Patents

Literature

40results about How to "Uniform heating area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibrating washing device

PendingCN106283451ASimple structureReasonable designTextile treatment machine arrangementsTextile treatment by spraying/projectingWater channelPulp and paper industry

The invention discloses a vibrating washing device. The vibrating washing device comprises a water channel tank. A forward and reverse vibrating net roller, a spraying net roller and a spraying device are installed in the water channel tank. The forward and reverse vibrating net roller is wrapped by a heating bottom pipe. The vibrating washing device is simple in structure, reasonable in design and environmentally friendly, the washing effect is effectively improved, and energy is saved.

Owner:SHAOXING LIANKE MACHINERY

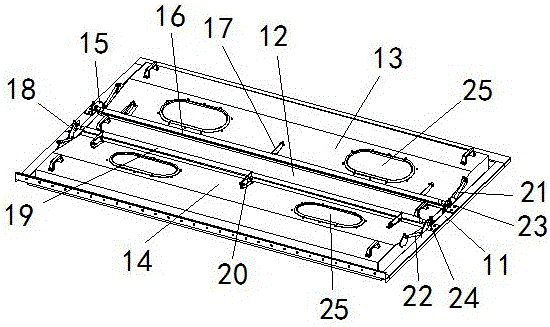

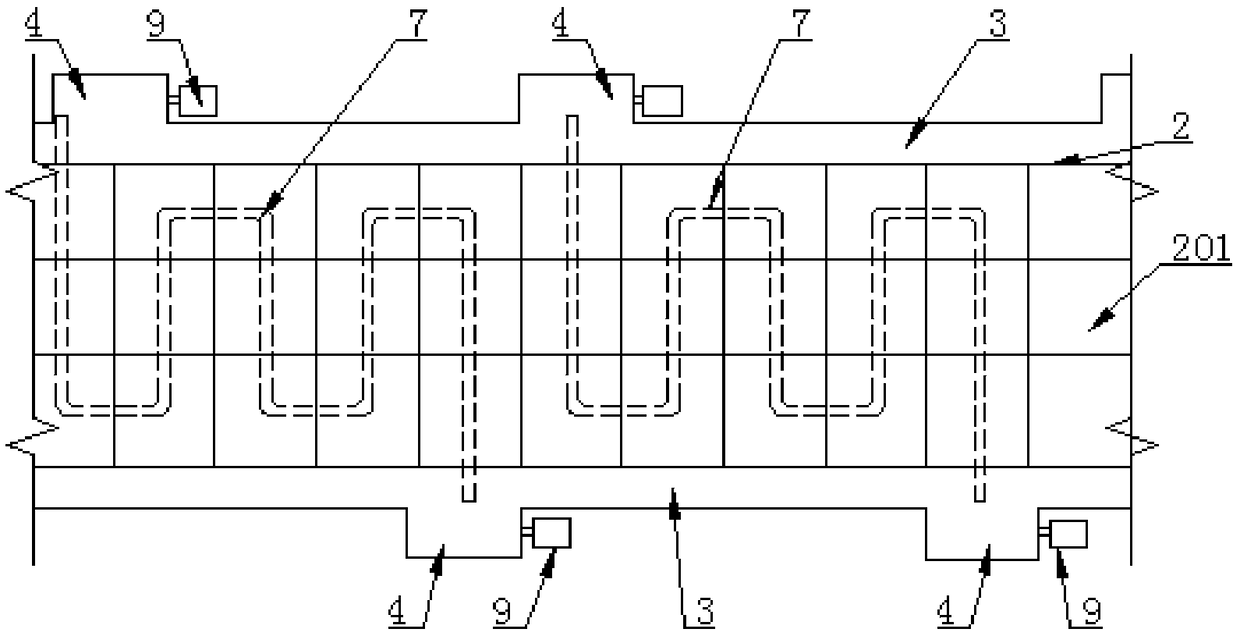

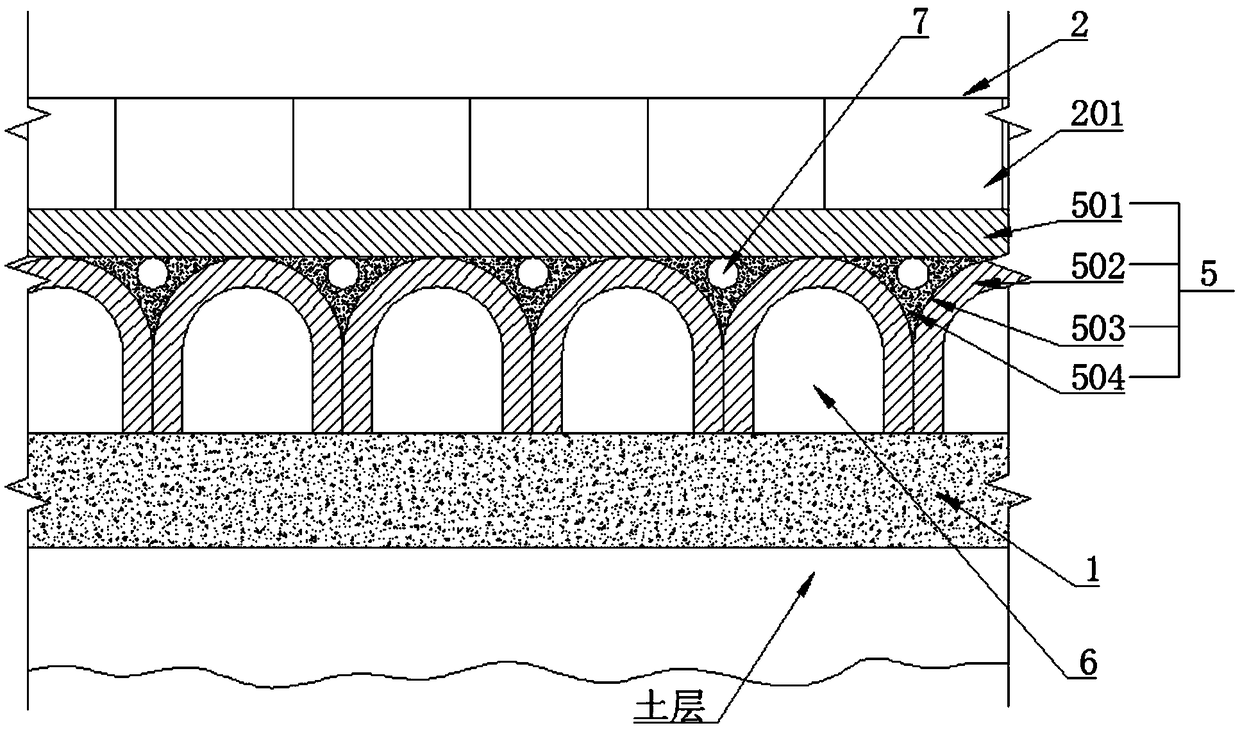

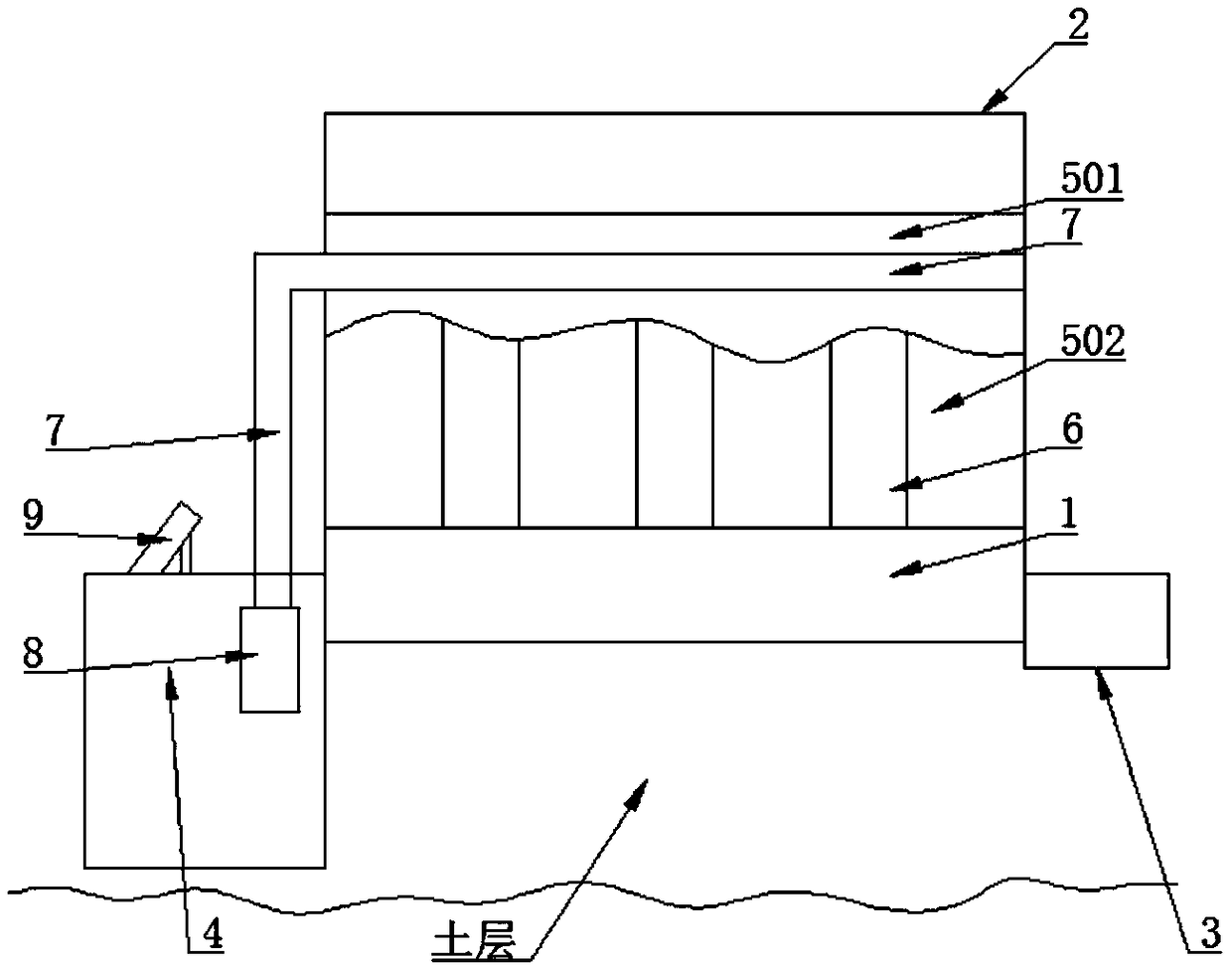

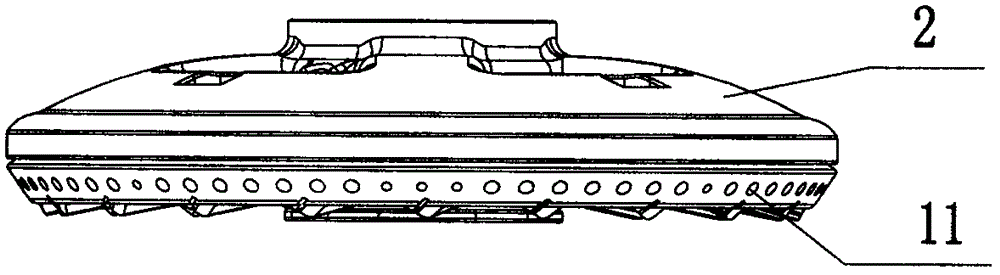

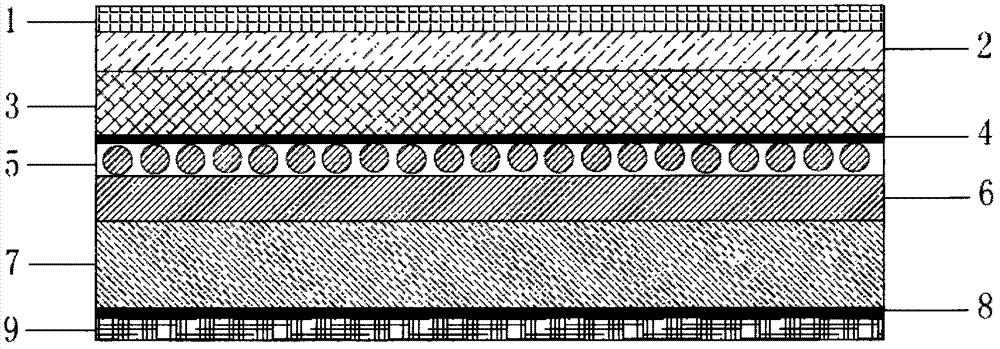

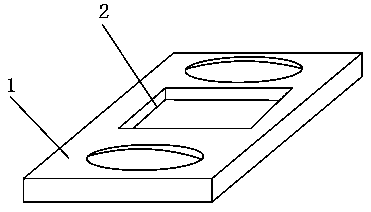

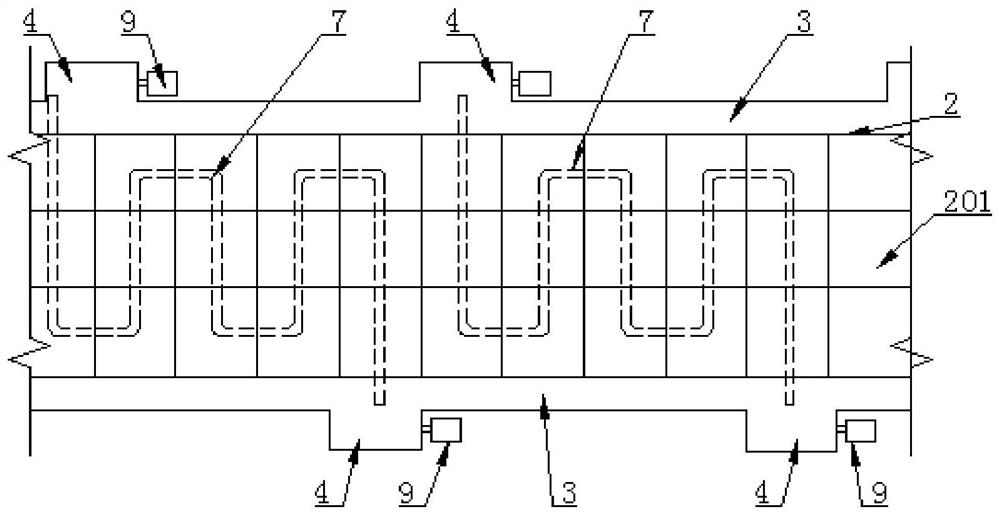

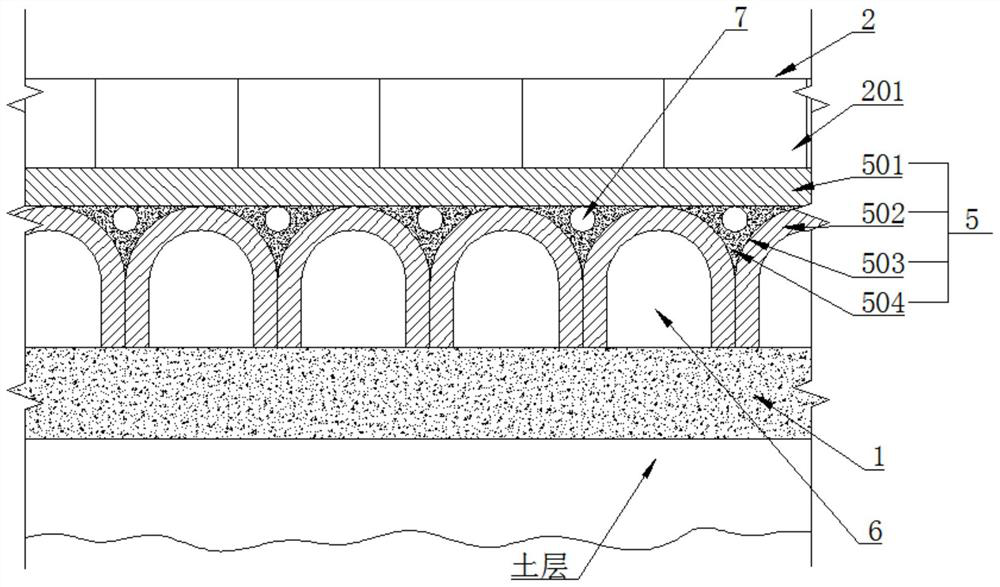

Photovoltaic pavement system

ActiveCN108755327AImprove cooling effectGood effectPaving gutters/kerbsTemporary pavingsHot weatherRoad surface

The invention discloses a photovoltaic pavement system. The photovoltaic pavement system comprises a general control unit, a roadbed, a photovoltaic pavement and drainage troughs on both sides of thephotovoltaic pavement. The photovoltaic pavement comprises a plurality of photovoltaic panel modules. The photovoltaic pavement system is characterized in that the roadbed is provided with a support part, the support part is used for supporting the photovoltaic module, a water collecting channel is formed between the roadbed and the support part, a water collecting tank is provided with water collection tanks at intervals, the support part is paved with the photovoltaic panel modules, a circulating water pipe is disposed between the photovoltaic panel module and the support part, a heat collector is arranged at the water collecting tank, and the circulating water pipe is communicated with the heat collector through a first water pump. The photovoltaic pavement system realizes cooling of the photovoltaic pavement in the hot weather, and melting of the snow and the ice layer on the photovoltaic pavement in the cold weather. The support part transforms the bending moment stress generatedby the load on the photovoltaic panel module into compressive stress or transforms the most of the bending moment stress into compressive stress and prolongs the service life of the photovoltaic panelmodule and the service life of the whole photovoltaic pavement.

