Assembly type shoulder joint prosthesis and manufacturing method thereof

A shoulder joint and modular technology, applied in the field of modular shoulder joint prosthesis and its manufacturing, can solve problems such as prosthesis loosening, surrounding tissue damage, and the inability to meet the needs of simultaneous treatment and replacement of patients with shoulder joint damage as a whole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

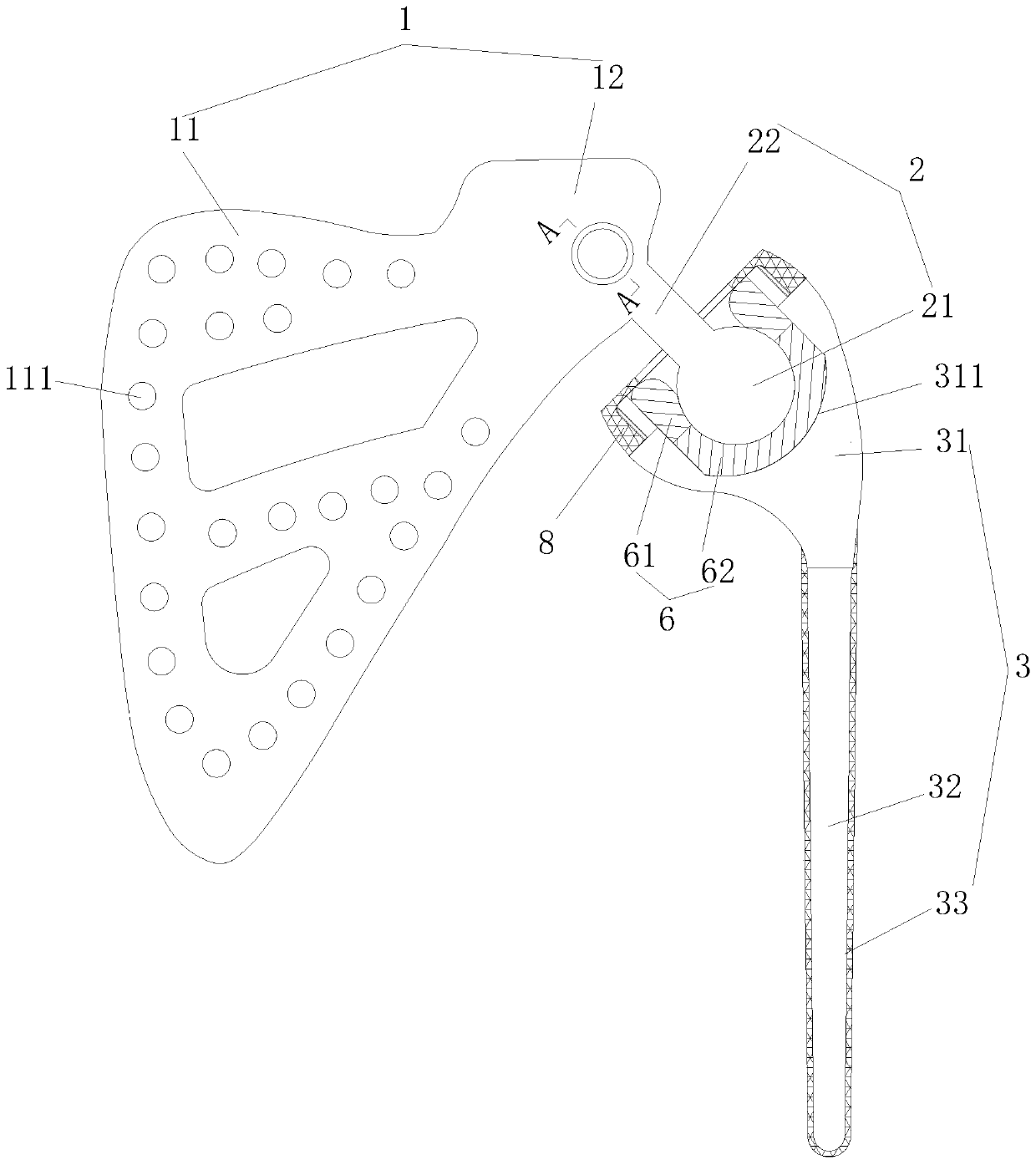

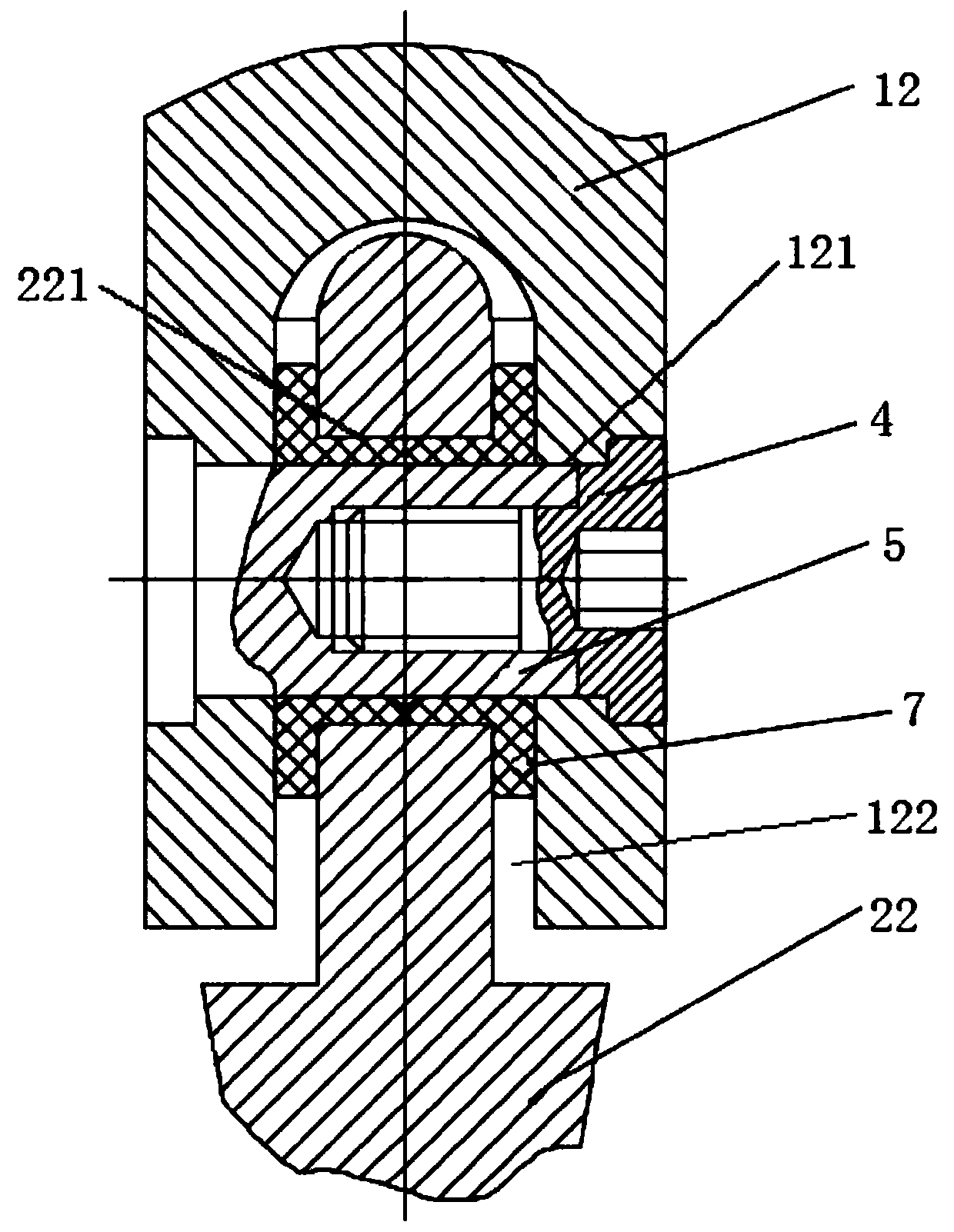

[0050] Embodiment 1 of the present invention provides a kind of modular shoulder joint prosthesis, such as figure 1 As shown, it includes a scapular prosthesis 1, a glenoid prosthesis 2, and a humeral prosthesis 3. The shape and size of the scapular prosthesis 1, glenoid prosthesis 2, and humeral prosthesis 3 are all based on the patient's own scapula The dimensions of the scapula, glenoid and humerus are optimized to make them nearly consistent with the structural dimensions of the scapula, glenoid and humerus in the normal period of the patient. Specifically, the scapula prosthesis 1 is preferably made of titanium alloy and polyetheretherketone material, wherein the polyetheretherketone material has high load-bearing strength and low elastic modulus, thereby allowing physiological load-bearing conditions Therefore, the scapula prosthesis 1 made of polyetheretherketone material can be well integrated with the human body, and can significantly reduce stress shielding and avoid...

