Tantalum metal bone trabecula femoral condyle prosthesis and knee joint replacement body

A technology of knee joint replacement and metal bone, applied in the direction of knee joints, prostheses, elbow joints, etc., can solve the problems of inability to realize the physiological internal and external rotation angle of the knee joint, the wear of the lower surface of the polyethylene tibial plateau pad, and the inability to effectively meet the friction coefficient at the same time To achieve superior knee dynamics, good biocompatibility, and reduce the risk of prosthetic loosening and dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

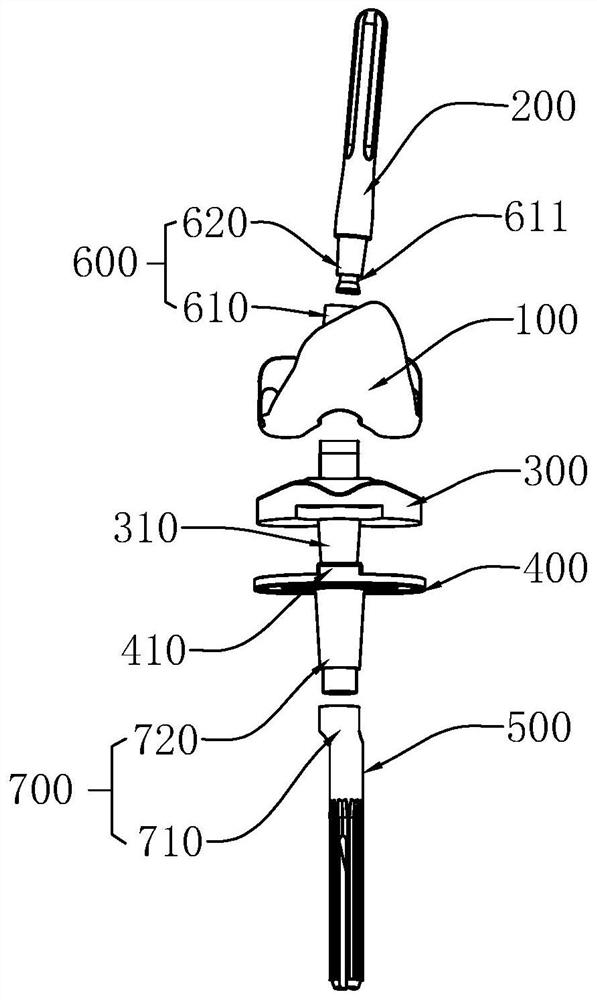

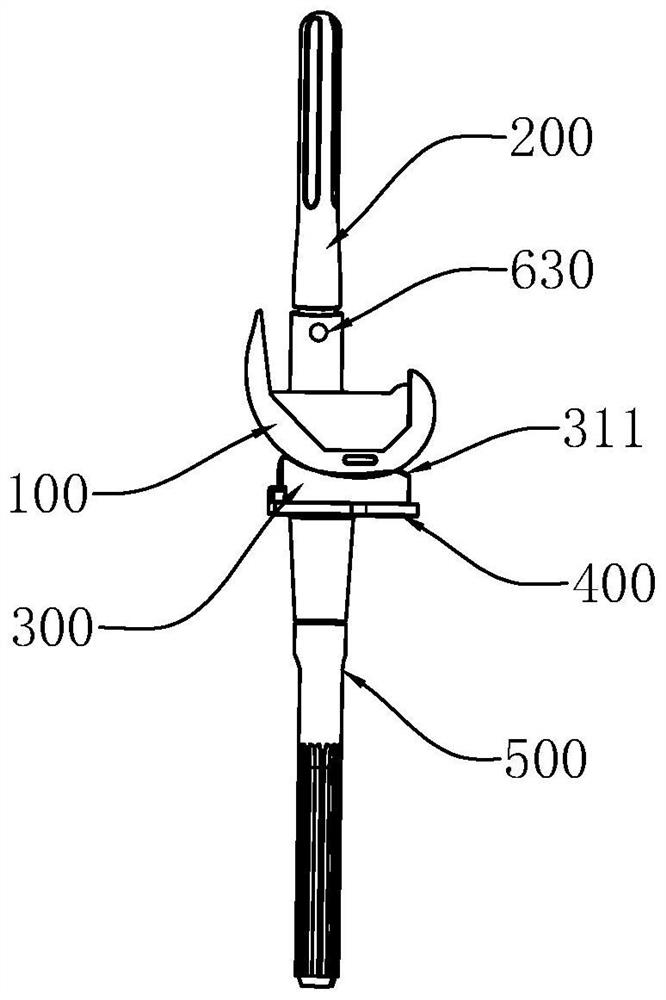

[0041] The following is attached Figure 1-3 The application is described in further detail.

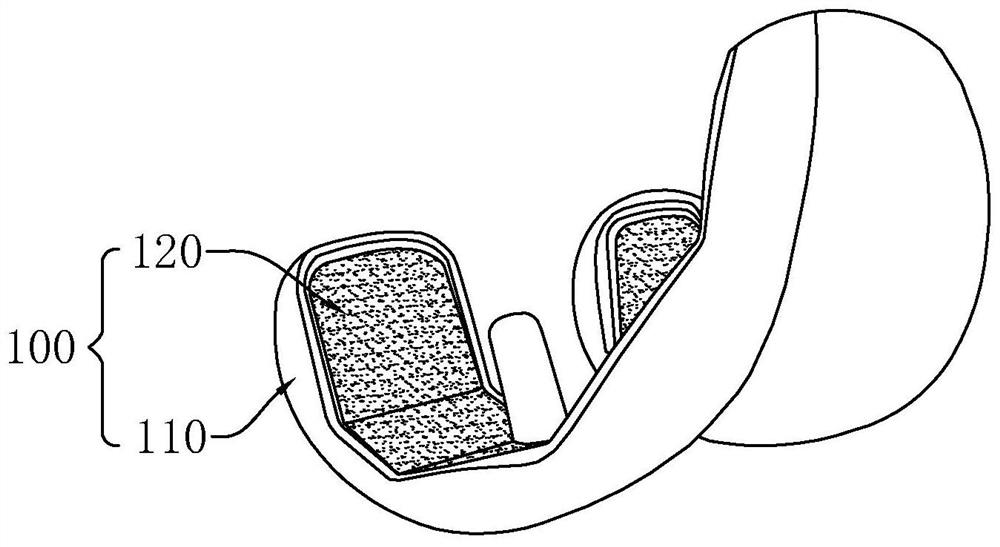

[0042] In the first aspect, the embodiment of the present application discloses a tantalum metal trabecular femoral condyle prosthesis 100, referring to figure 1, including a cobalt-chromium-molybdenum matrix 110 and a porous tantalum metal trabecular bone inner shell 120 welded in the cobalt-chromium-molybdenum matrix 110, the porous tantalum metal trabecular bone structure is porous, and is made by chemical vapor deposition using CVD equipment, and then The porous tantalum metal trabecular bone inner shell 120 and the cobalt-chromium-molybdenum femoral condyle are welded together by a diffusion welding process, thereby obtaining the tantalum metal trabecular bone femoral condyle prosthesis 100 . Porous tantalum trabecular bone prosthesis is highly interconnected and its honeycomb structure similar to bone trabecula can provide a wide range of bone ingrowth space, the high friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com