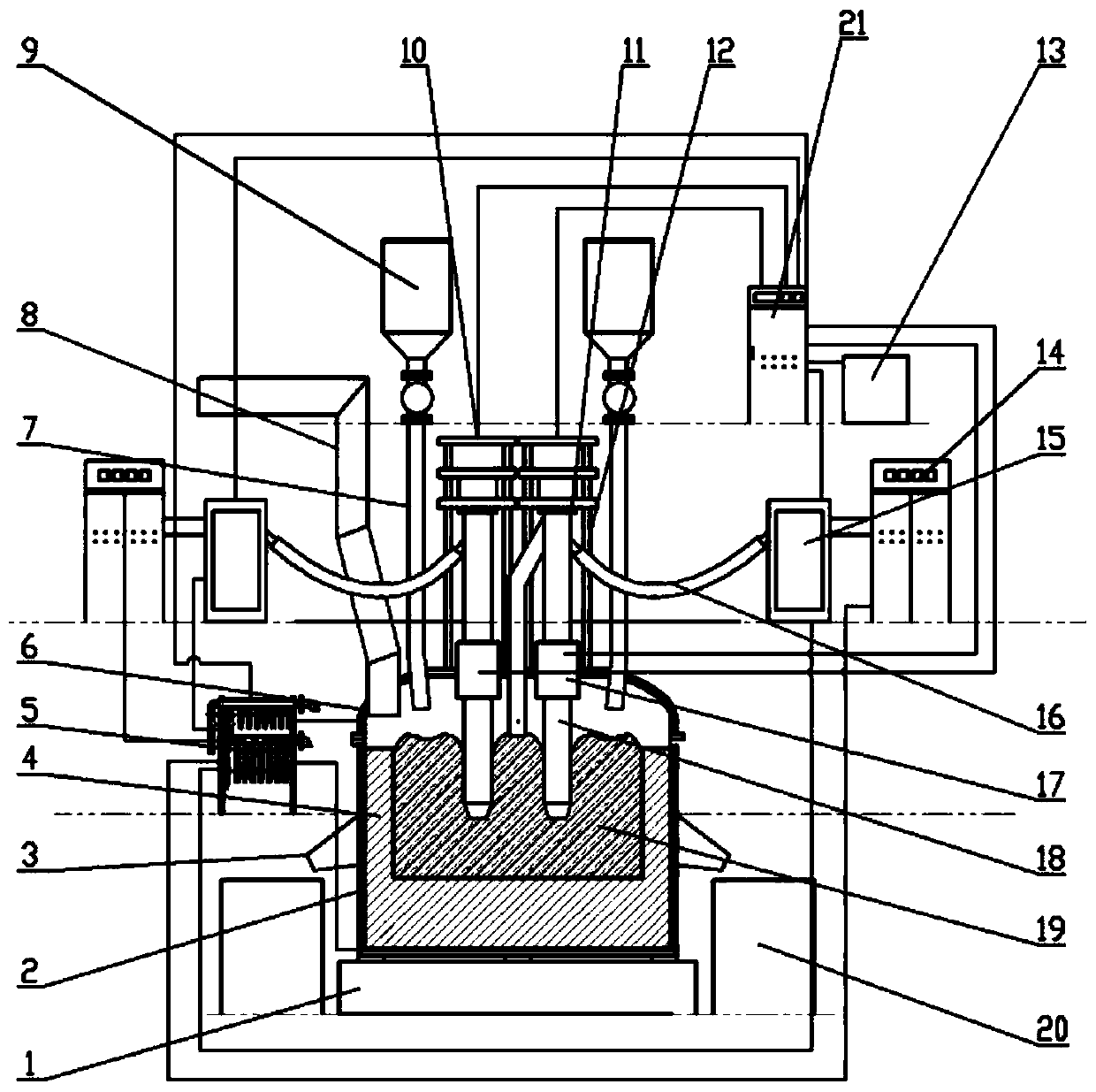

Direct-current aluminum-silicon alloy submerged arc furnace

A technology of gold mine and hot furnace, applied in the field of electric furnace, can solve the problems of furnace bottom rising, difficult to maintain long-term use, etc., to achieve the effect of continuous feeding and discharging, less heat loss, and adjustable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] (1) Use andalusite concentrate (containing 57.02% alumina, 38.02% silica, and 1.31% ferric oxide) as raw material, and use a combination of bituminous coal, petroleum coke, and charcoal at a ratio of 7:2:1 as a reducing agent. Firstly, the raw materials are made into powder with a particle size of 60-120 mesh, and the binder sodium lignosulfonate is added, and a certain proportion of water is added, and the andalusite concentrate and the reducing agent are mixed in a ratio of 8:2, and the mixing 6% sodium lignosulfonate binder, add 12% water of the total mixture and mix and stir. Then press into pellets on the JK-100 industrial pellet machine under the pressure of 30-50MPa, and dry in the electric drying equipment at a temperature of 150-250°C. The moisture content of the pellets is less than 1%. 2cm oval oblate ball.

[0100] (2) Add the dry pellets into the top bin 9 of the submerged arc furnace through a belt conveyor, and then feed the raw materials into the furnac...

Embodiment 2

[0105] (1) Use high-alumina coal gangue (containing 44.61% alumina, 46.08% silicon oxide, and 2.40% ferric oxide) as raw materials, and a combination of bituminous coal and petroleum coke 8:2 as the reducing agent. Firstly, the raw materials are made into powder with a particle size of 80-120 mesh, and a binder is added to the dry material of papermaking wastewater, and a certain proportion of water is added. % papermaking wastewater dry matter binder, add 10% water of the total mixture and mix and stir. Then press into pellets on the JK-100 industrial pelletizing machine under the pressure of 40-50MPa, and dry in the electric drying equipment at a temperature of 200-250°C. The moisture content of the pellets is less than 1%. 3cm oval oblate ball.

[0106] (2) Add the dry pellets into the top bin 9 of the submerged arc furnace by hanging the tank, and then feed the raw materials into the furnace continuously through the feeding pipe 7, the inside of the feeding pipe 7 is alwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com