Embodiment 2

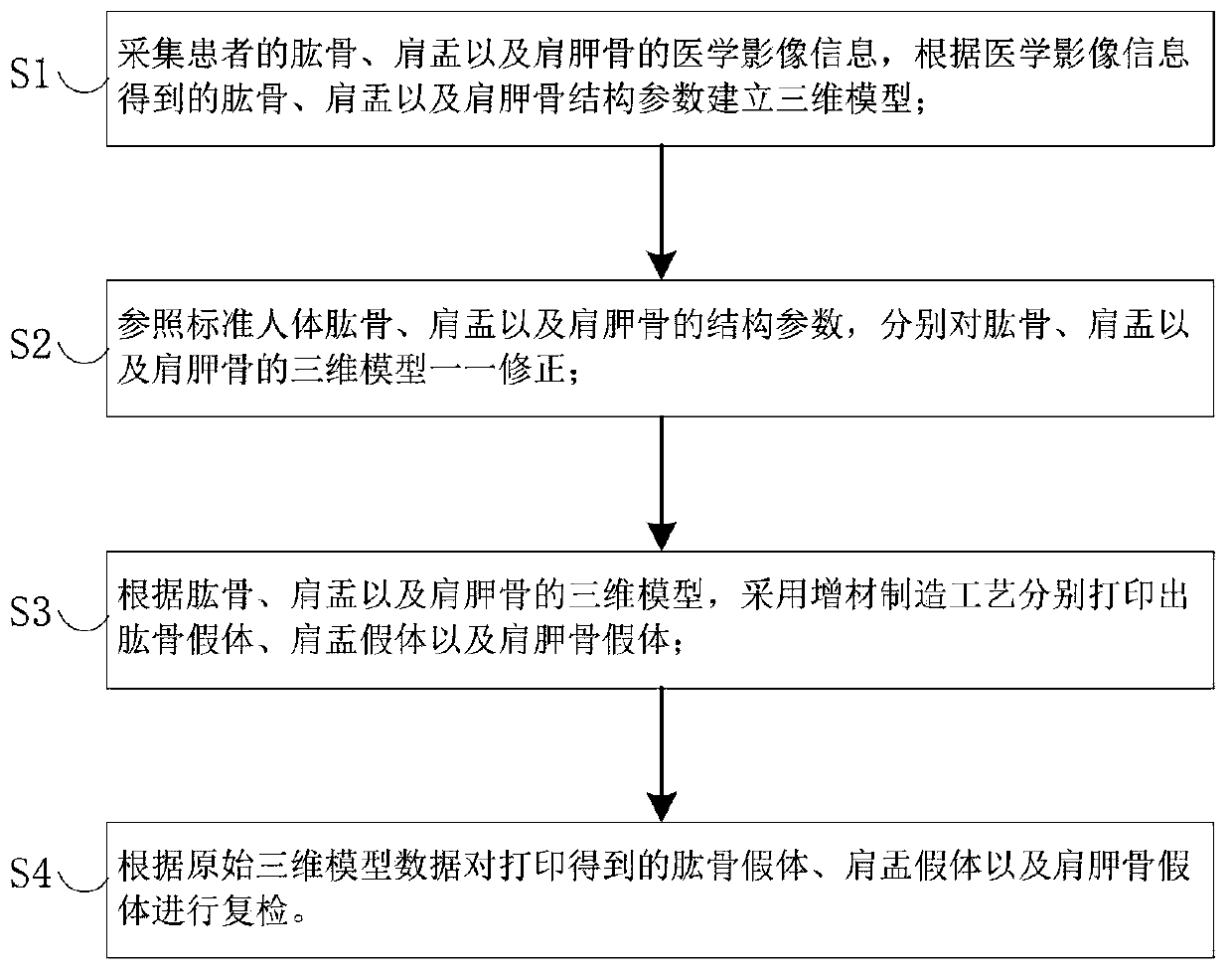

[0055] Embodiment 2 of the present invention provides a method for manufacturing a modular shoulder joint prosthesis, such as image 3 As shown, the manufacturing method includes the steps of:

[0056] S1. Collect medical imaging information of the patient's humerus, glenoid, and scapula, and establish a three-dimensional model based on the structural parameters of the humerus, glenoid, and scapula obtained from the medical imaging information;

[0057] S2. With reference to the structural parameters of the standard human humerus, glenoid and scapula, the three-dimensional models of the humerus, glenoid and scapula are corrected one by one;

[0058] S3. According to the three-dimensional models of the humerus, glenoid and scapula, the humeral prosthesis 3, the glenoid prosthesis 2 and the scapular prosthesis 1 are printed out by additive manufacturing process;

[0059] S4. Recheck the printed humeral prosthesis 3, glenoid prosthesis 2 and scapular prosthesis 1 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com