Owner:榛硕(武汉)智能科技有限公司

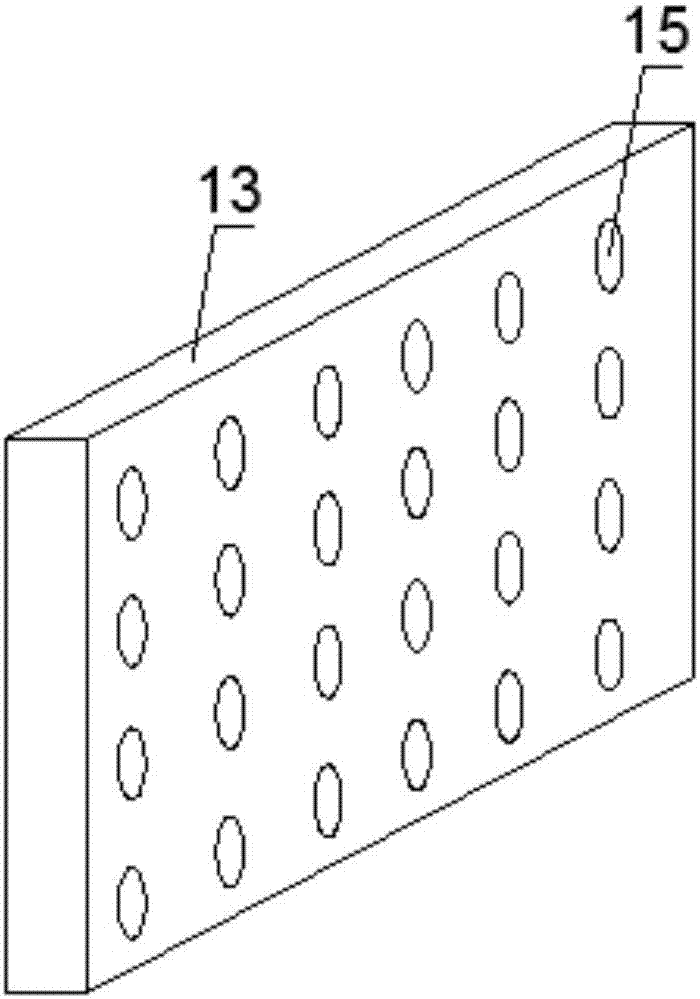

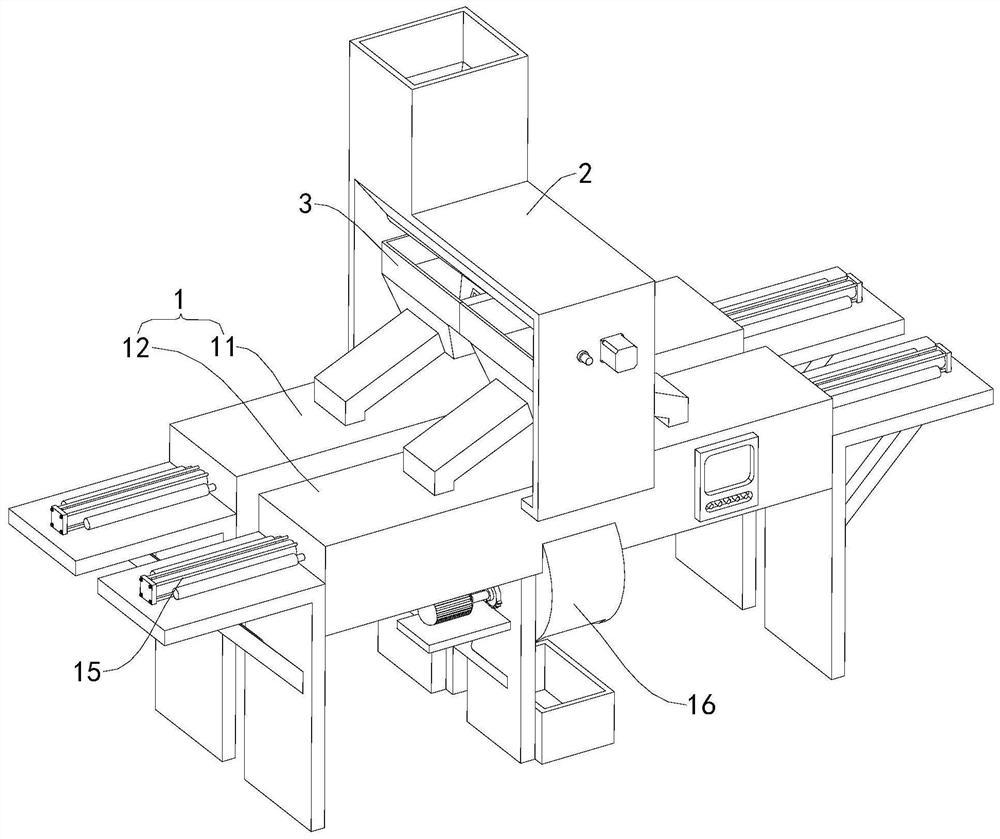

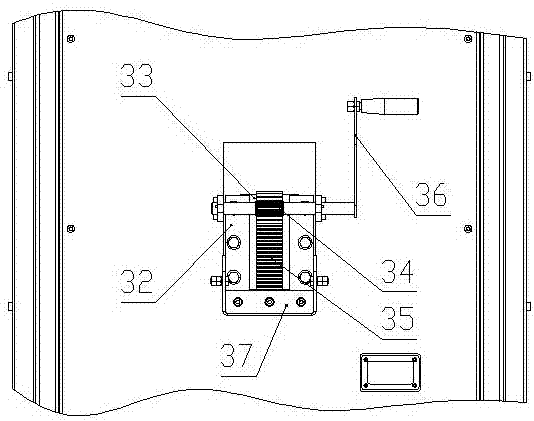

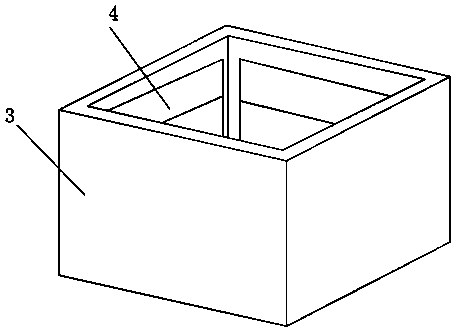

Waste recovery equipment

InactiveCN107321596AUniform heating areaFast dryingSievingScreeningEngineeringPulp and paper industry

The invention discloses waste recovery equipment. The waste recovery equipment comprises an equipment body. A feeding port is formed in the surface of one end of the equipment body. A discharging port is formed in the bottom surface of the other end of the equipment body. The equipment body is supported by two sets of supports. A fixing plate is further arranged between the two sets of supports. A vibrating motor is arranged on the surface of the fixing plate, and one end of the vibrating motor is connected with a screen inside a screen box. Baffles are arranged on the two sides of the screen box correspondingly. Meshes are formed in the surface of the screen. Damping springs are further arranged between the screen box and the supports. A funnel is arranged at the bottom end of the screen box. A collection device is arranged at the bottom end of the funnel. An air heater is arranged on one side of the feeding port. An air outlet is formed in one end of the air heater, and a protective plate is arranged at one end of the air outlet. Through holes are formed in the surface of the protective plate. By using a linear vibrating sieve and the air heater in cooperation, wet waste can be treated, the heated area of the wet waste is uniform under the vibrating effect of the vibrating sieve, the drying speed is high, and substances adhering to the surface of the wet waste can be shaken away from the surface of the wet waste through the vibrating sieve.

