Patents

Literature

31 results about "Prosthesis Loosenings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

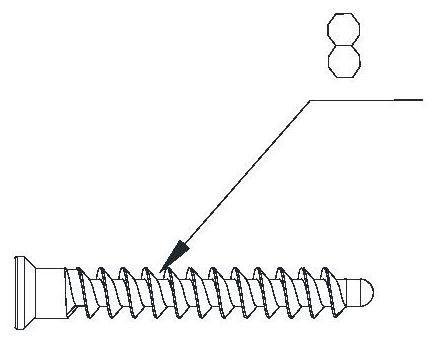

Systems for percutaneous bone and spinal stabilization, fixation and repair

InactiveUS6127597ASize of wire can be enlarged and reducedEnlarging and reducing sizeInternal osteosythesisFluid pressure measurement using pistonsSpinal columnProsthesis

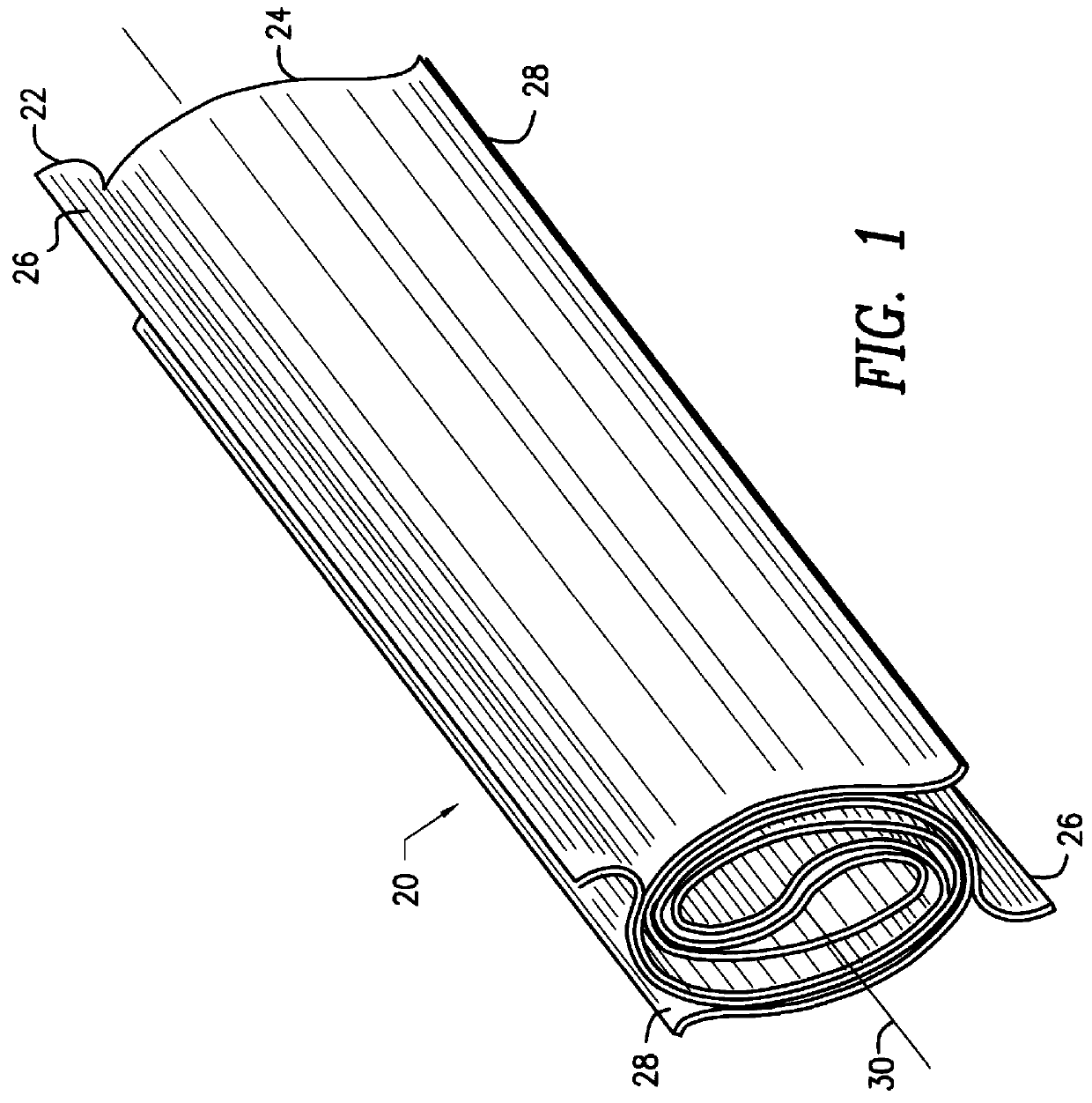

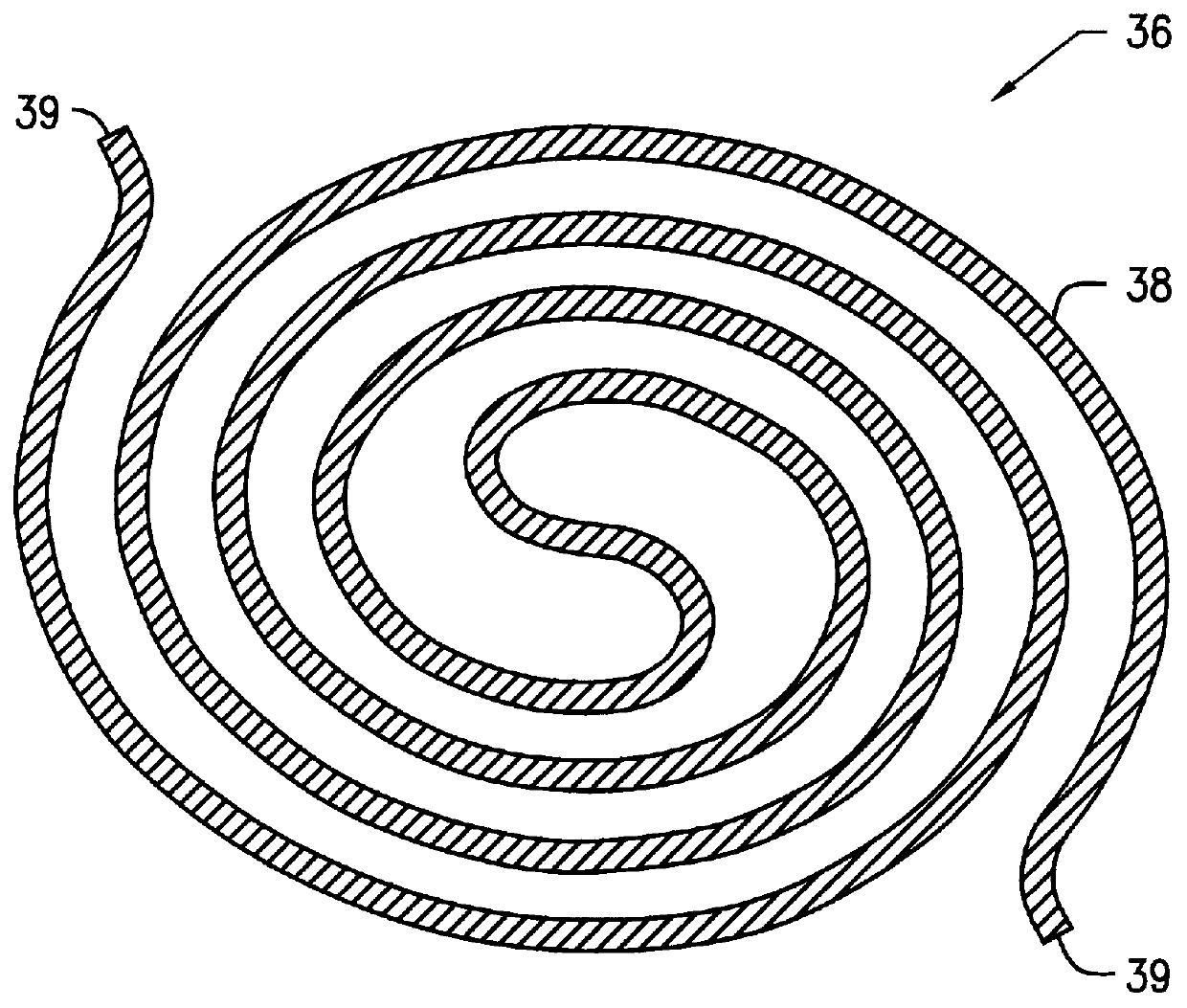

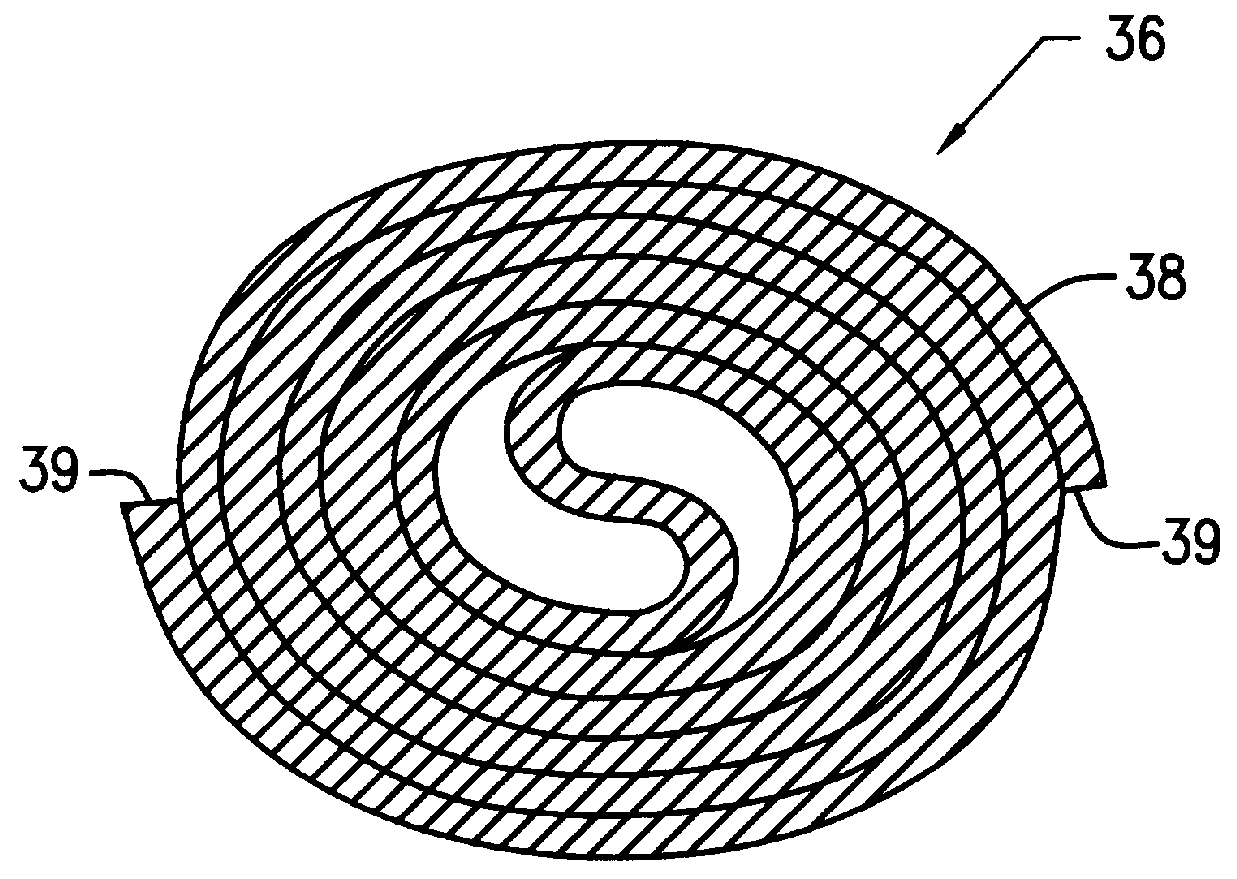

Systems for bone and spinal stabilization, fixation and repair include intramedullar nails, intervertebral cages and prostheses, remotely activatable prostheses, tissue extraction devices, and electrocautery probes. The intramedullar nails, intervertebral cages and prostheses, are designed for expansion from a small diameter for insertion into place to a larger diameter which stabilizes, fixates or repairs the bone, and further can be inserted percutaneously. Remotely activatable prostheses can be activated from an external unit to expand and treat prosthesis loosening. Tissue extraction devices, and electrocautery probes are used to remove tissue from desired areas.

