Cobalt-chromium-molybdenum-tungsten alloy powder as well as preparation method and application thereof

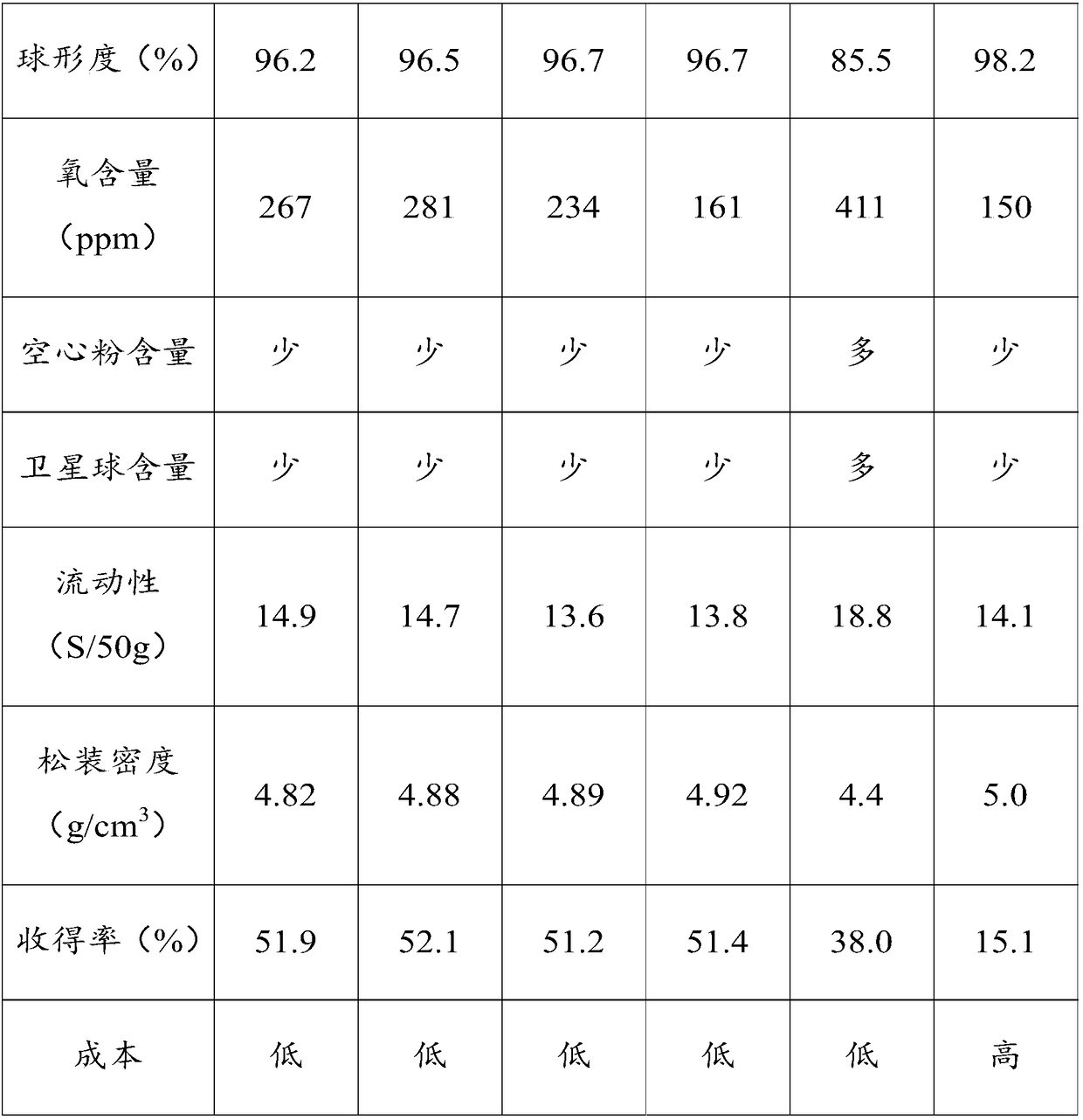

A cobalt-chromium-molybdenum-molybdenum-tungsten alloy technology, which is applied in the field of cobalt-chromium-molybdenum-tungsten alloy powder and its preparation, can solve the problem of affecting the performance of the final product by melting and forming the metal powder, the high production cost of the plasma rotary atomization method, and the fine-grained powder yield. Low-level problems, to achieve the effect of high sphericity, small particle size and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the cobalt-chromium-molybdenum-tungsten alloy powder provided by the embodiment of the present invention comprises the following steps: melting the cobalt-chromium-molybdenum-tungsten raw material, atomizing, sieving, and retaining the powder particles with a particle size of 15-53 μm to obtain the cobalt-chromium-molybdenum-tungsten alloy powder .

[0019] Cobalt chromium molybdenum tungsten raw materials include the following components in weight percentage: 58-70wt% of Co; 23-27wt% of Cr; 4-6wt% of Mo; 4-6wt% of W; <1.5wt% of Si; The amount is impurity.

[0020] For reference, the above cobalt chromium molybdenum tungsten raw materials may include the following components in weight percentage: 59-69wt% Co; 24-25wt% Cr; 4.5-5.5wt% Mo; 4.5-5.5wt% W; <1.5wt% Si; the balance is impurities.

[0021] The cobalt-chromium-molybdenum-tungsten alloy with the above ratio has better wear resistance, corrosion resistance and high temperature oxidation ...

Embodiment 1

[0036] Put cobalt, chromium, molybdenum and tungsten raw materials into a vacuum intermediate frequency induction furnace, vacuumize the melting chamber and atomization chamber, and energize and heat the leaking package in the middle of the resistor and the melting furnace at the same time. The temperature of the middle leakage bag is controlled at 1100°C. The cobalt, chromium, molybdenum and tungsten raw materials in the vacuum intermediate frequency induction furnace are refined under the condition of 1600°C to obtain molten metal.

[0037] The above cobalt chromium molybdenum tungsten raw material contains the following components by weight percentage: 58wt% Co; 23wt% Cr; 4wt% Mo; 4wt% W; 1.4wt% Si;

[0038] First close the main vacuum system, and pass the first inert gas into the vacuum intermediate frequency induction furnace. After opening the atomization inlet valve and the leakage valve of the middle leakage bag, turn on the exhaust fan, and pour the molten metal into...

Embodiment 2

[0043] Put cobalt, chromium, molybdenum and tungsten raw materials into a vacuum intermediate frequency induction furnace, vacuumize the melting chamber and atomization chamber, and energize and heat the leaking package in the middle of the resistor and the melting furnace at the same time. The temperature of the middle leakage bag is controlled at 1200°C. The cobalt, chromium, molybdenum and tungsten raw materials in the vacuum intermediate frequency induction furnace are refined under the condition of 1700°C to obtain molten metal.

[0044] The above cobalt chromium molybdenum tungsten raw material contains the following components by weight percentage: 70wt% Co; 27wt% Cr; 6wt% Mo; 6wt% W; 1.3wt% Si;

[0045] First close the main vacuum system, and pass the first inert gas into the vacuum intermediate frequency induction furnace. After opening the atomization inlet valve and the leakage valve of the middle leakage bag, turn on the exhaust fan, and pour the molten metal into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com