A method for antibacterial modification of the surface of an implant material

A technology for surface antibacterial and implanted materials, applied in the field of biomaterials and multifunctional nanomaterials, which can solve problems such as bacterial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

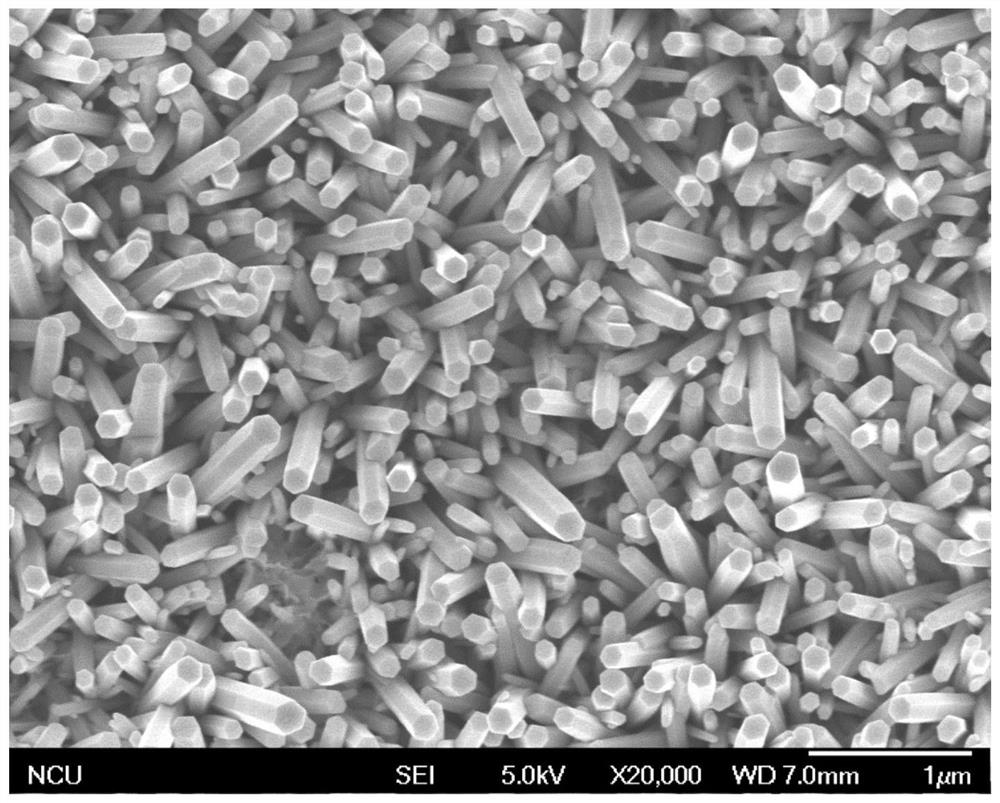

[0027] Embodiment 1: a kind of method for implant material surface antibacterial modification, comprises the steps:

[0028] (1) Slowly add 100ml of 0.03M methanol solution of sodium hydroxide into 100ml of 0.01M methanol solution of zinc acetate, heat to 60°C and stir for 2h;

[0029] (2) Repeat and evenly coat the solution prepared in step (1) on the surface of the titanium metal material by spin coating, and calcinate at 150° C. to ensure that the solid particles are attached to the surface of the material;

[0030] (3) Immerse the material prepared in step (2) in 100 mL of a mixed solution containing 0.025M zinc nitrate hydrate and 0.025M hexamethyleneimine, heat to 90°C, and react for 0.5-6h;

[0031] (4) After the reaction in step (3) is finished, the solution is naturally cooled to room temperature, then the material is taken out, washed with deionized water, and dried naturally;

[0032] (5) Dissolve 80mM ammonia water, 50mM zinc oxide hydrate and 25mM hexamethylenete...