Owner:KYPHON

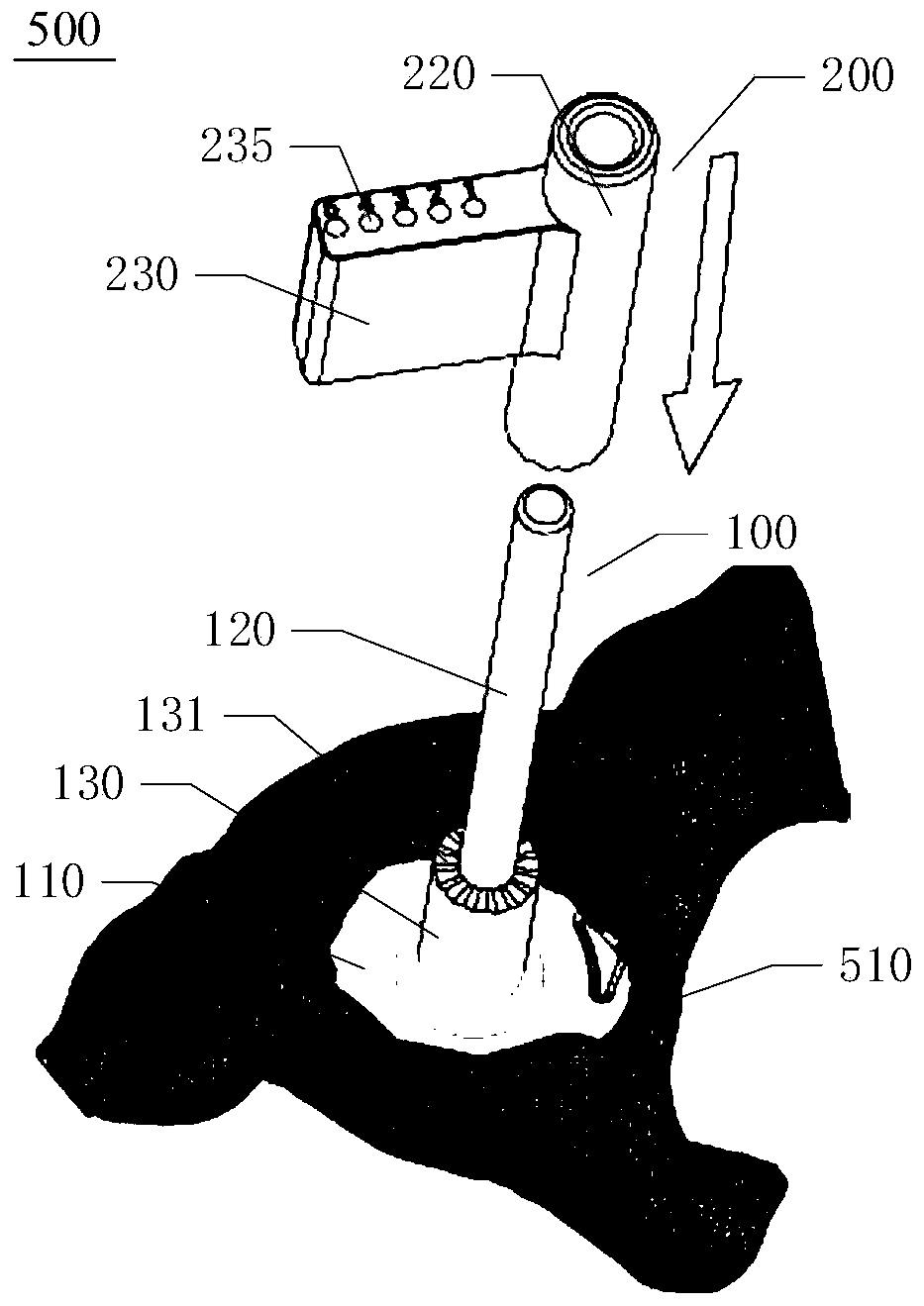

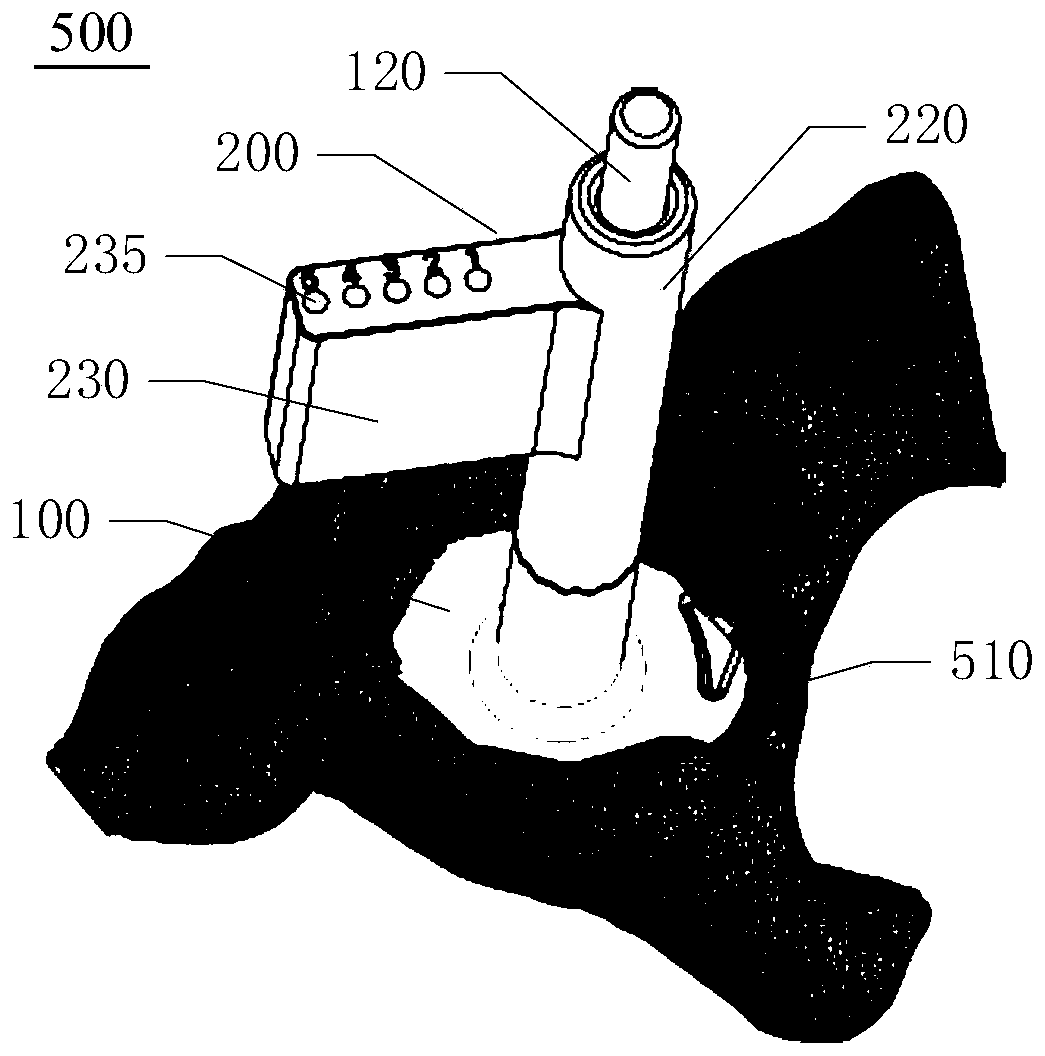

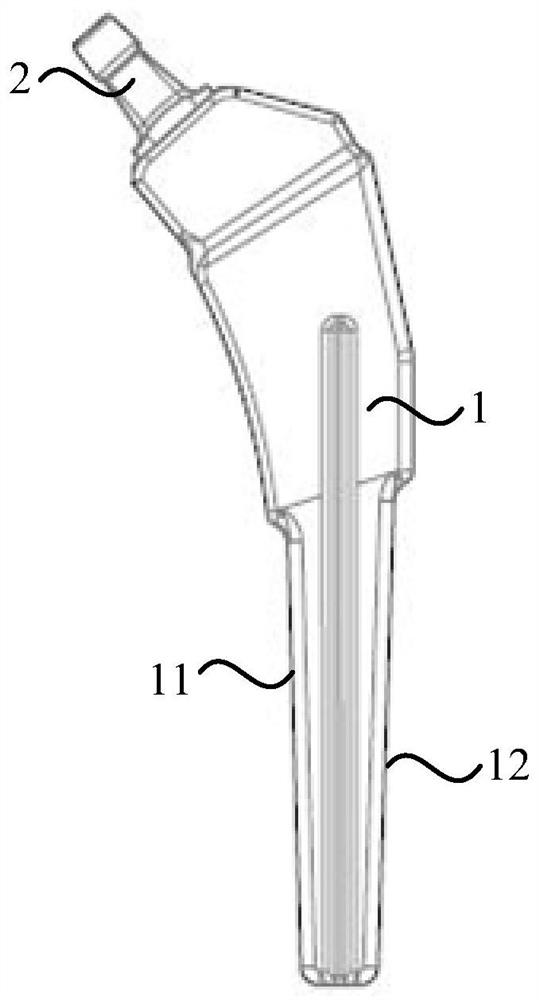

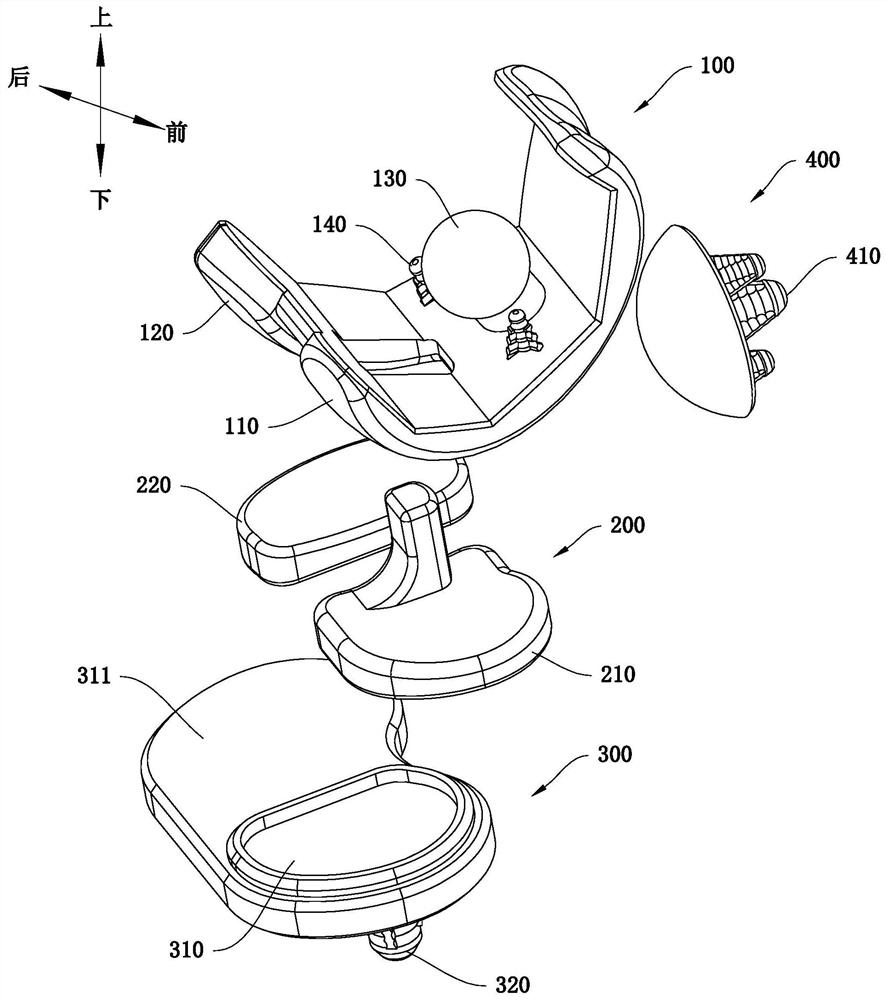

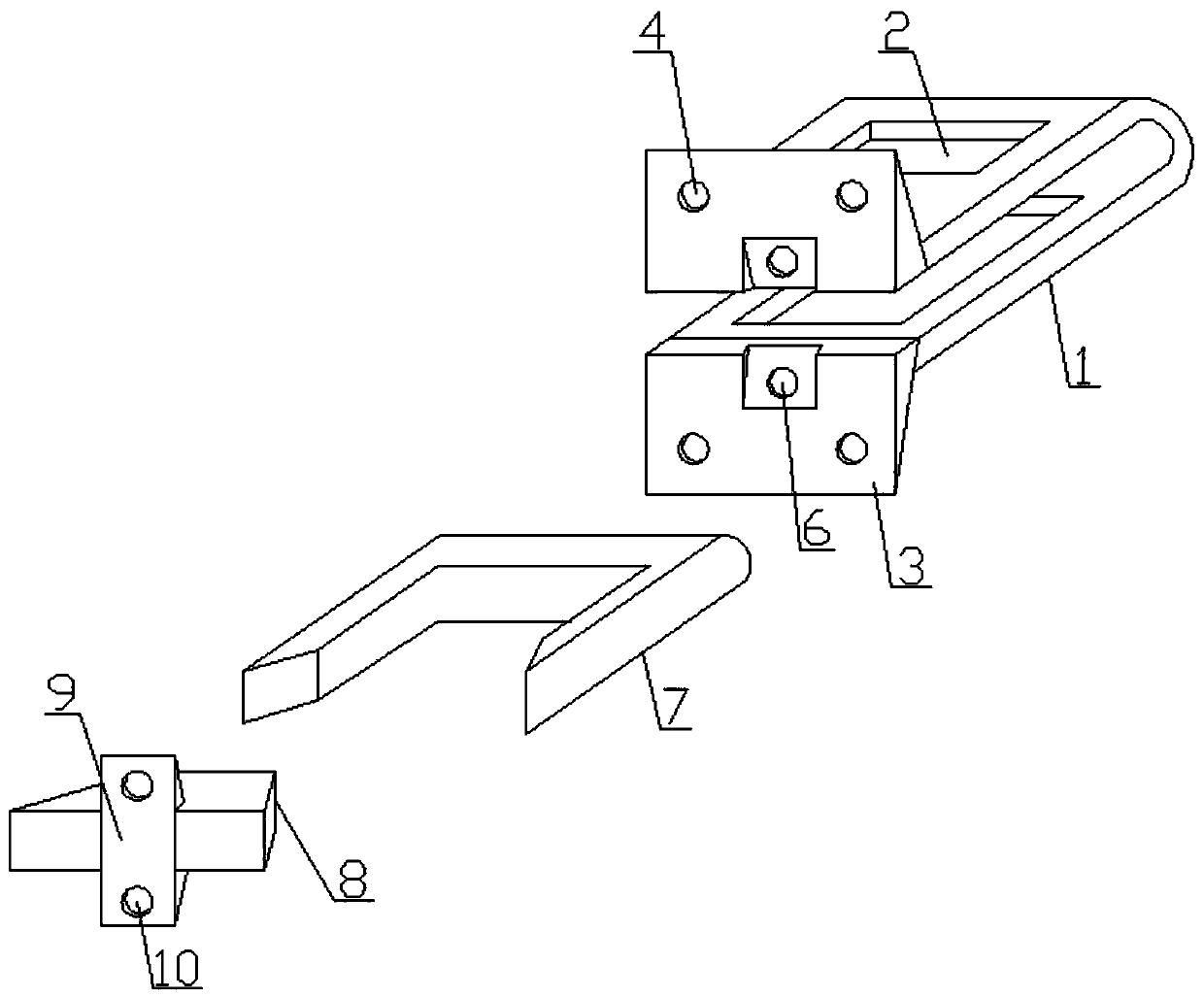

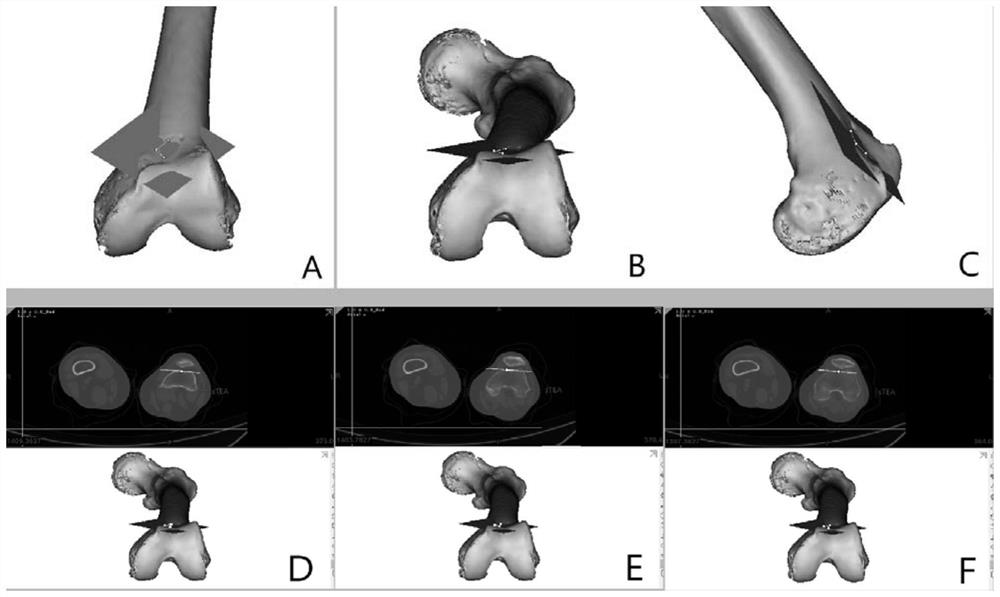

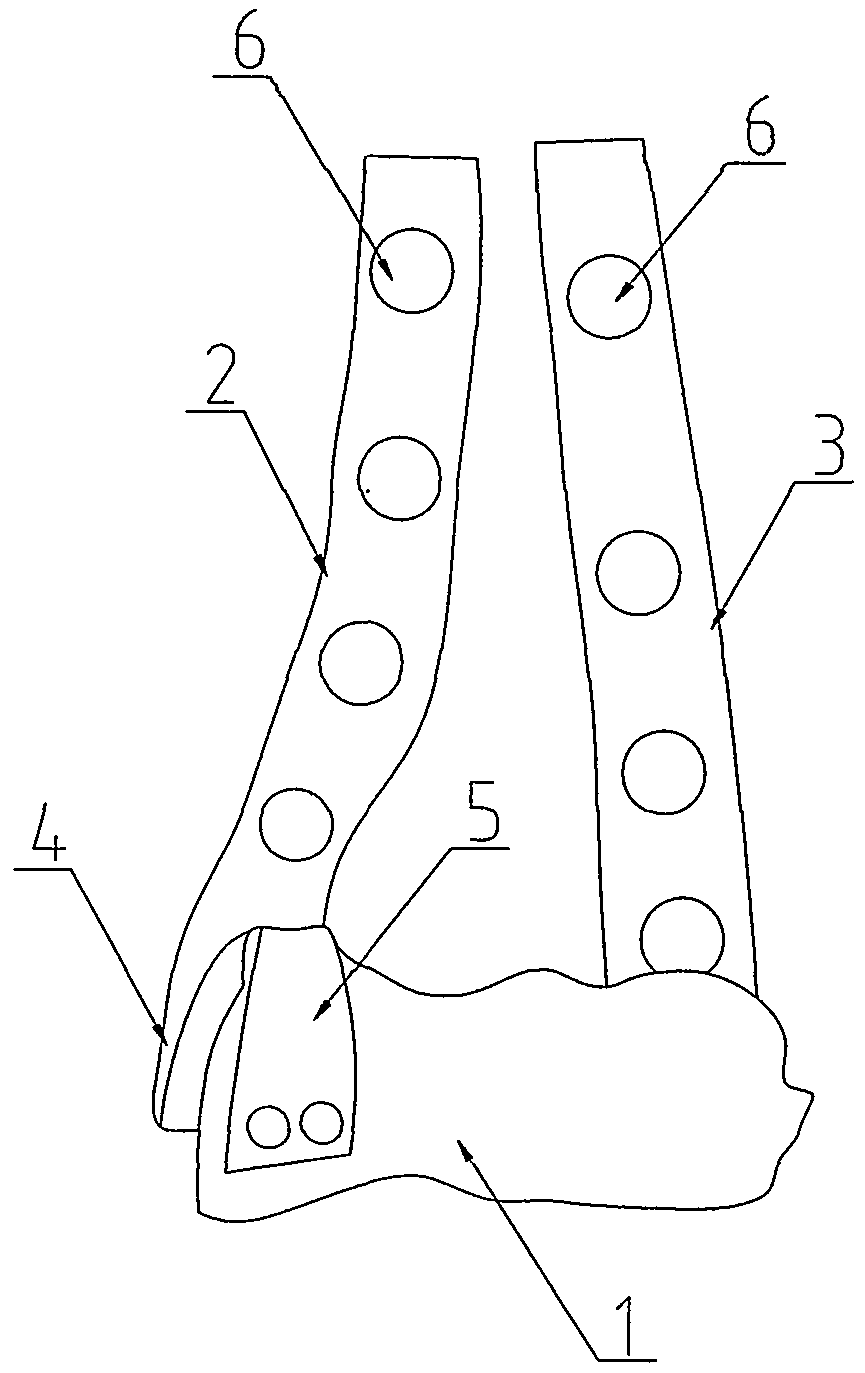

Positioning and navigation system and prosthesis implantation method

PendingCN110495975AAccurate placementThe placement is accurateSurgical navigation systemsJoint implantsProsthesis ImplantationNavigation system

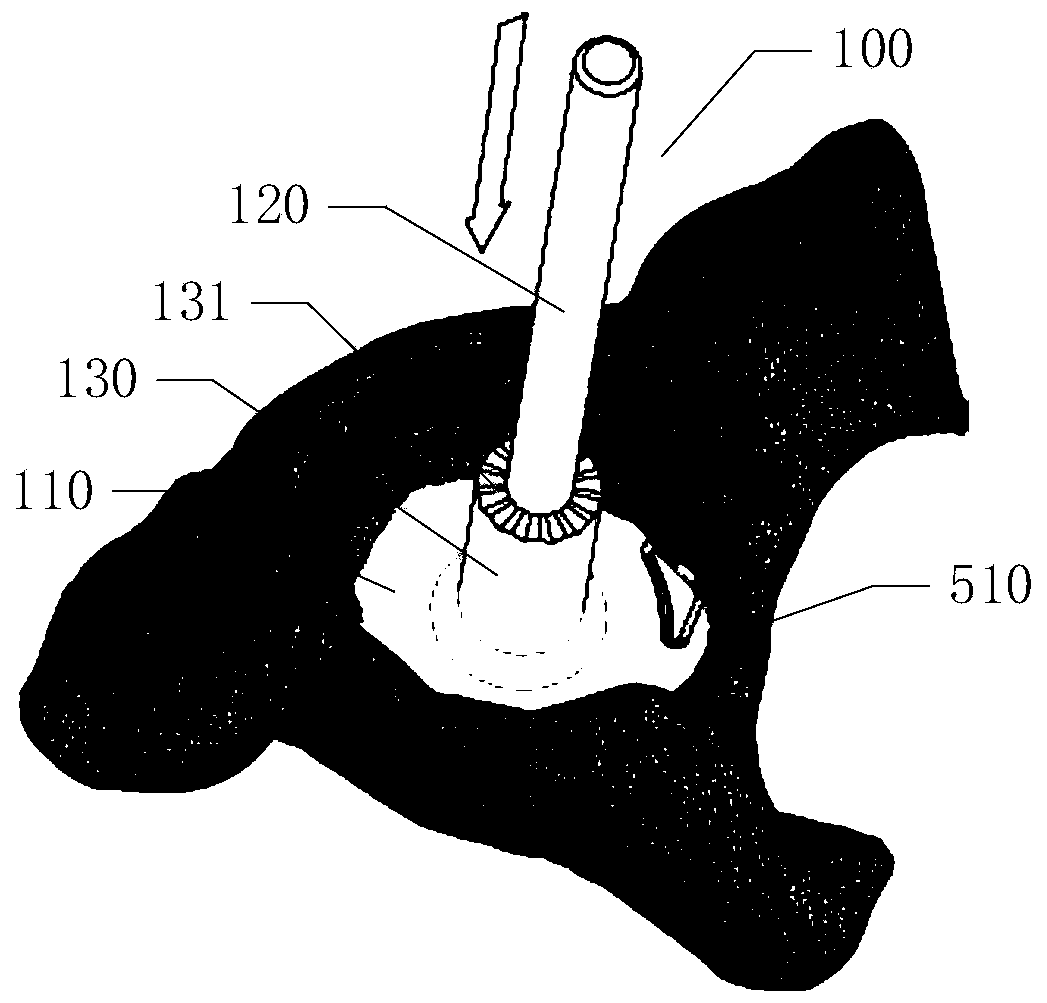

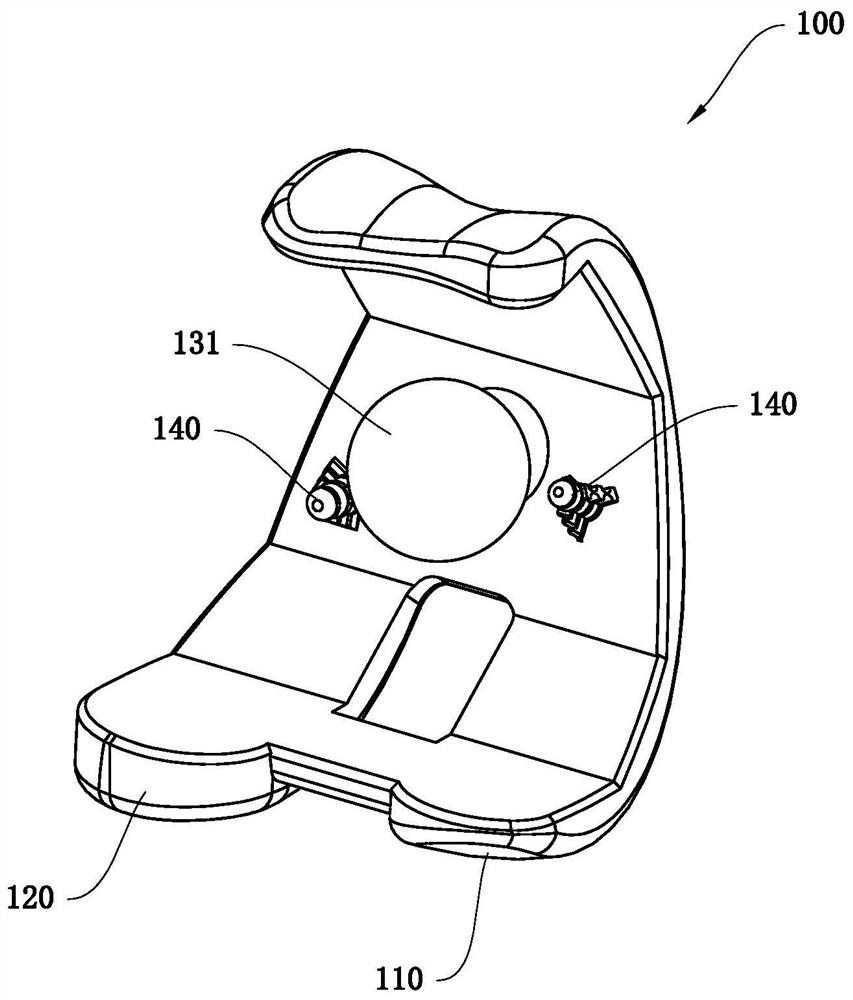

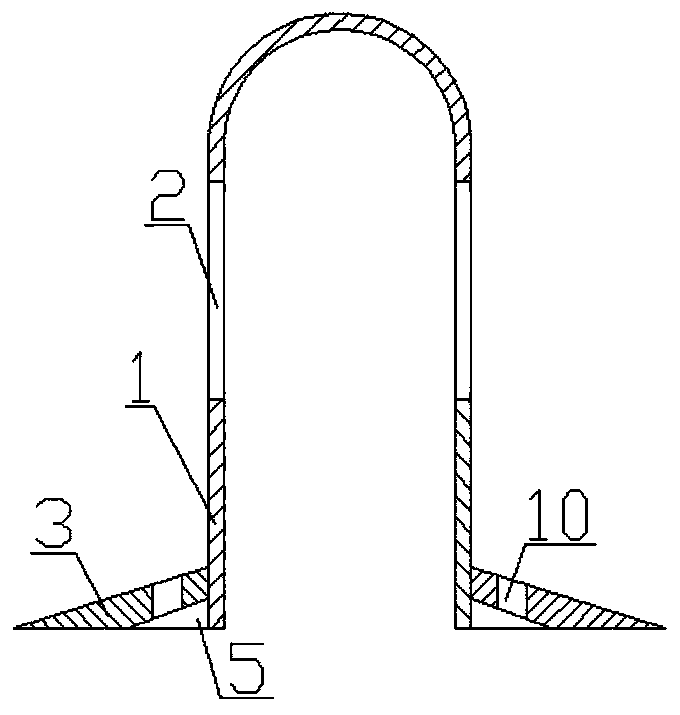

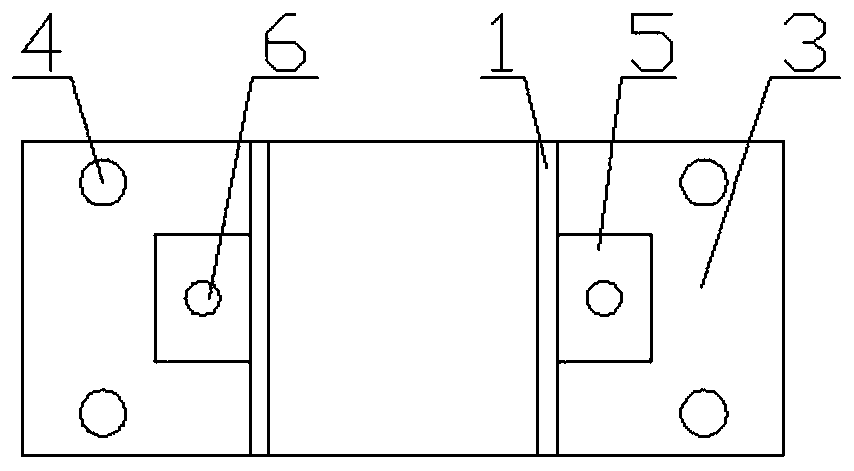

The invention discloses a positioning and navigation system. The positioning and navigation system is used for leading a prosthesis to be implanted into acetabular fossa. The positioning and navigation system comprises a positioning base and a positioner, wherein the positioning base comprises a jointing base and a guide rod, the jointing base cooperates with the acetabular fossa to be jointed tothe acetabular fossa for fixation; the guide rod is fixed to the jointing base and is coaxial with the acetabular fossa; the positioner comprises a sleeve and a guide arm which is formed in a manner that the sleeve extends, the sleeve is suitable for sleeving of the guide rod, and a plurality of guide holes being parallel to the axis of the sleeve are formed in the guide arm; and the guide holes are suitable for positioning needles in a manner of beating in, so that the positioning needles can be beaten into the outer region of the acetabular fossa and are parallel with the axis of the acetabular fossa. The invention further discloses a prosthesis implantation method. The positioning and navigation system can accurately position the milling and softening direction of the acetabular fossa and the implantation position of an acetabular cup, so that during operation, the acetabular cup can be accurately implanted, the acetabular cup can be guaranteed to be implanted to the best position,and the incidence rate of complications of prosthesis dislocation, prosthesis loosening, pain and the like can be reduced.