Owner:谢明辽

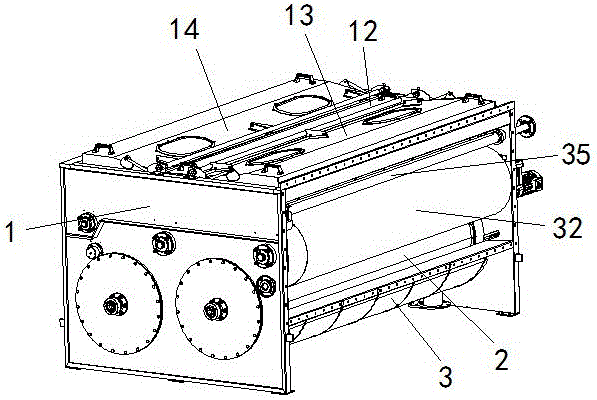

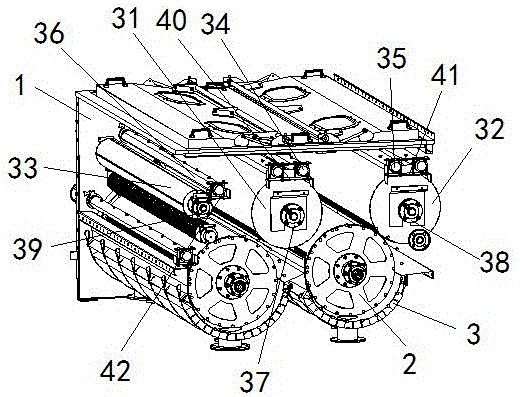

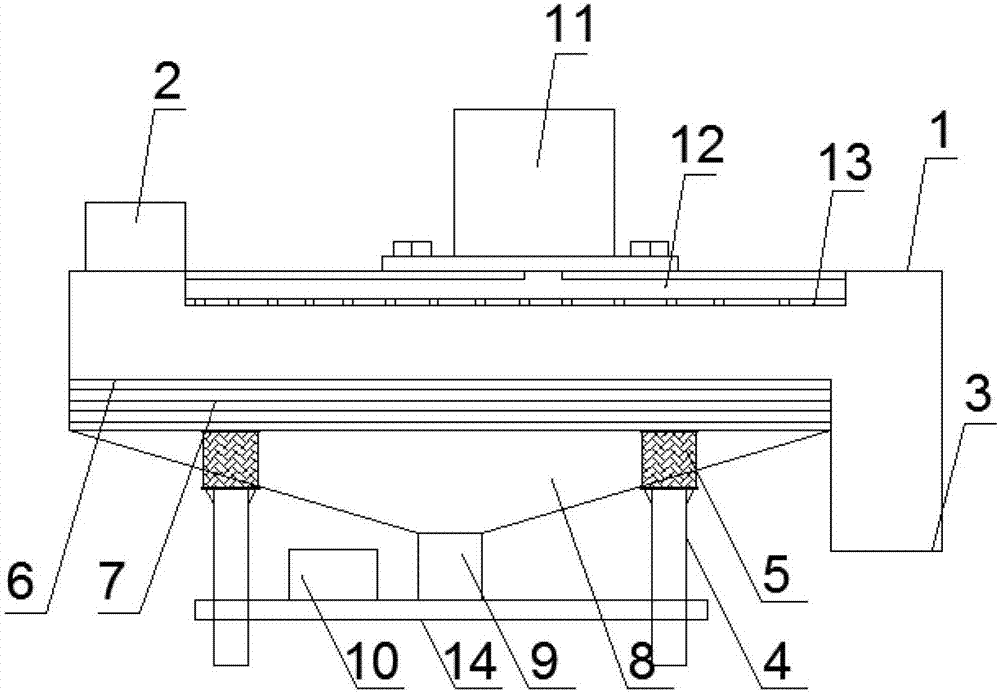

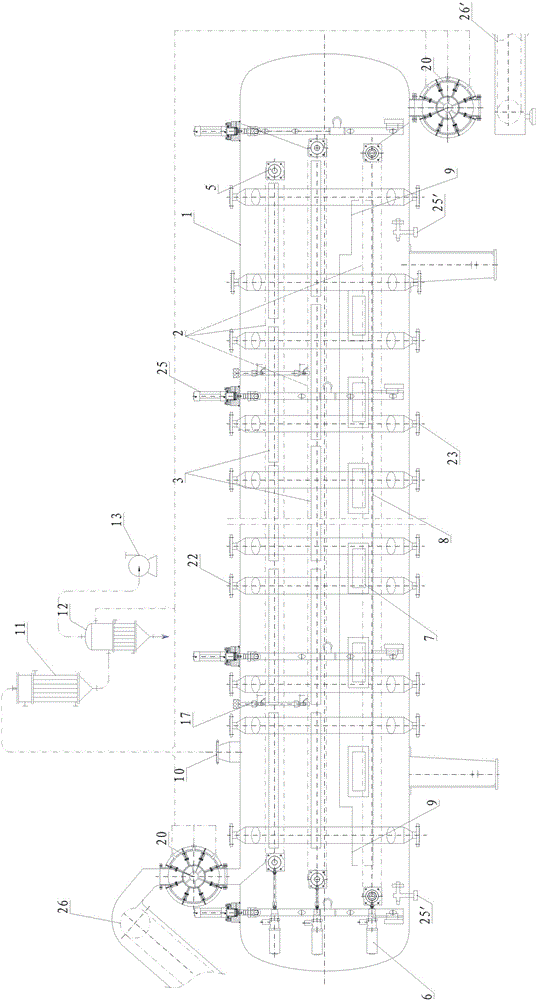

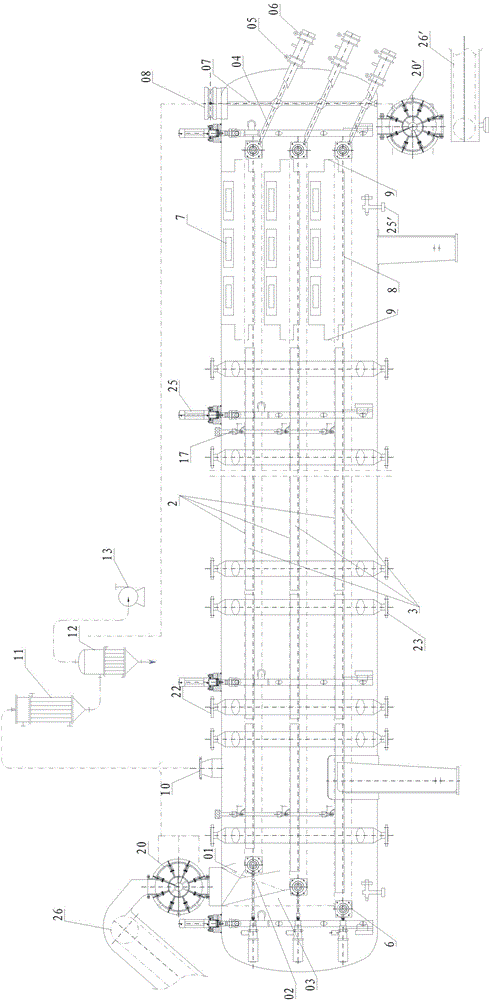

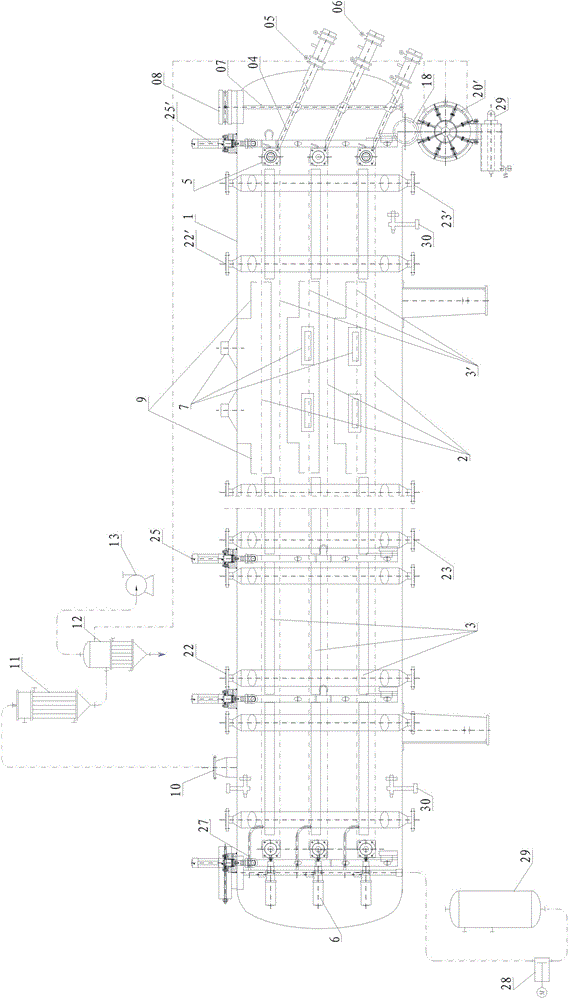

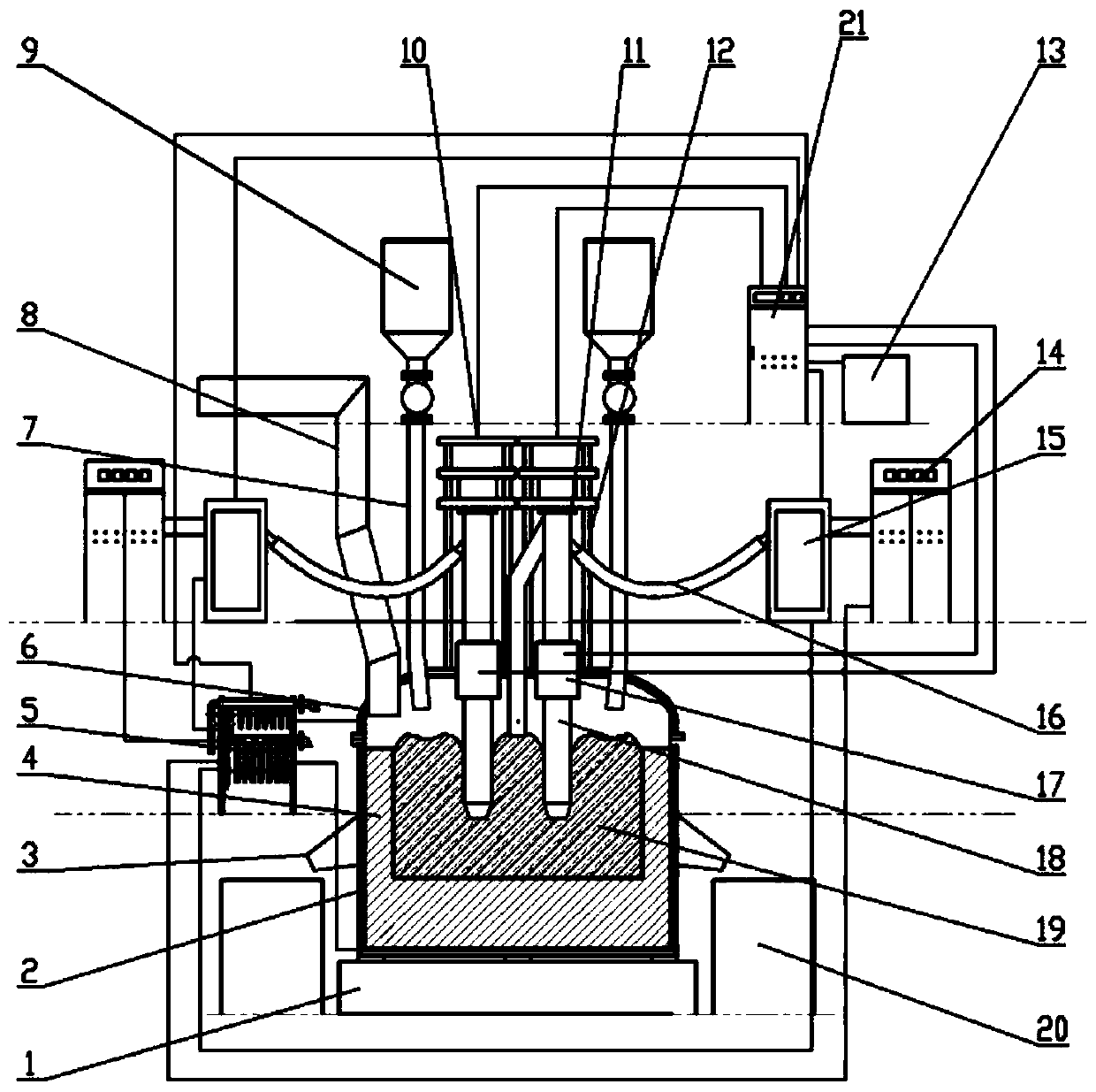

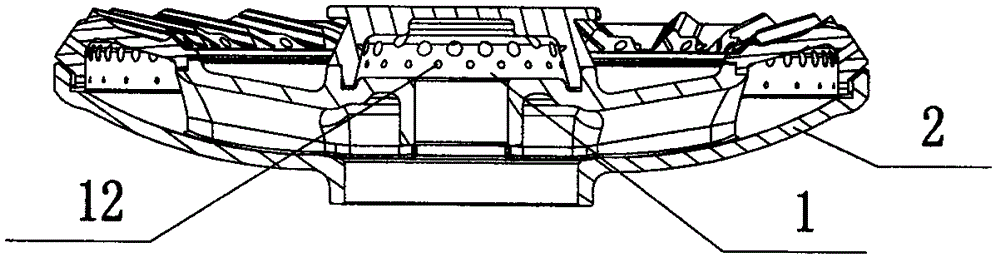

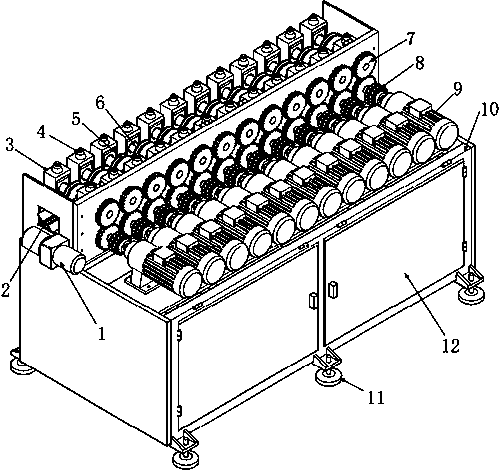

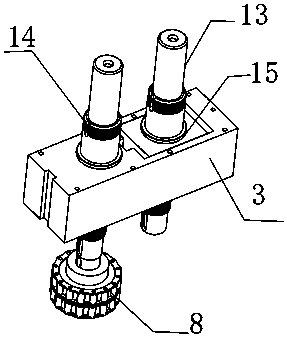

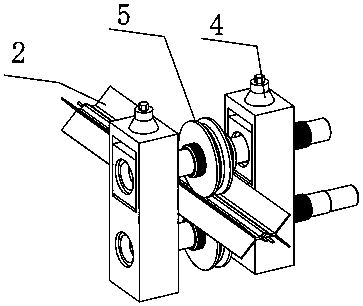

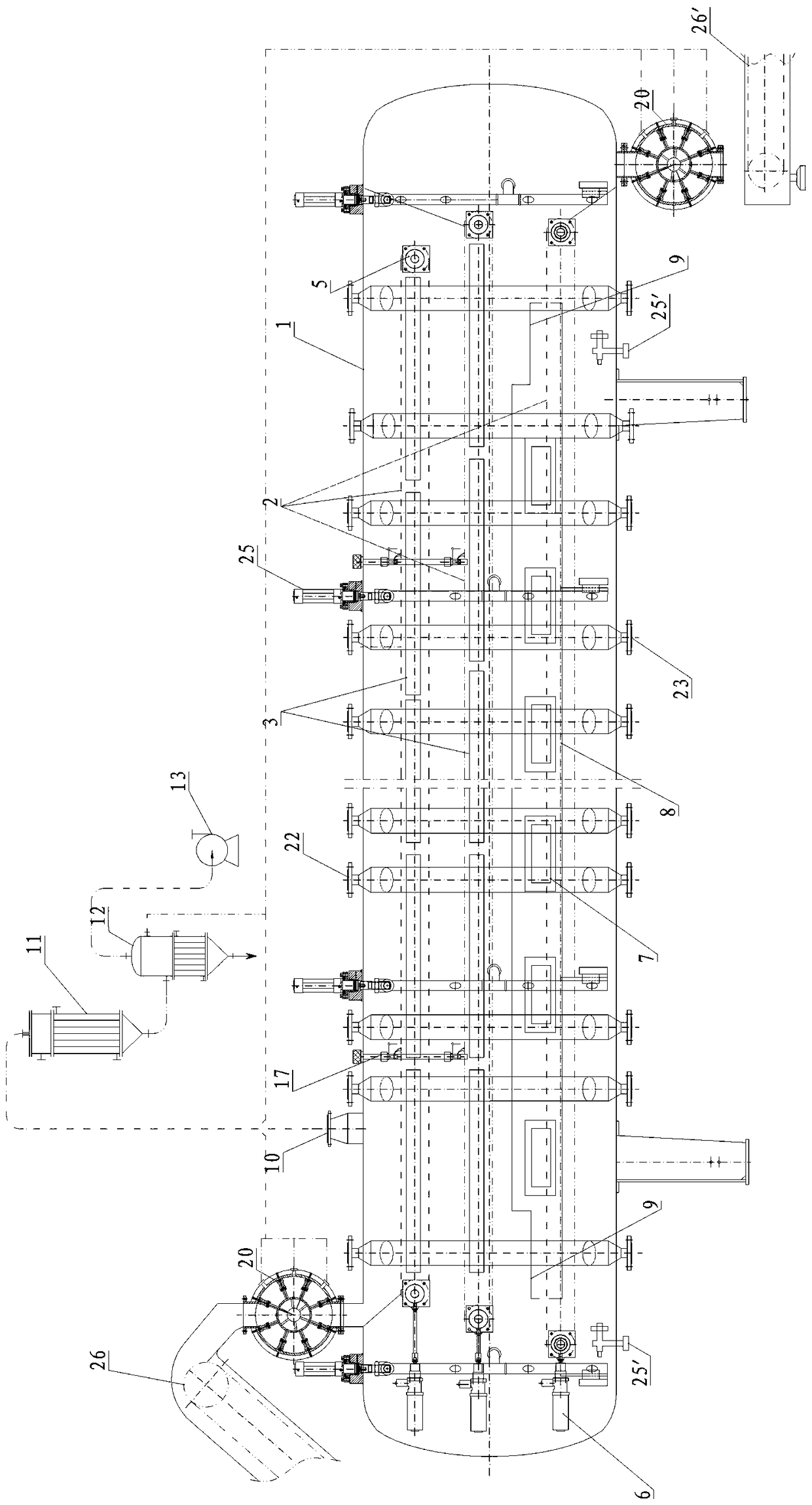

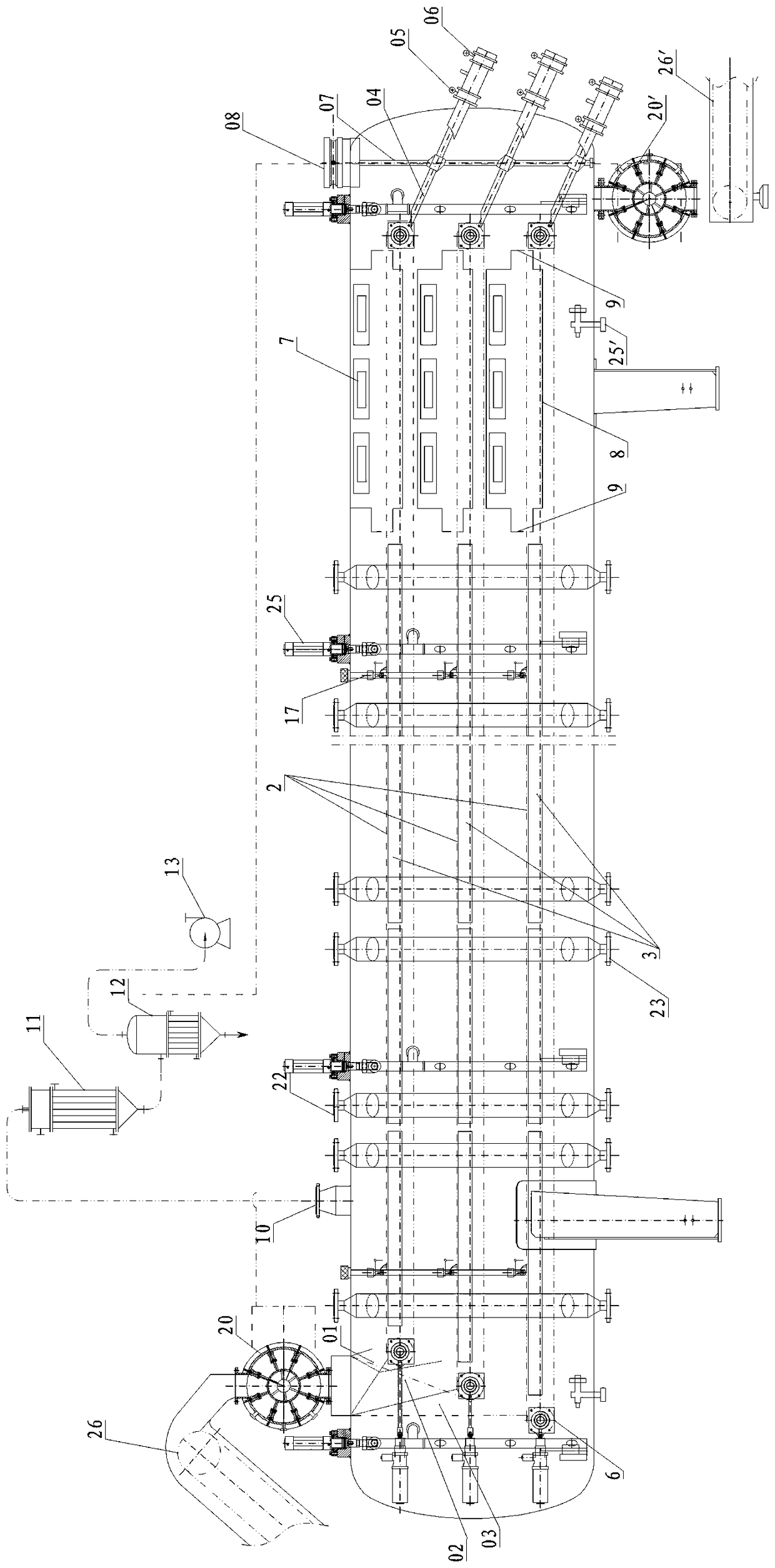

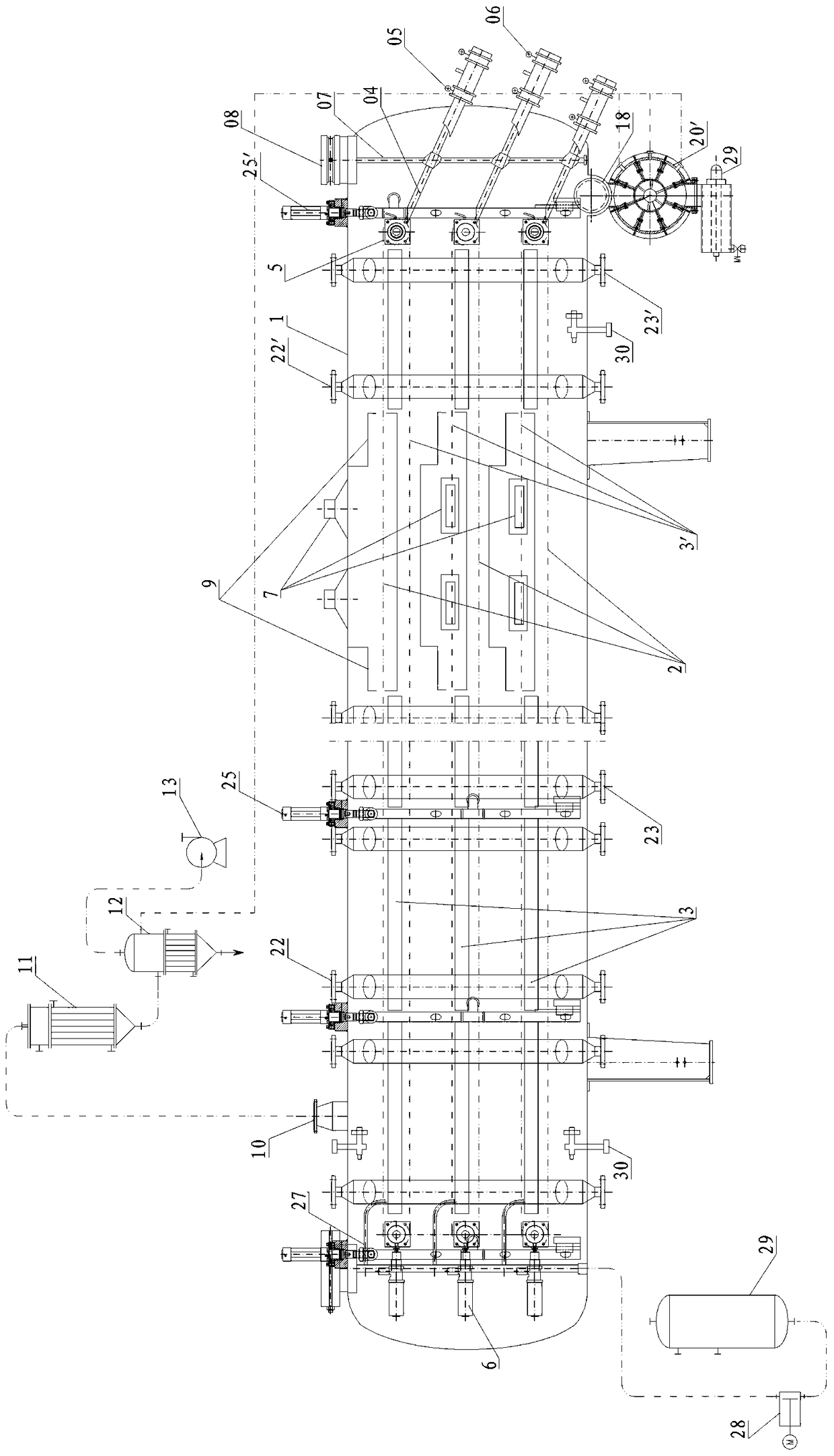

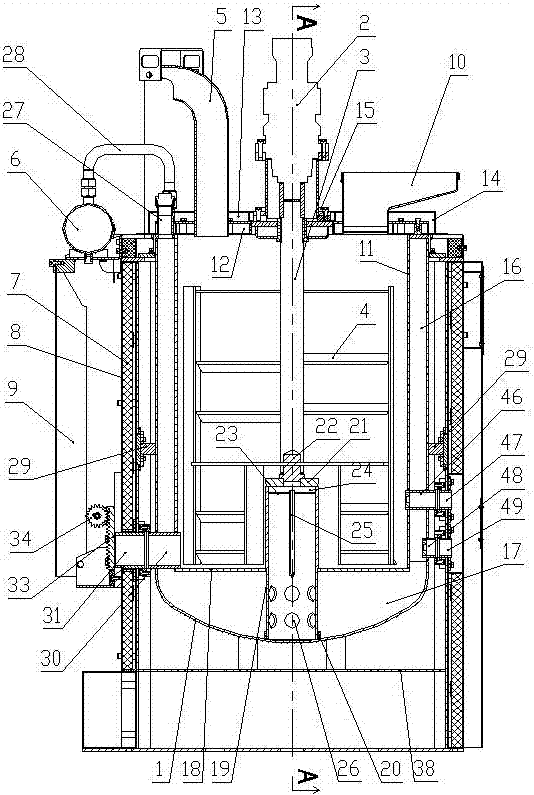

