Cobalt-chromium-molybdenum-tungsten-silicon alloy bar

An alloy bar, cobalt-chromium-molybdenum technology, applied in the field of cobalt-chromium-molybdenum alloy, can solve problems such as imperfect research on cobalt-chromium porcelain alloy bars and poor bar performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

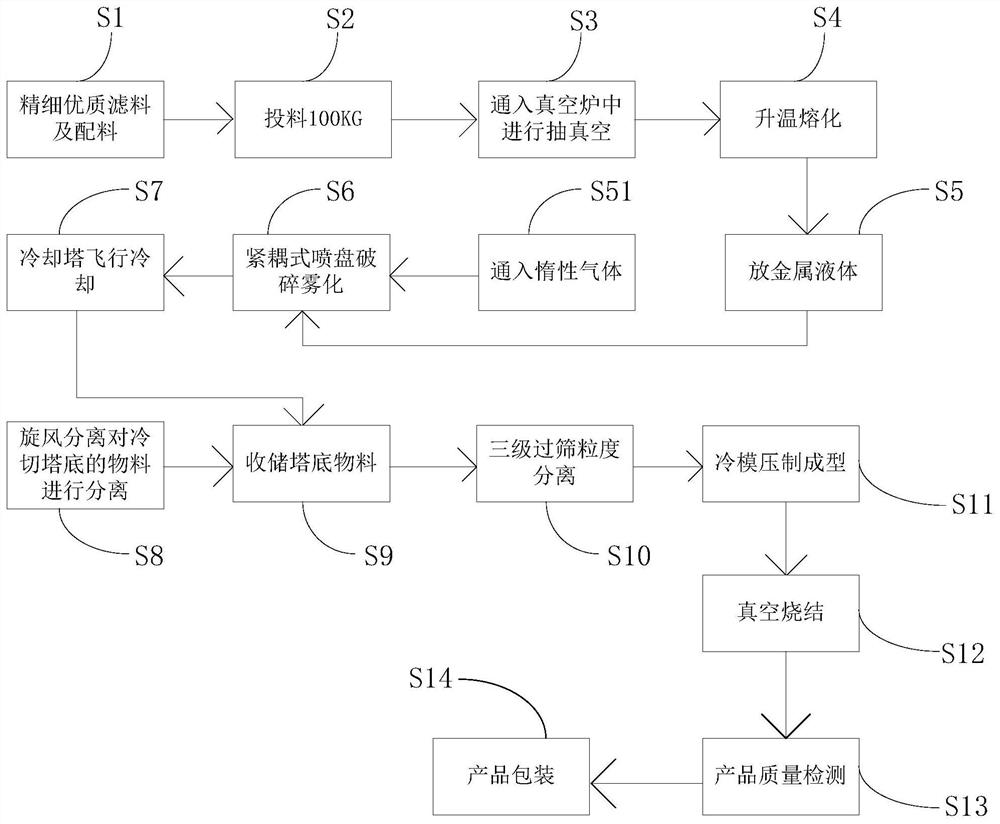

[0038] The present invention also provides a method for preparing a cobalt-chromium-molybdenum-tungsten-silicon alloy rod, comprising the following steps:

[0039] (1) preparing cobalt-chromium-molybdenum-tungsten-silicon alloy powder;

[0040] (2) The powder obtained in step (1) is subjected to cold mold compression molding;

[0041] (3) The alloy rod is obtained after vacuum sintering.

[0042] The cobalt-chromium-molybdenum-tungsten-silicon alloy rod prepared by the preparation method provided in this example has a cylindrical appearance and a grain weight of 1-10g, preferably 2-8g, more preferably 4- 6g. Rods are suitable for dental restorative materials.

[0043] The preparation method of the cobalt-chromium-molybdenum-tungsten-silicon alloy rod provided in this example yields an alloy rod with better appearance, color and luster, and better performance.

[0044] In a preferred embodiment, the pressure of cold molding is 80-100 tons, and in a further preferred embodim...