Owner:LONGWOOD VALLEY MEDICAL TECH CO LTD

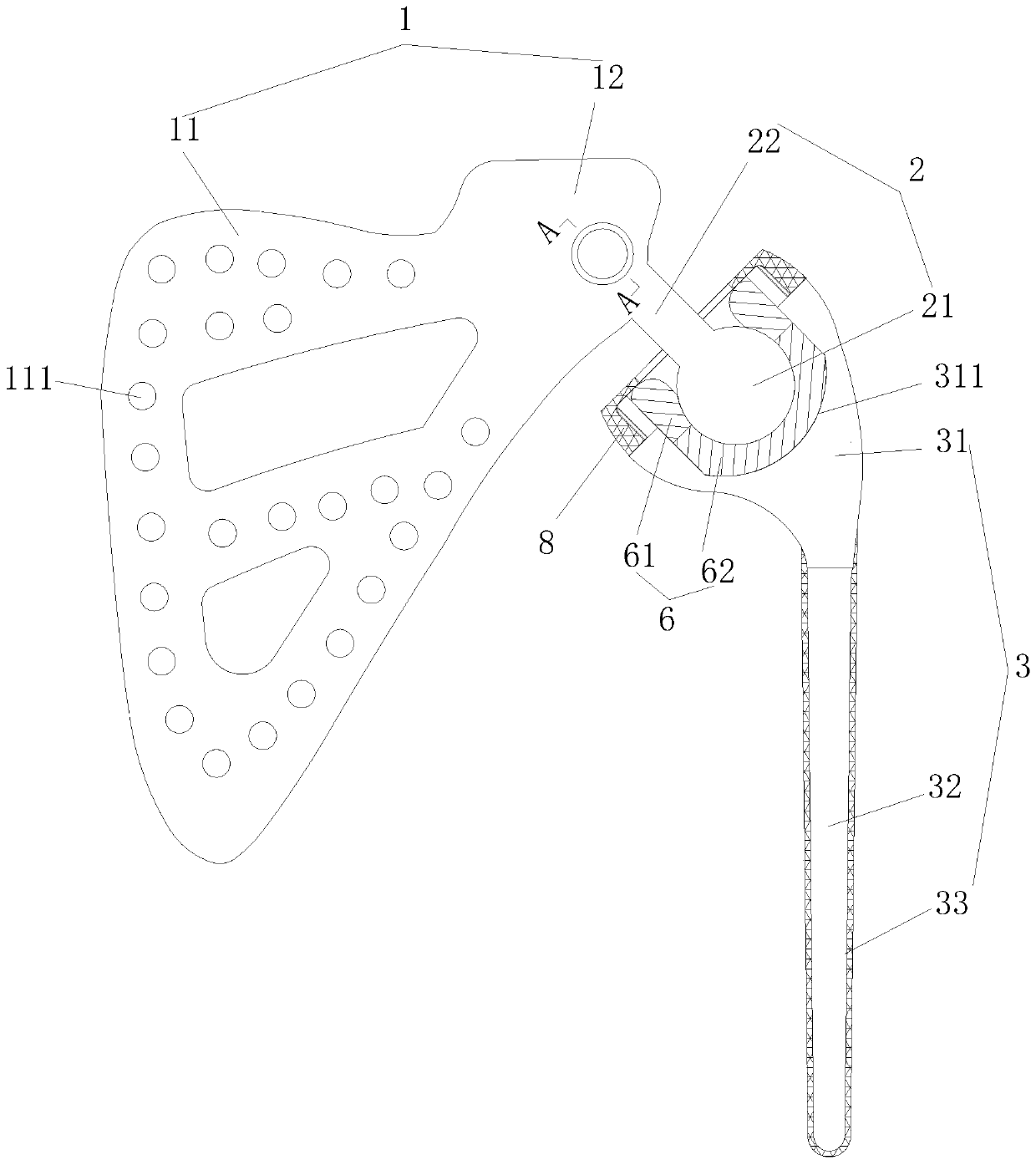

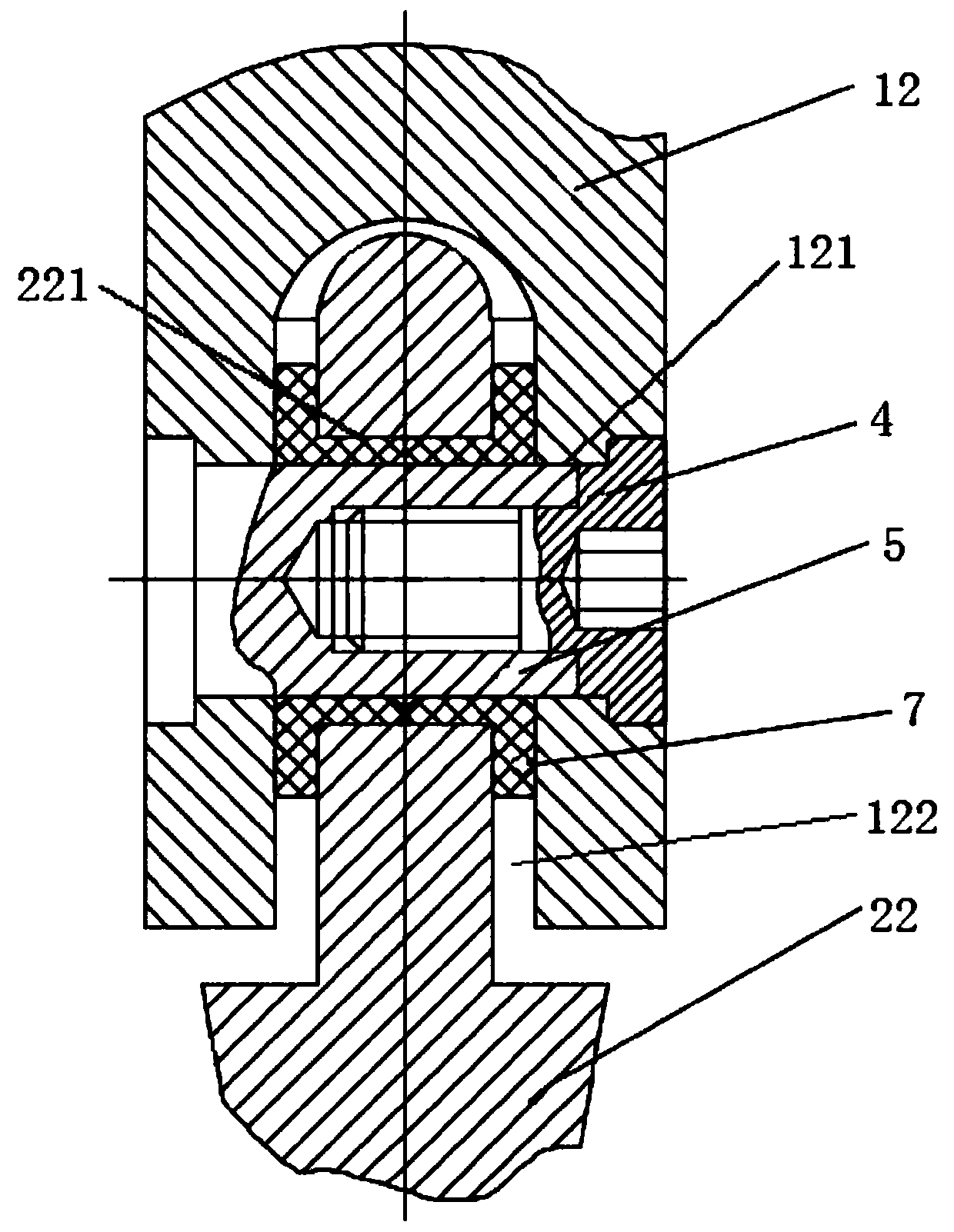

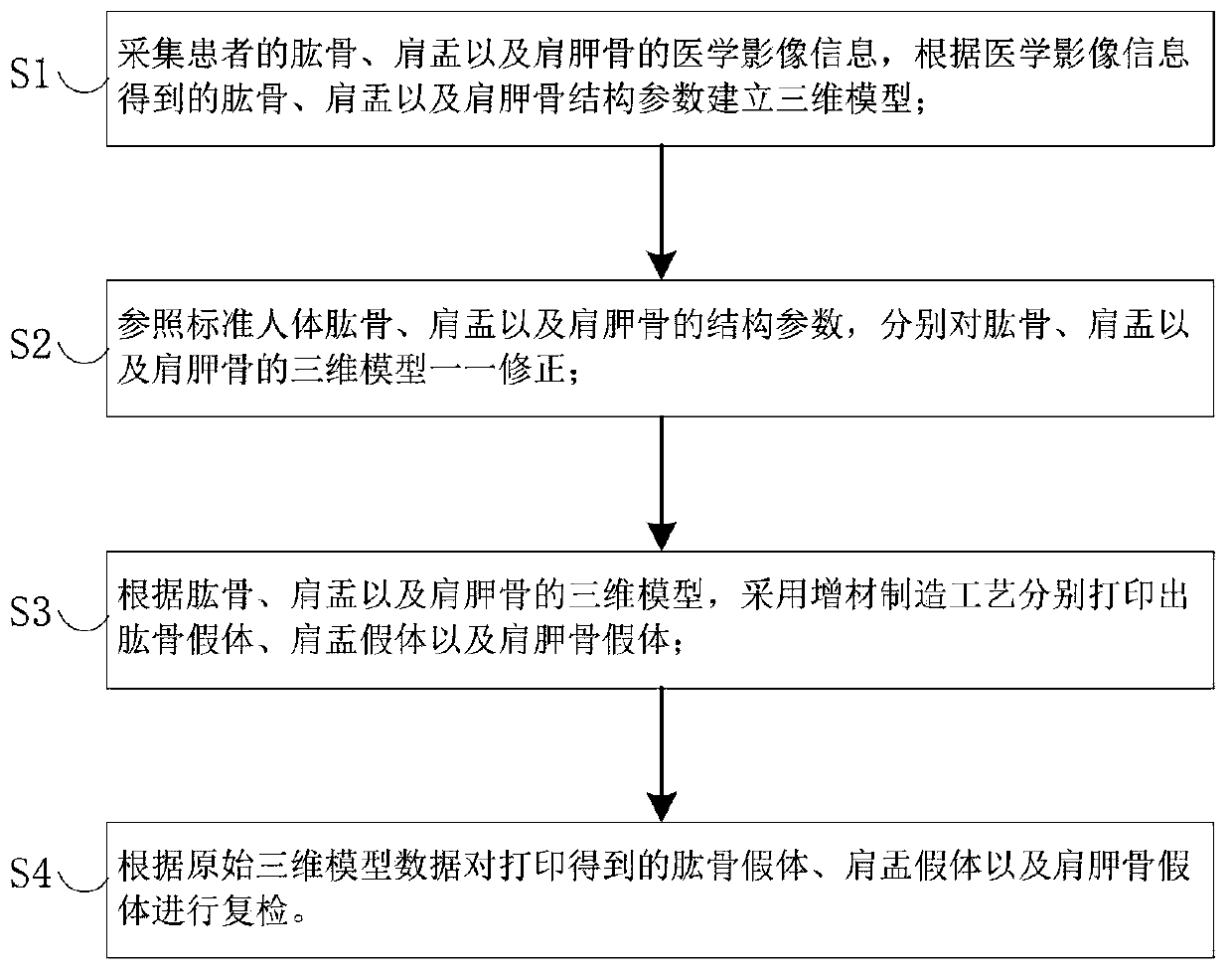

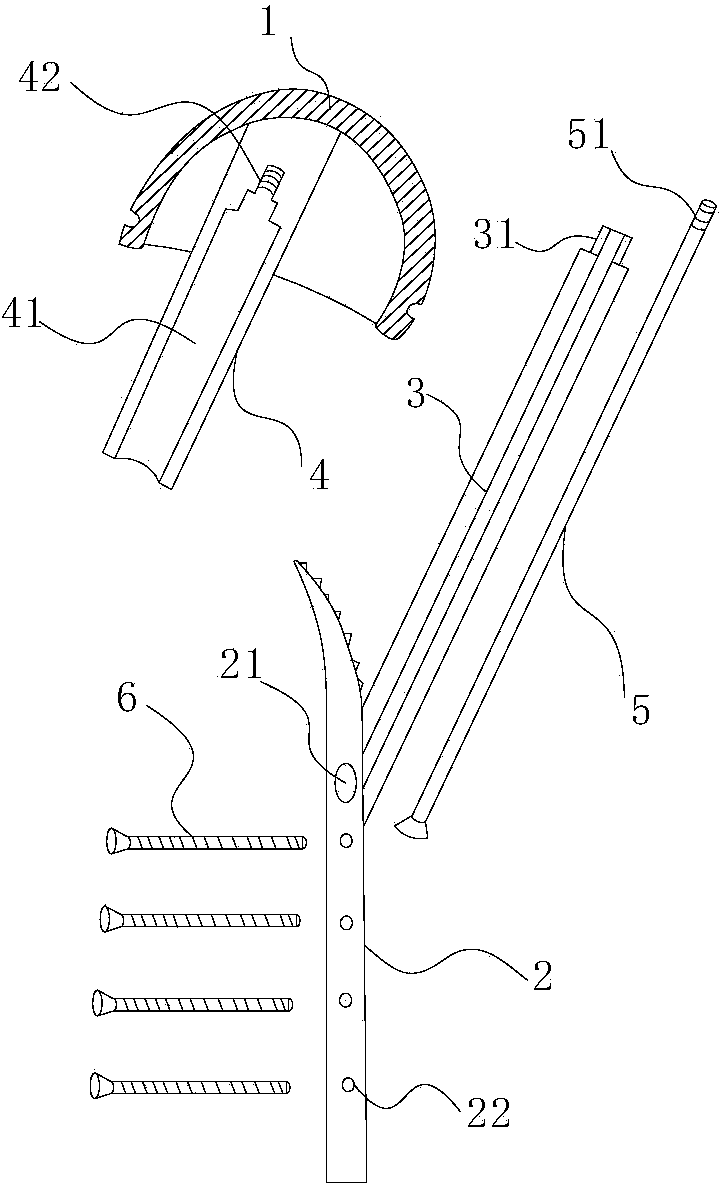

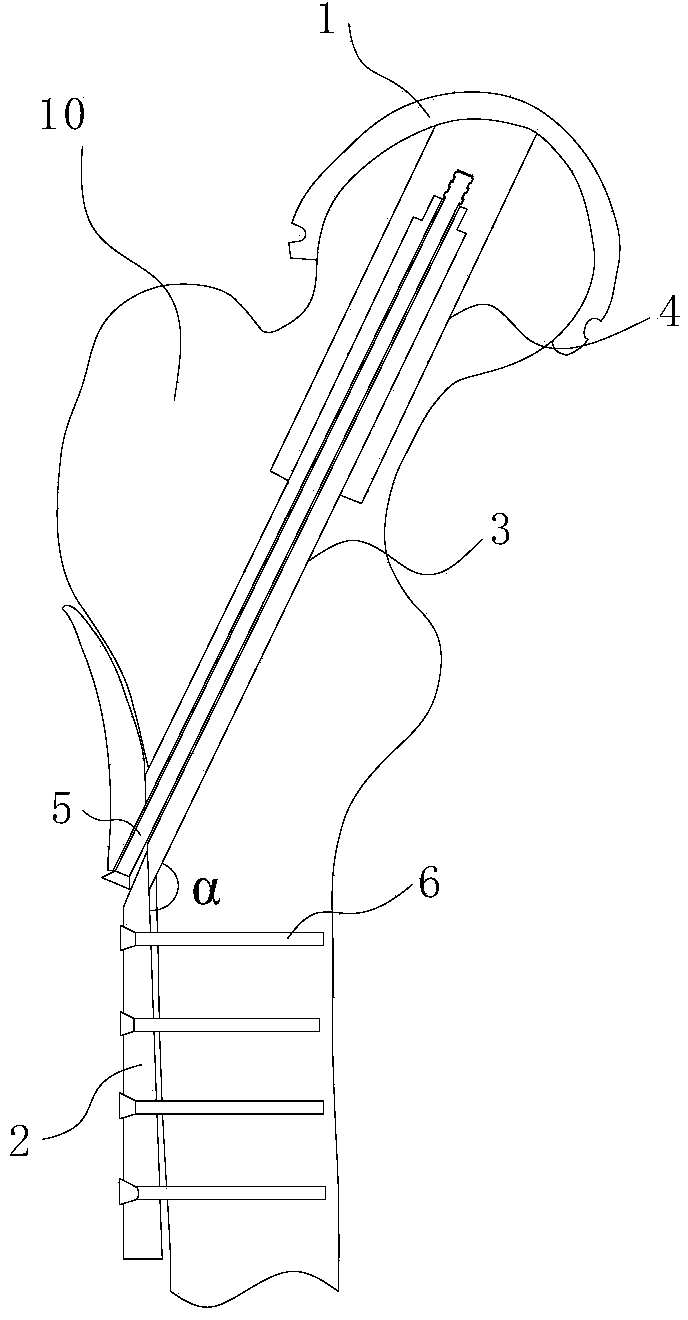

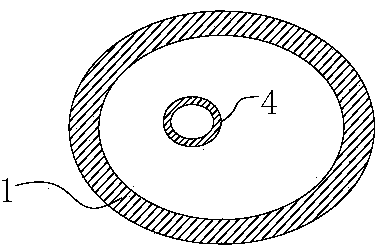

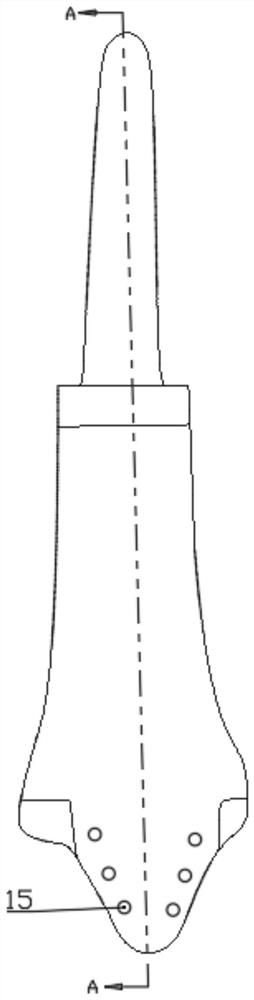

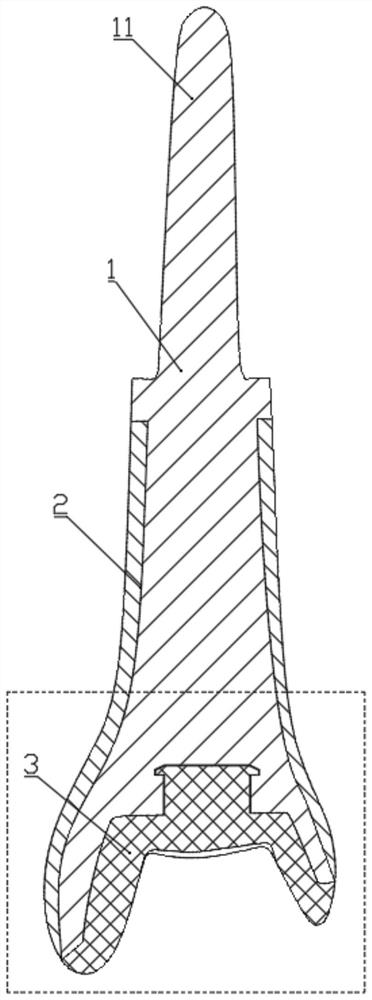

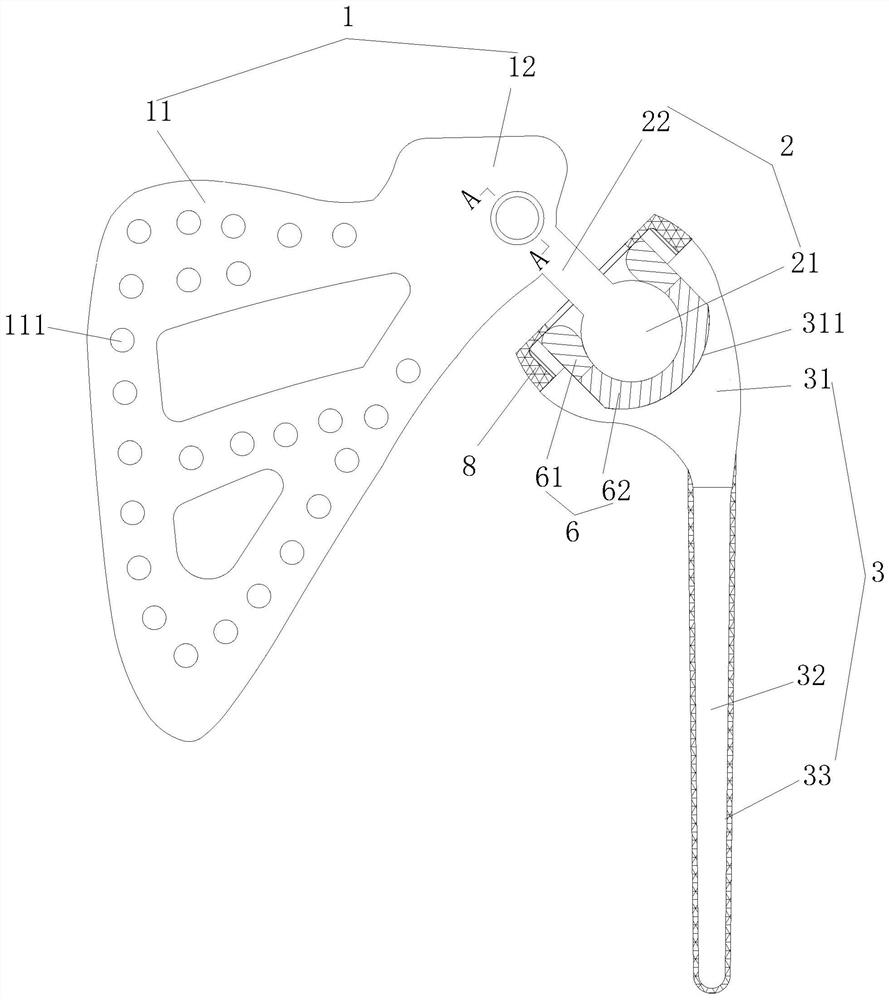

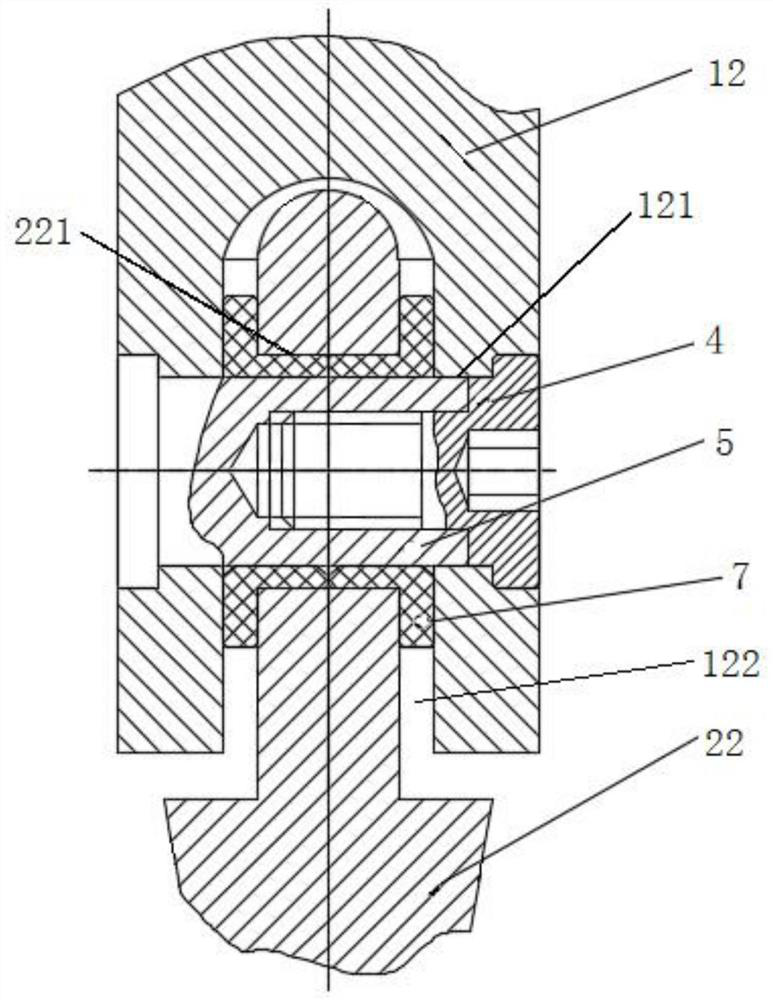

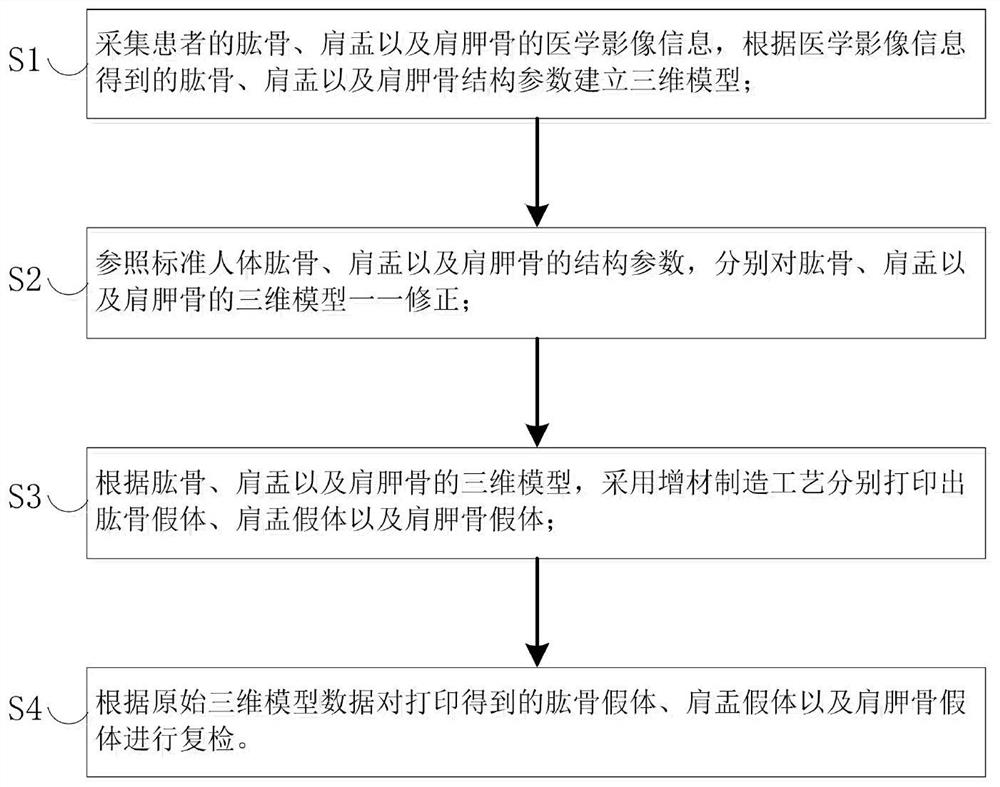

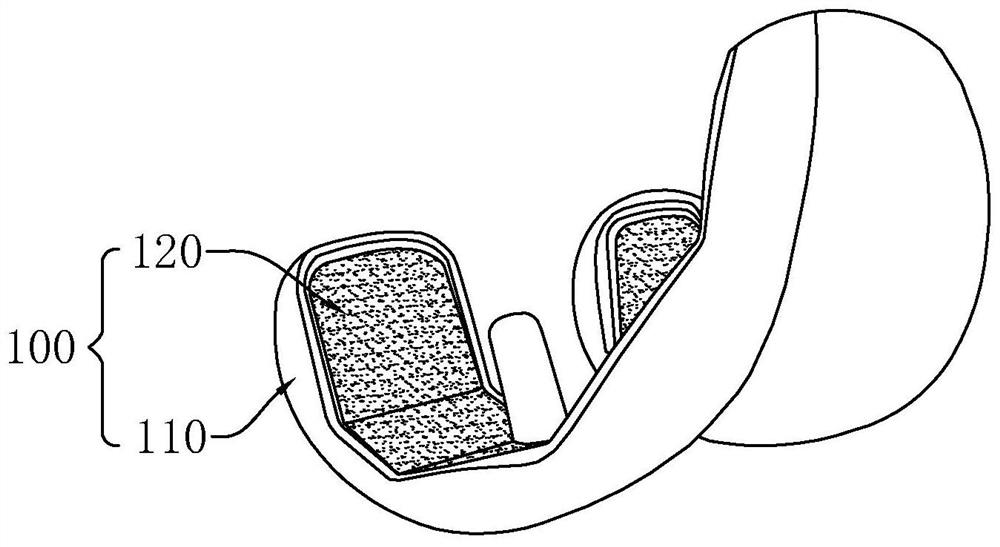

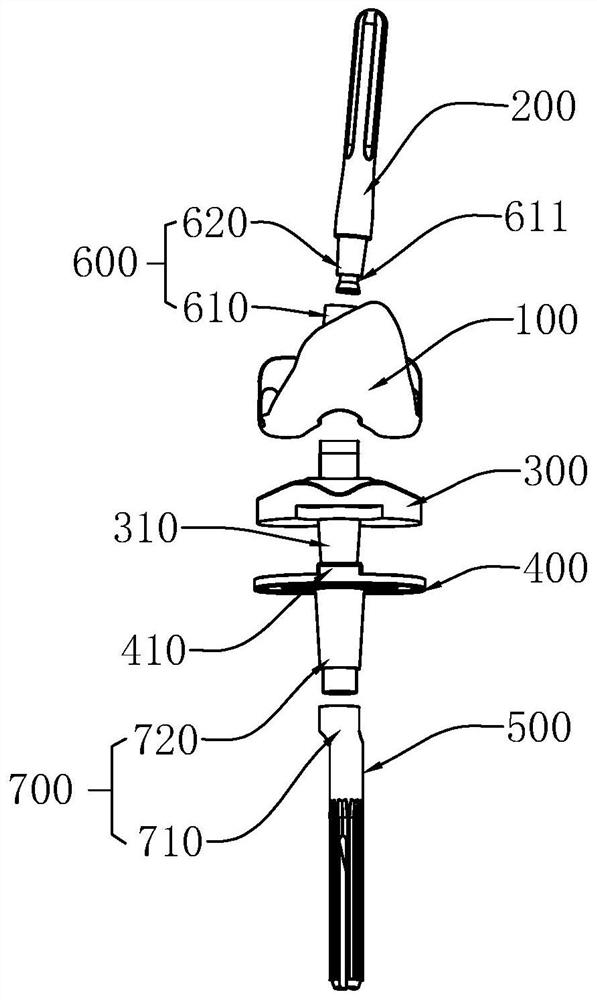

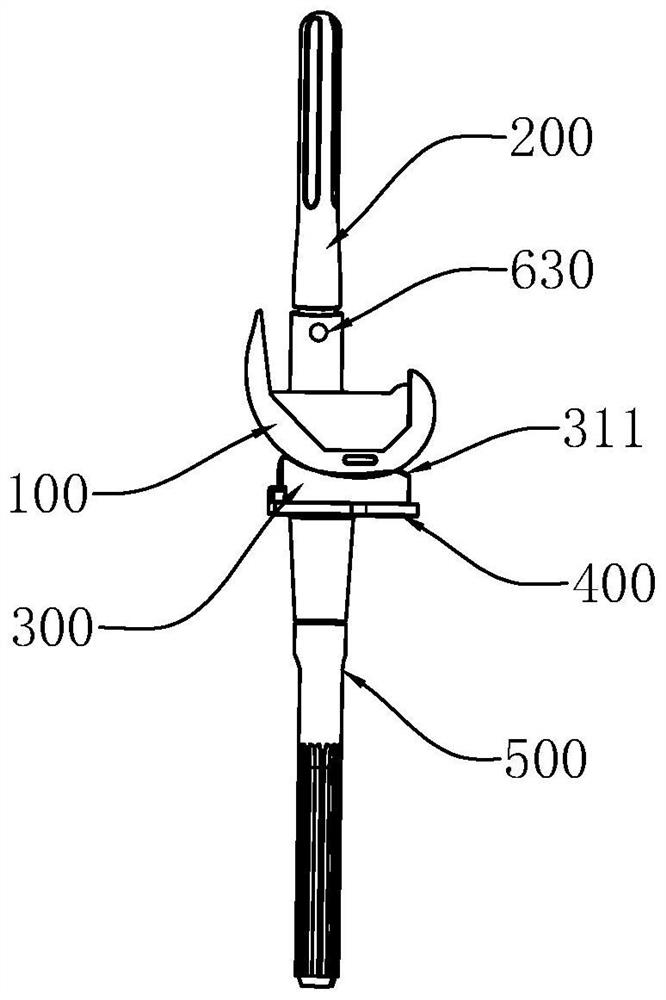

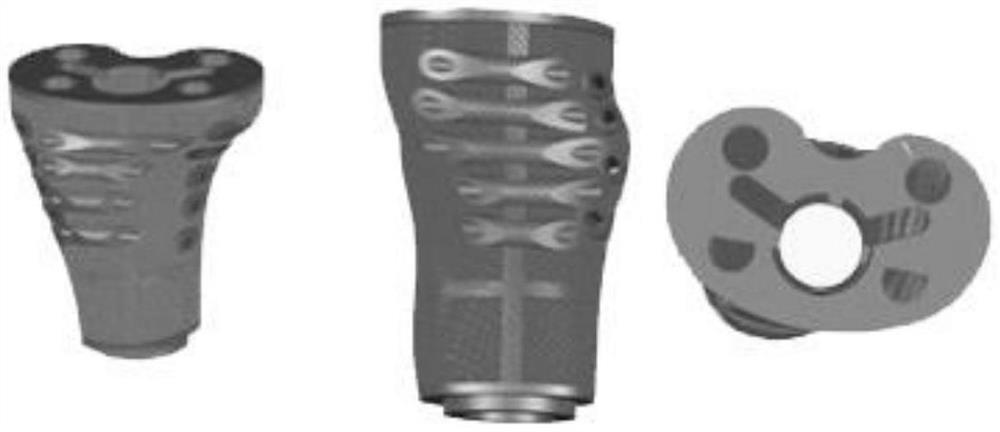

Assembly type shoulder joint prosthesis and manufacturing method thereof

ActiveCN111374805ASolve the errorAvoid printing errorsJoint implantsTomographyBone humerusBone cement

The invention provides an assembly type shoulder joint prosthesis and a manufacturing method thereof. The assembly type shoulder joint prosthesis comprises a scapula prosthesis, a glenoid cavity prosthesis and a humerus prosthesis, wherein the free end of a glenoid cavity supporting rod of the glenoid cavity prosthesis is in movable pivot connection with a glenoid cavity part of the scapula prosthesis; a glenoid cavity bone inner sleeve of the glenoid cavity prosthesis is arranged in a humeral head hinging groove of the humerus prosthesis; and a bone trabecula structure is arranged on the outer wall of a humerus handle in a coating manner. Through the adoption of the assembly type shoulder joint prosthesis disclosed by the invention, a set of the scapula prosthesis, the glenoid cavity prosthesis and the humerus prosthesis which are assembled in a cooperating manner and are mutually connected and in cooperation is provided, so that the prosthetic replacement requirements of a patient ofwhich the humerus, the glenoid cavity and the scapula are damaged can be met, and relative moving relationship between the scapula and the glenoid cavity of the human body is also practically simulated; and the bone trabecula structure is arranged on the outer wall of the humerus handle in a coating manner, so that the human organism can be quickly and firmly adhered to the prosthesis, and the problem that prosthesis loosening is easy to generate through bone cement, and during polymerization of the bone cement monomer, a large amount of heat is released, and periphery tissue damages are generated are solved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

