Ultra-high-molecular-weight-polyethylene and drug complexes artificial joint material and preparation method thereof, and artificial joint prepared therefrom

An ultra-high molecular weight, artificial joint technology, applied in artificial joint materials and its preparation, and in the field of hip joints, can solve problems such as artificial joint prosthesis loosening, and achieve the goal of overcoming low bioavailability, inhibition of differentiation and activity, and obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

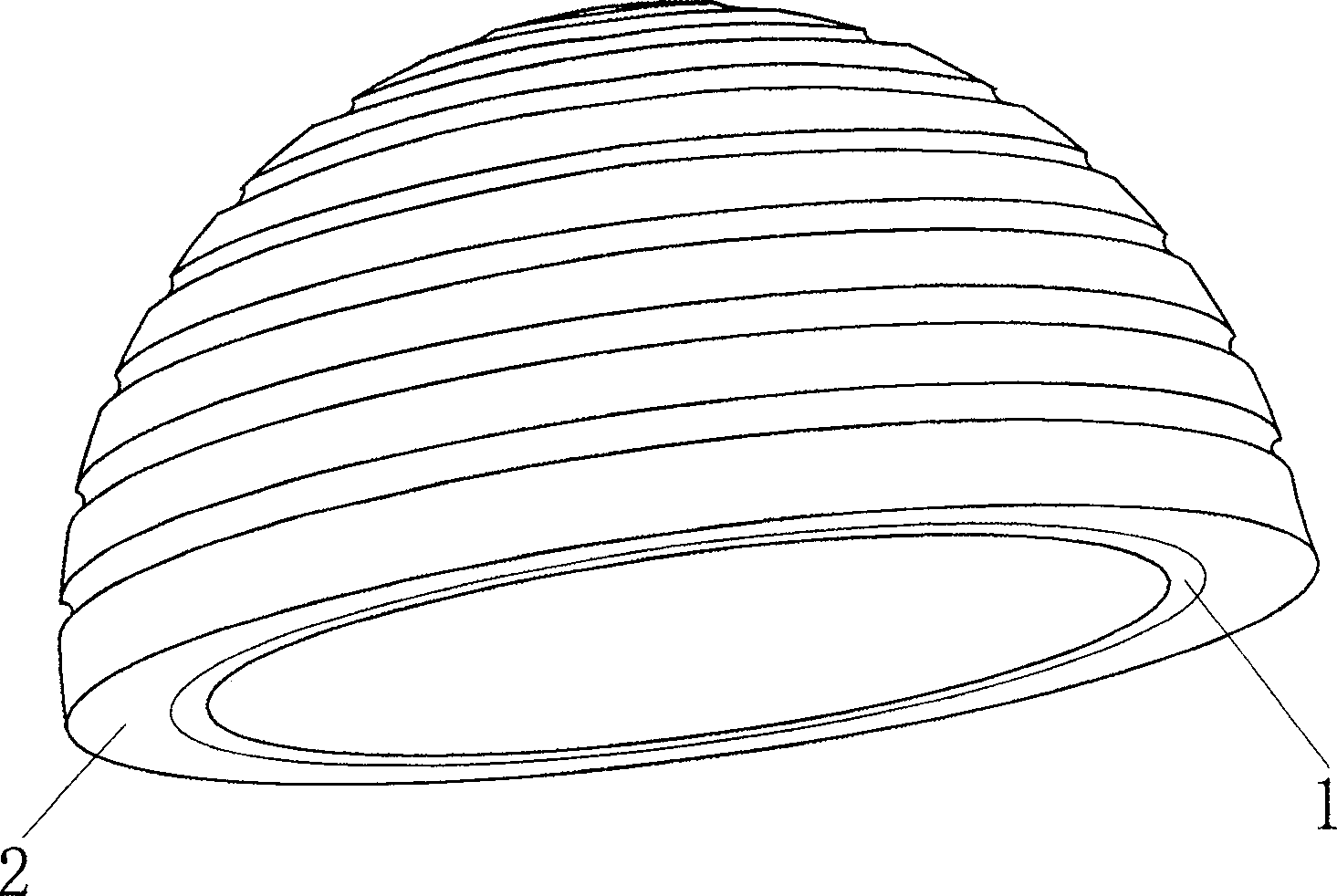

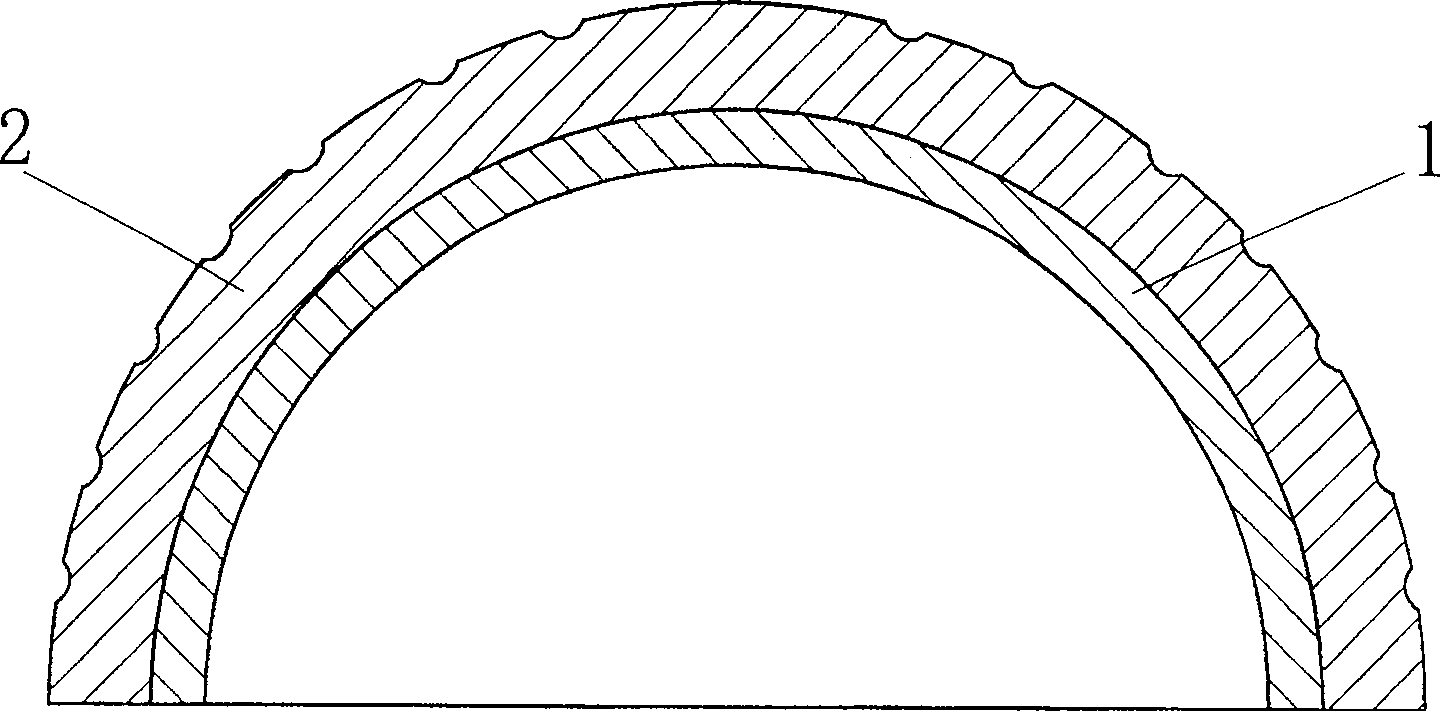

Image

Examples

Embodiment 1

[0026] Add 0.5 parts of estradiol to 99.5 parts of ultra-high molecular weight polyethylene powder with a diameter of 60 μm to 270 μm and a molecular weight of 2.50±500,000, and mix evenly to obtain a powdery composite artificial joint material.

Embodiment 2

[0028] Take 10 parts of estradiol and add it to its solvent—acetone, then add 90 parts of ultra-high molecular weight polyethylene powder with a molecular weight of 4.5 million ± 500,000 and a diameter of 60 μm to 270 μm, mix evenly to form a suspension, and vacuum dry it. A composite material in powder form is obtained.

Embodiment 3

[0030] Take 6 parts of estradiol alendronate sodium and add it into distilled water to dissolve, then add 94 parts of ultra-high molecular weight polyethylene powder with a molecular weight of 3.50±500,000 and a diameter of 60 μm to 270 μm, and mix evenly to form a suspension. After vacuum drying, a uniformly dispersed mixture is made, and then placed in a hot press mold for hot pressing. After four stages of pre-pressing, heating, heat preservation, and cooling, the mold is taken out to obtain a shaped solid composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com