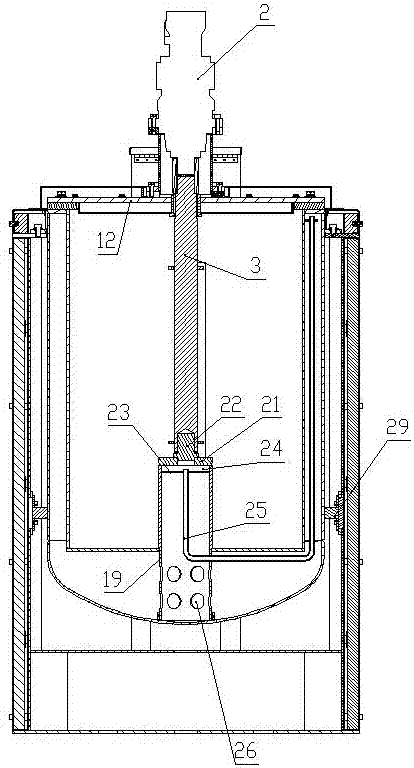

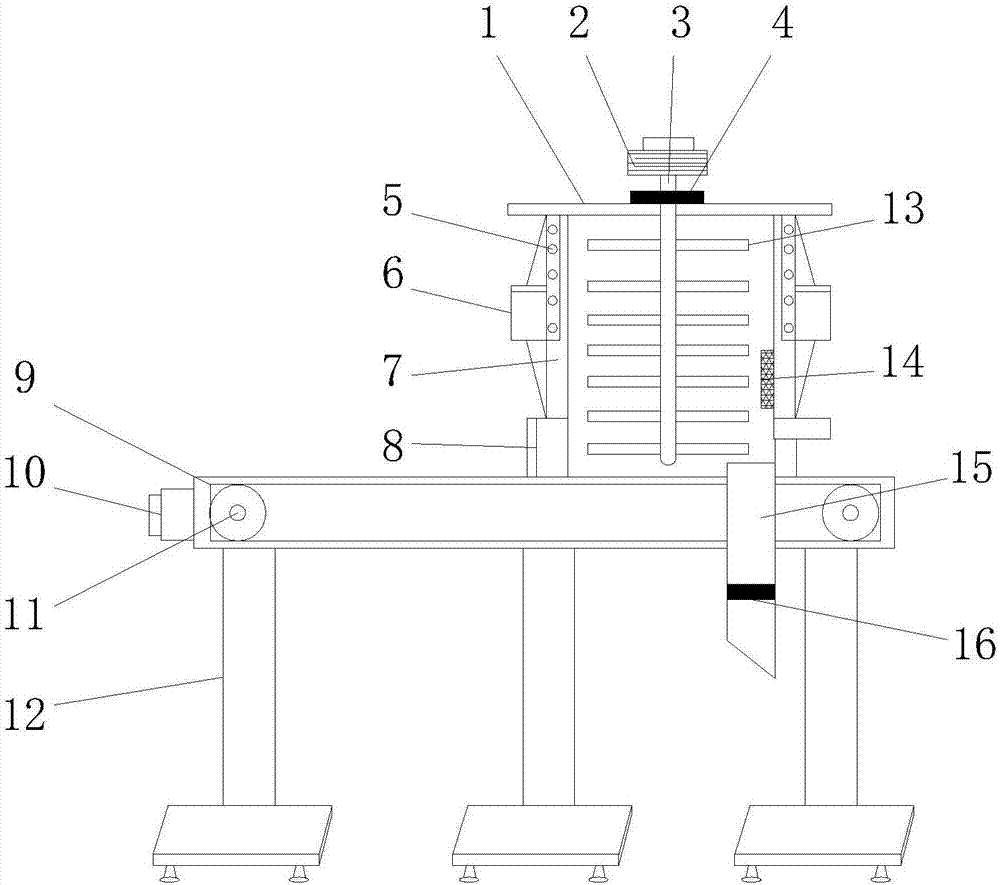

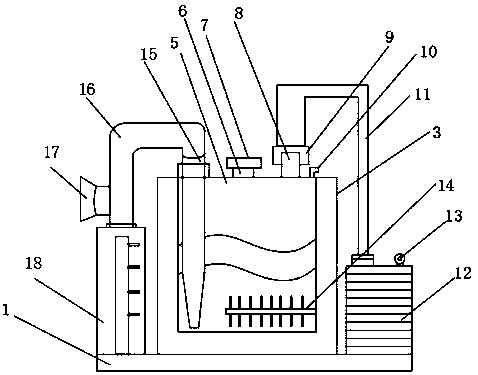

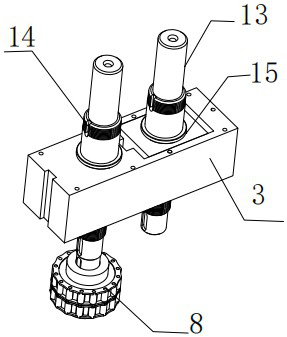

Efficient continuous vacuum microwave drying machine

ActiveCN105258480AFeed amount can be set freelyAdjustable drying temperatureEngine sealsPharmaceutical product form changeProcess engineeringSolid-state

Owner:陈长清

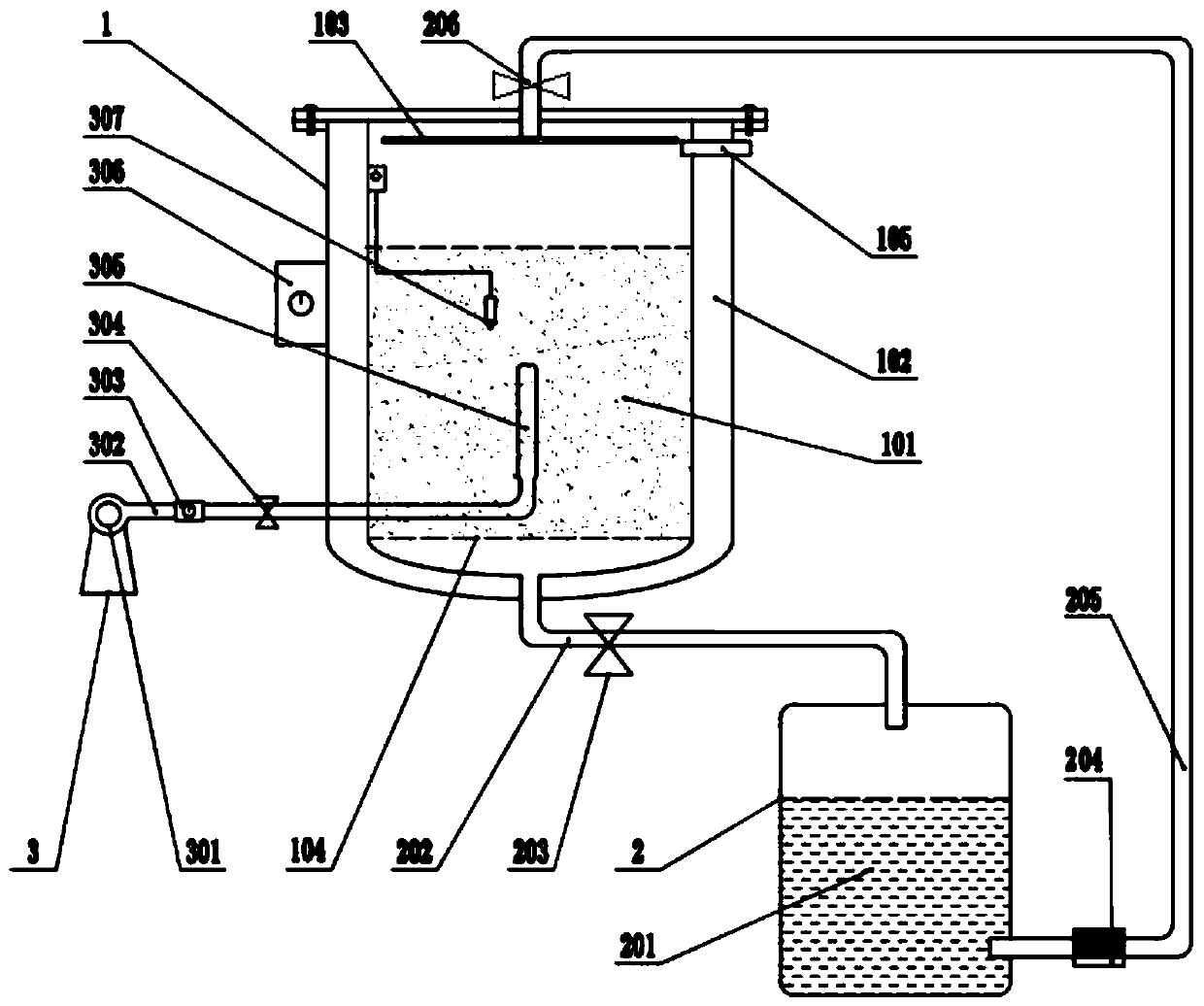

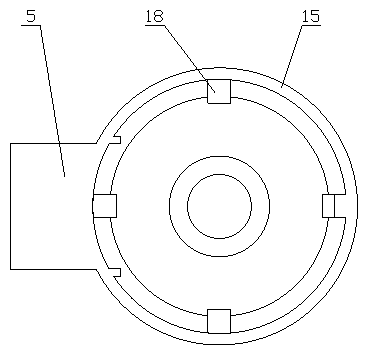

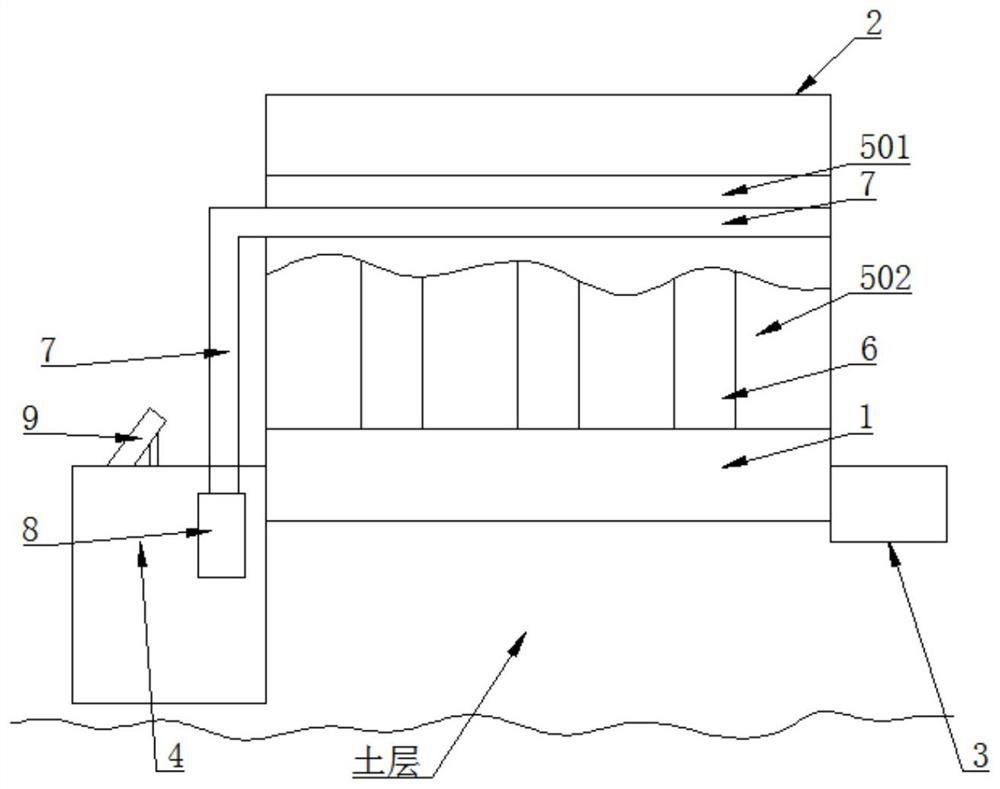

Anaerobic dry fermentation device and method of pre-aeration temperature-rising sequencing batch type