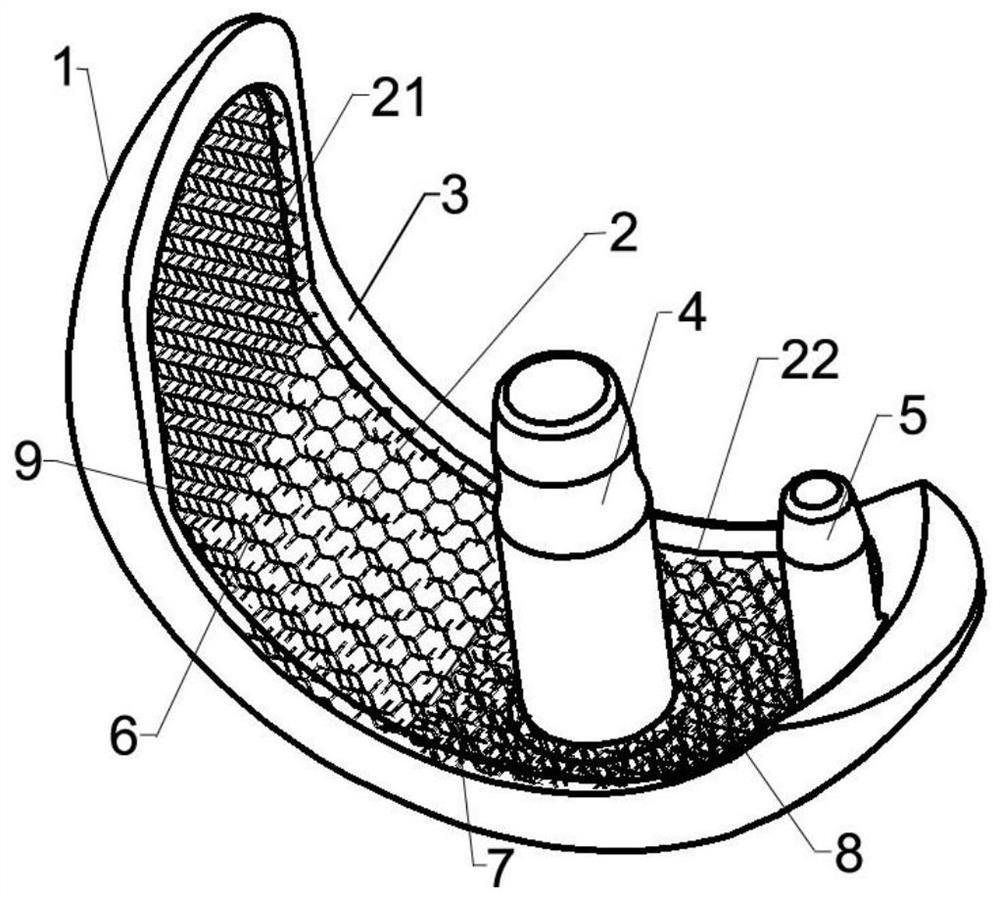

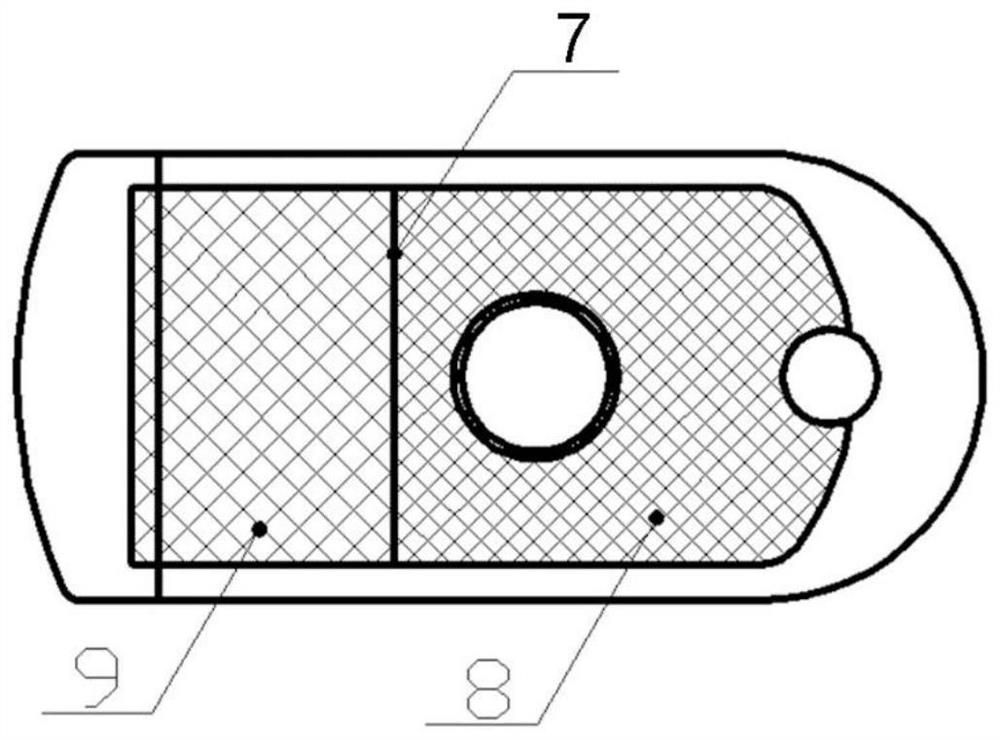

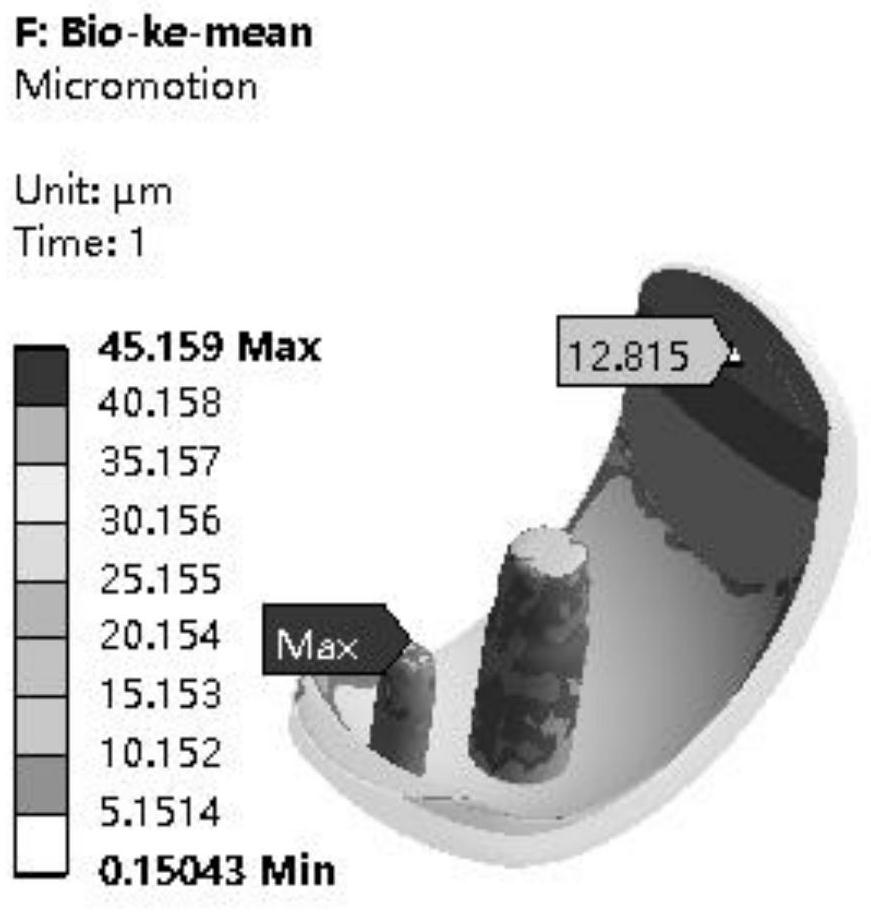

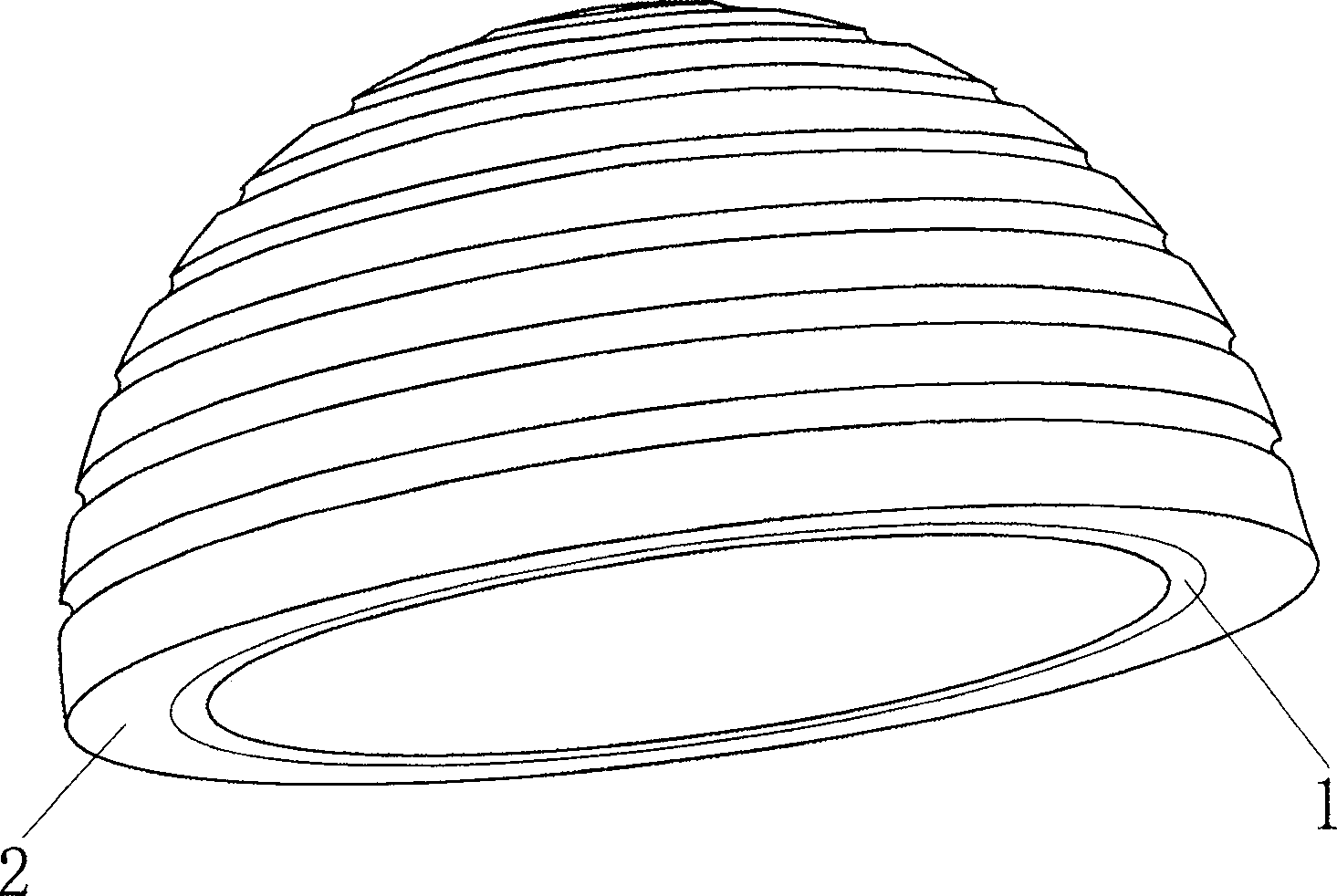

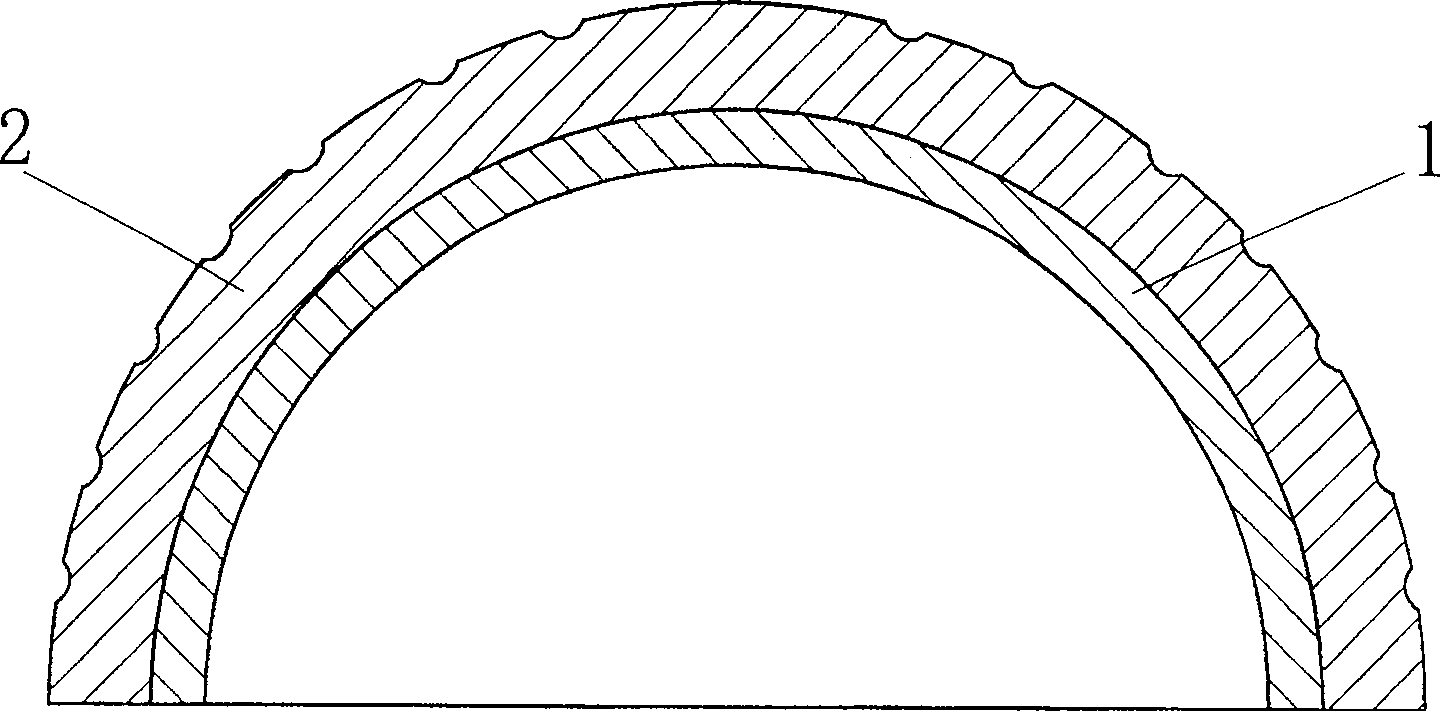

Biotype artificial hip joint surface replacement prostheses

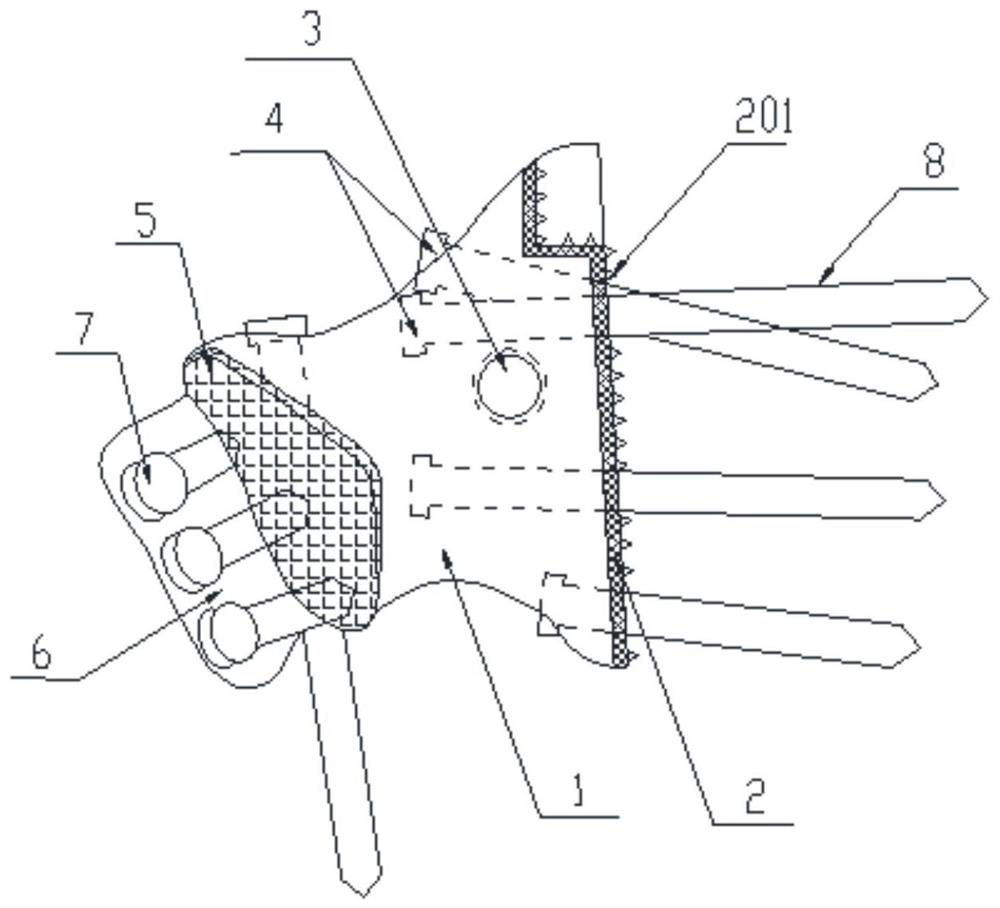

ActiveCN103445886AReduces the possibility of looseningHigh mechanical strengthInternal osteosythesisJoint implantsArtificial hip jointsFemoral bone

The invention discloses a biotype artificial hip joint surface replacement prosthesis comprising a hemispheric prosthesis cap, which is cooperated with the shape of the caput femoris and is disposed on the caput femoris; a carrying steel plate, which is fixedly disposed on one side of the tuberosity of the caput femoris; a carrying column; an inserting column; a main bolt used for fixing the carrying column; and at least one auxiliary bolt. The invention can be used to prevent the loosening of the prosthesis and the fracture of the femoral neck around the prosthesis effectively.

Owner:刘礼初

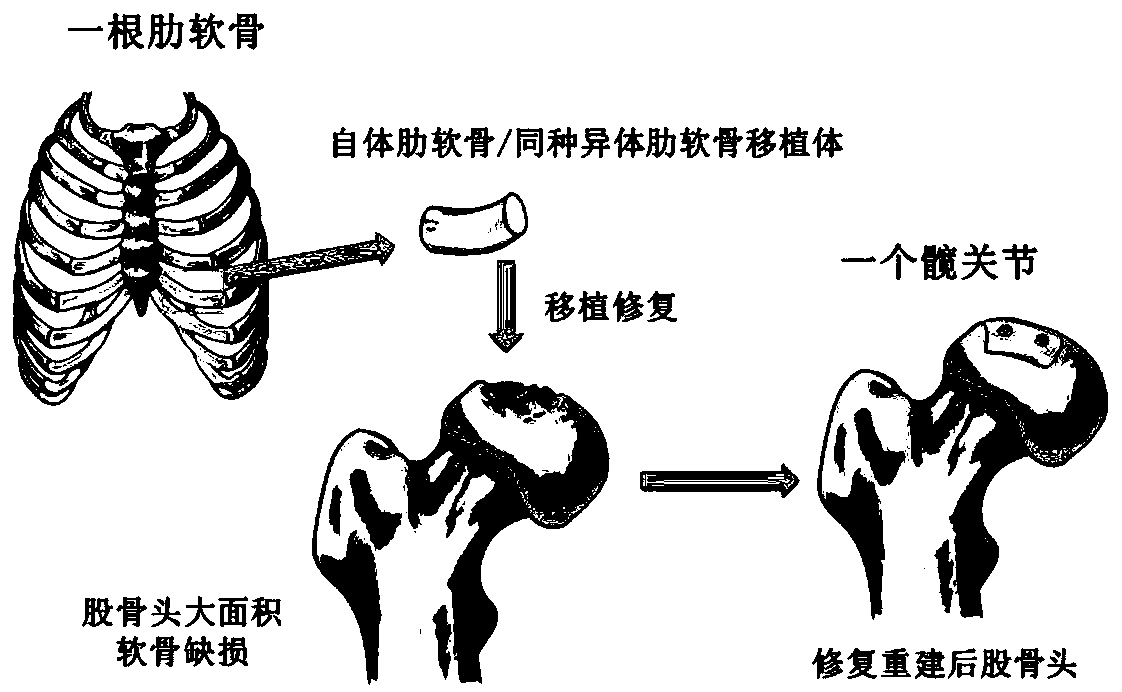

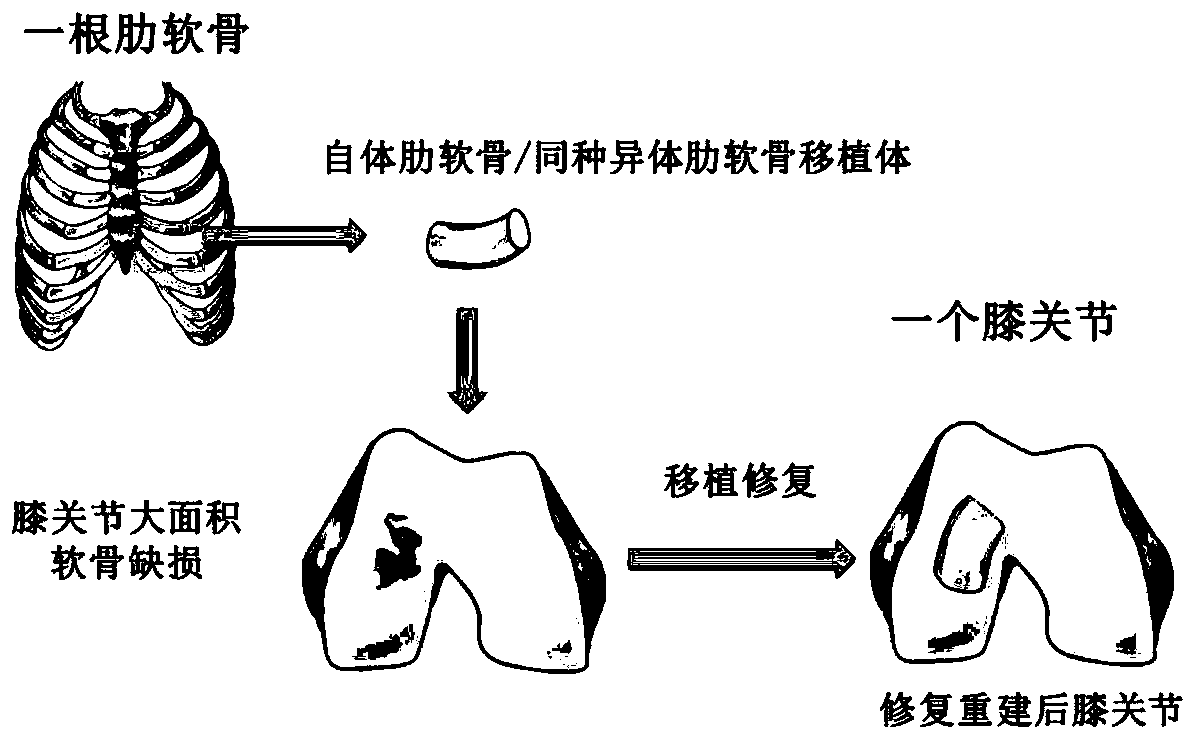

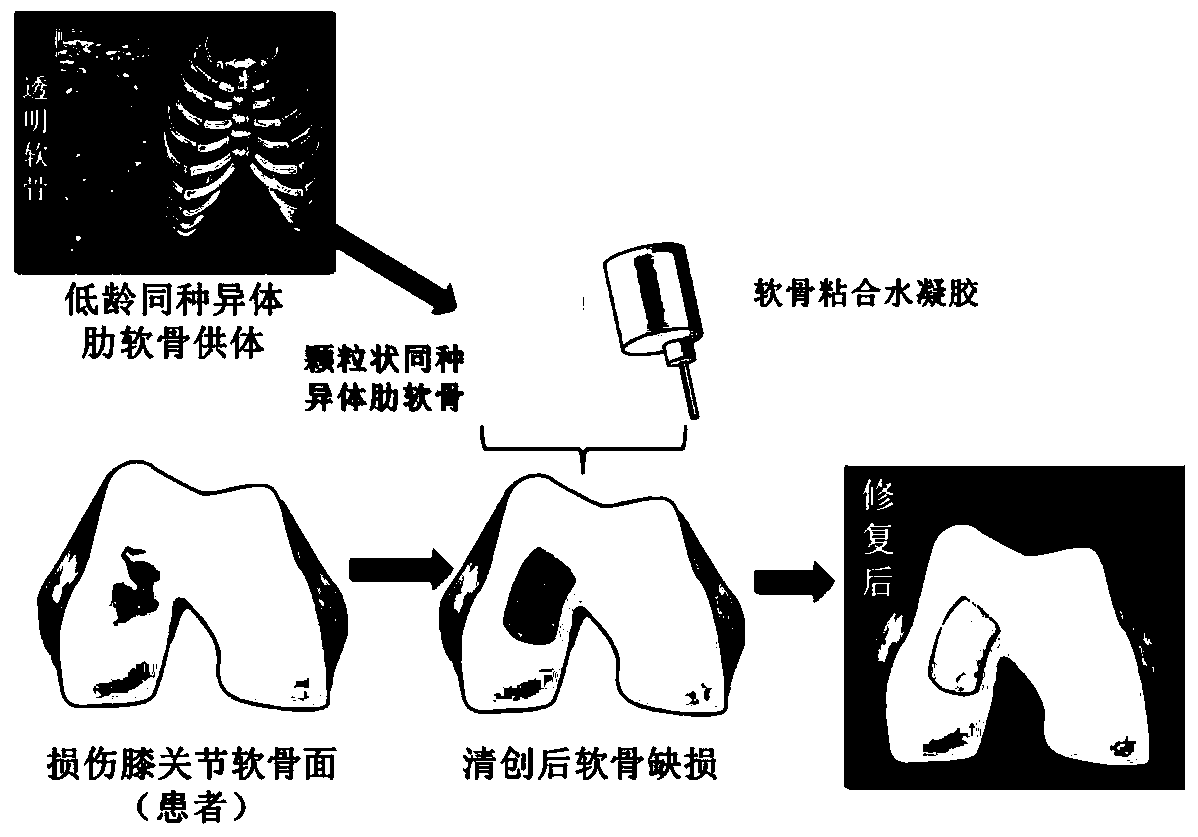

Transplant and method for repairing articular cartilage defects

InactiveCN109893301AAvoid painReduce riskBone implantJoint implantsArtificial jointsSacroiliac joint

The invention provides a transplant for repairing articular cartilage defects. The transplant comprises at least one of autologous costicartilage and allogeneic costicartilage; the transplant can be specially a whole-section costicartilage or cartilage particle combined hydrogel transplant. The invention further relates to application of the transplant and a method for repairing the articular cartilage defects. The transplant and method for repairing the articular cartilage defects and the application of the transplant have the advantages that by adopting costal cartilage grafting, vice-damageis small, and minimally invasive operation can be carried out to avoid the risk of prosthesis loosening, infection and other complications which are caused by artificial joint replacement; the amountof the costicartilage is sufficient, and the needs of multiple times of cartilage reconstruction and revision surgeries can be met; it can be achieved that the reconstruction of the damaged articularcartilage surface is personalized, and the repairing method with higher safety and stronger operability is provided for patients with the articular cartilage defects.

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

Combined femoral stem

The invention relates to the technical field of medical prostheses, in particular to a combined femoral stem. The combined femoral stem comprises a stem body, a femoral neck and a filling layer, wherein the stem body is provided with a mounting groove; one end of the femoral neck extends into a mounting groove; the filling layer is stuffed between the femoral neck and the inner wall of the mounting groove, and the filling layer is fixedly connected with the stem body and the femoral neck. According to the combined femoral stem, the stem body and the femoral neck are of a split structure, the femoral neck with different forward inclination angles can be prepared, the combined femoral stem can adapt to wider forward inclination angle changes, the choice of a patient is increased, and besides, compared with an existing integrated femoral stem structure, the production cost can be reduced. The femoral neck and the stem body are connected through the filling layer, so that connection firmness of the femoral neck and the stem body is guaranteed, the problem of fretting abrasion of an existing press-fit type femoral stem is solved, and the problem of prosthesis looseness and failure caused by osteolysis is also solved.

Owner:WUHAN UNITED IMAGING HEALTHCARE SURGICAL TECH CO LTD

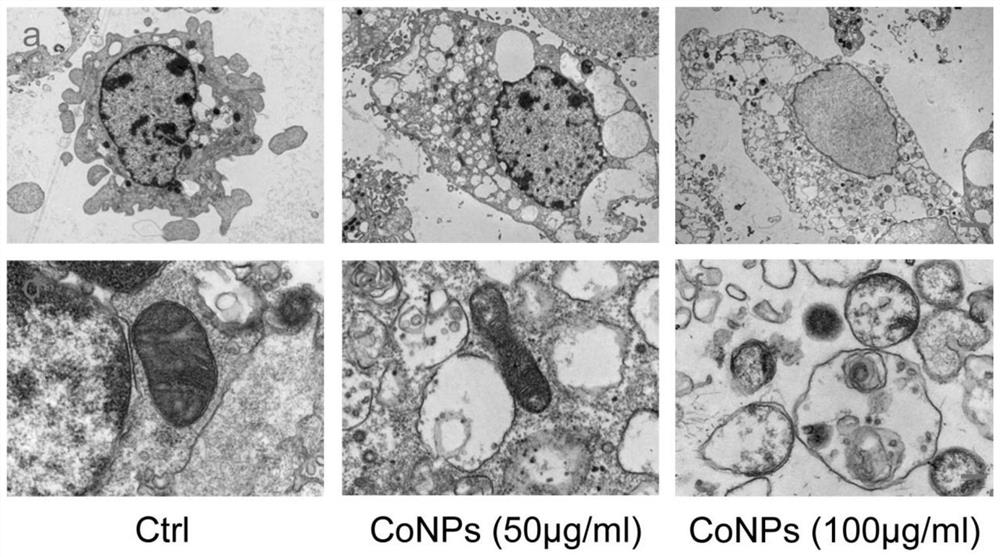

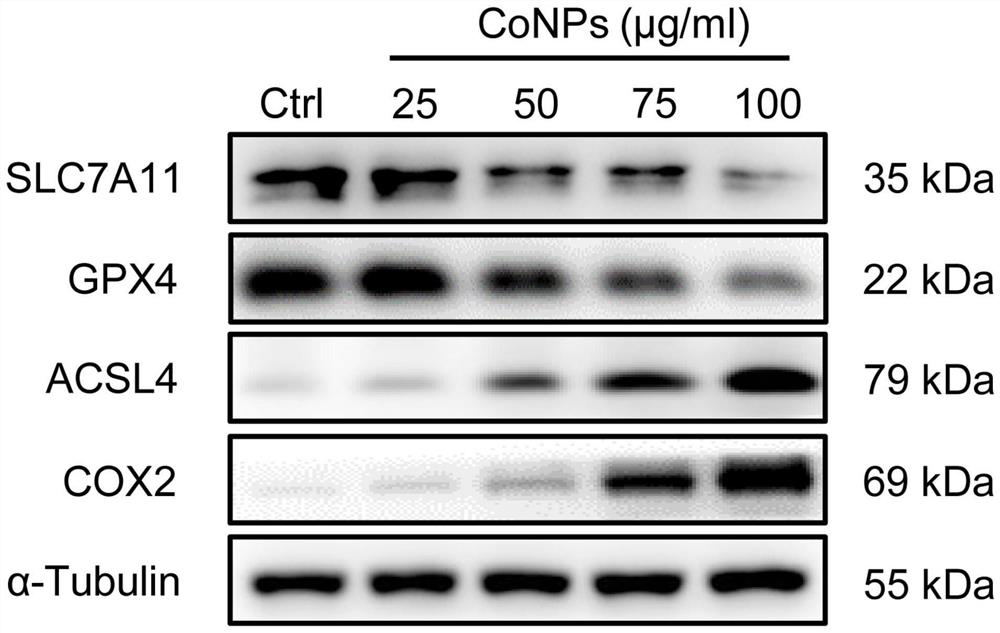

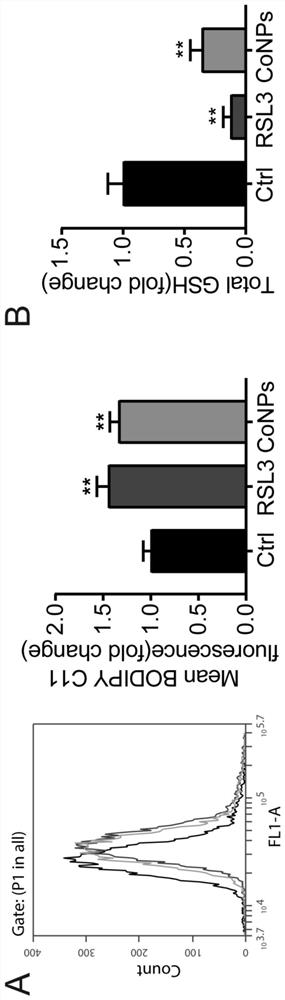

Application of Ferrostatin-1 in preparation of medicine for resisting periprosthetic osteolysis induced by wear particles of joint prosthesis

ActiveCN113440509AInhibition of ferroptosisBreak the balanceOrganic active ingredientsAntinoxious agentsIntraperitoneal routeOsteocyte

The invention discloses application of Ferrostatin-1 in preparation of a medicine for resisting prosthesis looseness induced by wear particles derived from an artificial joint prosthesis, and research shows that the wear particles of the joint prosthesis can induce excessive accumulation of reactive oxygen species (ROS) in osteoblasts, inhibit the function of an osteoblast cystine / glutamic acid antitransporter (System Xc-), and reduce the ROS removing capability of glutathione peroxidase 4 (GPX4), so that ROS generation and degradation homeostasis are disordered, secondary ferroptosis of osteoblasts is caused, and the balance between osteoclasts and osteoblasts is broken. After the ferroptosis specific inhibitor Ferrostatin-1 is added, the content of the GPX4 in cells is obviously increased, the stimulation of the wear particles to the generation of ROS in the osteoblasts is obviously inhibited, and the ferroptosis of the osteoblasts is reduced. In addition, a mouse skull osteolysis model is established by implanting the CoCrMo nano wear particles under the skin of a mouse skull, effective intervention is applied by intraperitoneal injection of the Ferrostatin-1, and an in-vivo experiment further proves that the Ferrostatin-1 has a remarkable inhibition effect on osteolysis induced by the wear particles.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

