Automobile steel with low cost and high strength ductility balance and preparation method thereof

A high-strength plastic product, low-cost technology, used in temperature control and other directions, can solve problems such as poor process performance, high cost, and difficult metallurgical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] This embodiment is mainly aimed at the development of hot-rolled steel sheets and cold-rolled steel sheets for automobiles, and the test process simulates the continuous hot-rolling and cold-rolling processes of steel sheets. But the process is also suitable for medium and thick plates, profiles and rods and wires.

[0058] Steel smelting:

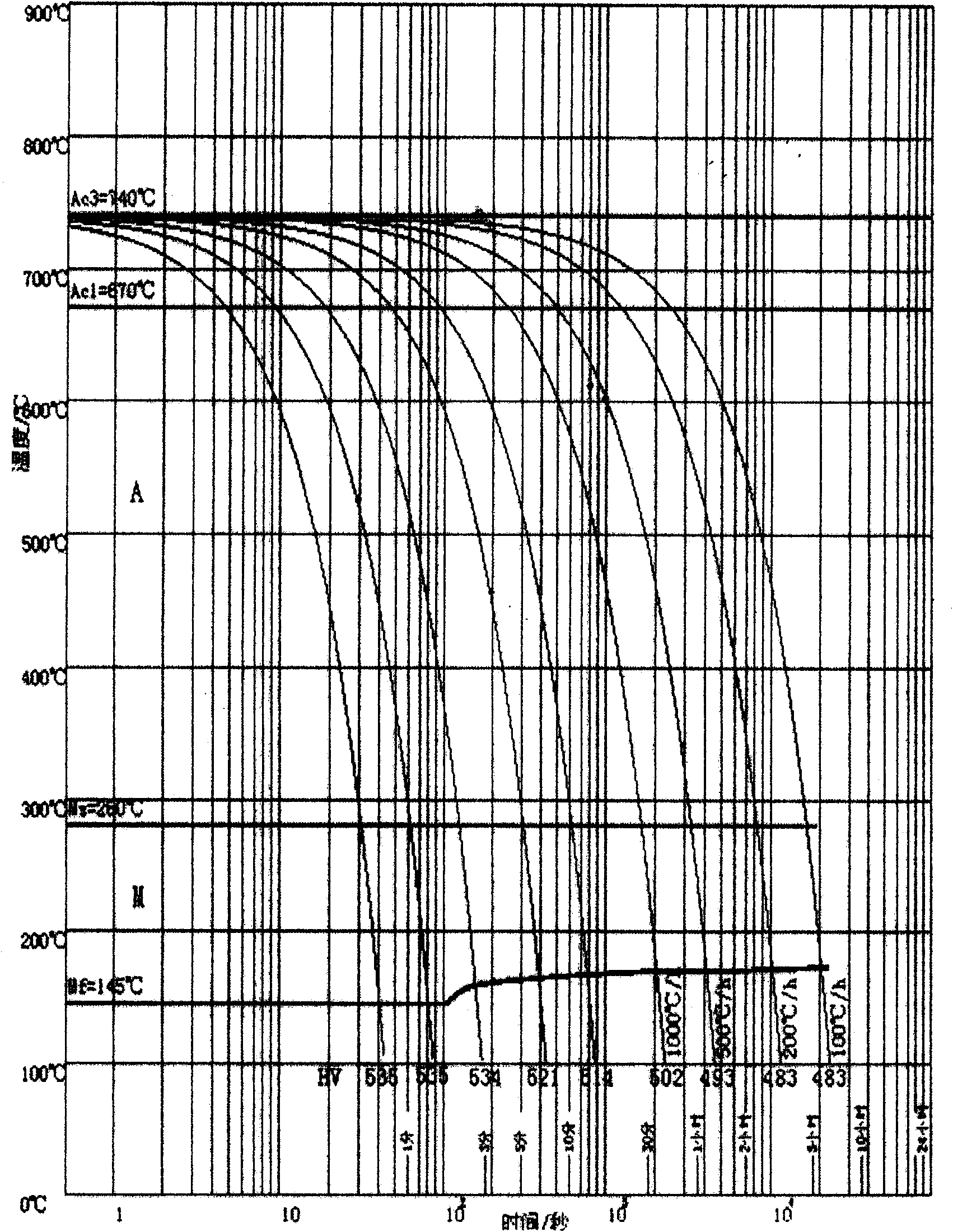

[0059] The steel of the present invention is smelted by a laboratory vacuum induction furnace, and the cast ingots are round ingots of 150 kg and 50 kg. A total of 14 furnaces of steel were smelted, of which 1-8# used a 150kg ingot shape, and 9-14# used a 50Kg ingot shape. The chemical composition is shown in Table 1. The CCT curve of 4# steel shows that the steel has good hardenability. and bainite transformation have a very long incubation period, with figure 1 .

[0060] Table 1 Chemical composition of the invented steel

[0061] C

mn

P

S

Nb

Ti

other

Ac1(°C)

1

0.02 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com