PendingCN110468045AUniform heating areaImprove reaction efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsChemistrySelf heating

The invention discloses an anaerobic dry fermentation device of pre-aeration temperature-rising sequencing batch type. The fermentation device comprises an anaerobic dry fermentation reactor and an aeration mechanism. The anaerobic dry fermentation reactor is detachably covered with a sealing cover, a material reaction zone is arranged in the anaerobic dry fermentation reactor, the material reaction zone is used for placing reaction materials, the upper end of the anaerobic dry fermentation reactor is provided with an air outlet hole, and the lower end of the anaerobic dry fermentation reactoris provided with a liquid outlet hole; the aeration mechanism comprises a fan, an air inlet pipe and an aeration pipe, one end of the air inlet pipe is communicated with the fan, the other end of theair inlet pipe is communicated with the aeration pipe through the air inlet hole of the anaerobic dry fermentation reactor, and the aeration pipe is located inside the material reaction zone; and theupper part inside the anaerobic dry fermentation reactor is provided with a spray head, liquid can be sprayed from the spray head to the material reaction zone, so as to realize self-heating of the reaction materials, ensure the temperature requirements of the materials for anaerobic fermentation, and improve the reaction efficiency and output rate.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

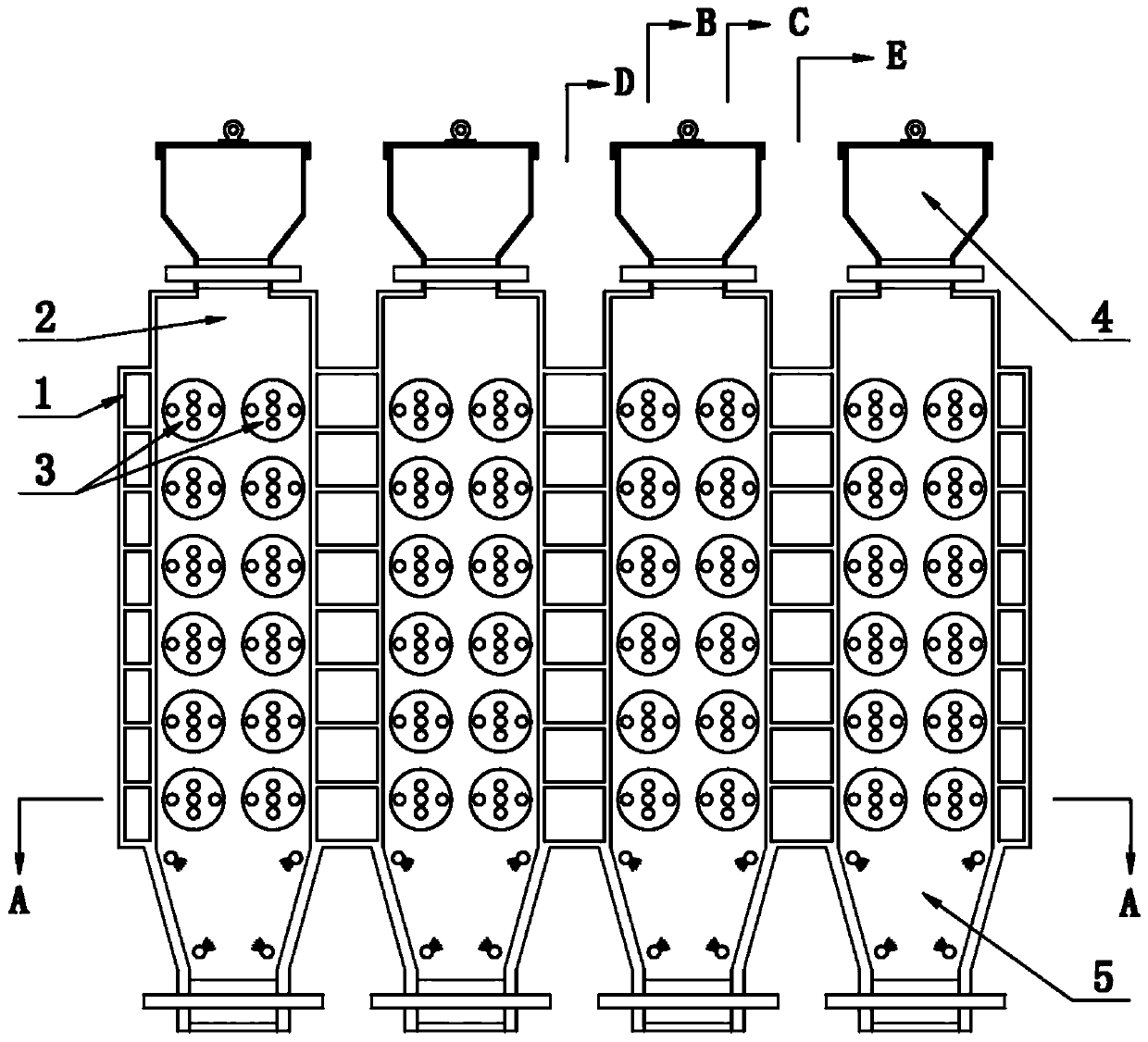

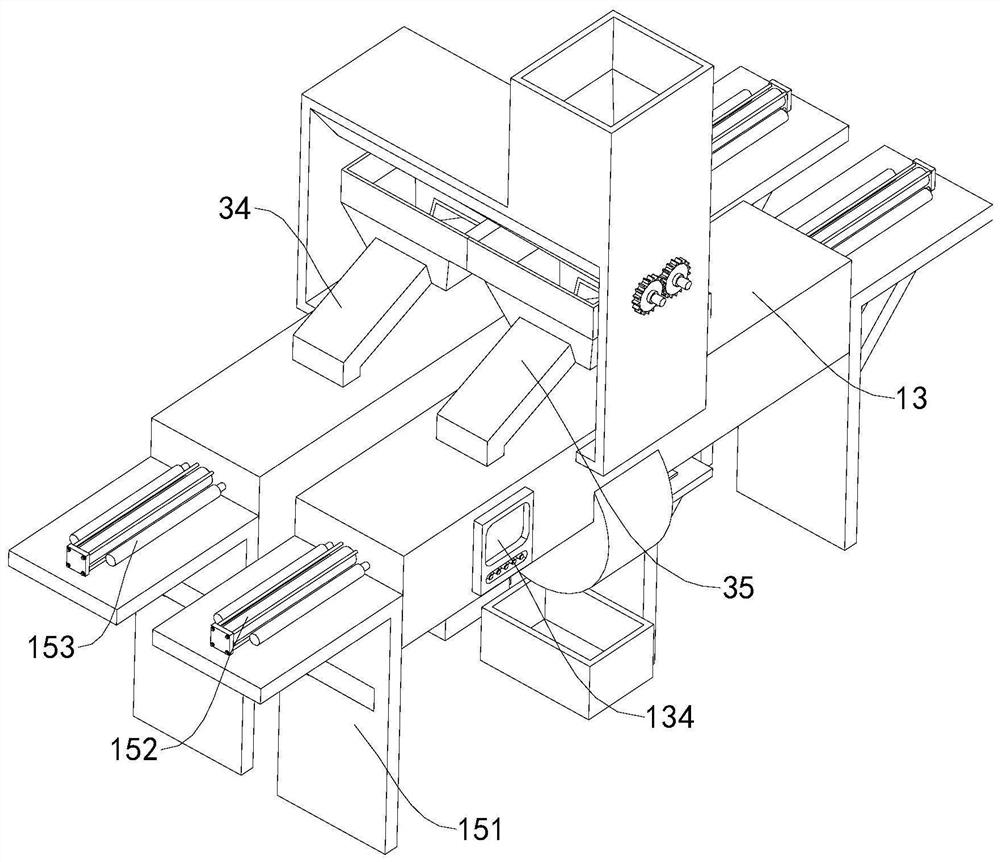

A low-rank coal fast pyrolysis device

ActiveCN108728137BReduce dust contentReduce qualitySpecial form destructive distillationProduction rateGear drive

A fast pyrolysis device for ow-rank coal comprises a plurality of vertical pyrolysis chambers and heating chambers which are arranged at intervals alternately side by side, wherein each heating chamber is divided into multiple horizontal flues; heating gas in every two adjacent heating chambers flows reversely; two columns of stirrers are arranged in each vertical pyrolysis chamber, heating gas between the two columns of stirrers flows reversely, and heating gas in each column of stirrer and the heating chamber adjacent to the stirrer flows reversely; stirring pipes are arranged in the middleof each stirrer, shaft drums and beam barrels are arranged at two ends of the stirring pipes, gears driving the stirrers to rotate are arranged on the beam barrels on one sides, and every two columnsof stirrers rotate oppositely; a feed device is mounted at the top of each vertical pyrolysis chamber, and a discharge device is mounted at the bottom. Internal and external dynamic heating and dynamic and static integration are adopted, so that the defects of low oil-gas production rate, high difficulty of separation of oil-gas dust, poor quality, difficult control after pollution and the like ofa direct heating method are overcome; the defects of small static heating area, large thermal resistance, non-uniform heating, low capacity and the like of an indirect heating method are overcome.

Owner:青岛伊诺威能源化工新技术有限公司

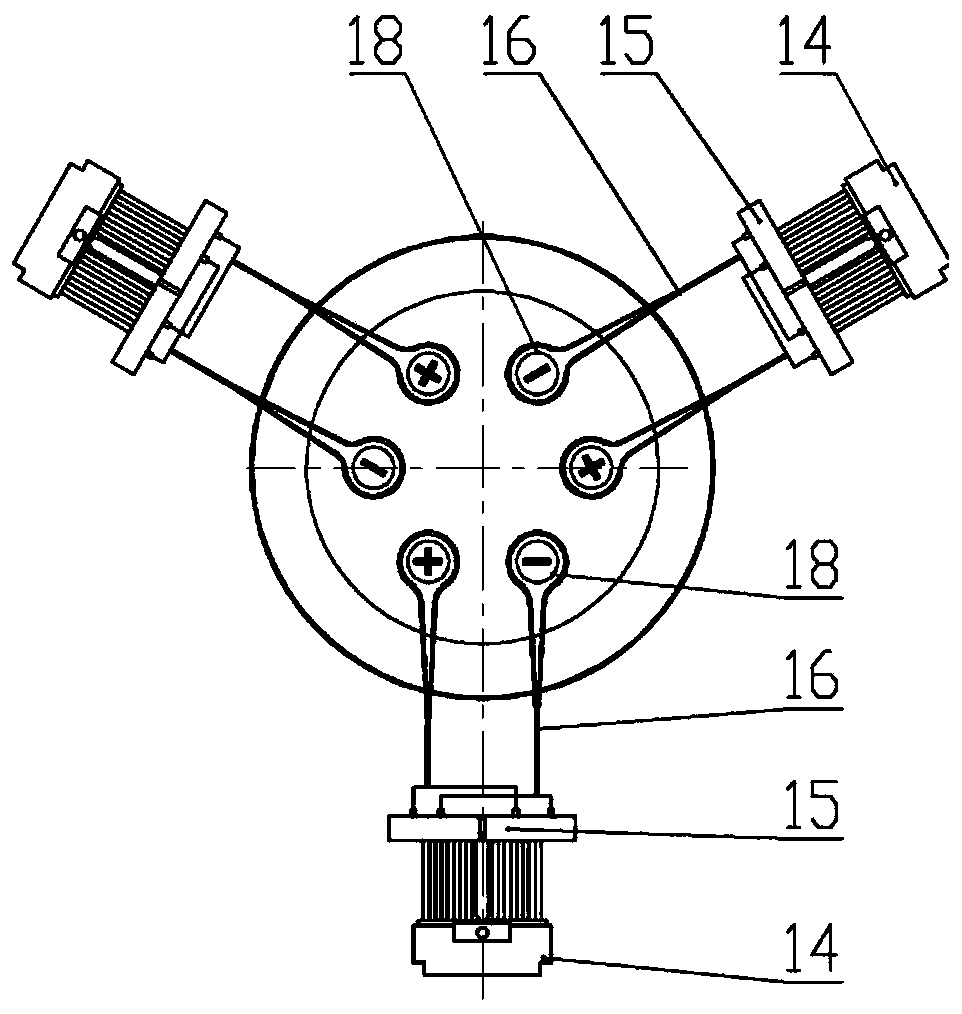

Direct-current aluminum-silicon alloy submerged arc furnace

PendingCN111187909ANo bondingNo riseCharge manipulationIncreasing energy efficiencySilicon alloyElectric control

The invention provides a direct-current aluminum-silicon alloy submerged arc furnace. The direct-current aluminum-silicon alloy submerged arc furnace comprises a furnace body foundation and a furnaceshell, a furnace outlet is formed in the bottom of the furnace shell, a furnace lining is arranged in the furnace shell, and a cooling water system is arranged outside the furnace shell; a furnace cover is arranged at the top of the furnace shell; a material falling pipe, a clean furnace gas flue and electrodes are arranged on the furnace cover; the material falling pipe is connected with a furnace top bin; an electrode lifting mechanism is connected with the electrodes through an electrode holder; an electrode guide mechanism is further arranged, and the electrodes are connected with an electrode bottom structure; the direct-current aluminum-silicon alloy submerged arc furnace further comprises an electric furnace transformer, the electric furnace transformer is connected with a rectifier, a short net and an electric control system, and the electric furnace transformer supplies direct current to the electrode bottom structure; the hydraulic system is connected with the electrode holder; and the electric control system is further connected with a temperature measuring system, a liquid aluminum-silicon alloy material level sensor in the furnace body, the electrode holder and an electrode lifting system. According to the direct-current aluminum-silicon alloy submerged arc furnace, the temperature in the furnace body is high, a hearth is integrally built without gaps, the depth and the diameter of the hearth are in geometric relation with the electrodes, the power density in unit volume is high, feeding and discharging are continuous, and the temperature can be adjusted.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

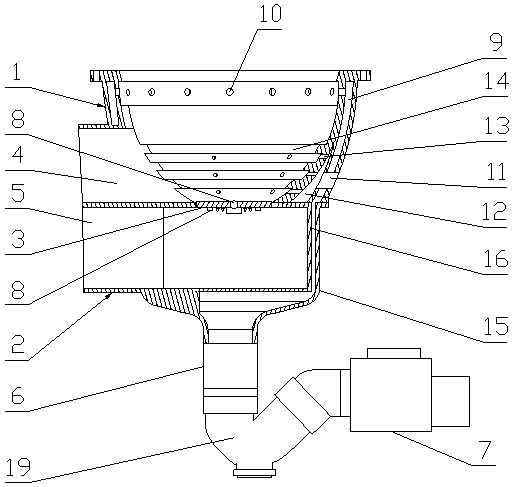

Firewood and gas dual-purpose stove

InactiveCN109424984ABurn fullyReduce burnDomestic stoves or rangesLighting and heating apparatusFirewoodEngineering

The invention discloses a firewood and gas dual-purpose stove, and belongs to the technical field of stoves. The firewood and gas dual-purpose stove comprises a furnace body composed of a furnace chamber (1) and an oven (2), and the furnace chamber (1) communicates with the oven (2) through an oven hole. A turning plate (3) with a furnace head (8) on one surface is rotatably arranged on the furnace body, the turning plate (3) is rotatably arranged in the oven hole and can close the oven hole, and the turning plate (3) can be turned over and used as a gas stove and a firewood stove separately.An exhaust pipe (6) is arranged at the bottom of the oven (2), and the exhaust pipe (6) is provided with a suction fan (7). A plurality of exhaust holes (10) are evenly formed in the inner wall of thetop of the furnace chamber (1), air outlet channels (9) are correspondingly arranged in the side walls of the furnace chamber (1) and the oven (2), and the exhaust holes (10) communicate with the exhaust pipe (6) through the air outlet channels (9). A plurality of air inlet holes externally communicating with the furnace chamber (1) are uniformly distributed in the inner wall of the lower part ofthe furnace chamber (1).