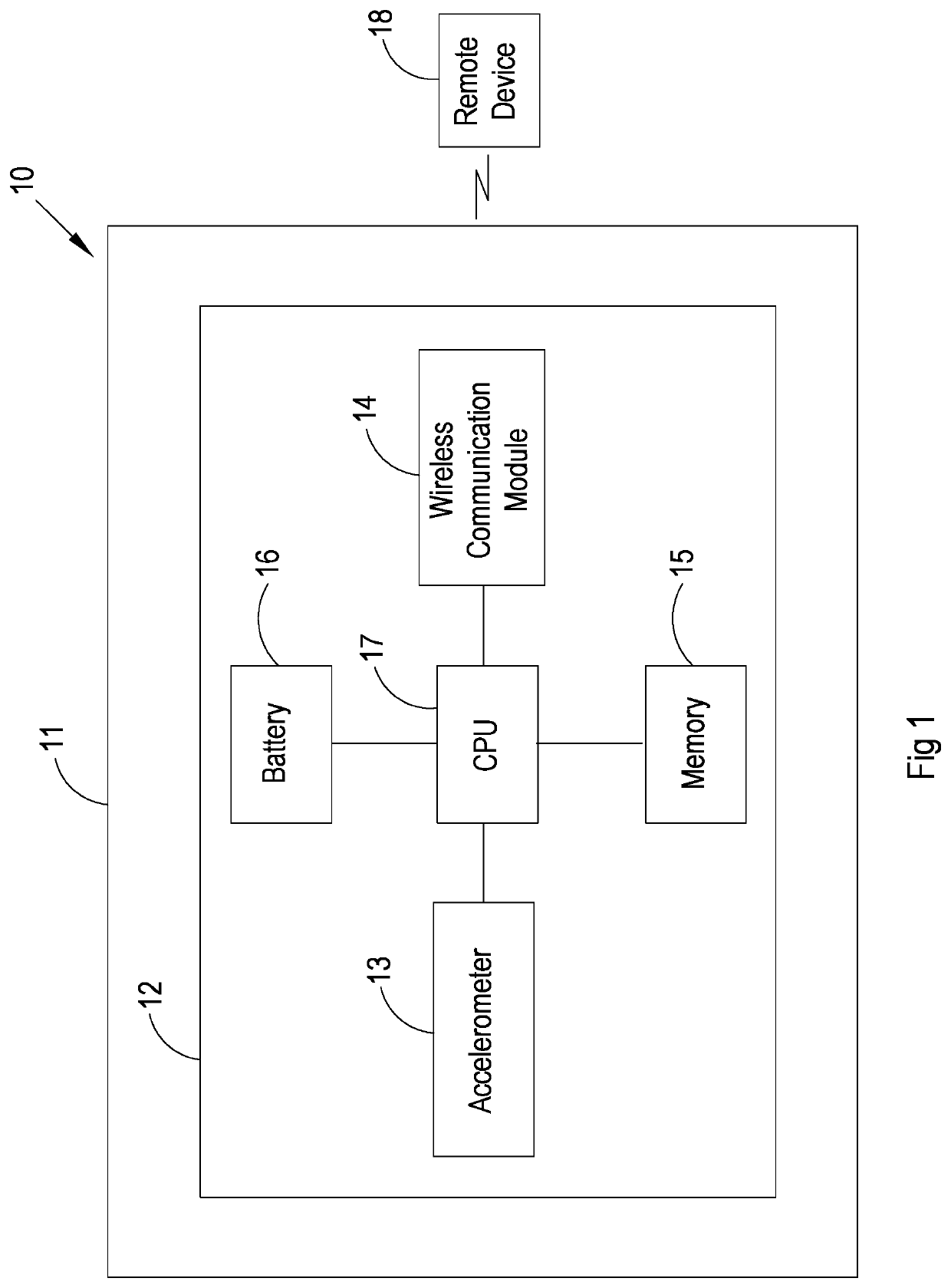

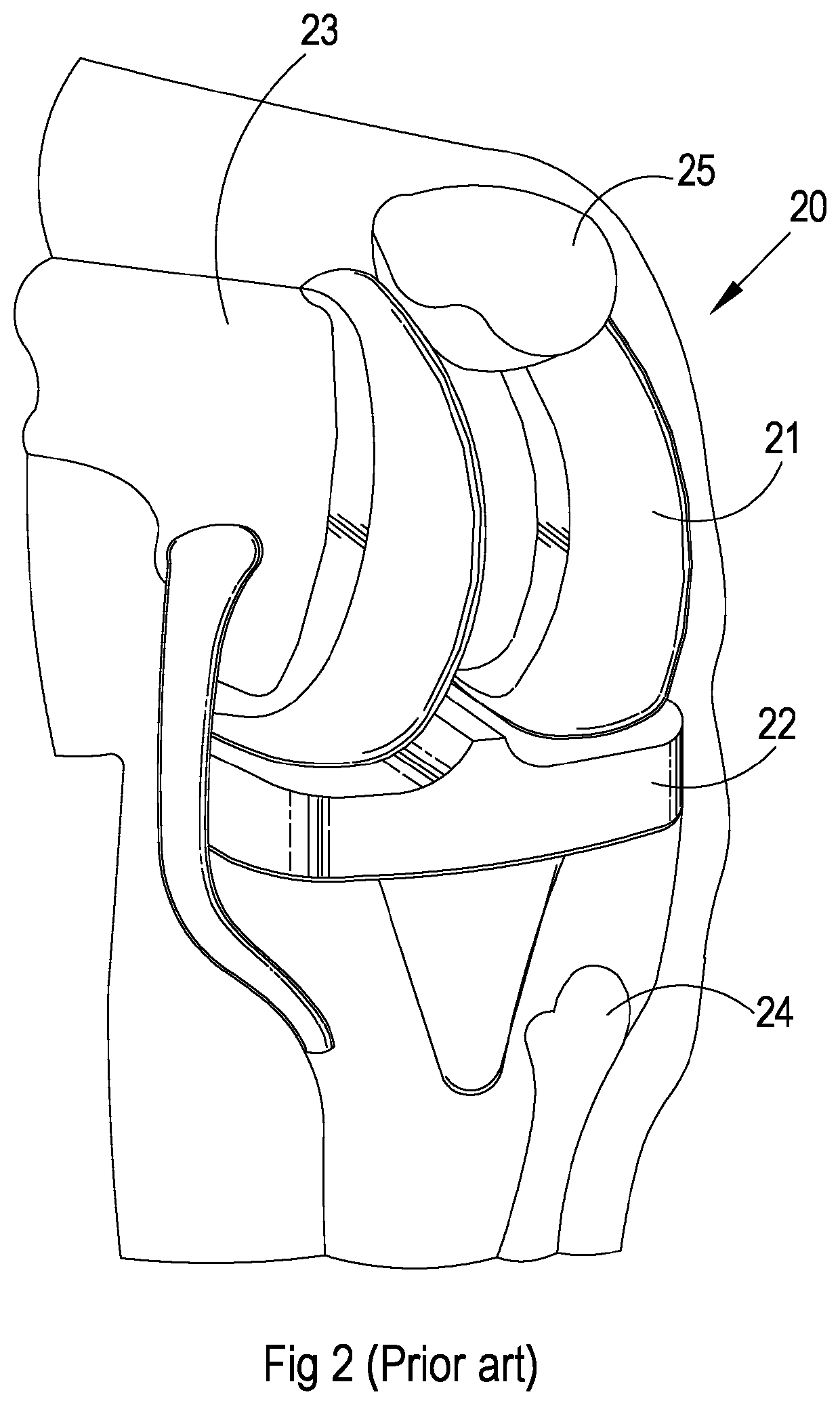

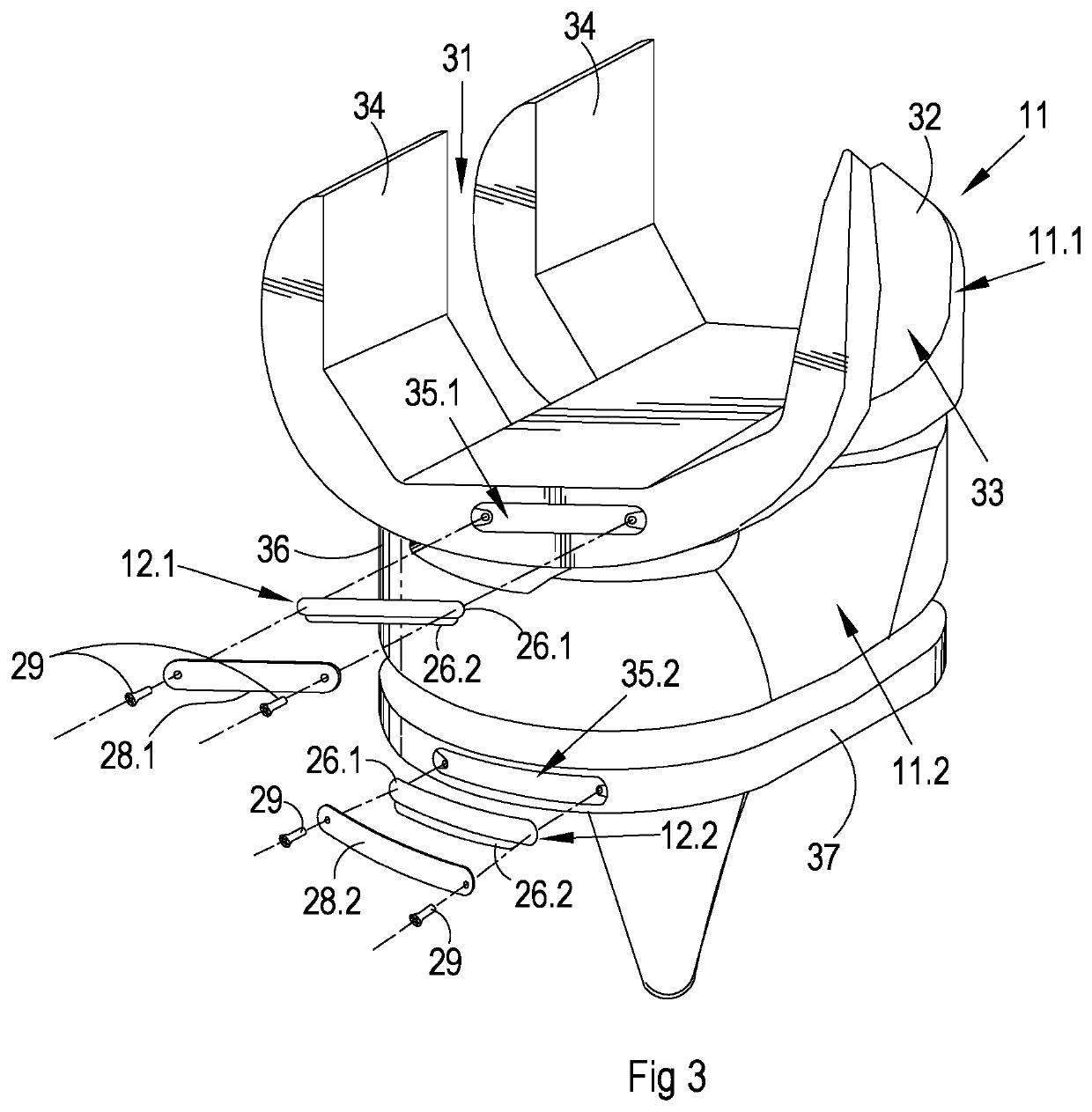

Implantable electronic device and endoprosthesis

An implantable electronic device (12) and an endoprosthesis activity monitoring system (10) with a knee prosthesis (11) are developed. Knee prosthesis (11) has at least two blind cavities (35.1, 35.2), one in a lateral aspect of a femoral component (11.1) or tibial component (11.2), within which devices (12) are removably mounted and remote device (18) in wireless communication with devices (12) to receive data transmitted from it. Devices (12) are configured to track movement of the prosthesis (11) and to report same to the remote device (18). Devices (12) are self-contained and include an accelerometer (13), memory (15), a wireless communication module (14), processor (17) and a battery (16). Activity information analysed allows for early diagnosis of implant specific problems like loosening of the prosthesis. Location of devices (12) in the lateral aspects improves accessibility. Devices can be removed by minor surgery without compromising structural integrity of the knee prosthesis.

Owner:MOKETE LIPALO

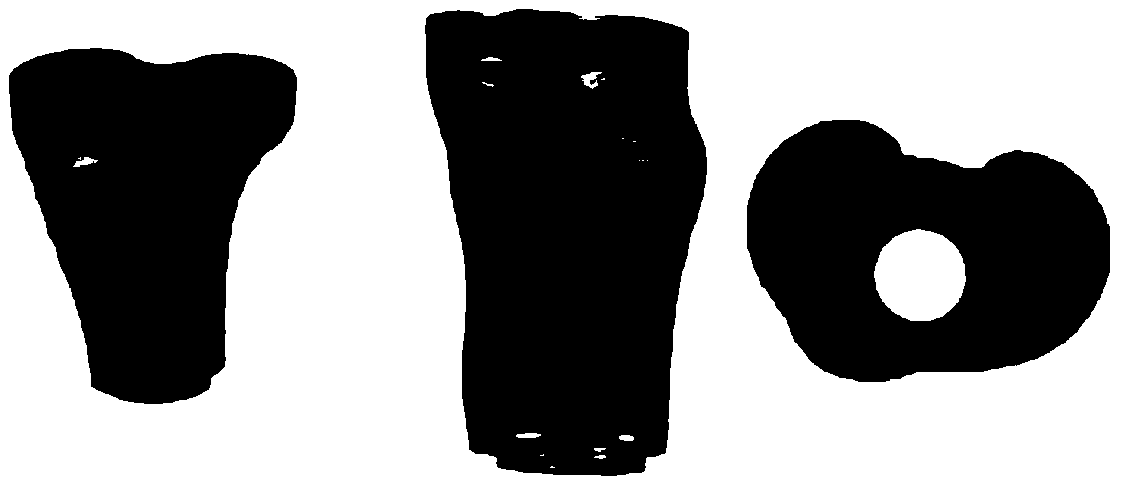

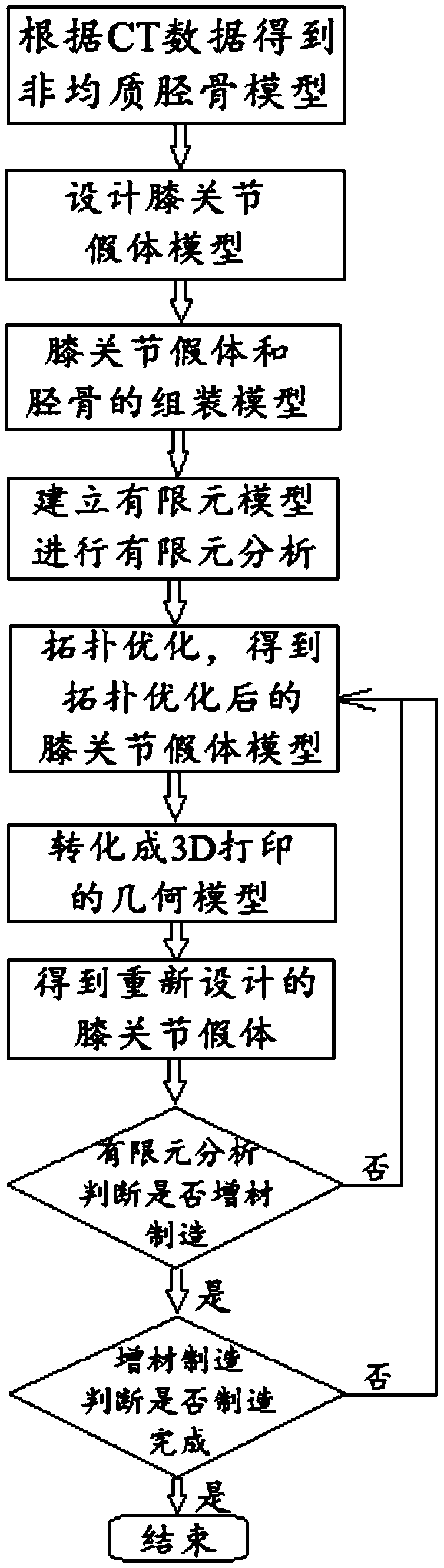

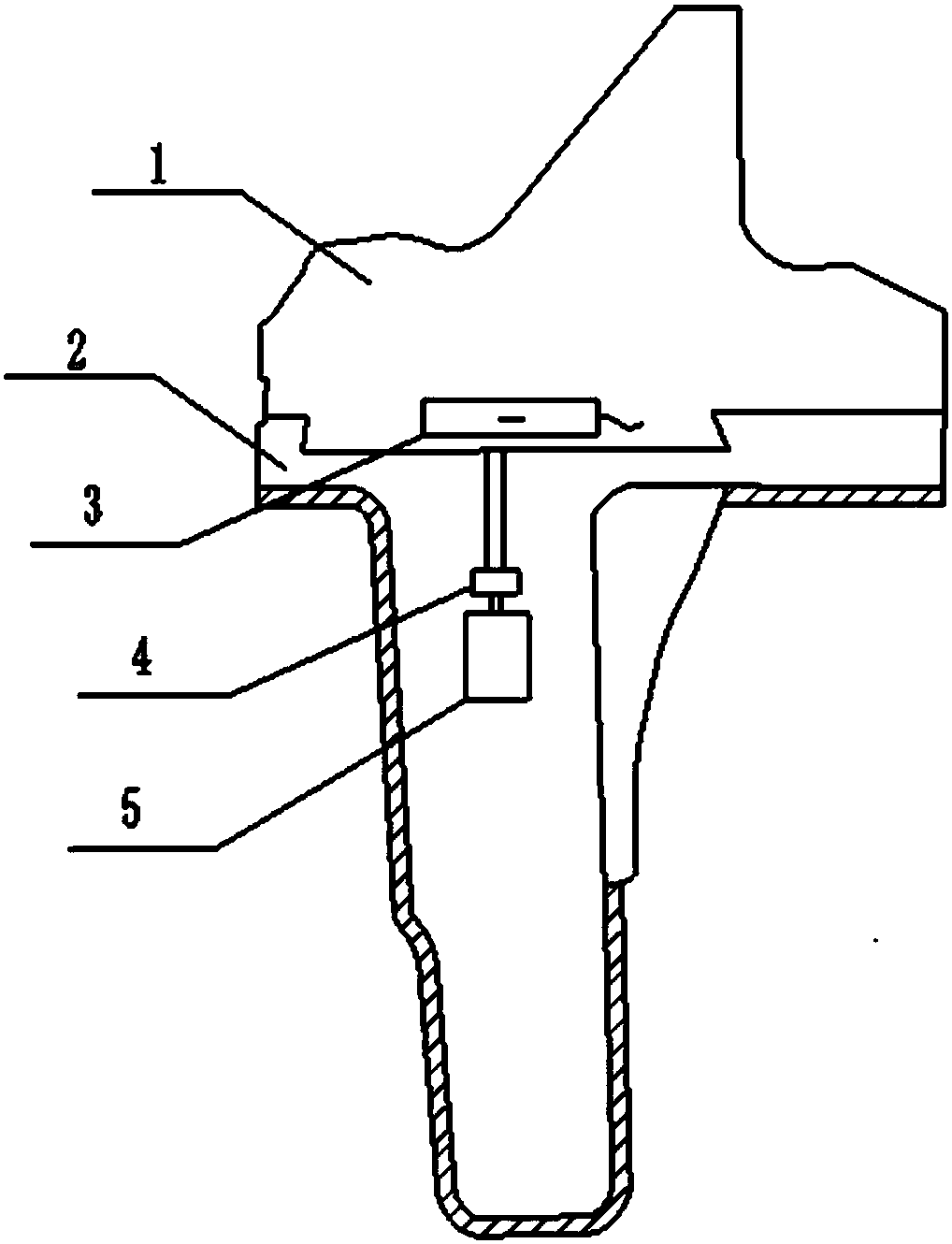

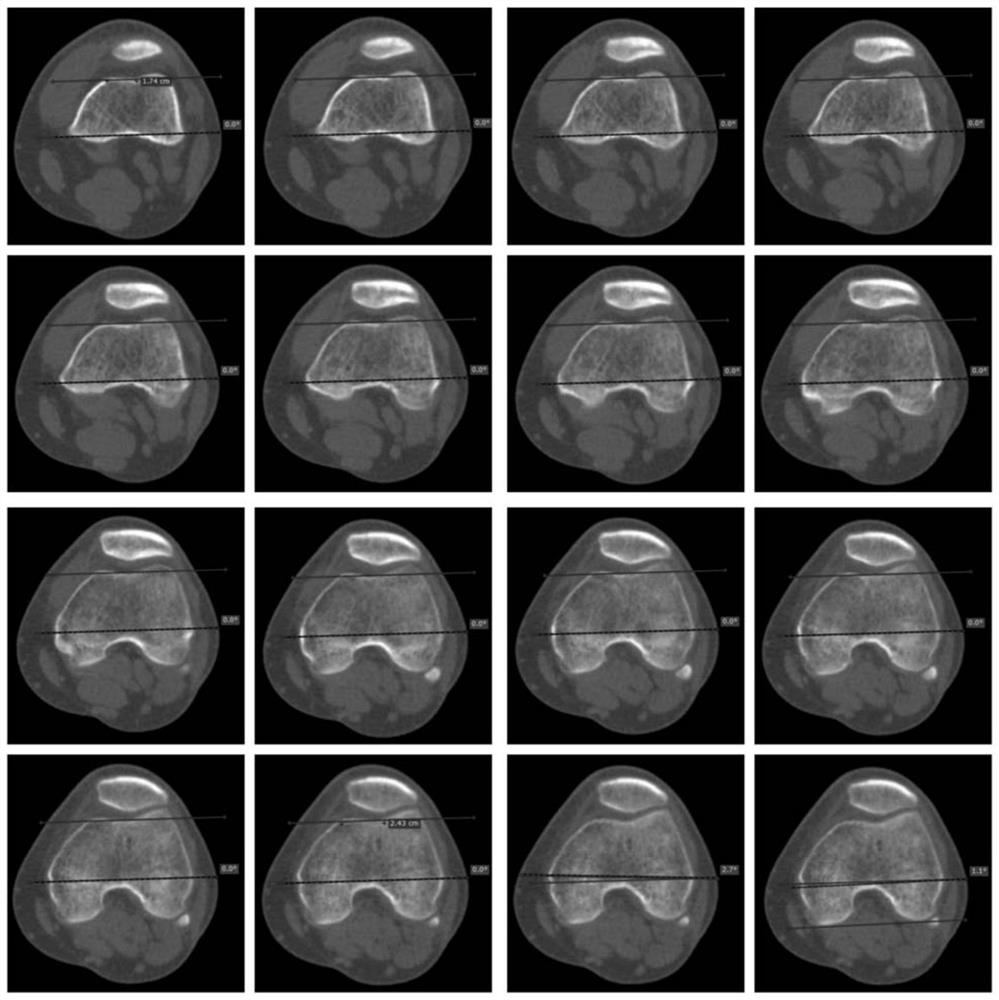

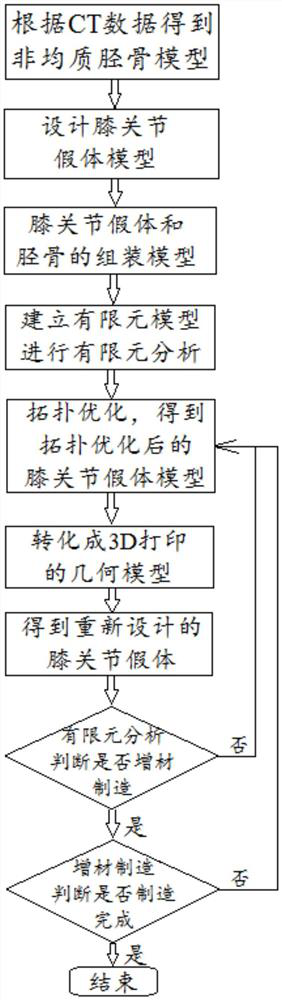

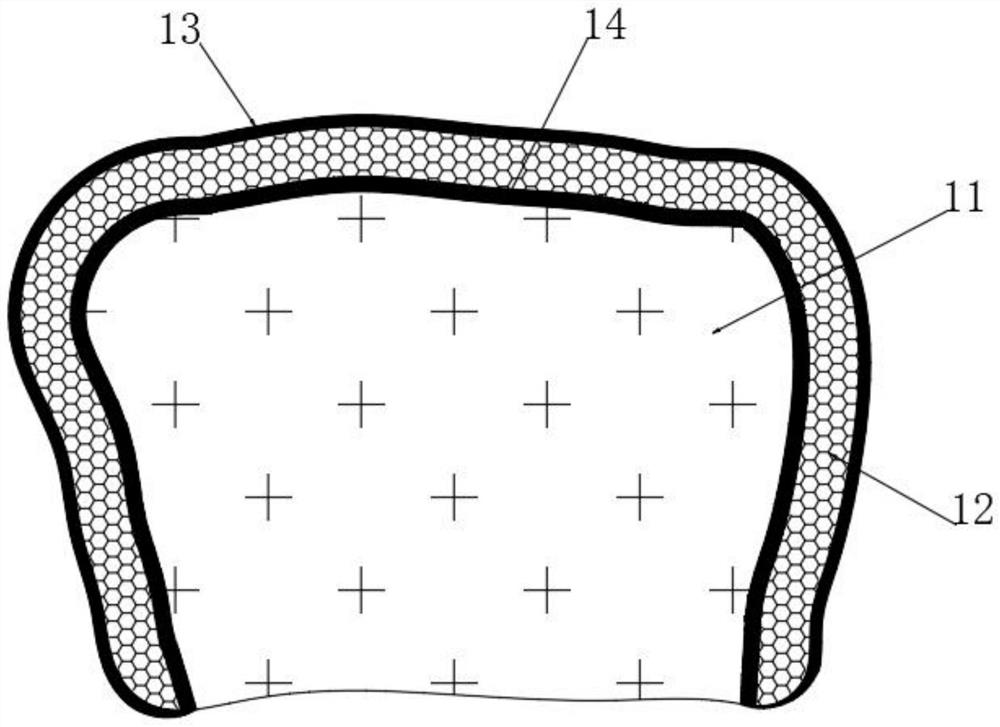

Manufacturing method of individualized customized knee joint bionic prosthesis based on 3D printing

ActiveCN110833472AUniform stress distributionGood biomechanical propertiesJoint implantsTomographyElement analysisKnee Joint

The invention discloses a manufacturing method of an individualized customized knee joint topological optimization bionic prosthesis based on 3D printing, which relates to the technical field of medical artificial joints. The problem that the manufacturing method is urgently needed to reduce prosthesis looseness or fracture around the prosthesis is solved, and the method comprises the steps: establishing and assembling a tibia model and a knee joint prosthesis model, and performing finite element analysis and topological optimization; carrying out fairing; designing a specific structure of themodel, optimally reserving an internal region by adopting a solid structure, optimally reserving an outer layer region and optimally removing the region by adopting a grid structure, and forming a gradient between the regions; introducing back an assembly state of a tibia model, performing finite element analysis, comparing with a first finite element analysis result, judging whether 3D manufacturing and application are performed or not, and performing topological optimization again if the 3D manufacturing and application cannot be performed. The prosthesis prepared by the invention reduces the problem of prosthesis looseness or prosthesis peripheral fracture, provides space for ligament stop point implantation and internal bone grafting, is light in weight, and is beneficial to bone tissue ingrowth.

Owner:JILIN UNIV

Customized bone-like trabecular structure knee joint prosthesis and manufacturing method

The invention discloses a customized bone-like trabecular structure knee joint prosthesis, including a tibia holder and a tibia pad. A tibia medullary space is formed between the tibia holder and thetibia pad. The tibia medullary space is provided with a bone trabecular grid structure. Appearance of an upper end and a lower end of the knee joint prosthesis meets a human body anatomical structureand fits the medullary space. A PEEK material is used to reduce product weight, stress shielding is reduced, and conditions of bone resorption and prosthesis loosening are prevented. The tibia pad component is provided with an induction device, and an adjusting mechanism and a control structure are arranged in the tibia holder. An objective of installing the induction device is that through adjusting pressure between a femoral condyle and the tibia pad by the device, pressure of a gasket, applied by a femoral condyle prosthesis part, is better balanced, so that the inner side and the outer side of bones on a distal femur and a tibia near-end have uniform pressure. Bone loss and prosthesis failure caused by life styles and other factors are eliminated, and the knee joint prosthesis improvesmedium and long term life of a patient prosthesis.

