Method for measuring content of boron in cobalt-base alloy

A cobalt-based alloy, boron content technology, used in the preparation of test samples, color/spectral properties measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

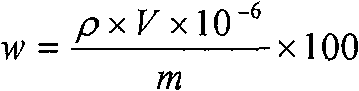

Examples

Embodiment 1

[0041] (1.2), nitric acid, ρ1.42g / mL; superior grade;

[0042] (1.3), hydrofluoric acid, ρ1.15g / mL; superior grade;

[0043] (1.4), cobalt standard solution: 10.0mg / mL; weigh 5.000g; >99.98% metal cobalt is placed in a 250mL beaker, heated and dissolved with 15mL hydrochloric acid (1.1) at low temperature, cooled, transferred to a 500mL volumetric flask, and diluted with water to the mark, shake well;

[0044] (1.5), boron standard solution A: 1.00mg / mL; weigh 5.7192g of boric acid and dissolve it in 20mL of water, heat slightly to dissolve, transfer to a 500mL volumetric flask, dilute with water to the mark, and shake well;

[0045] (1.6), boron standard solution B: 0.10 mg / mL; pipette 25.00 mL of boron standard solution A (1.5) into a 250 mL volumetric flask, add 10 mL of nitric acid (1.2), dilute to the mark with water, and shake well;

[0046] (1.7), boron standard solution C: 0.01mg / mL; pipette 25.00mL boron standard solution B (1.6) into a 250mL volumetric flask, add 1...

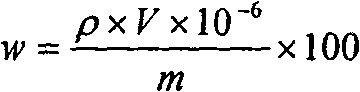

Embodiment 2

[0065] (1.2), nitric acid, ρ1.42g / mL; superior grade;

[0066] (1.3), hydrofluoric acid, ρ1.15g / mL; superior grade;

[0067] (1.4), cobalt standard solution: 10.0mg / mL; weigh 5.000g; >99.98% metal cobalt is placed in a 250mL beaker, heat and dissolve with 5-15mL hydrochloric acid (1.1) at low temperature, cool, transfer to a 500mL volumetric flask, Dilute to the mark with water and shake well;

[0068] (1.5), boron standard solution A: 1.00mg / mL; weigh 5.7192g of boric acid and dissolve it in 20mL of water, heat slightly to dissolve, transfer to a 500mL volumetric flask, dilute with water to the mark, and shake well;

[0069] (1.6), boron standard solution B: 0.10 mg / mL; pipette 25.00 mL of boron standard solution A (1.5) into a 250 mL volumetric flask, add 10 mL of nitric acid (1.2), dilute to the mark with water, and shake well;

[0070] (1.7), boron standard solution C: 0.01mg / mL; pipette 25.00mL boron standard solution B (1.6) into a 250mL volumetric flask, add 10mL nitr...

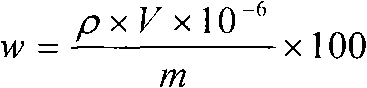

Embodiment 3

[0088] (1.2), nitric acid, ρ1.42g / mL; superior grade;

[0089] (1.3), hydrofluoric acid, ρ1.15g / mL; superior grade;

[0090] (1.4), cobalt standard solution: 10.0mg / mL; weigh 5.000g; >99.98% metal cobalt is placed in a 250mL beaker, heated and dissolved with 15mL hydrochloric acid (1.1) at low temperature, cooled, transferred to a 500mL volumetric flask, and diluted with water to the mark, shake well;

[0091] (1.5), boron standard solution A: 1.00mg / mL; weigh 5.7192g of boric acid and dissolve it in 20mL of water, heat slightly to dissolve, transfer to a 500mL volumetric flask, dilute with water to the mark, and shake well;

[0092] (1.6), boron standard solution B: 0.10 mg / mL; pipette 25.00 mL of boron standard solution A (1.5) into a 250 mL volumetric flask, add 10 mL of nitric acid (1.2), dilute to the mark with water, and shake well;

[0093] (1.7), boron standard solution C: 0.01mg / mL; pipette 25.00mL boron standard solution B (1.6) into a 250mL volumetric flask, add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com