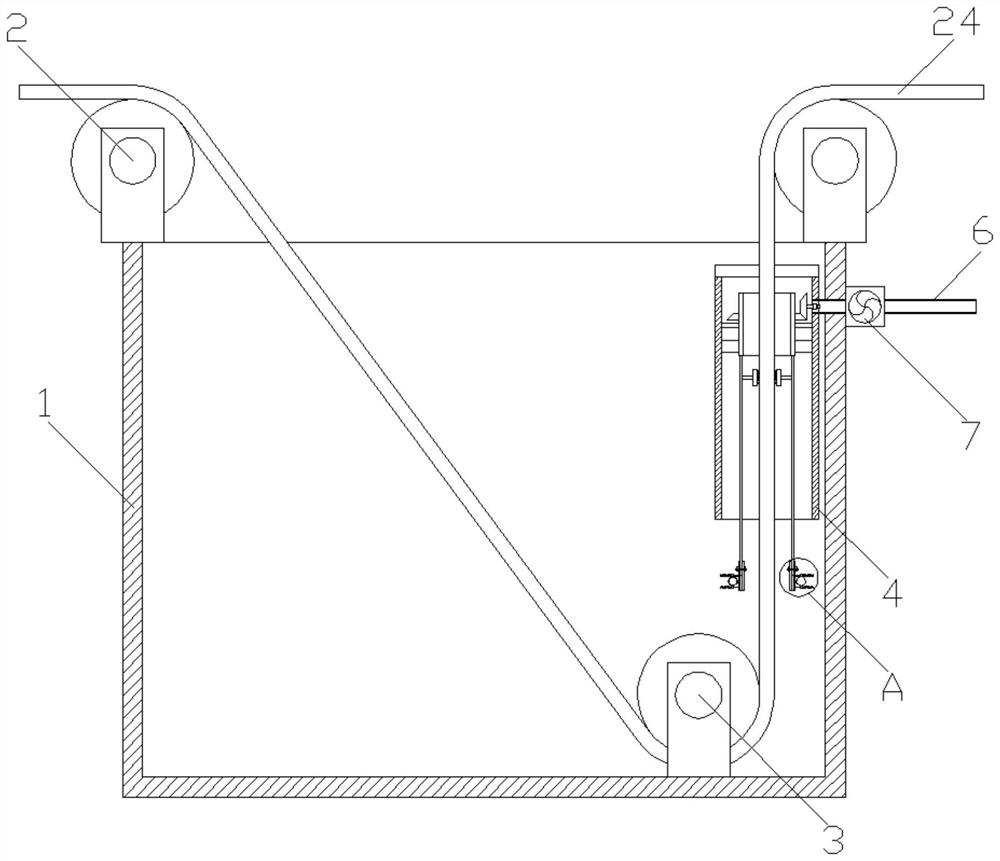

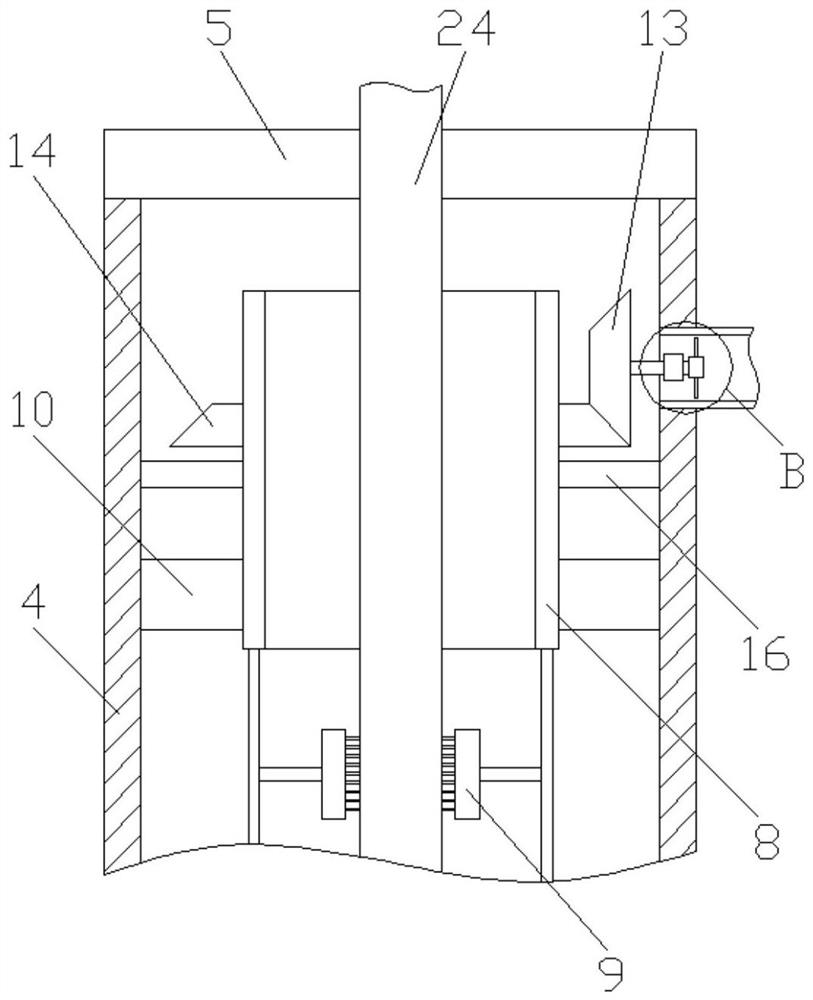

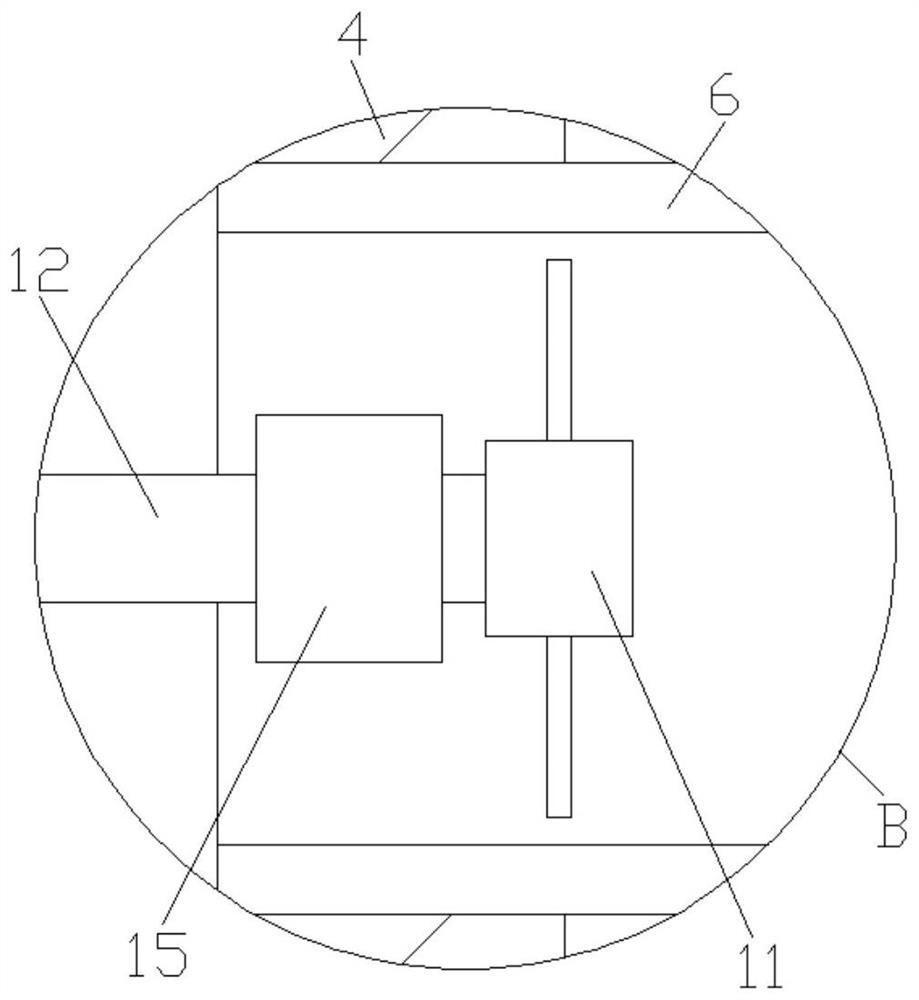

[0031] like Figure 1-5 As shown, a nickel-cobalt alloy stainless steel wire in this embodiment is prepared by weight percentage: iron Fe: 0.001-1.25%, cobalt Co: 1.22-1.25%, chromium Cr: 10-20%, molybdenum Mo: 1- 5%, Neodymium Nb+Tantalum Ta: 4~6%, Aluminum Al: 0.001~3%, Titanium Ti: 0.001~2%, Carbon C: 0.001~0.1%, Phosphorus P: 0.01~0.03%, Magnesium Mg: 0.001~ 0.01%, boron B: 0.001-0.02%, zirconium Zr: 0.001-0.1%, silicon Si: 3-8%, and the balance is nickel Ni.

[0032] Table 1: Silicon Si and anti-oxidation coefficient R table in harsh environments such as high humidity and high temperature

[0033]

[0034]

[0035] Table 2: Antioxidant coefficient R evaluation table

[0036] Antioxidant coefficient R Antioxidant classification <0.1 full antioxidant 0.1-1 Antioxidant 1-3 Secondary Antioxidant 3-10 weak antioxidant >10 Not antioxidant

[0037] This results in:

[0038] Adding 3-8% of silicon Si to the nickel-cobalt all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com