Owner:北京中安泰华科技有限公司

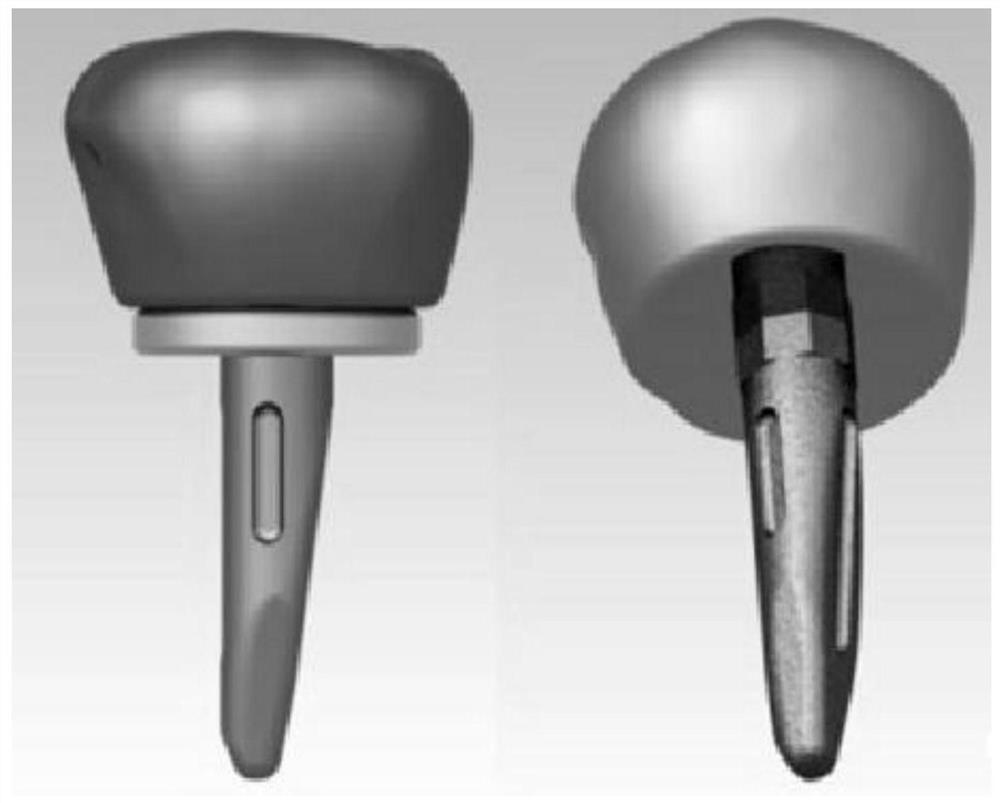

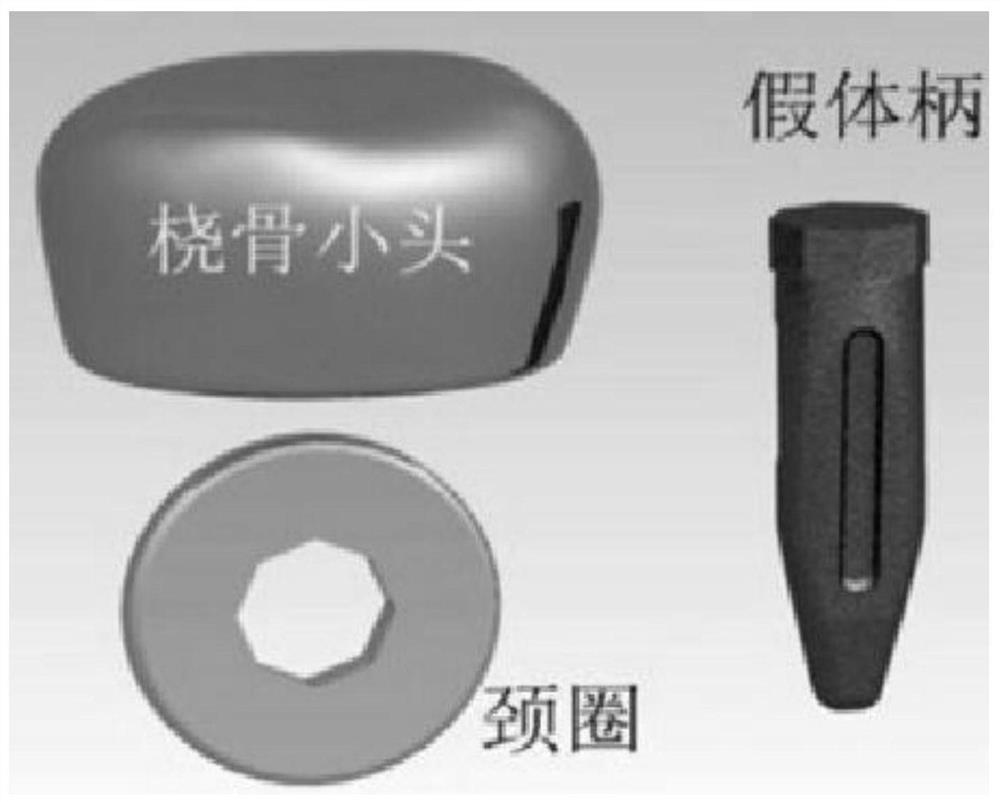

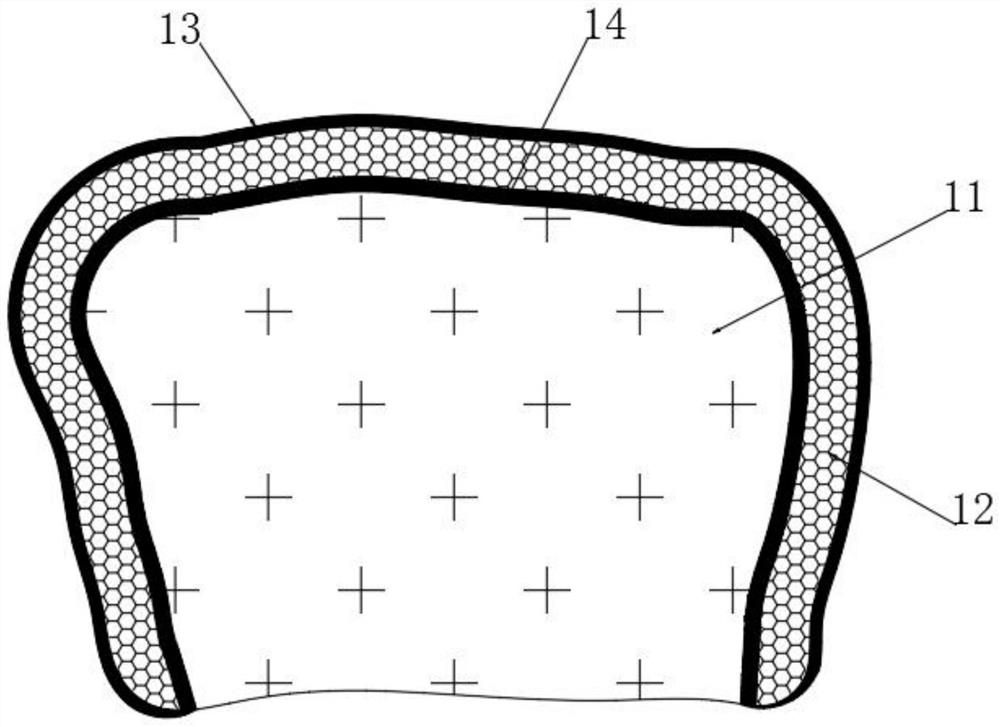

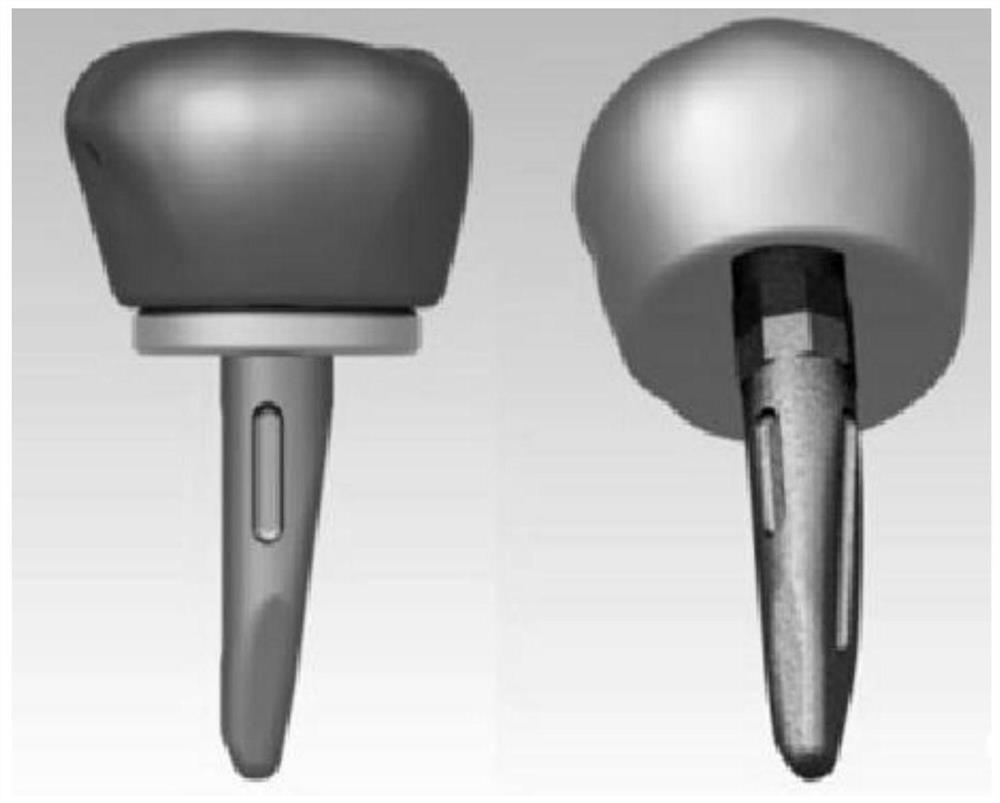

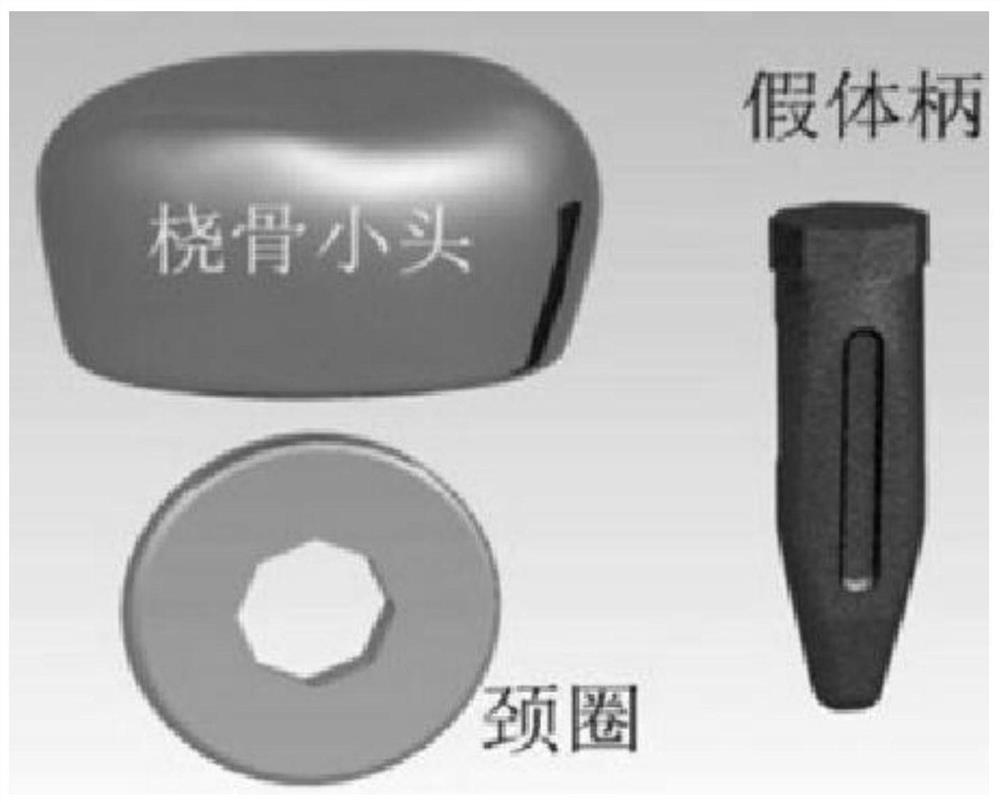

Customized radius head prosthesis based on three-dimensional anatomy of proximal radius on uninjured side

ActiveCN113081398AImprove matchExtended service lifeBone implantJoint implantsCartilage cellsBiomechanics

The invention discloses a customized radial head prosthesis based on three-dimensional anatomy of the proximal radius of the uninjured side, and belongs to the field of radial head prosthesis customization. According to the customized radial head prosthesis based on three-dimensional anatomy of the proximal radius of the uninjured side, the radial head prosthesis is customized, so that the prosthesis is excellent in matching and excellent in biomechanical property, and osteoporosis and articular cartilage surface damage of the small head of humerus can be effectively avoided. In addition, in the multi-time printing process, a cartilage supporting layer can be formed in an outer cartilage layer in the prior art, so that the supporting strength of the cartilage layer is high, the situation that in the prior art, after cartilage on a prosthesis is locally abraded, the prosthesis is loosened is effectively avoided. Meanwhile, after the local part of the outer cartilage layer is abraded, cartilage growth liquid in the radius layer of the outer multi-through hole seeps out along the abraded part, cartilage cells are effectively guided to grow at the abraded part, and then the self-repairing effect of the abraded cartilage part is achieved. Compared with the prior art, the adaptability of the prosthesis and a patient is effectively guaranteed, and the service life of the prosthesis in the body of the patient is prolonged.

Owner:南通市海门区人民医院

Application of artificial joint prosthesis with biomimetic function in preparation of large segmental bone defect reconstruction material

InactiveCN110215319AExtended service lifeReduce complicationsJoint implantsTissue regenerationSpecial designPolyamide

The invention discloses an application of an artificial joint prosthesis with a biomimetic function in preparation of a large segmental bone defect reconstruction material, and the artificial joint prosthesis with the biomimetic function is composed of a porous layer, a compact layer and an embedding layer. The artificial joint prosthesis combines a special design of the porous layer, the compactlayer and the embedding layer of the invention by utilizing a specific nano hydroxyapatite / polyamide 66 material, for example, due to a design of a pore structure in the porous layer and cultivation of a chondrocyte layer on a porous structure to form an articular cartilage surface, a motion function is achieved; for another example, a large pore structure is added in the compact layer to fill autologous bone tissue, so that the artificial joint prosthesis "grows" with surrounding bone tissue into one body; and therefore, the artificial joint prosthesis with the biomimetic function and used for large segmental bone defect reconstruction is obtained and prepared, complications of loosening and sinking of the prosthesis are reduced, and the service life of an artificial joint is prolonged.

Owner:SHANGHAI CHANGZHENG HOSPITAL

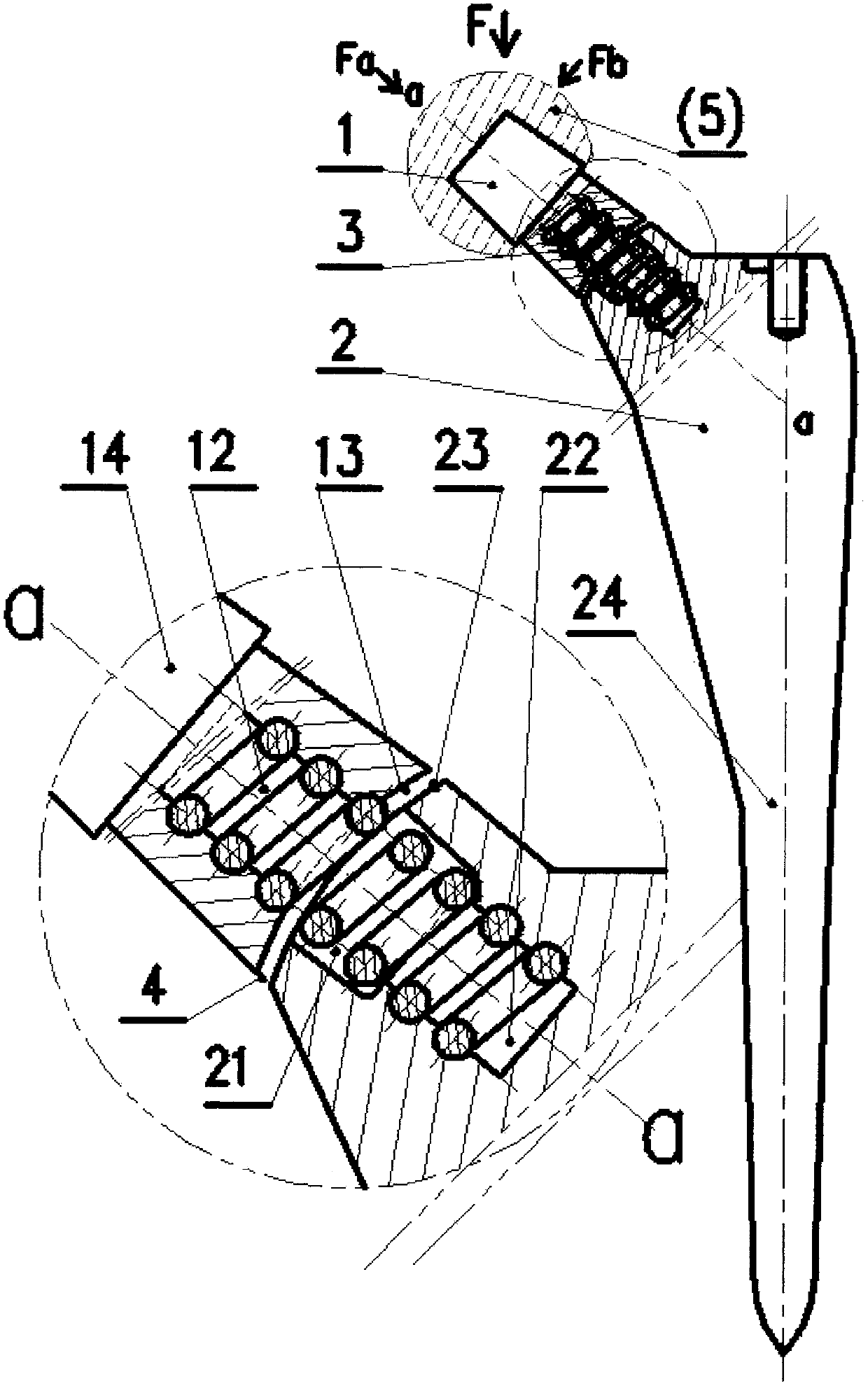

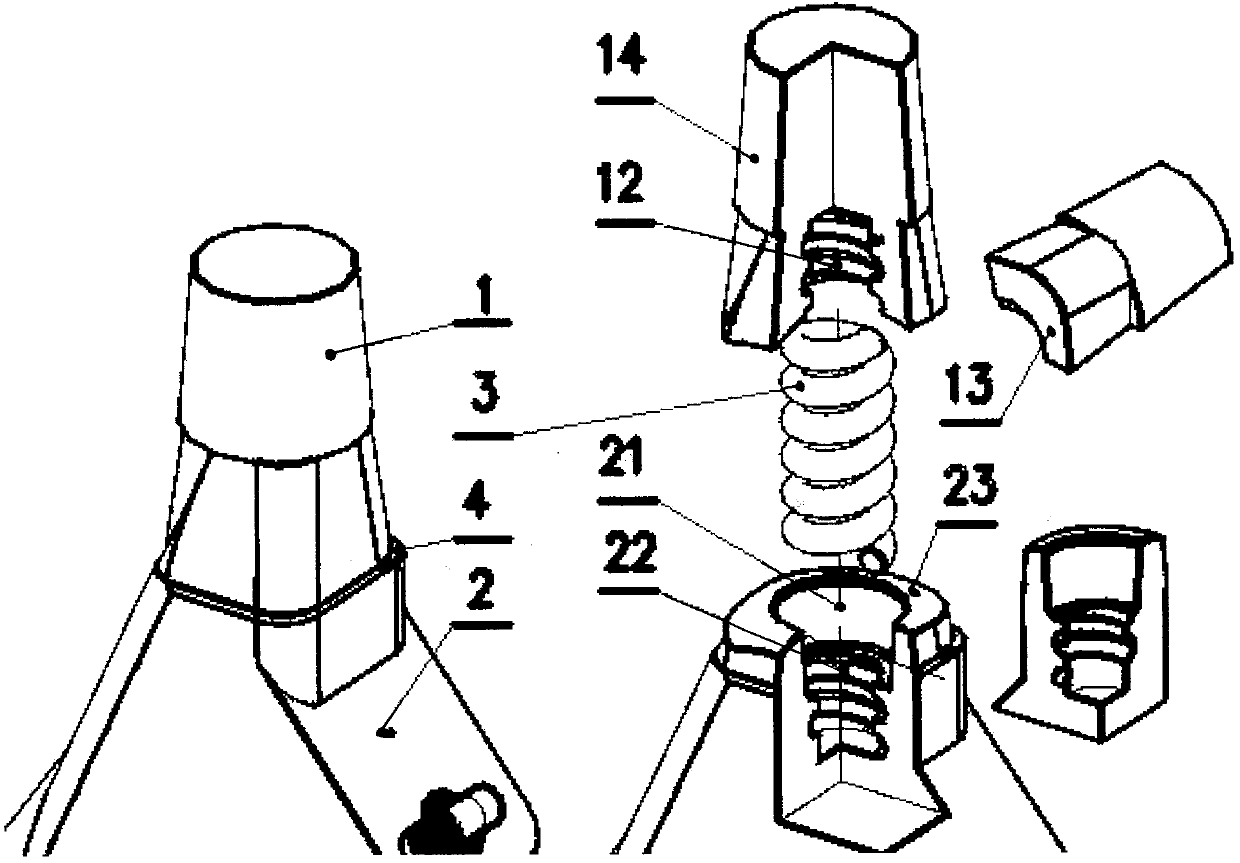

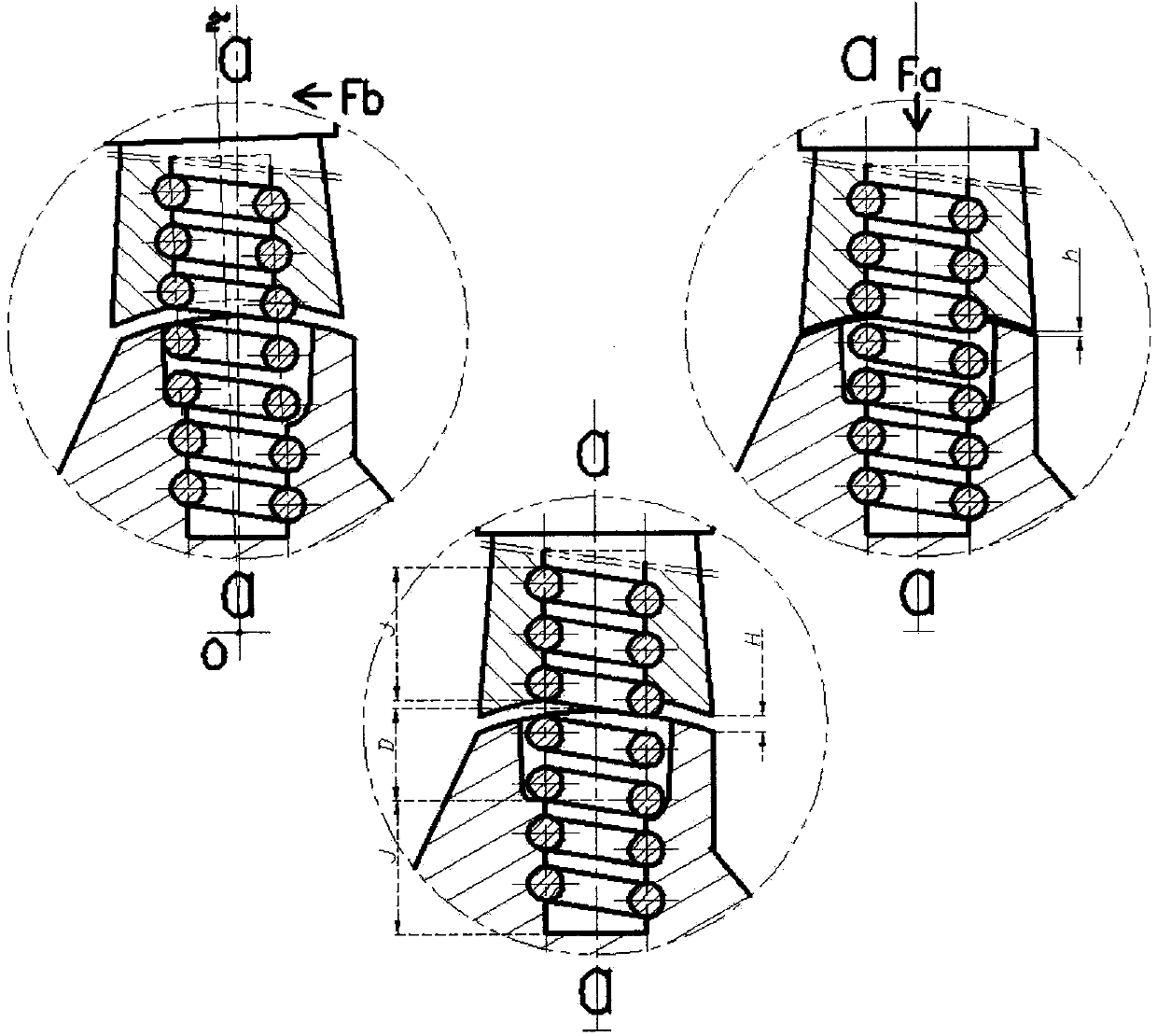

Artificial hip joint with micro-dynamic function

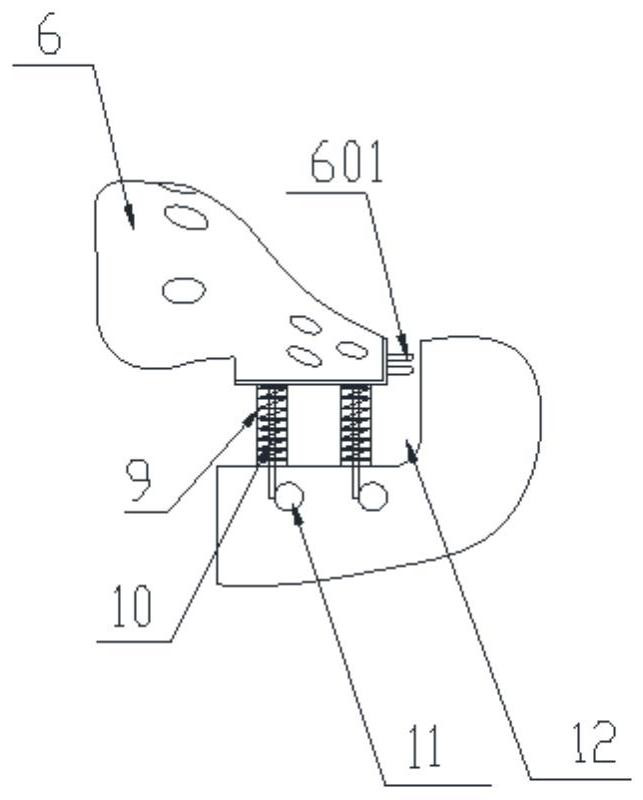

PendingCN110547899ASimple structureAvoid prosthetic looseningJoint implantsFemoral headsHuman bodyHip joint replacement operation

The invention discloses an artificial hip joint with a micro-dynamic function. An artificial implant applied to a hip joint replacement surgery. The artificial hip joint with the micro-dynamic function comprises a neck, a handle body and a columnar spring for flexibly connecting the neck with the handle body. For the artificial hip joint, by utilizing the characteristics of the columnar spring, acting force, generated by movement of a human body, on a thighbone is effectively reduced, and thus the possibility of prosthesis loosening possibly causing surgery failure is reduced or avoided.