Owner:NANZHANG COUNTY HUASHENG MACHINERY MFG

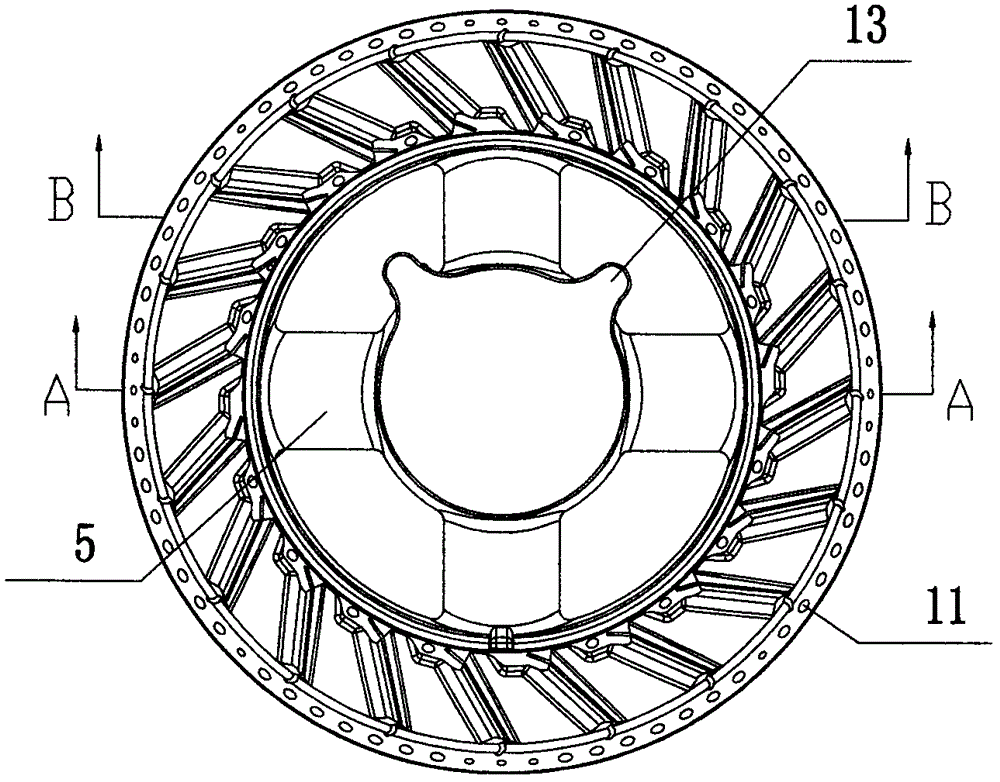

Combustor for household gas stove

InactiveCN106402867AImprove distributionEvenly distributedGaseous fuel burnerEngineeringThermal efficiency

The invention discloses a combustor for a household gas stove. The combustor comprises an inner fire cover base and an outer fire cover base. The inner fire cover base is provided with an inner fire cover. The outer fire cover base is provided with an outer fire cover. The inner fire cover base and the outer fire cover base are connected through a fuel gas channel. The bottom of the inner fire cover base is provided with a gas input channel. The top face of the outer fire cover is a slope inclining from outside to inside. The slope is provided with a circle of L-shaped bosses which are distributed uniformly in the circumferential direction of the fire cover and protrude out of the slope. The L-shaped bosses are arranged on the slope in an inclined manner to form a rounding-up shape. Each L-shaped boss is provided with a linear fire output hole and a round fire output hole. The circumferential face of the outer fire cover is provided with a circle of outer fire output holes distributed uniformly in the circumferential direction. By the adoption of the structure, distribution of the fire output holes of the outer ring fire cover and the fire output holes of the inner ring fire cover is improved, the fire output holes can be distributed more uniformly, the heating area of the pot bottom is more uniform, and the heat efficiency is improved.

Owner:ZHEJIANG YITIAN INTELLIGENT KITCHEN ELECTRICITY CO LTD

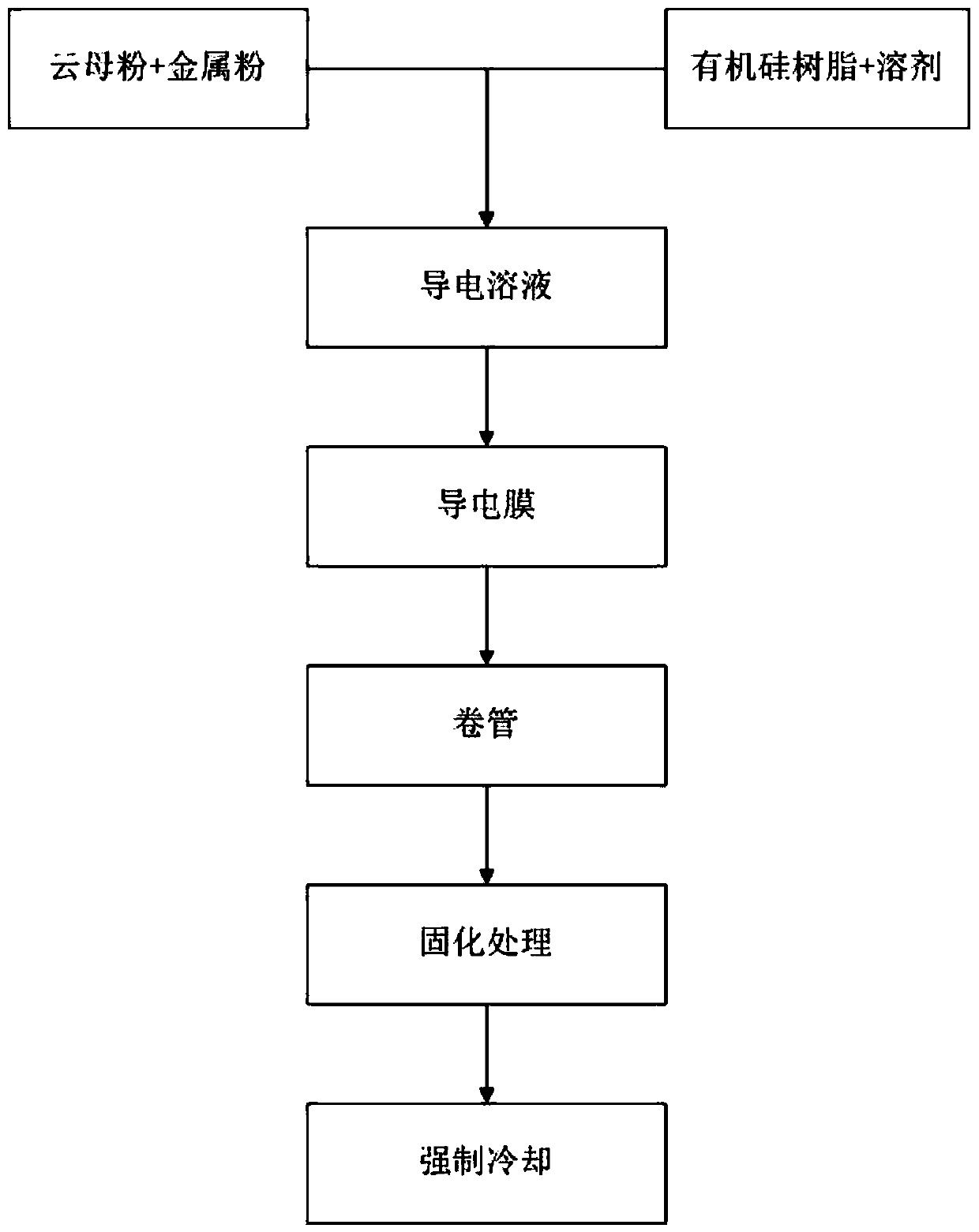

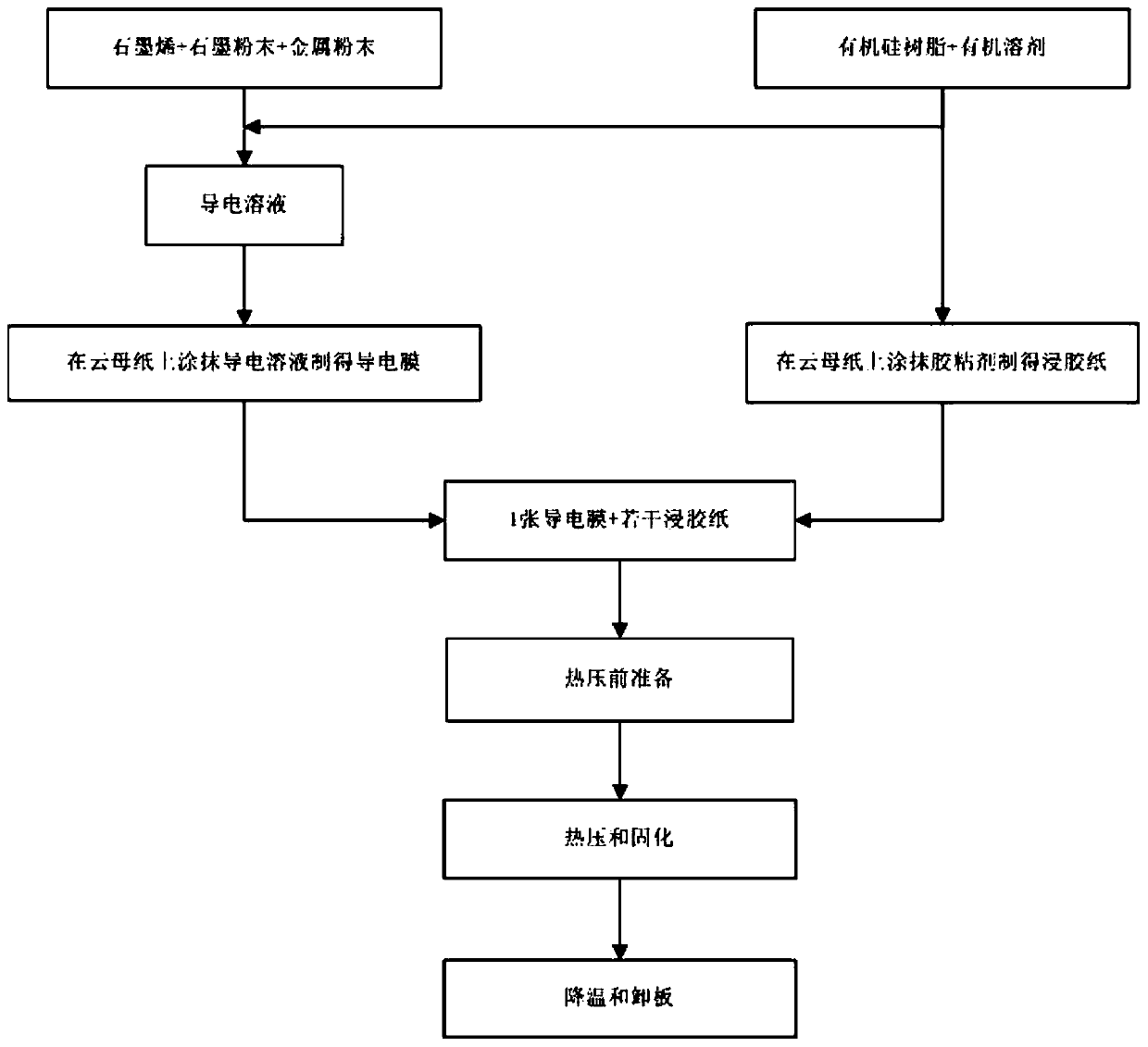

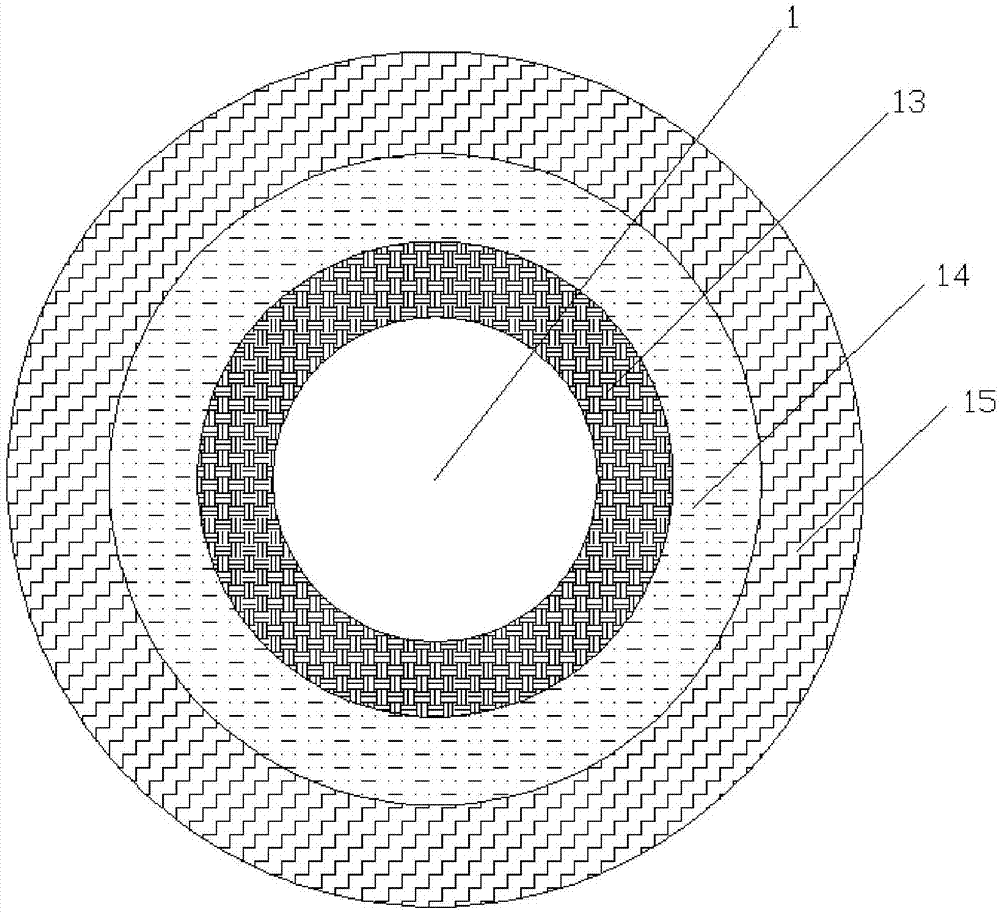

Conductive film and preparation method thereof, heatable mica tube and manufacturing method thereof

InactiveCN110798922AFast heatingUniform heating areaHeating element shapesHeating element materialsSilicone resinElectrically conductive

The invention discloses a conductive film. The conductive film comprises raw materials, by weight, 45-60 parts of mica powder, 30-40 parts of metal powder and 15-10 parts of adhesive, wherein the adhesive comprises components, by weight, 20-25 parts of organic silicon resin adhesive with the solid content of 50-52% and 75-80 parts of organic solvent. The invention further discloses a preparation method of the conductive film. The invention discloses a heatable mica tube. The mica tube comprises mica paper and the conductive film cured on the mica paper. The invention discloses a manufacturingmethod of heatable mica tube. The mica tube is characterized in that structural arrangement of the mica tube is changed, so resistivity of the mica tube can meet application conditions of heating elements of small household appliances such as electric blowers.