Embodiment 1-3

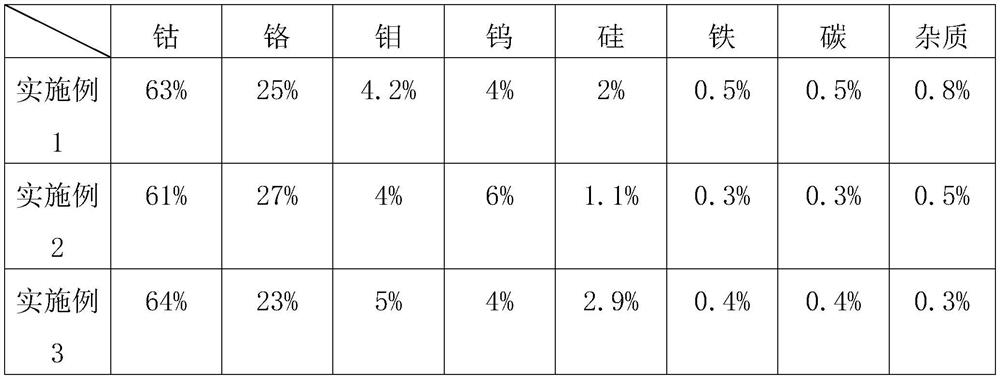

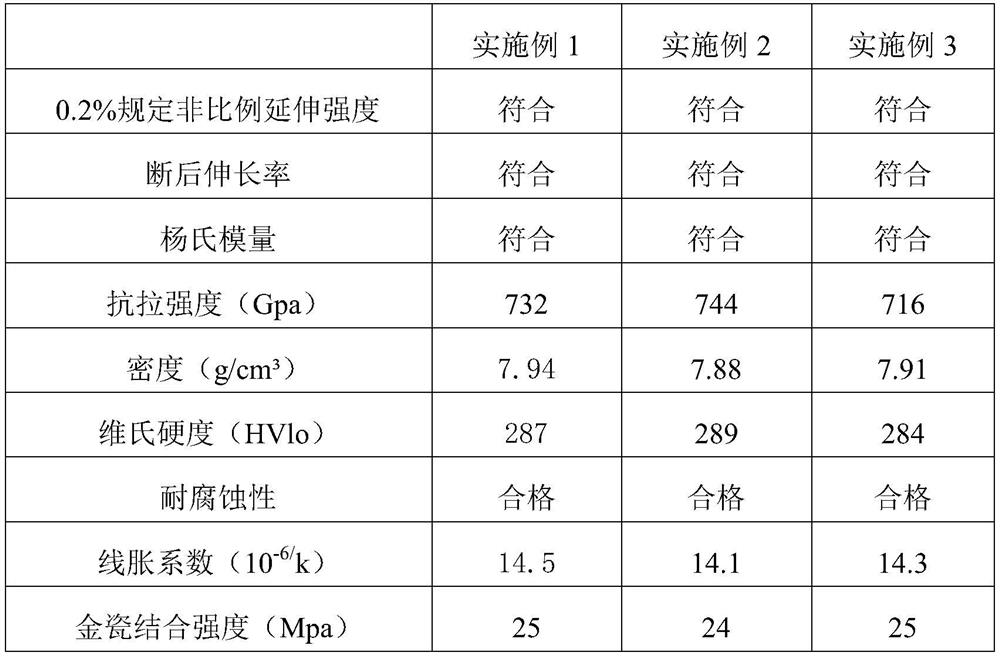

[0078] Dosing according to the formula in Table 1, feed 1000kg into the vacuum furnace, vacuumize with a pressure of 10Pa, and heat up and melt the vacuumized material in the melting furnace at a temperature of 1680°C to 1700°C to obtain a metal liquid. The metal liquid is passed into the close-coupled atomization spray plate device for crushing and atomization, and at the same time, an ultra-high-speed inert gas (nitrogen) is introduced into the close-coupled atomization spray plate. The flow rate of the ultra-high-speed inert gas is per 3000 cubic meters per hour. The atomized material is passed into the cooling tower for flight cooling. The tower diameter of the cooling tower is 1800mm and the tower height is 9000mm. The cyclone separation device is used to separate the materials collected at the bottom of the cooling tower, and the particles with smaller particle sizes are collected, and then the three-stage sieving particle size separation is carried out, and the collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com