Owner:何伟义

Cobalt alloy partitioned bone trabecula single-compartment femoral condyle prosthesis and preparation method

PendingCN112168433APrevent looseningReduce frettingAdditive manufacturing apparatusJoint implants3d printArticular surfaces

The invention discloses a cobalt alloy partitioned bone trabecula single-compartment femoral condyle prosthesis and a preparation method. The preparation method comprises the following steps: by taking cobalt alloy powder as a raw material, performing 3D printing integrated molding to obtain an intermediate product of the cobalt alloy partitioned bone trabecula single-compartment femoral condyle prosthesis, and performing hot isostatic pressing and a deep cooling process to obtain the cobalt alloy partitioned bone trabecula single-compartment femoral condyle prosthesis. The prosthesis comprises a femoral condyle articular surface and an osseointegration surface. Due to the partitioned bone trabecula, micro motion of the prosthesis and a bone interface can be reduced, and the initial stability is achieved; the stress shielding effect of the prosthesis on bone tissues is reduced, the femoral condyle bone tissue stress is uniform, excellent and uniform bone ingrowth performance is achieved, prosthesis looseness caused by osteoporosis after long-term implantation of the prosthesis is avoided, and long-term stability is achieved. Due to 3D printing integrated molding, the bone trabeculaand the entity are high in bonding strength, the bone trabecula does not easily drop, and the service life of the prosthesis is prolonged. The bone trabecula part of the prosthesis has excellent compression resistance; and the entity part releases residual stress, and the plasticity is enhanced.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Knee joint prosthesis structure

PendingCN112869918AImprove long-term stabilityReduce the probability of looseningJoint implantsFemurSurgical RevisionKnee Joint

A knee joint prosthesis structure comprises a thighbone component, a cushion block component, a tibia component and a patella component, the thighbone component is provided with an intercondylar fixing block, the intercondylar fixing block is provided with a protruding part, the inner wall of the thighbone component is provided with a first coating used for bone ingrowth or bone growth, the cushion block component is located between the thighbone component and the tibia component, the outer wall of the lower end of the tibia component is provided with a second coating used for bone growth or bone length, the patella component is located in front of the thighbone component, and the inner wall of the patella component is provided with a third coating used for bone growth or bone length. The knee joint prosthesis structure is a biological type fixed prosthesis structure, various defects and complications caused by bone cement fixation can be avoided, harm to patients and surgical related medical staff due to current bone cement application is reduced, the long-term stability of the prosthesis is improved, the prosthesis loosening rate and the surgical revision rate are reduced, the cost is saved, and the cost is reduced. and the problem of precious medical observation is solved, and great social effect and economic benefit are achieved.

Owner:邬黎平

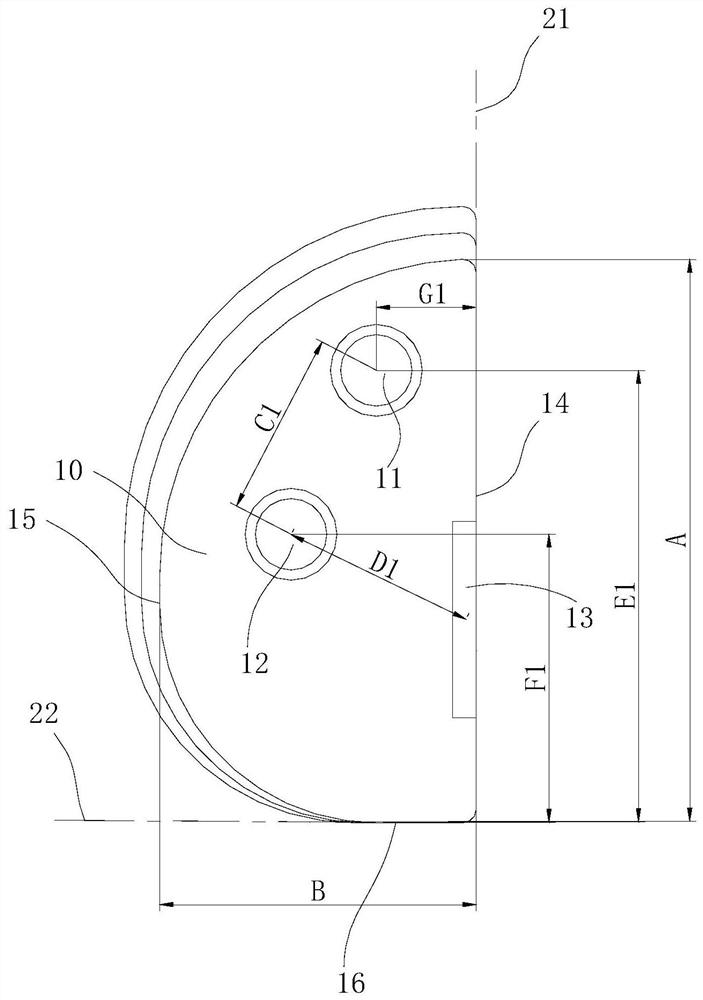

Tibial tray prosthesis

PendingCN111467091AIncrease coverageReduce the probability of painJoint implantsSkullHuman bodyKnee Joint

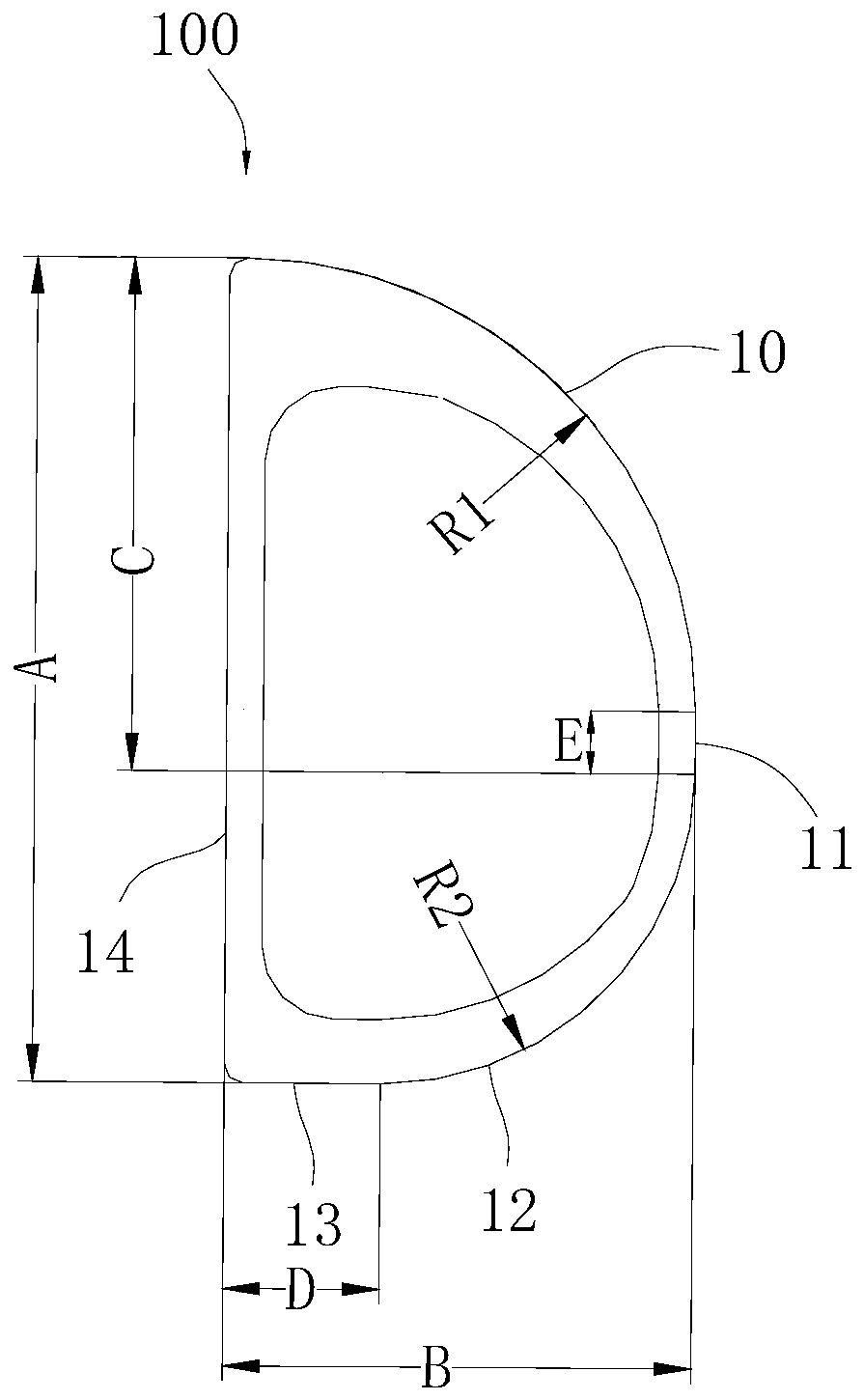

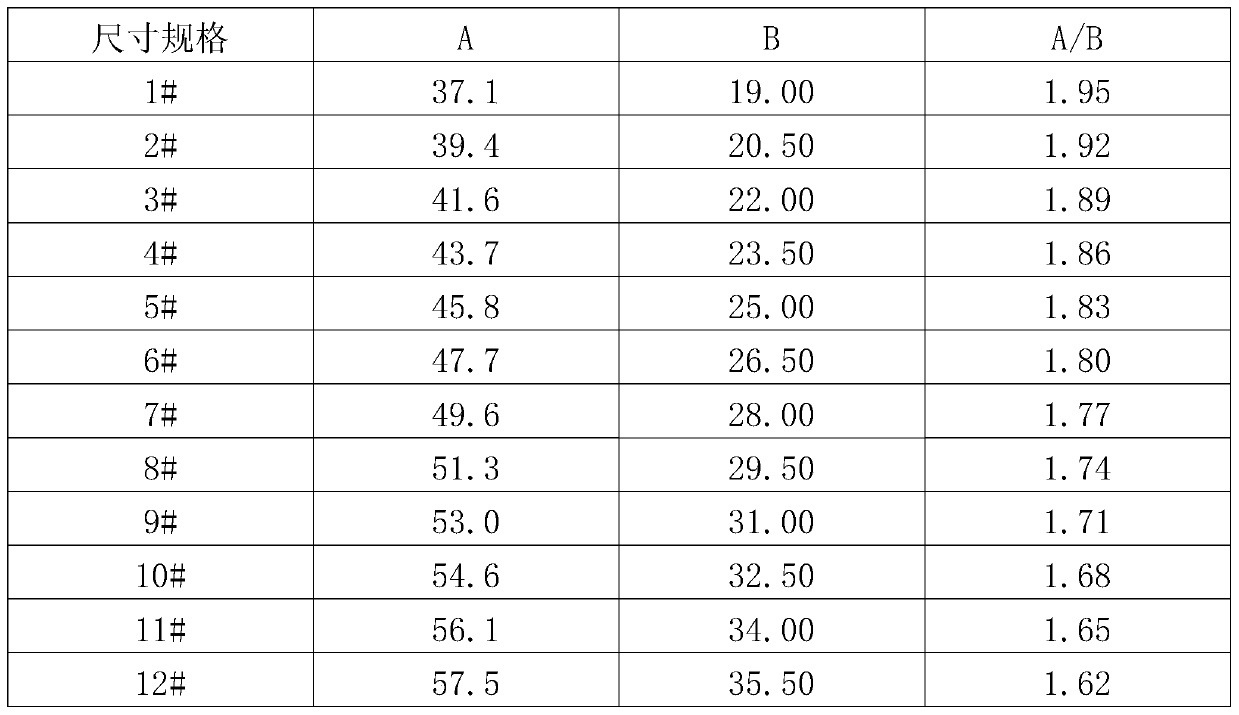

The invention relates to a tibial tray prosthesis. The tibial tray prosthesis is characterized by comprising a front-rear diameter A and a left-right diameter B, wherein the front-rear diameter A is in an increasing trend along with the increase of the left-right diameter B, and the ratio A / B of the front-rear diameter A to the left-right diameter B is in a decreasing trend along with the increase of the left-right diameter B. The tibial tray prosthesis can be closer to the anatomical shape of the knee tibia of the human body, so that the coverage rate of the tibial tray prosthesis is increased, and the probability of prosthesis loosening and postoperative pain of a patient is reduced.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

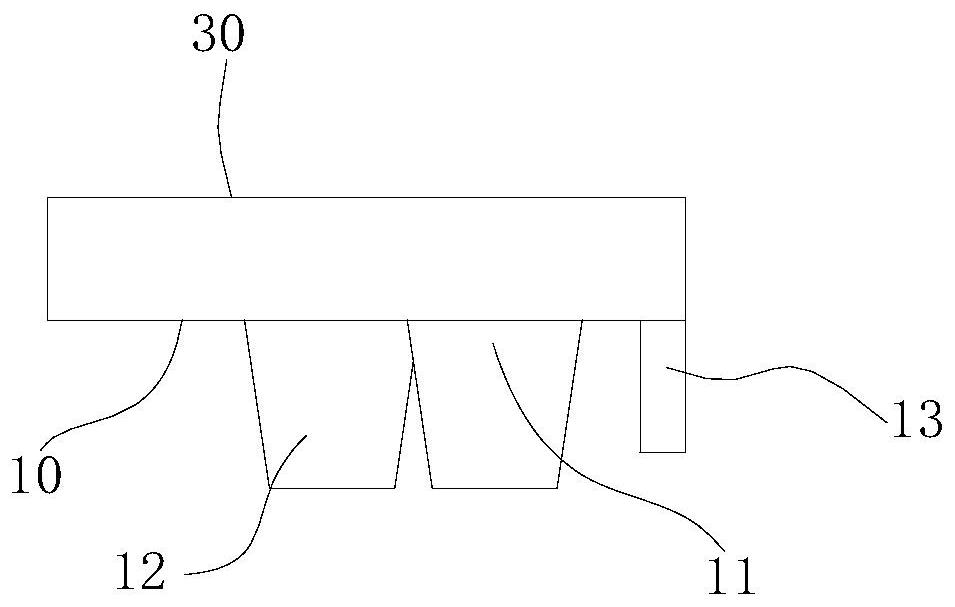

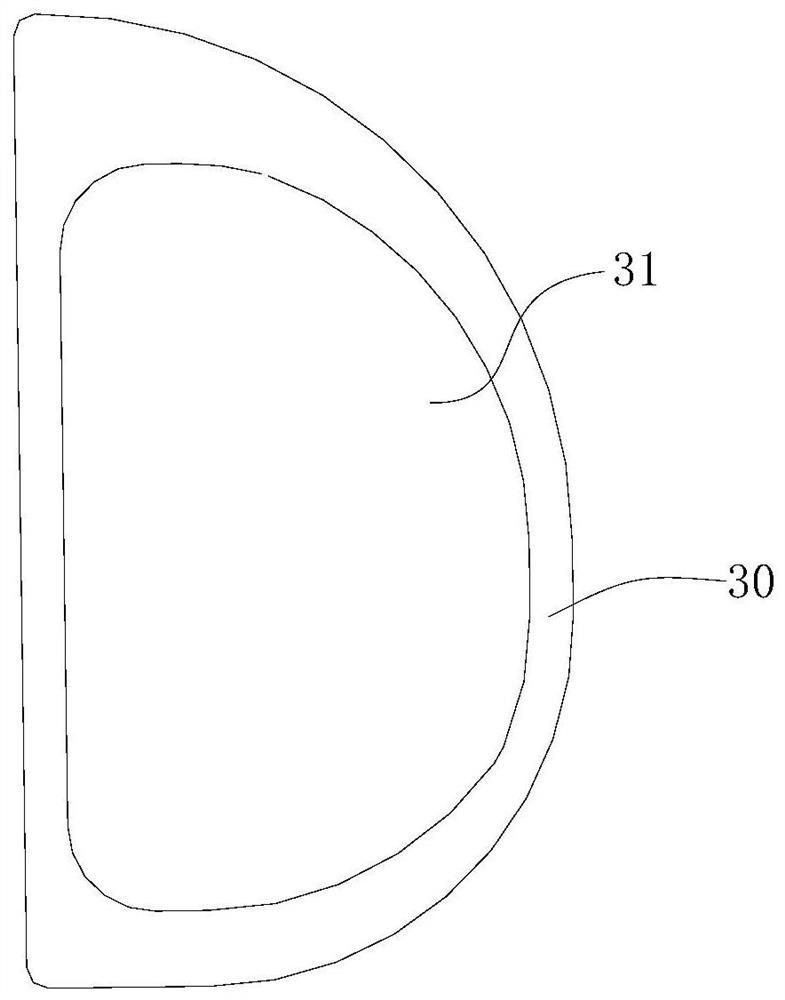

Knee joint system, tibial prosthesis, tibial tray prosthesis series and tibial tray prosthesis group

PendingCN111772887AImprove fixation stabilityReduce the probability of looseningJoint implantsKnee jointsPhysical medicine and rehabilitationKnee Joint

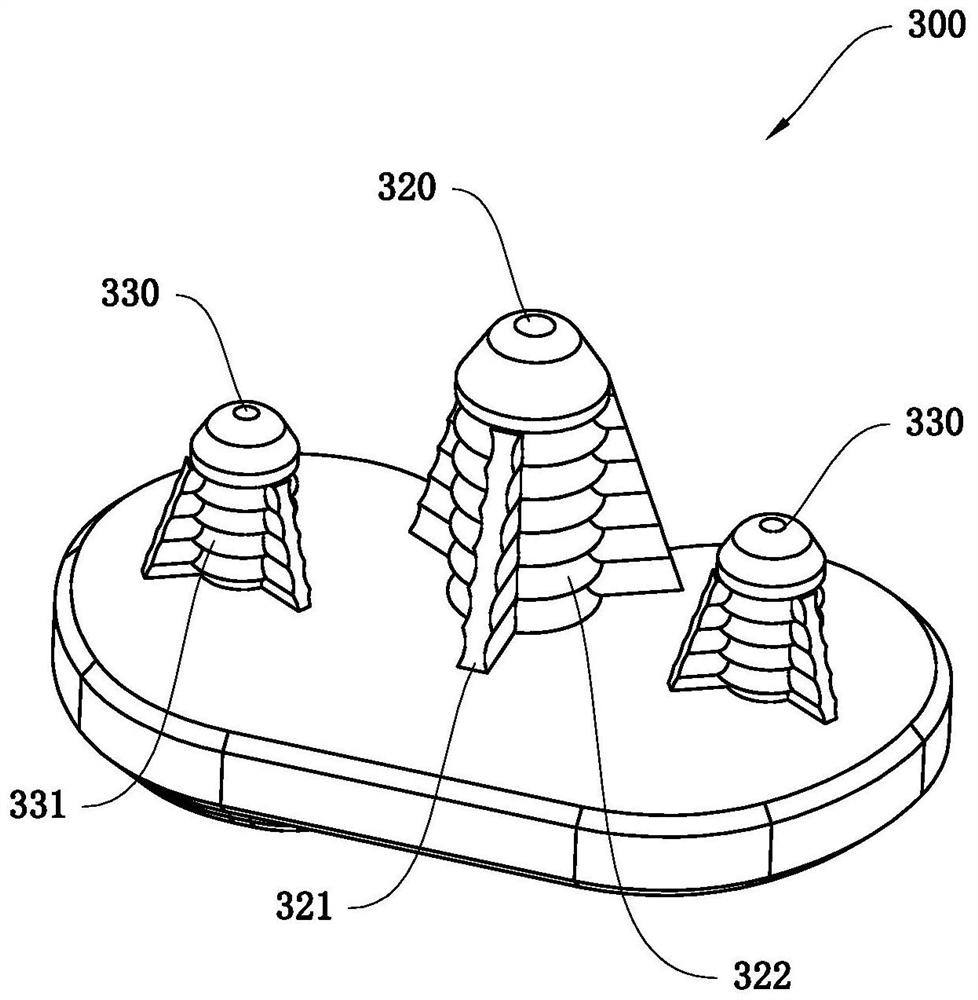

The invention relates to a knee joint system, a tibial prosthesis, a tibial tray prosthesis series and a tibial tray prosthesis group. The tibial tray prosthesis group comprises at least two tibial tray prostheses of different models, wherein each tibial tray prosthesis is provided with a stand column connected with a tibia and a keel; each tibial tray prosthesis is further provided with a first reference surface and a second reference surface; the second reference surface is intersected with the first reference surface; and when the first reference surfaces of the tibial tray prostheses of different models are aligned and the second reference surfaces are aligned, the stand columns of the tibial tray prostheses of different models are overlapped and the keels are overlapped. According tothe tibial tray prosthesis group, the fixing stability of the tibial tray prostheses is improved and the loosening probability of the tibial tray prostheses is reduced. Meanwhile, stand column holes and keel 13 grooves do not need to be formed again so that the operation efficiency is also improved, the operation time is shortened and the infection probability of patients is reduced.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