Owner:苏州苏绝电工材料股份有限公司

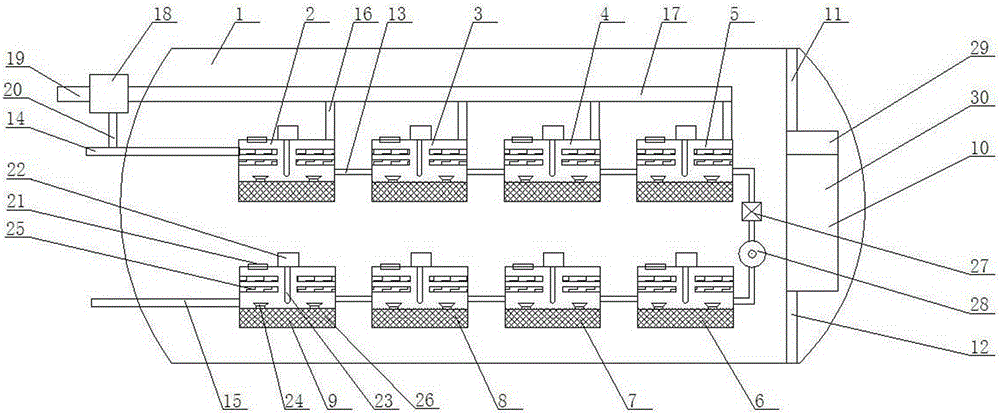

Efficient and energy-saving electric boiler

InactiveCN105222111AImprove heating efficiencyUniform heating areaSteam generation heating methodsWater heatersProcess engineeringThermal efficiency

An efficient and energy-saving electric boiler comprises a boiler body, a first heating box, a second heating box, a third heating box, a fourth heating box, a fifth heating box, a sixth heating box, a seventh heating box, an eighth heating box and a control cabinet. The first heating box, the second heating box, the third heating box and the fourth heating box are arranged at the upper end of the interior of the boiler body side by side. The fifth heating box, the sixth heating box, the seventh heating box and the eighth heating box are arranged at the lower end of the interior of the boiler body side by side. The control cabinet is arranged at the right end of the interior of the boiler body through an upper fixing frame and a lower fixing frame. The eight heating boxes are connected through water guide pipes. The heating boxes are arranged in the efficient and energy-saving electric boiler, each heating box can conduct dual heating through a heating rod and a heater, the heating efficiency is high, and the heating area is uniform.

Owner:HARBIN JINJING BOILER

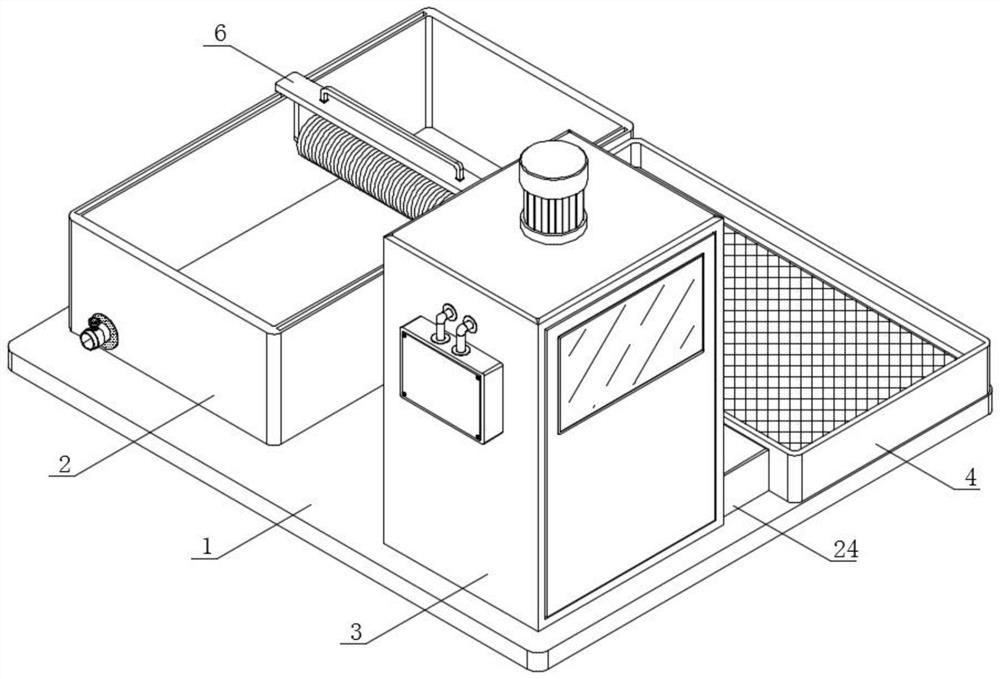

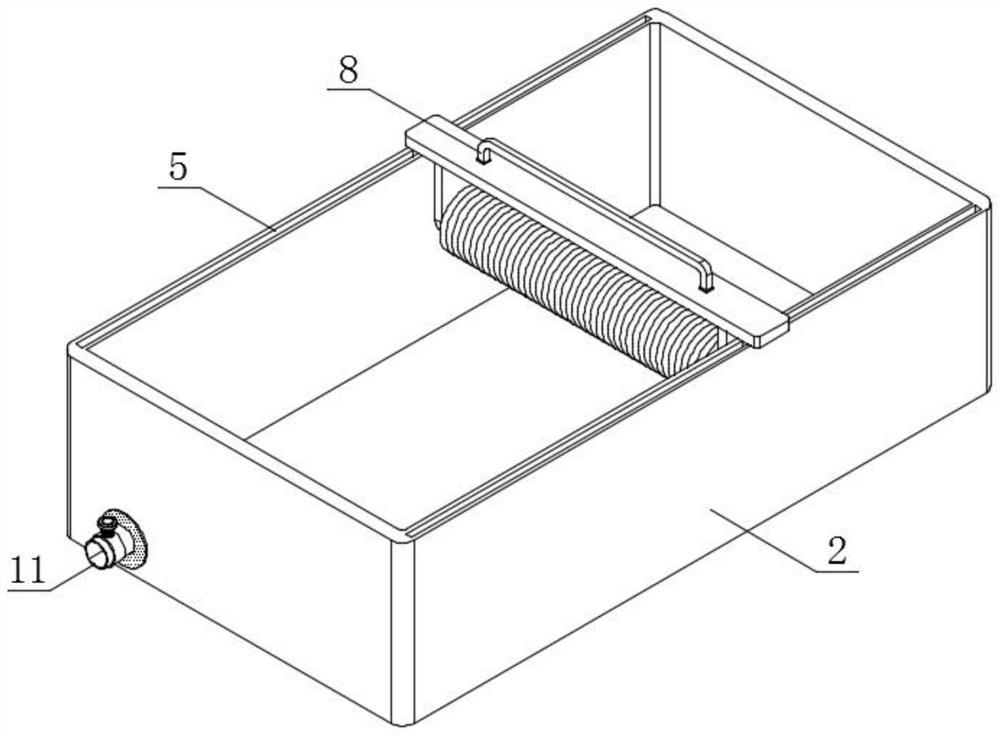

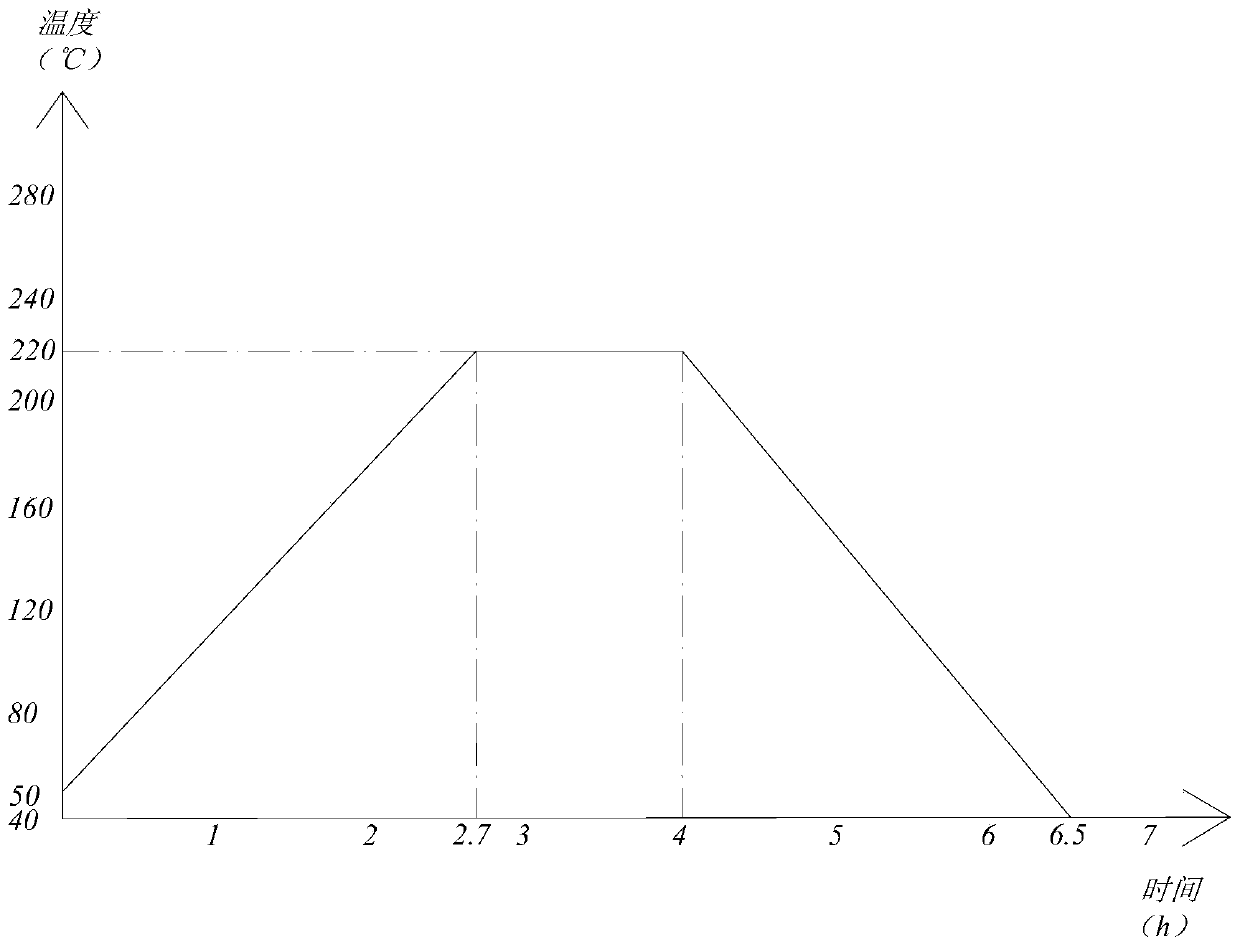

Vacuum diffusion welding equipment for borosilicate glass with high light transmittance and use method of vacuum diffusion welding equipment

ActiveCN114349321AImprove structural strength and sealing performanceEliminate Weld InterfaceGlass reforming apparatusHeat conservationPhotocatalytic reaction

The invention discloses vacuum diffusion welding equipment for high-light-transmittance borosilicate glass and a using method of the vacuum diffusion welding equipment. The vacuum diffusion welding equipment comprises a supporting bottom plate, a cleaning tank, a heating box and a cooling tank, and the top of the supporting bottom plate is provided with the cleaning tank, the heating box and the cooling tank. By adopting the welded glass structural part, the formed glass is a unified whole, cannot be split, is high in structural strength and sealing performance, plays a role in protecting the product structural design, has the same light transmittance as the glass before welding, can be used for special applications such as photocatalytic reaction, does not add materials such as welding flux and brazing filler metal in the forming process, and is low in production cost. Stainless steel is selected as a solder resist material, the surface and light transmission performance of the glass are not affected, a heating-pressurizing heat preservation-heating-pressure relief heat preservation-cooling process curve is adopted in the method, the main significance is to eliminate a glass welding seam interface, meanwhile, plastic deformation of the glass structure is reduced, and the heat preservation performance of the glass is improved. The light transmittance of the glass is improved.

Owner:江苏博联硕焊接技术有限公司

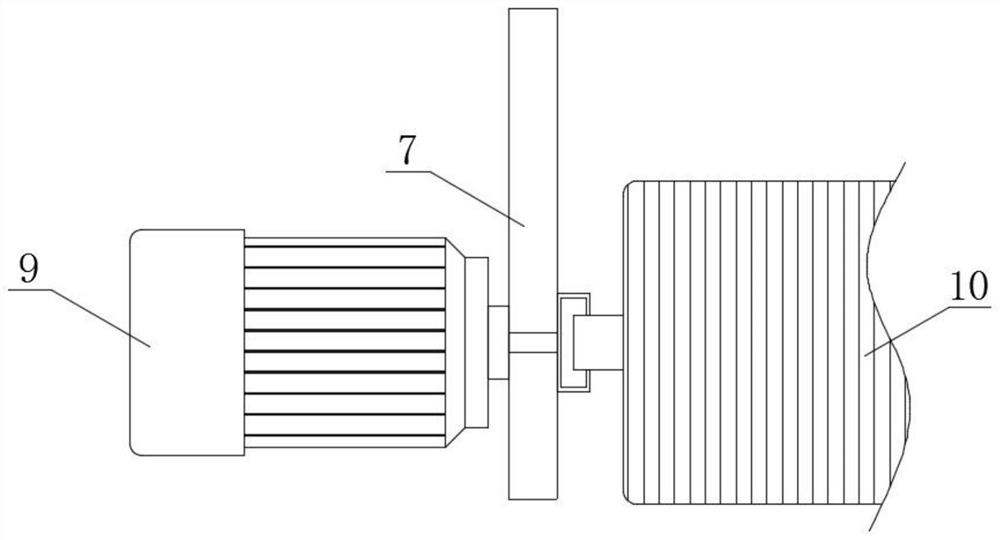

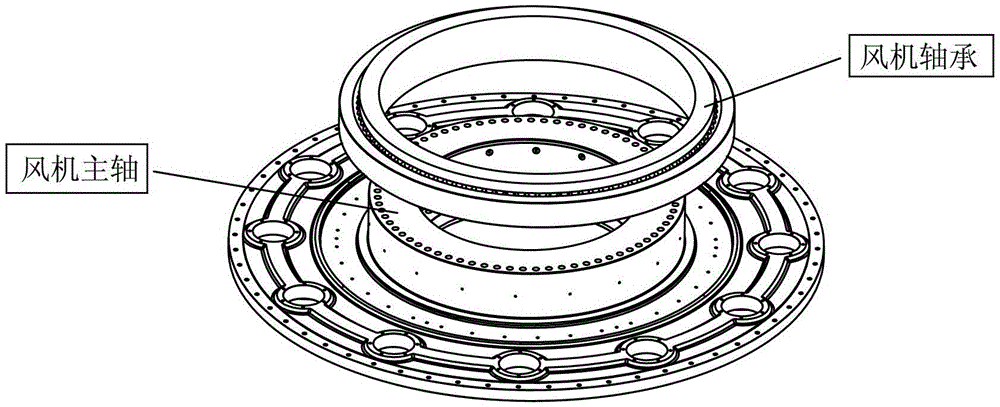

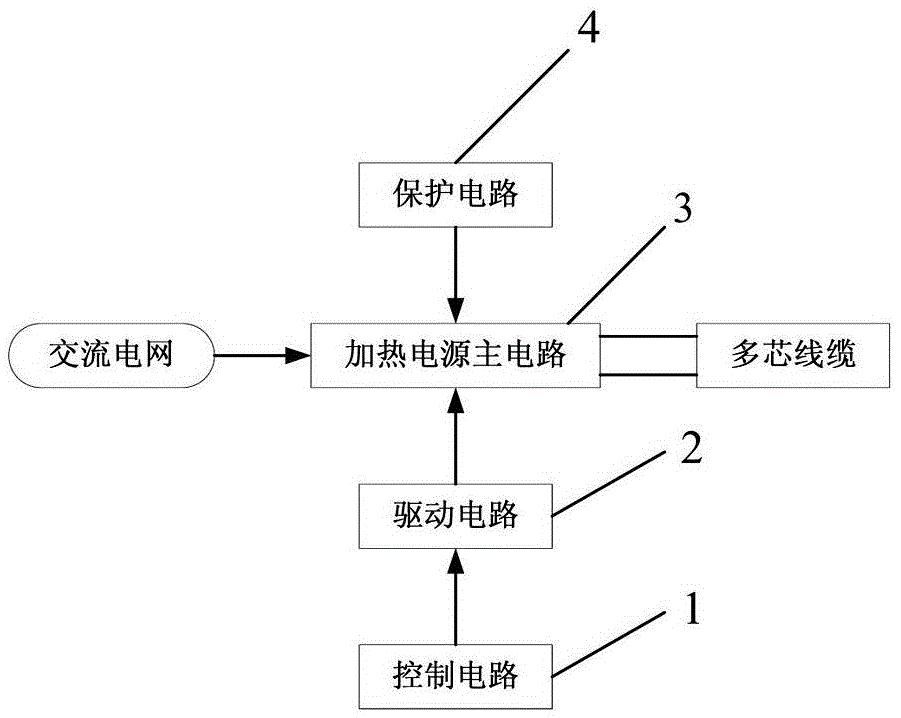

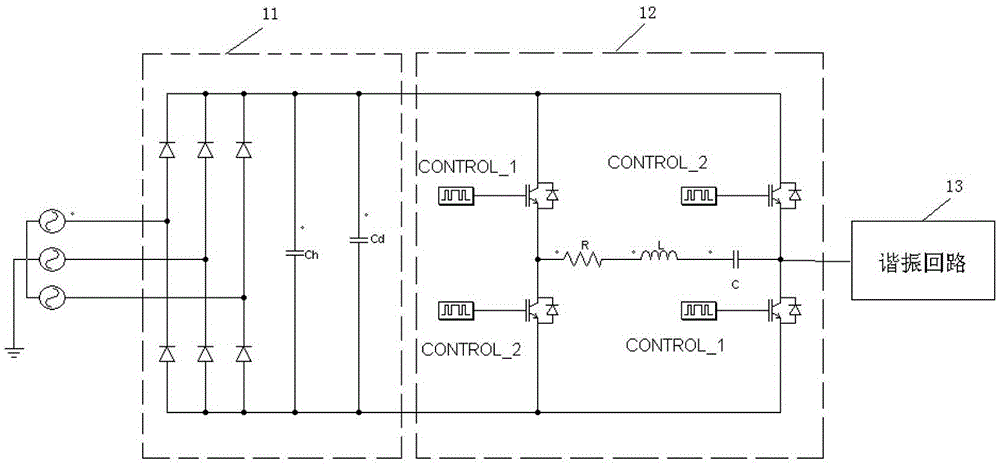

Flexible induction heating power supply and its control method for fan bearing disassembly

