Method for preparing spherical cobalt-chromium-molybdenum alloy powder for micron-level additive material manufacturing

A cobalt-chromium-molybdenum alloy and additive manufacturing technology, applied in the field of materials, can solve problems such as poor fluidity of cobalt-chromium-molybdenum alloy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

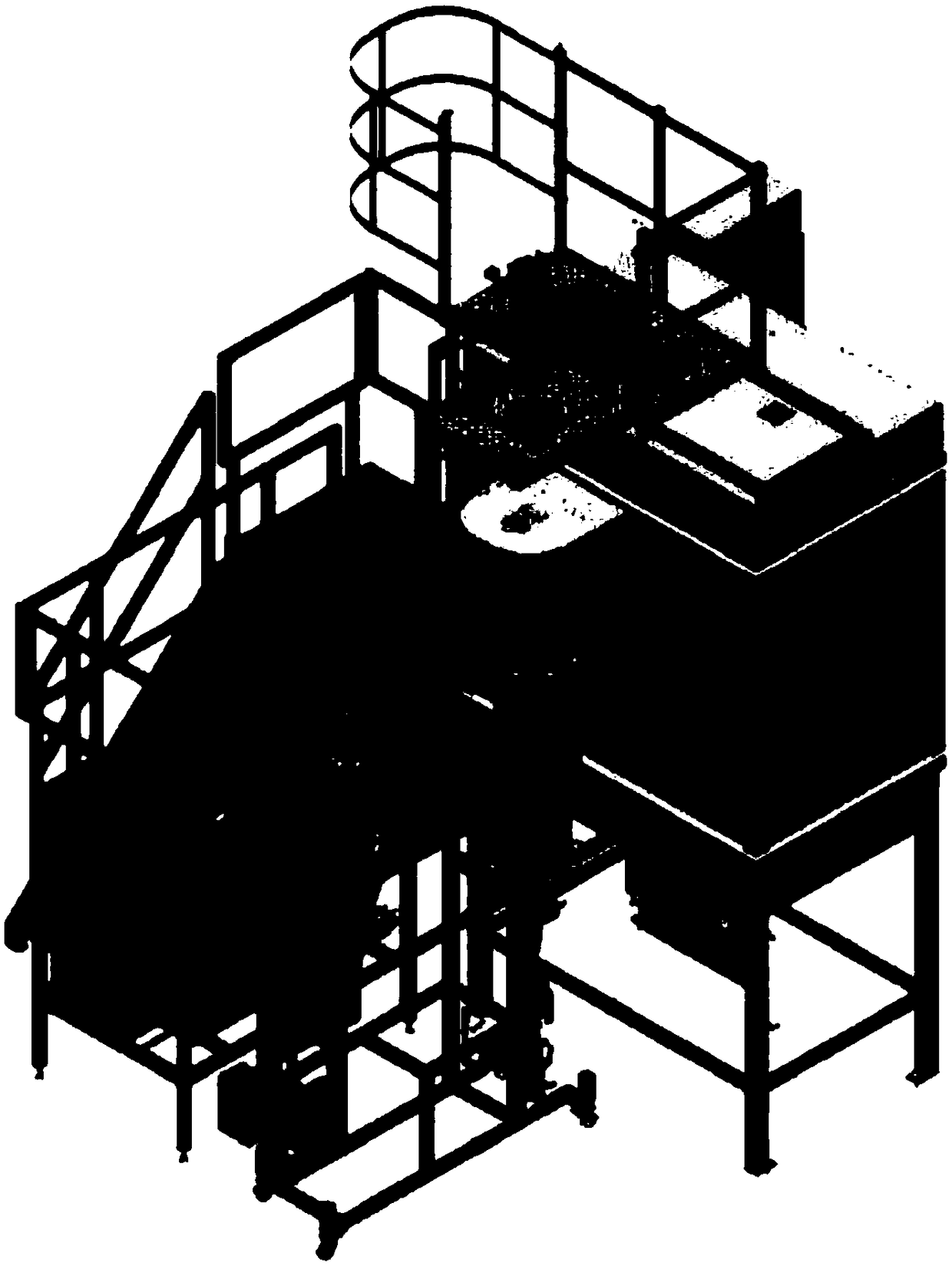

Method used

Image

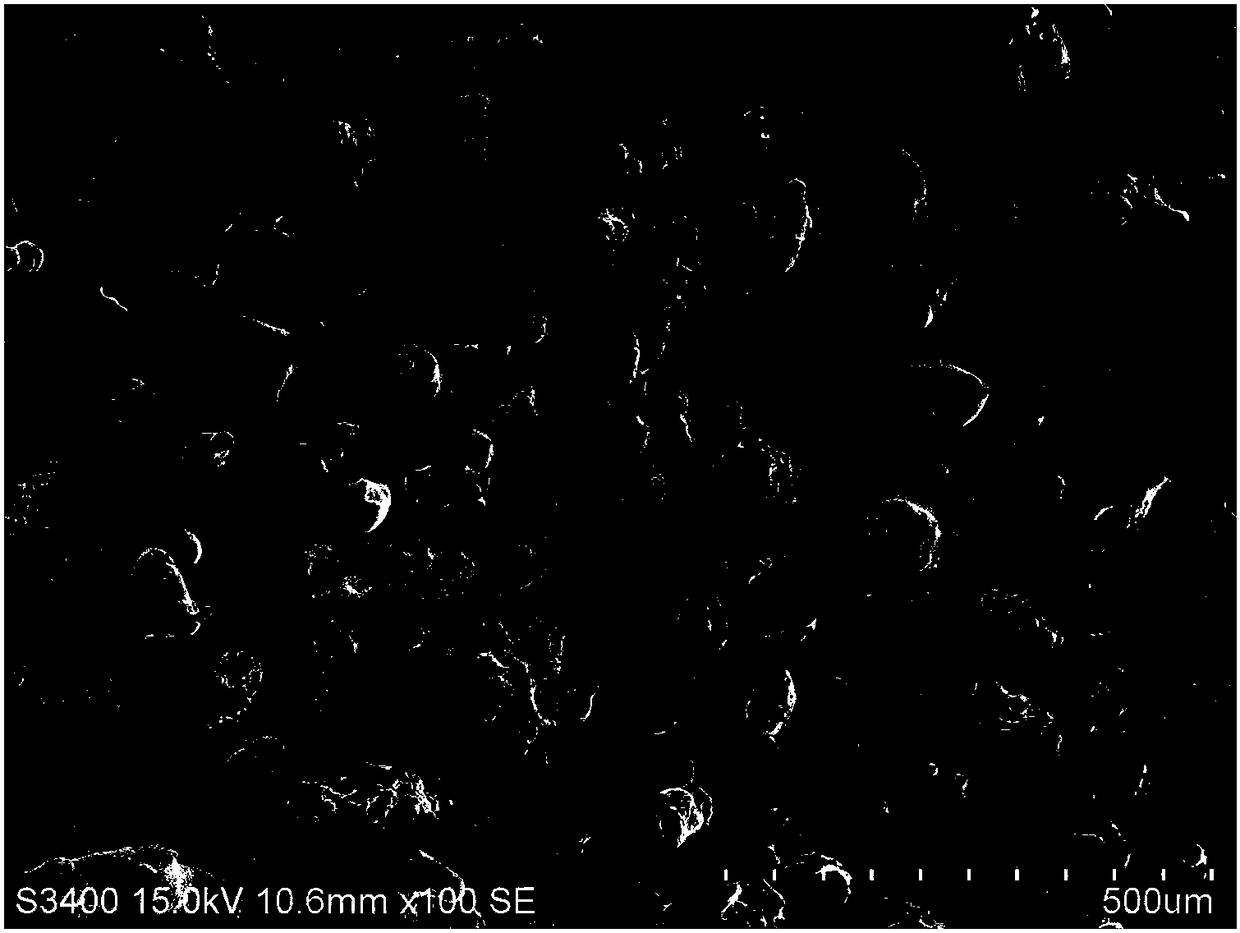

Examples

Embodiment 2

[0037] The experimental parameters selected for the spheroidization experiment are: the air pressure in the final reaction vessel is 15.0psia; the grid current is 0.43A; the plate voltage is 7.0KV; the plate current is 3.6A; the feeding speed is 4.5rpm; 50 psig; argon central gas flow pressure is 15 psig; argon powder supply gas flow pressure is 8 psig; hydrogen gas inlet pressure is 8 psig.

[0038]The spheroidization rate of the micron-sized spherical cobalt-chromium-molybdenum alloy powder after spheroidization is not lower than 90%.

Embodiment 3

[0040] The experimental parameters selected for the spheroidization experiment are: the air pressure in the final reaction vessel is 14.7psia; the grid current is 0.45A; the plate voltage is 7.5KV; the plate current is 3.9A; the feeding speed is 4.6rpm; The pressure of the argon central gas flow is 13 psig; the pressure of the argon powder supply gas flow is 7 psig; the pressure of the hydrogen gas inlet is 6 psig.

[0041] The spheroidization rate of the micron-sized spherical cobalt-chromium-molybdenum alloy powder after spheroidization is not lower than 90%.

Embodiment 4

[0043] The experimental parameters selected for the spheroidization experiment are: the air pressure in the final reaction vessel is 14.3psia; the grid current is 0.44A; the plate voltage is 8.0KV; the plate current is 4.2A; the feeding speed is 4.8rpm; It is 63 psig; the pressure of argon central gas flow is 17 psig; the pressure of argon powder supply gas flow is 9 psig;

[0044] The spheroidization rate of the micron-sized spherical cobalt-chromium-molybdenum alloy powder after spheroidization is not lower than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com