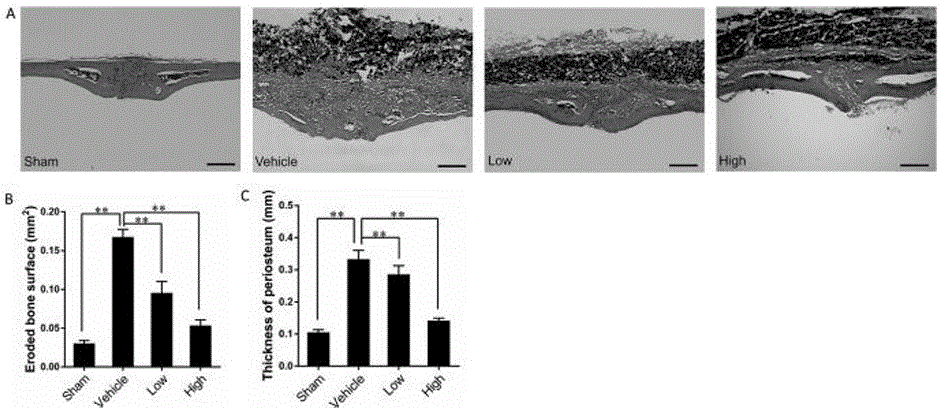

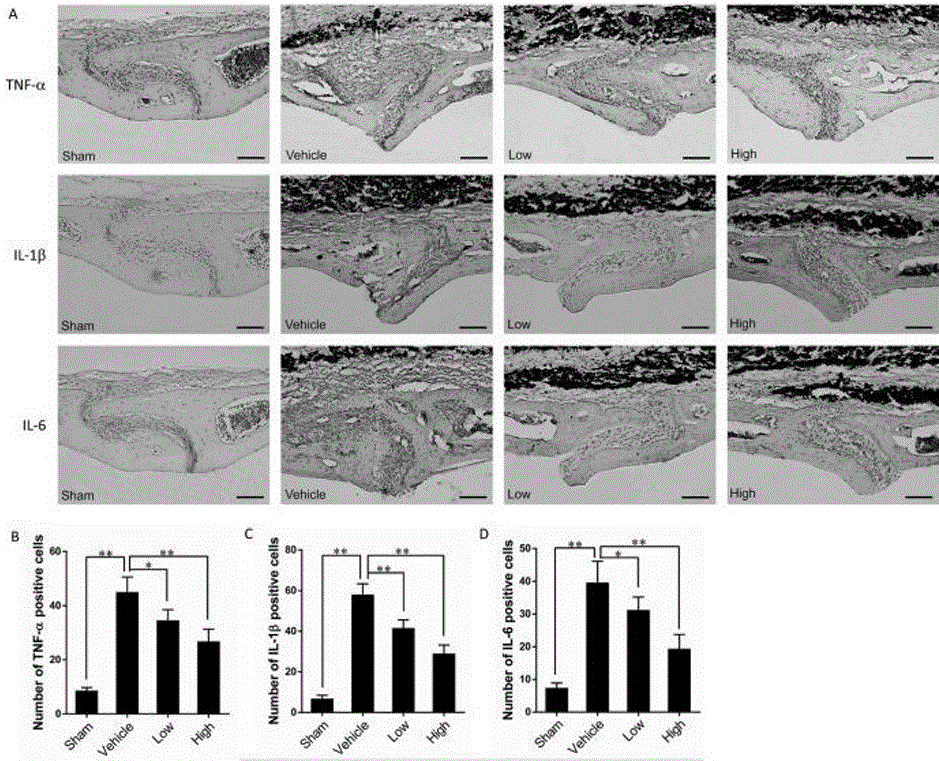

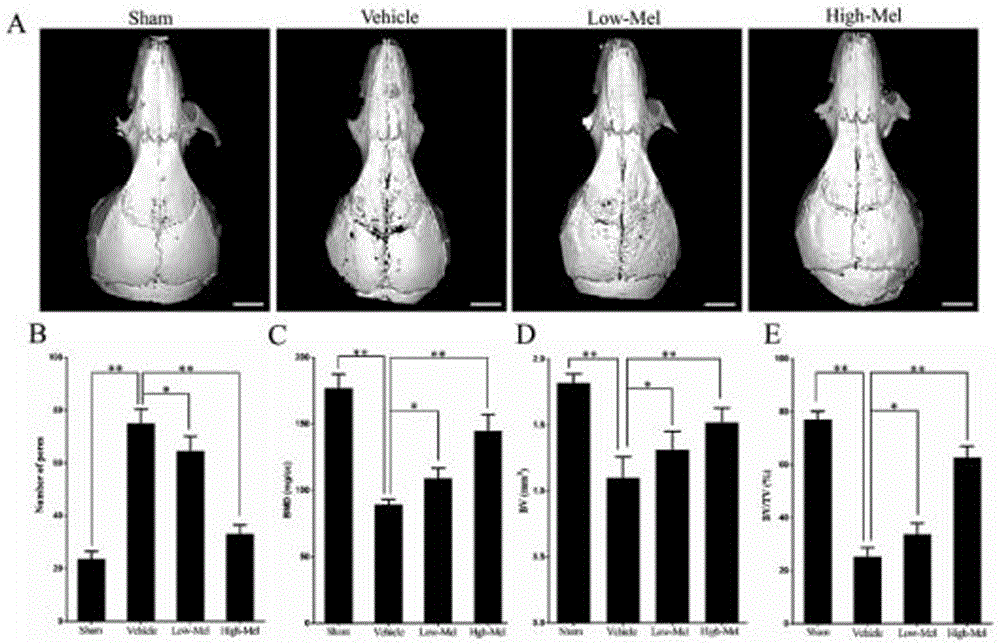

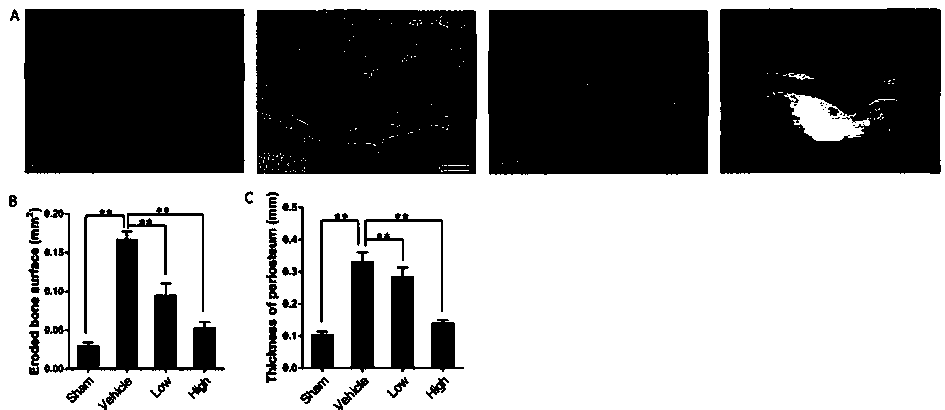

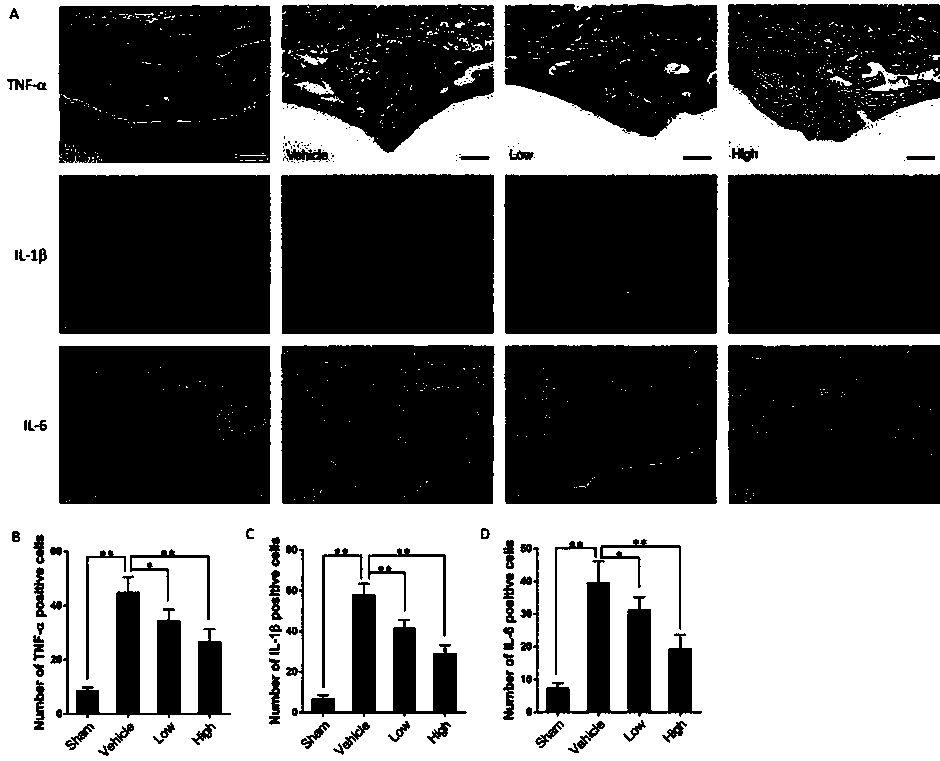

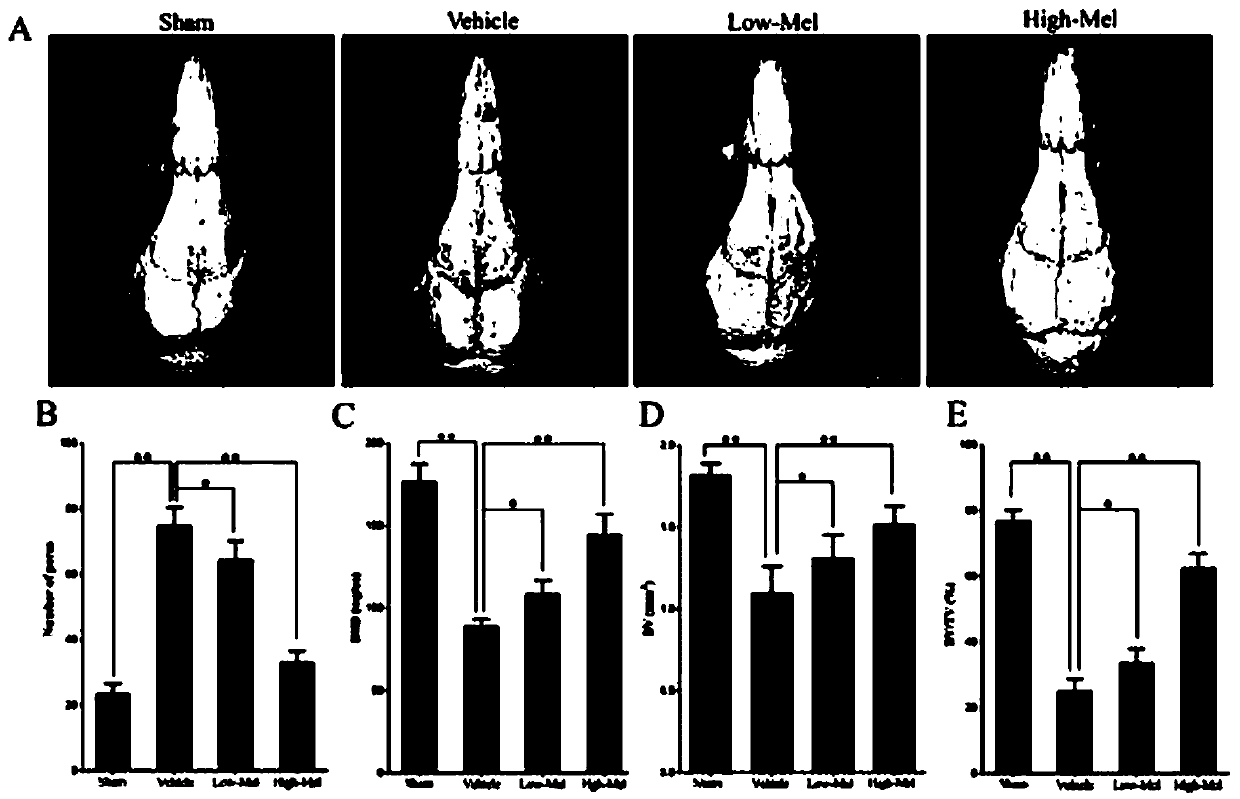

Application of melatonin to preparation of medicine for treating loose periprosthetic chronic inflammation and bone destruction

ActiveCN106727511AReduce inflammationReduce expressionOrganic active ingredientsAntipyreticInflammatory factorsPhysiology

The invention provides application of melatonin to the preparation of a medicine for treating loose periprosthetic chronic inflammation and bone destruction. The chemical structural formula of melatonin is shown in a specification, and the medicine comprises a compound at pharmaceutically effective dose and a pharmaceutically acceptable carrier. According to the application, a novel medicinal prospect of melatonin is explored, a novel medicinal area is developed, the application has an exact effect of prosthesis loosening, and has the purpose of effectively preventing and treating prosthesis loosening caused by wear particles, besides, expression of inflammatory factors can be obviously reduced, inflammatory response caused by the wear particles is reduced, osteoclast activation is restrained, the formation of local new bones after osteolysis is promoted, and bone destruction caused by the wear particles is reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF SOOCHOW UNIV

Zero-incisura fixing fusion cage for treating cervical spondylosis

InactiveCN111544161APrevent displacementImprove stabilitySpinal implantsPhysical medicine and rehabilitationCervical spondylopathy

The invention discloses a zero-incisura fixing fusion cage for treating cervical spondylosis, and particularly relates to the technical field of medical instruments. The zero-incisura fixing fusion cage for cervical spondylosis treatment comprises a fixing plate, bone grafting holes are formed in the two sides of the fixing plate, a connecting plate is arranged on the fixing plate, and threaded holes are formed in the connecting plate. By adopting the technical scheme of the invention, the defects that the existing zero-incisura fusion cage is easy to loosen and shift the prosthesis is overcome and the problem that the fusion cage of Cage and Plate is easy to swallow after an operation is solved. The stability of the fusion cage is enhanced, the problem of difficulty in swallowing after anoperation is solved, meanwhile, the cervical vertebra fusion cage is suitable for patients with different cervical vertebra curvature conditions by matching with the combined embedded parts with different radians, and the optimal postoperative cervical vertebra curvature state is achieved.

Owner:郭英俊

Pelvic prosthesis

ActiveCN112155793AEasy to installImprove stabilityJoint implantsAcetabular cupsPelvic regionSacrum bone

The invention provides a pelvic prosthesis, and belongs to the technical field of orthopedic implants. The pelvic prosthesis comprises a body, wherein one end of the body is a sacrum connecting end, and the other end of the body is an ilium connecting end. The body is provided with a first through hole for a fixing nail to penetrate through, and the first through hole extends to the sacrum connecting end face of the body from the side face of the body. A connecting plate is arranged on the side face of the ilium connecting end of the body, and a second through hole used for allowing the fixingnail to penetrate through is formed in the connecting plate. According to the scheme, the pelvic prosthesis can perform excision osteotomy on sacrum on the basis that the acetabular fossa rotation center is not damaged, one end of the pelvic prosthesis is connected with sacrum in a press-fit mode, the other end of the pelvic prosthesis is connected with ilium in a press-fit mode, and therefore, prosthesis replacement is achieved, and the pelvic prosthesis is easy and convenient to install, has enough bonding strength with a host bone interface and is high in stability, and the prosthesis loosening probability is low.

Owner:BEIJING LIDAKANG TECH

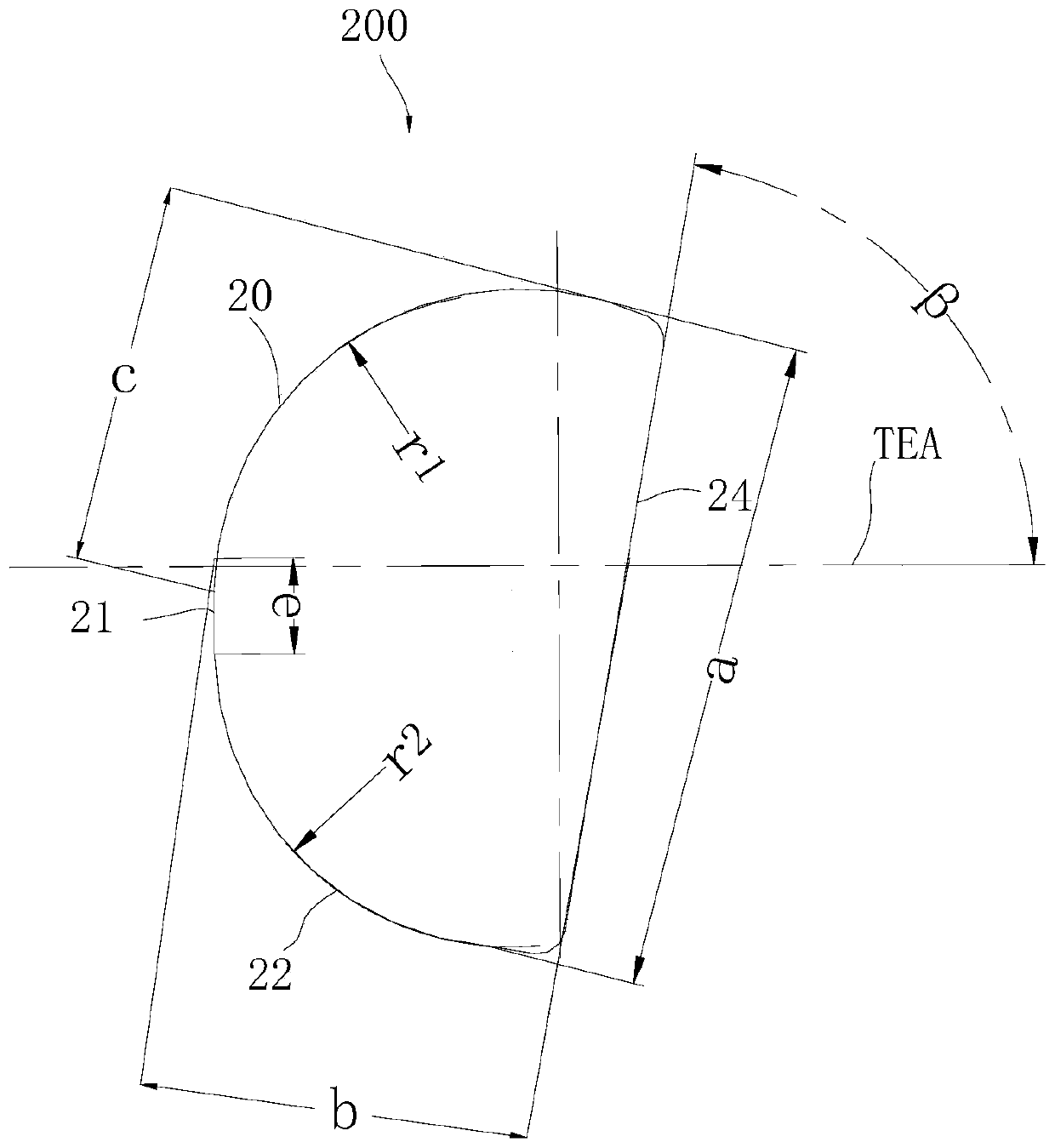

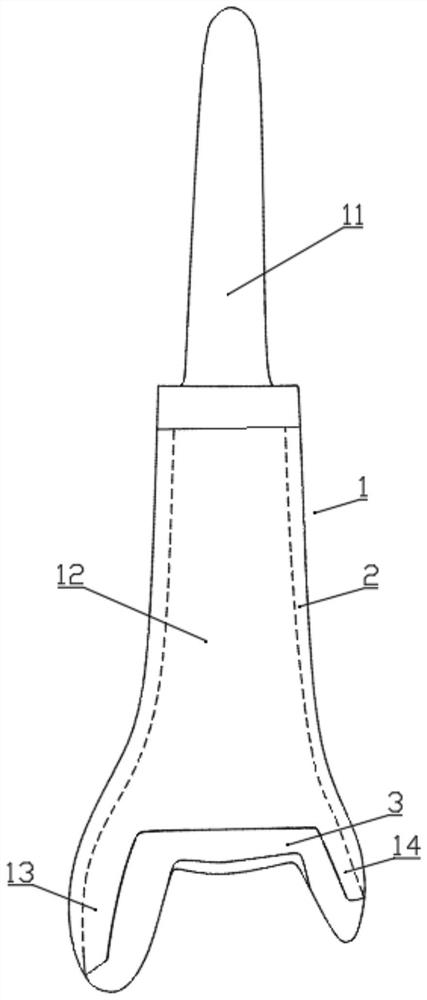

Reference system for rotational positioning of femoral prosthesis

The invention discloses a reference system for rotational positioning of a femoral prosthesis in total knee arthroplasty, namely an inner cortical plane in front of a distal femur, a part of the plane is positioned below an upper incisura of an upper patella of a femoral tackle, the inner side starts from the medial condyle, and the outer side ends at a connecting recess of the medial condyle and the lateral condyle. According to the method, an existing prosthesis rotation positioning reference system is broken through, operability and accuracy of rotation alignment of the femoral prosthesis in total knee arthroplasty are improved, and after a new reference method is applied, postoperative functional recovery of the prosthesis is expected to be enhanced, adverse events such as looseness and infection of the prosthesis are reduced, and the survival rate of the prosthesis is increased.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

3D printing customized half-ankle joint prosthesis

The invention discloses a 3D printing customized half-ankle joint prosthesis. The 3D printing customized half-ankle joint prosthesis comprises a tibia far-end prosthesis and a liner; the middle of the tibia far-end prosthesis is a circular truncated cone; the lower portion of the circular truncated cone is a supporting section; a bone trabecula structure is arranged on the peripheral surface of the supporting section; a concave opening is formed in the bottom of the supporting section; a lateral ankle part and a medial ankle part are arranged on the two sides of the concave opening respectively; and the liner is connected into the concave opening in the bottom of the supporting section. According to the 3D printing customized half-ankle joint prosthesis in the invention, a monopole mode is adopted; the sclerotin of a patient can be reserved to the maximum degree; the risks of prosthesis loosening and infection are small; according to the invention, the tibia far-end prosthesis of a solid structure is adopted; the overall mechanical strength is guaranteed; the bone trabecula structure has the good bone ingrowth and thigh crawling capacity; the stability of the prosthesis is improved; the liner can buffer the impact between the prosthesis and the talus of a human body in the movement process; and the biomechanical requirement is met.

Owner:WEST CHINA PRECISION MEDICINE IND TECH INST +1

A kind of modular shoulder joint prosthesis and its manufacturing method

ActiveCN111374805BSolve the errorAvoid printing errorsJoint implantsTomographyBone humerusShoulder joint prosthesis

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Tantalum metal bone trabecula femoral condyle prosthesis and knee joint replacement body

The invention relates to a tantalum metal bone trabecula femoral condyle prosthesis and a knee joint replacement body. The femoral condyle prosthesis comprises a cobalt-chromium-molybdenum substrate and a porous tantalum metal bone trabecula inner shell welded into the cobalt-chromium-molybdenum substrate, the knee joint prosthesis comprises the femoral condyle prosthesis and further comprises a femoral marrow needle, a tibial plateau pad, a tibial plateau support and a tibial marrow needle, the femoral marrow needle and the femoral condyle prosthesis are connected through a first taper locking mechanism, the tibial marrow needle and the tibial plateau support are connected through a second taper locking mechanism, the upper end face of the tibial plateau support and the lower end face of the tibial plateau pad are both planes, and a rotary limiting hole is formed in the upper end face of the tibial plateau support; and the lower end face of the tibial plateau pad is provided with a rotary limiting column corresponding to the rotary limiting hole, and the rotary limiting column is arranged in the rotary limiting hole. The femoral condyle prosthesis has the beneficial effects that a wide bone ingrowth space can be provided, stress shielding can be reduced, chemical erosion can be resisted, and the risk of prosthesis loosening and dislocation can be effectively reduced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

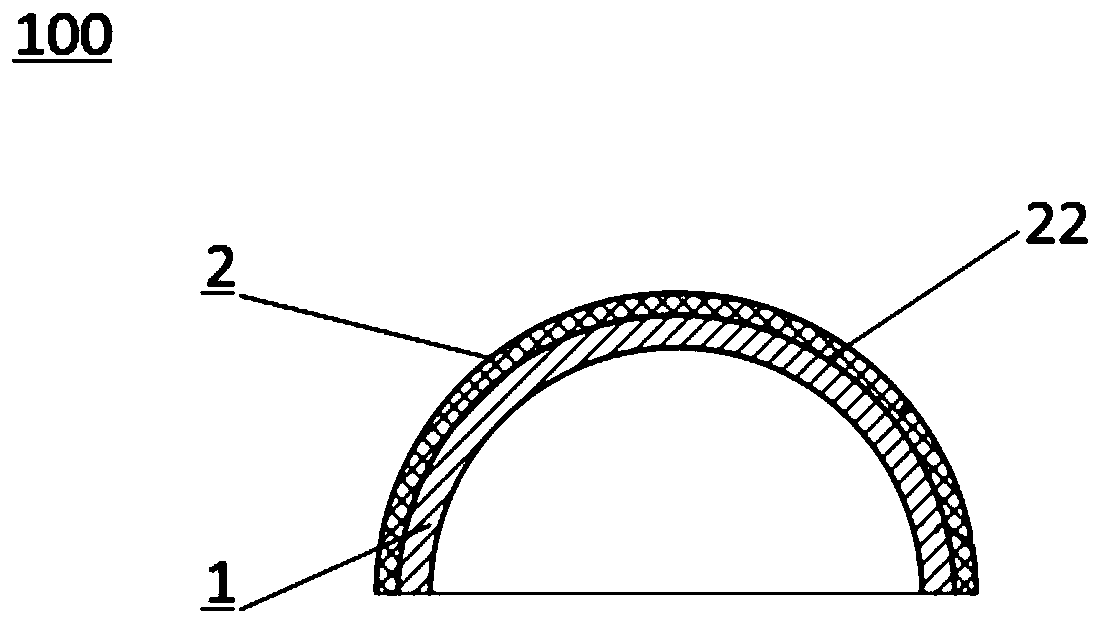

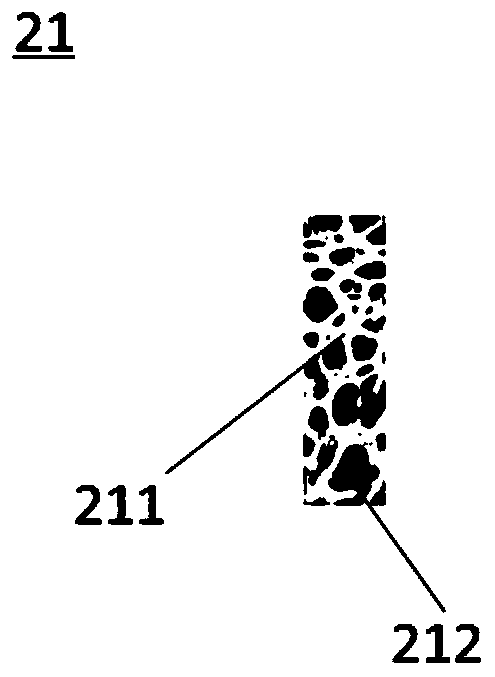

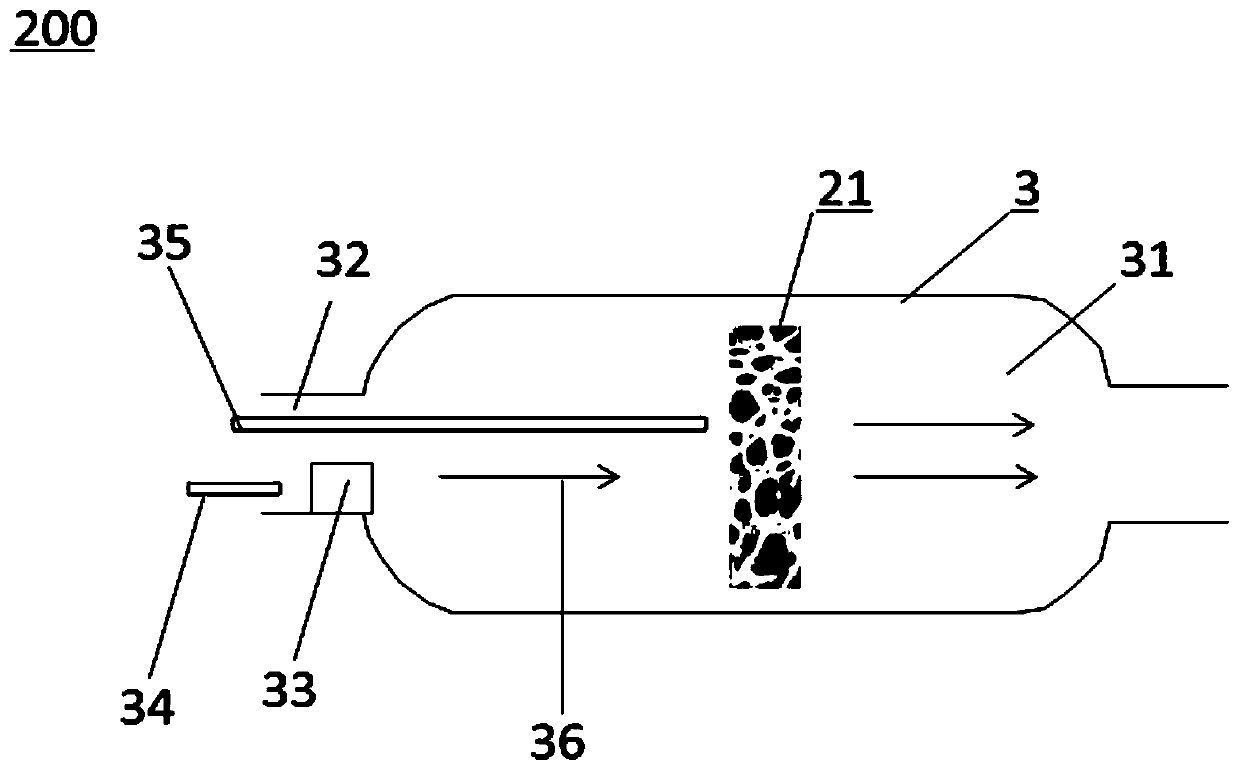

Acetabular cup prosthesis

PendingCN111513895AImprove stabilityImprove recovery effectJoint implantsCoatingsProsthesis ImplantationBone quality

The invention belongs to the technical field of medical prostheses, and discloses an acetabular cup prosthesis. The acetabular cup prosthesis comprises a prosthesis body and a bone fusion layer whichis fixedly attached to the outer surface of the prosthesis body, wherein the bone fusion layer comprises a glassy carbon matrix which is constructed into a spatial three-dimensional structure, and a tantalum metal layer which is attached to the surface of the glassy carbon matrix; the glassy carbon matrix comprises a plurality of glassy carbon wires and a plurality of pores which are formed by connecting the plurality of glassy carbon wires in a staggered manner; and the pores communicate with one another and are different in diameter. The acetabular cup prosthesis has the advantages of facilitating bone ingrowth, providing relatively high friction force, reducing stress shielding and the like, so that the stability of the prosthesis after implantation is improved, and the phenomena of prosthesis loosening, dislocation, fracture and the like are reduced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Manufacturing method of personalized knee bionic prosthesis based on 3D printing

ActiveCN110833472BUniform stress distributionGood biomechanical propertiesJoint implantsTomographyElement analysisKnee Joint

The invention discloses a manufacturing method of an individualized customized knee joint topological optimization bionic prosthesis based on 3D printing, which relates to the technical field of medical artificial joints. The problem that the manufacturing method is urgently needed to reduce prosthesis looseness or fracture around the prosthesis is solved, and the method comprises the steps: establishing and assembling a tibia model and a knee joint prosthesis model, and performing finite element analysis and topological optimization; carrying out fairing; designing a specific structure of themodel, optimally reserving an internal region by adopting a solid structure, optimally reserving an outer layer region and optimally removing the region by adopting a grid structure, and forming a gradient between the regions; introducing back an assembly state of a tibia model, performing finite element analysis, comparing with a first finite element analysis result, judging whether 3D manufacturing and application are performed or not, and performing topological optimization again if the 3D manufacturing and application cannot be performed. The prosthesis prepared by the invention reduces the problem of prosthesis looseness or prosthesis peripheral fracture, provides space for ligament stop point implantation and internal bone grafting, is light in weight, and is beneficial to bone tissue ingrowth.

Owner:JILIN UNIV

Customized radial head prosthesis based on 3D anatomy of the proximal radius of the unaffected side

ActiveCN113081398BImprove matchExtended service lifeBone implantJoint implantsBiomechanicsRadial head prosthesis

Owner:南通市海门区人民医院

Ultra-high-molecular-weight-polyethylene and drug complexes artificial joint material and preparation method thereof, and artificial joint prepared therefrom

InactiveCN100473423CInhibition of differentiationInhibitory activityJoint implantsAcetabular cupsHuman bodyHigh molecular mass

The invention disclosed a kind of super high molecular weight polyethylene / medicine compounded artificial joint as well as the preparing method and the prepared coax joint. The materials of the invention include 99.5-90 shares (by weight) of super high molecular weight polyethylene and 0.5-10 shares of medicine that can restrain osteolysis. After implanting the invention in human bodies, it can prevent the ostelysis of artificial hip joint and total knee prosthesis under common conditions; it can also prevent the cinch of prosth, prolong the service life of artificial joints, and ease the pain and burden of patients.

Owner:SOUTHWEST JIAOTONG UNIV

Use of melatonin in the preparation of medicines for treating chronic inflammation and bone destruction around loose prostheses

ActiveCN106727511BReduce inflammationReduce expressionOrganic active ingredientsAntipyreticInflammatory factorsPhysiology

The invention provides application of melatonin to the preparation of a medicine for treating loose periprosthetic chronic inflammation and bone destruction. The chemical structural formula of melatonin is shown in a specification, and the medicine comprises a compound at pharmaceutically effective dose and a pharmaceutically acceptable carrier. According to the application, a novel medicinal prospect of melatonin is explored, a novel medicinal area is developed, the application has an exact effect of prosthesis loosening, and has the purpose of effectively preventing and treating prosthesis loosening caused by wear particles, besides, expression of inflammatory factors can be obviously reduced, inflammatory response caused by the wear particles is reduced, osteoclast activation is restrained, the formation of local new bones after osteolysis is promoted, and bone destruction caused by the wear particles is reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF SOOCHOW UNIV

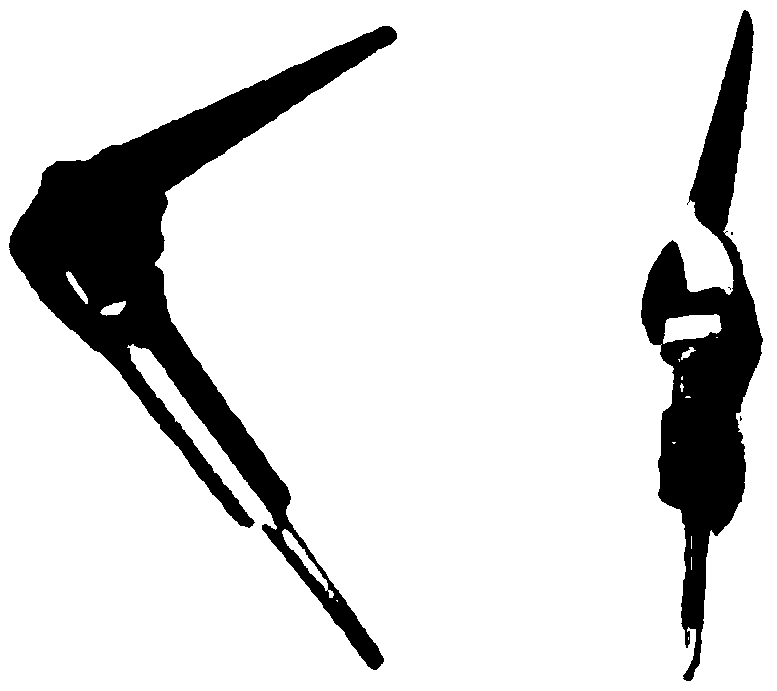

A kind of artificial elbow joint surface replacement prosthesis

ActiveCN105640673BAvoid destructionReduce the likelihood of fracturesJoint implantsKnee jointsArticular surfacesArticular surface

Owner:WUHAN UNITED IMAGING HEALTHCARE SURGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com