Method for electrochemically aided preparation of silver powder with special form

An electrochemical and nano-silver powder technology, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve the problems of complex process links of nano-silver powder, difficult to control the shape of silver powder, and difficult process. The effect of good shape control, stable product and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

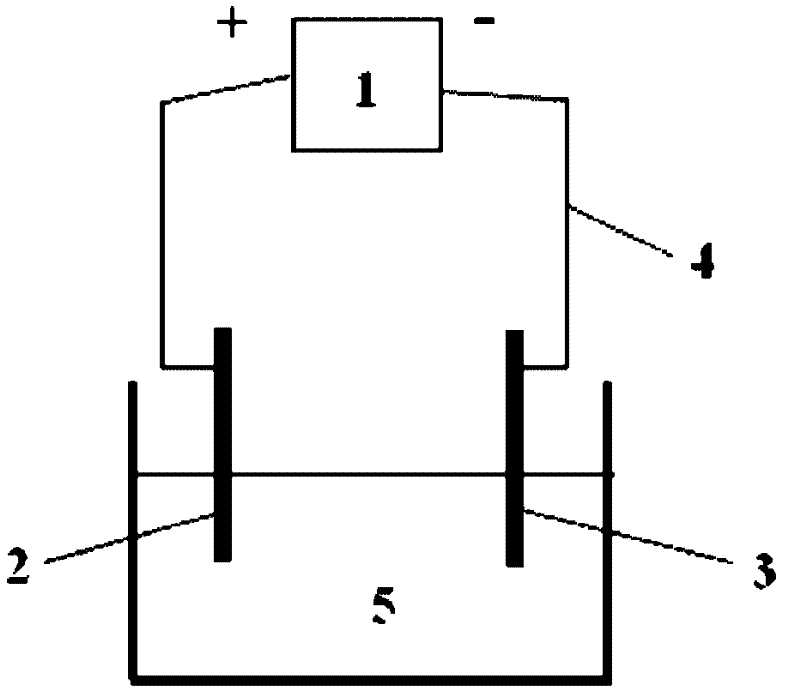

Method used

Image

Examples

Embodiment 1

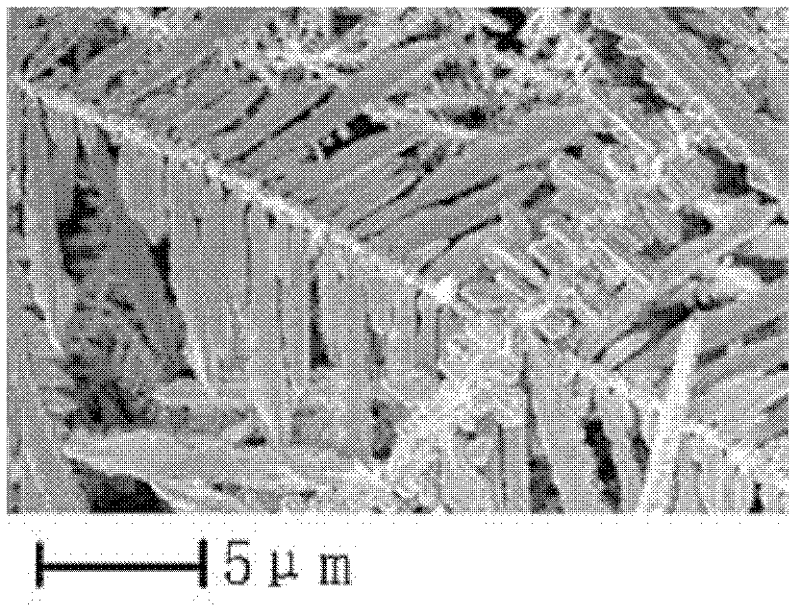

[0031] Choose bamboo charcoal as the cathode, glassy carbon as the anode, and 500ppm silver sulfate solution as the electrolyte. Connect the electrode to the constant current meter with a wire. Ultrasonic oscillation in absolute ethanol can obtain the ethanol dispersion of fibrous nano-silver powder, and drying can obtain fibrous nano-silver powder.

Embodiment 2

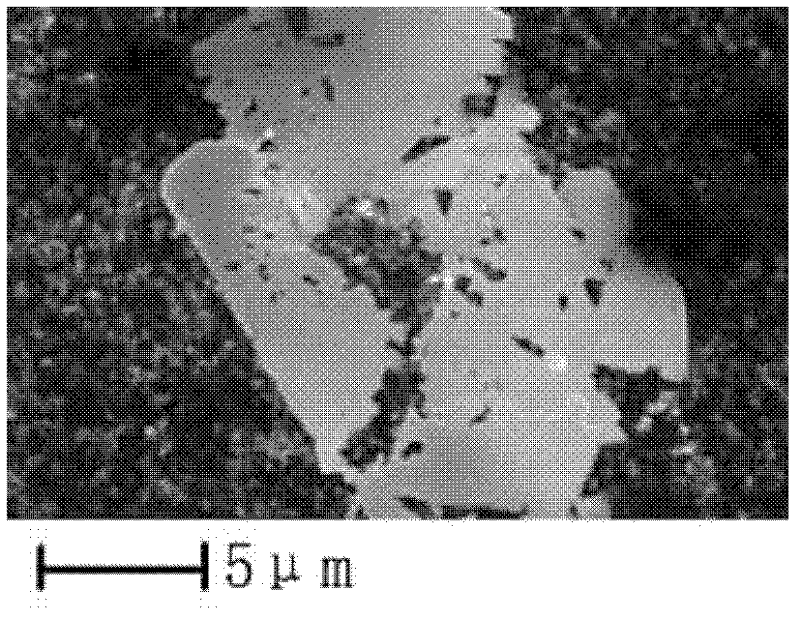

[0033] Choose graphite as the cathode, platinum wire as the anode, and 1000ppm silver nitrate solution as the electrolyte. Connect the electrode to the constant current meter with a wire. Ultrasonic oscillation in absolute ethanol to obtain the ethanol dispersion of the flaky nano-silver powder, and drying to obtain the flaky nano-silver powder.

Embodiment 3

[0035] Choose platinum mesh as the cathode, gold wire as the anode, and 10000ppm silver chloride sol as the electrolyte. Connect the electrode to the constant current meter with a wire. The electrode is placed in absolute ethanol for ultrasonic vibration to obtain an ethanol dispersion of the cubic cage-shaped silver nano powder, and drying to obtain the cubic cage-shaped nano-silver powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com