Embodiment 2

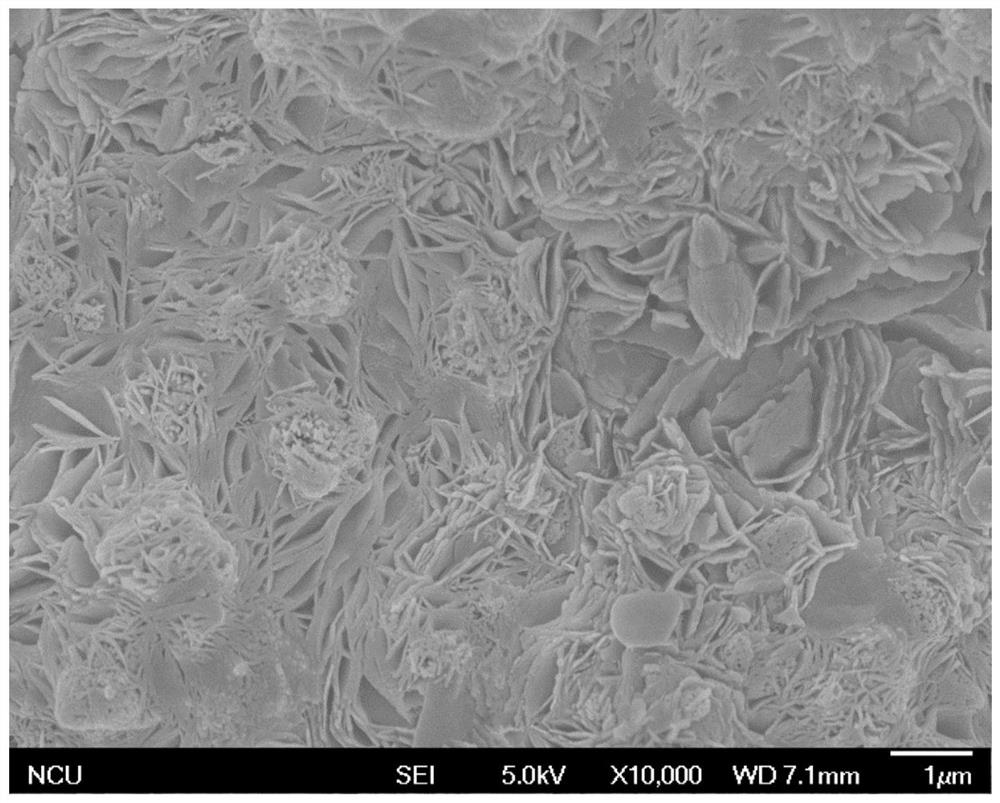

[0035] Embodiment 2: a kind of method for implant material surface antibacterial modification, comprises the steps:

[0036] (1) Slowly add 100ml of 0.03M methanol solution of sodium hydroxide into 100ml of 0.01M methanol solution of zinc acetate, heat to 60°C and stir for 2h;

[0037] (2) Repeat and evenly coat the solution prepared in step (1) on the surface of the polymer polyurethane material by spin coating, and calcinate at 150° C. to ensure that the solid particles are attached to the surface of the material;

[0038] (3) Immerse the material prepared in step (2) in 100 mL of a mixed solution containing 0.025M zinc nitrate hydrate and 0.025M hexamethyleneimine, heat to 90°C, and react for 0.5-6h;

[0039] (4) After the reaction in step (3) is finished, the solution is naturally cooled to room temperature, then the material is taken out, washed with deionized water, and dried naturally;

[0040] (5) Dissolve 80mM ammonia water, 50mM zinc oxide hydrate and 25mM hexamethy...

Embodiment 3

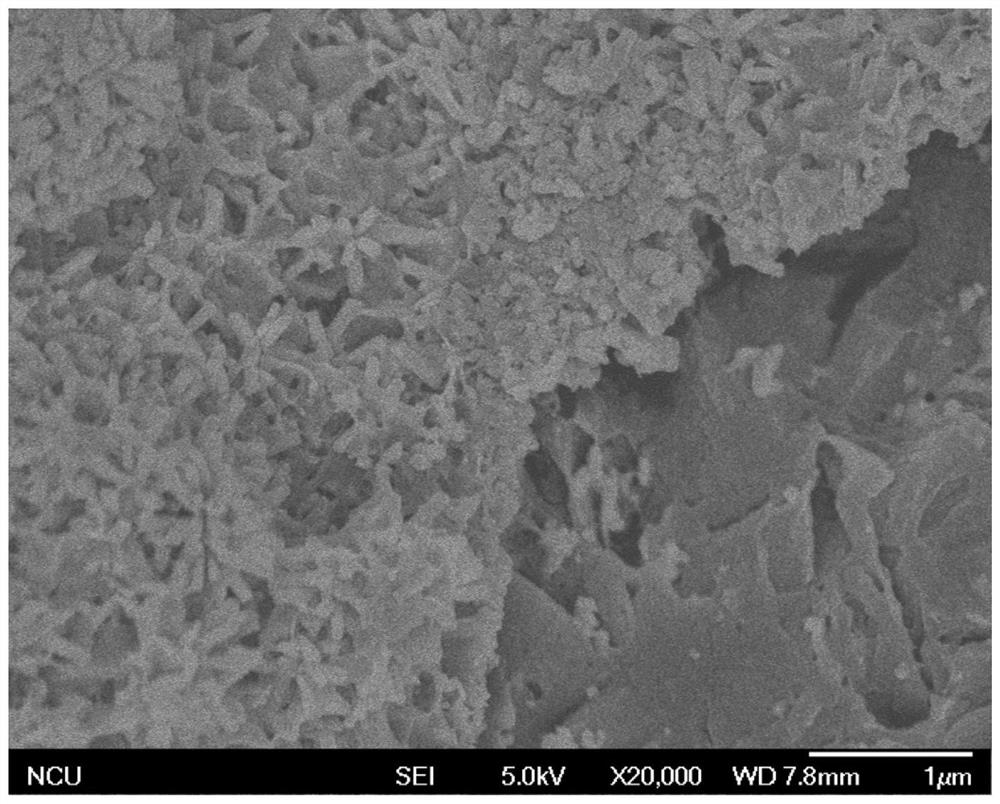

[0043] Embodiment 3: a kind of method for implant material surface antibacterial modification, comprises the steps:

[0044] (1) Slowly add 100ml of 0.03M methanol solution of sodium hydroxide into 100ml of 0.01M methanol solution of zinc acetate, heat to 60°C and stir for 2h;

[0045] (2) Repeat and evenly coat the solution prepared in step (1) on the surface of the metal tantalum material by spin coating, and calcinate at 150°C to ensure that the solid particles are attached to the surface of the material;

[0046] (3) Immerse the material prepared in step (2) in 100 mL of a mixed solution containing 0.025M zinc nitrate hydrate and 0.025M hexamethyleneimine, heat to 90°C, and react for 0.5-6h;

[0047](4) After the reaction in step (3) is finished, the solution is naturally cooled to room temperature, then the material is taken out, washed with deionized water, and dried naturally;

[0048] (5) Dissolve 80mM ammonia water, 50mM zinc oxide hydrate and 25mM hexamethylenetetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com