Metallographic erosion method for displaying cobalt-chromium alloy structure

A metallographic erosion, cobalt-chromium alloy technology, applied in the field of metallographic erosion, can solve problems such as poor effect, and achieve the effect of accurate metallographic structure and good erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The test material is a cobalt-chromium alloy tube for human implantation. The alloy ratio is: C: 0.05-0.15; Mg: 1.00-2.00; Si: ≤0.40; P: ≤0.040; S: ≤0.030; Cr: 19-21; Ni: 9-11; W: 14-16; Fe: ≤3; the balance is Co and unavoidable impurities.

[0033] The aqua regia in Example 1 refers to the mixed solution of nitric acid with a mass concentration of 69% and hydrochloric acid with a mass concentration of 36.5%, according to the volume ratio of nitric acid: hydrochloric acid = 1:3.

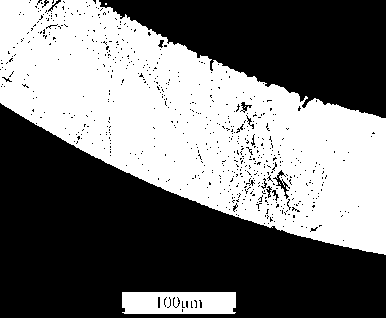

[0034] The room temperature is 28°C, when the prepared aqua regia is left for 7 minutes, the color of the aqua regia is dark yellow, and at this time, dip the cotton to wipe the sample, and the wiping time is about 50 seconds. When the test surface is no longer bright and slightly dark, the erosion effect is the best at this time, the surface of the sample is clear, the grain boundaries are clear, and the structure is twin crystal α, see Figure 4 .

Embodiment 2

[0036] The test material is a cobalt-chromium alloy pipe for human implantation. The alloy ratio is: C: 0.05-0.15; Mg: 1.00-2.00; Si: ≤0.40; P: ≤0.040; S: ≤0.030; Cr: 19-21; Ni : 9-11; W: 14-16; Fe: ≤3; the balance is Co and unavoidable impurities.

[0037] The aqua regia in Example 2 refers to the mixed solution of nitric acid with a mass concentration of 69% and hydrochloric acid with a mass concentration of 36.5%, according to the volume ratio of nitric acid: hydrochloric acid = 1:3.

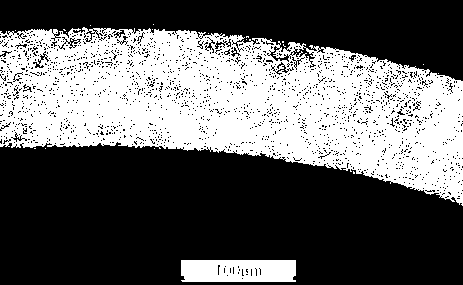

[0038] The room temperature is 28°C. When the prepared aqua regia is left for 1 minute, the color of the aqua regia is dark yellow. At this time, dip the cotton to wipe the sample, and the wiping time is about 60 seconds. When the test surface is no longer bright and slightly dark, the erosion effect is the best at this time, the surface of the sample is clear, the grain boundaries are clear, and the structure is twinned α.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com