ActiveCN104244479BReduce consumptionAvoid damageInduction current sourcesInduction heating controlOvervoltageTemperature difference

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

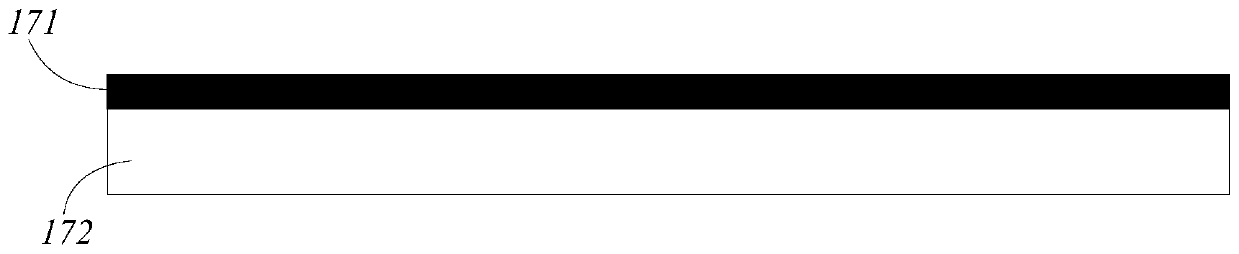

Conductive film and preparation method thereof, heatable mica plate and manufacturing method thereof

InactiveCN110809336AIncrease the areaReduce areaOhmic-resistance heating detailsHeating element materialsAdhesiveGraphite

The invention discloses a conductive film, which comprises 15-30 parts of conductive powder and 70-85 parts of adhesive, wherein the conductive powder comprises 50-75 parts of graphite powder and 10-30 parts of graphene. The invention also discloses a preparation method for the conductive film. The invention also discloses a heatable mica plate, which comprises at least one piece of impregnated paper and the conductive film cured on the surface of the impregnated paper. The invention discloses a manufacturing method for the heatable mica plate. The advantages that the resistivity of the mica plate is larger than that of a metal heating wire and smaller than that of graphite powder by changing the structural arrangement of the mica plate, so that the application of heating bodies with smallarea, high power and high heating temperature of ring-shaped heating elements, plate-shaped heating elements and special-shaped heating elements and the like is met.

Owner:苏州苏绝电工材料股份有限公司

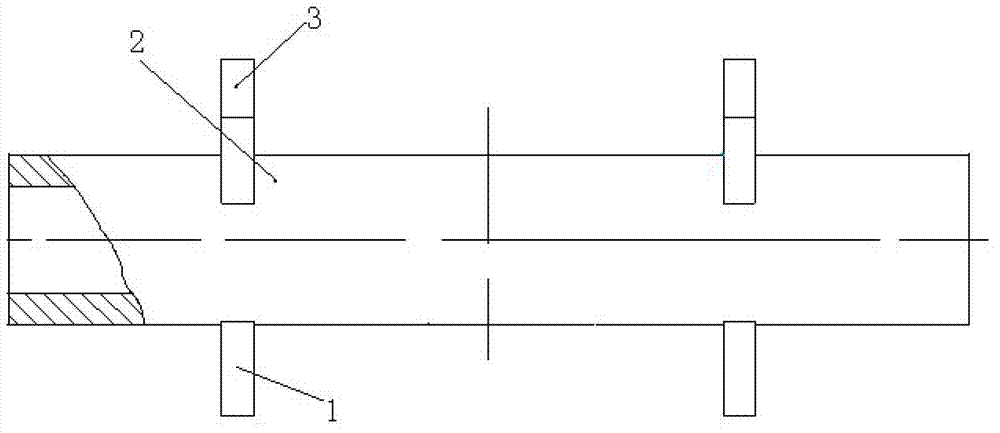

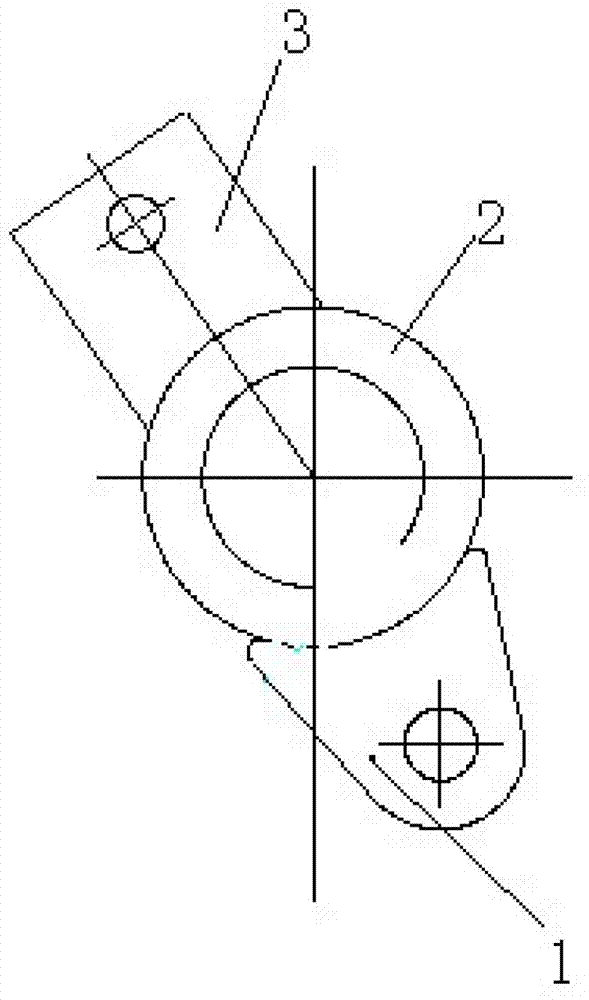

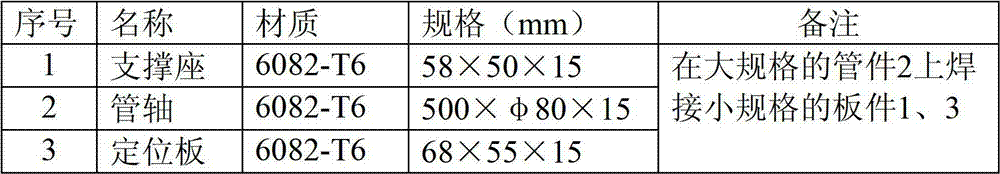

Preheating method before welding of thick-wall aluminum alloy

InactiveCN102962610AShort heating timeUniform heating areaWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingThick wall

The invention discloses a preheating method before the welding of thick-wall aluminum alloy. A small-specification plate piece is welded on a big-specification aluminum alloy pipe fitting, induction heating is carried out in the aluminum alloy pipe fitting before welding; the plate piece is heated by heat conduction; and therefore the aluminum alloy pipe fitting and the plate piece have the consistent temperature and balanced preheating. The product quality can be improved, the production efficiency is improved, and the welding structure is guaranteed to be safe.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

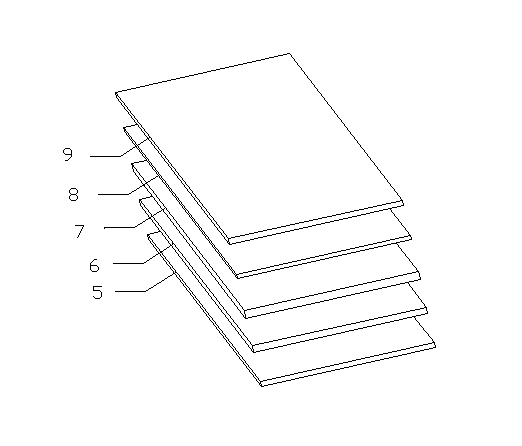

Heating tatami

InactiveCN103355980AIncrease elasticitySoft and comfortableStuffed mattressesSpring mattressesElectricityFiber

The invention relates to a heating tatami. The heating tatami comprises a seat surface, a nonwoven needle-punched cotton layer, a carbon fiber heating layer, a core material, a first waterproof layer and an antiskid layer which are arranged from top to bottom in sequence; the carbon fiber heating layer is electrically connected with a power supply; a second waterproof layer is preferably arranged between the nonwoven needle-punched cotton layer and the carbon fiber heating layer; and a nonwoven plate is preferably arranged between the nonwoven needle-punched cotton layer and the second waterproof layer. The heating tatami is high in elasticity, touches soft and comfortable, is high in durability, has the heating function, is uniform in heating area, fast to heat, energy-saving and safe, free of sense of dry heat, and capable of emitting far infrared ray in order to realize life cultivation and health preservation effects, thus meeting the application demands of different people groups in different regions.

Owner:太仓市陆渡镇宏诚草制品厂

Spherical graphite purification furnace

The present invention discloses a spherical graphite purification furnace, which comprises a thermal insulation housing, a top cover, a bracket, a rotation shaft and a base, and is characterized in that the inner wall of the thermal insulation housing is provided with an infrared heating layer, the thermal insulation housing and the top cover are movably connected and are fixed by using a snapping buckle, the thermal insulation housing is spherical, both ends of the thermal insulation housing are connected to the rotation shaft, the outer side of the rotation shaft is connected to the bracket, and the bottom portion of the bracket is connected to the base. According to the present invention, with the rotation shaft, the spherical graphite purification furnace can rotate during the working, such that the heating area is uniform, and the purification precision is high; and with the control panel, the rotation speed of the rotation shaft and the temperature of the infrared heating layer of the spherical graphite purification furnace can be precisely controlled, such that the graphite purification precision is improved, and after completing the purification, the inclination angle of the spherical graphite purification furnace can be controlled so as to conveniently collect or pour out the purified graphite.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

USB pedal

InactiveCN102840620AEvenly heatedAvoid sweatingLighting and heating apparatusElectric heating systemInterface designEngineering

The invention discloses a USB pedal, which comprises a bottom plate, an insulating layer, an epoxy plate, a plate cover, a reflecting layer and an ornamental surface, and further comprises a surface form heating unit, a lead and a USB interface. The USB pedal is provided with the surface form heating unit, has high heating speed and uniform heating areas, ensures that all positions of feet are uniformly heated, adopts the USB interface design, has a simple structure, and is wide in suitable crowd.

Owner:栾清杨

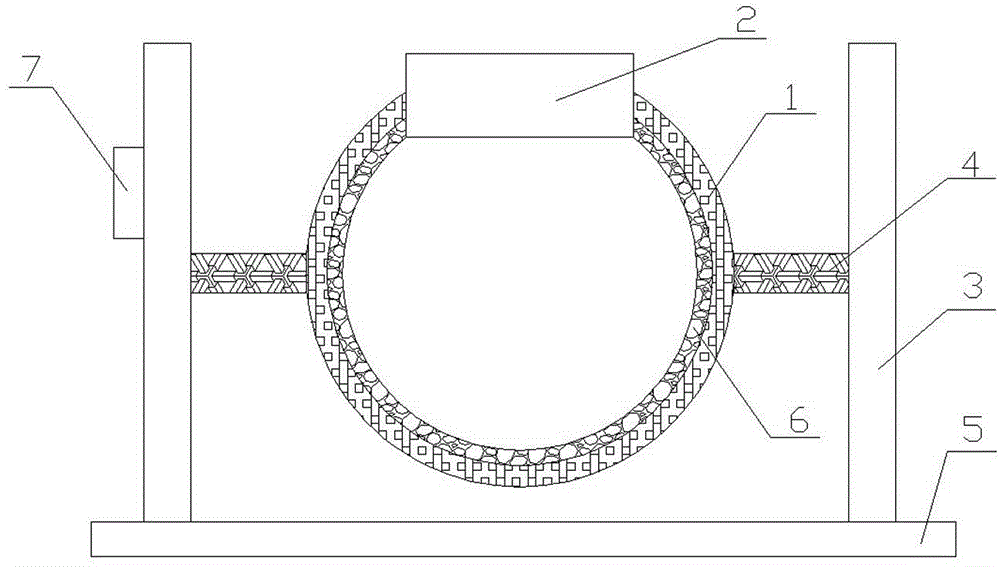

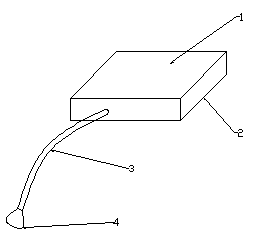

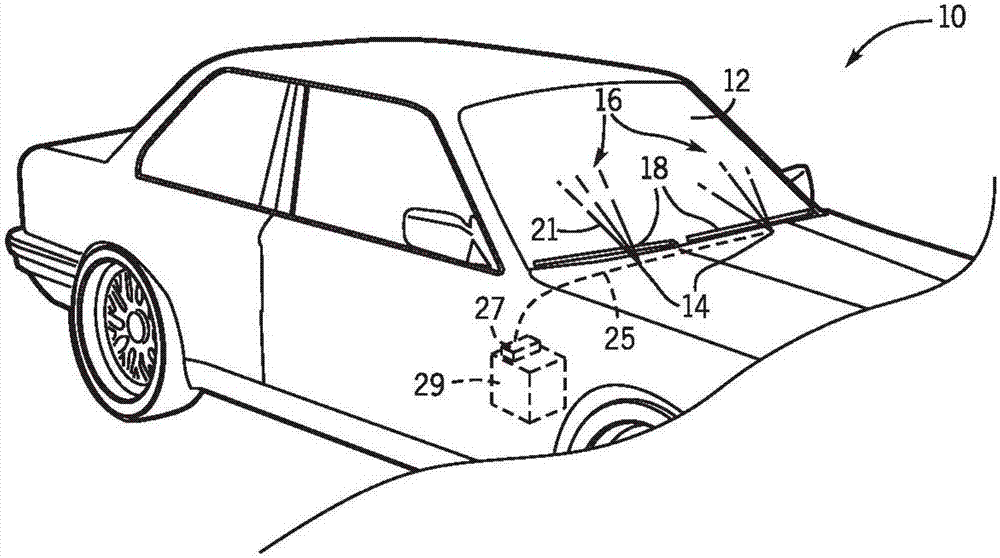

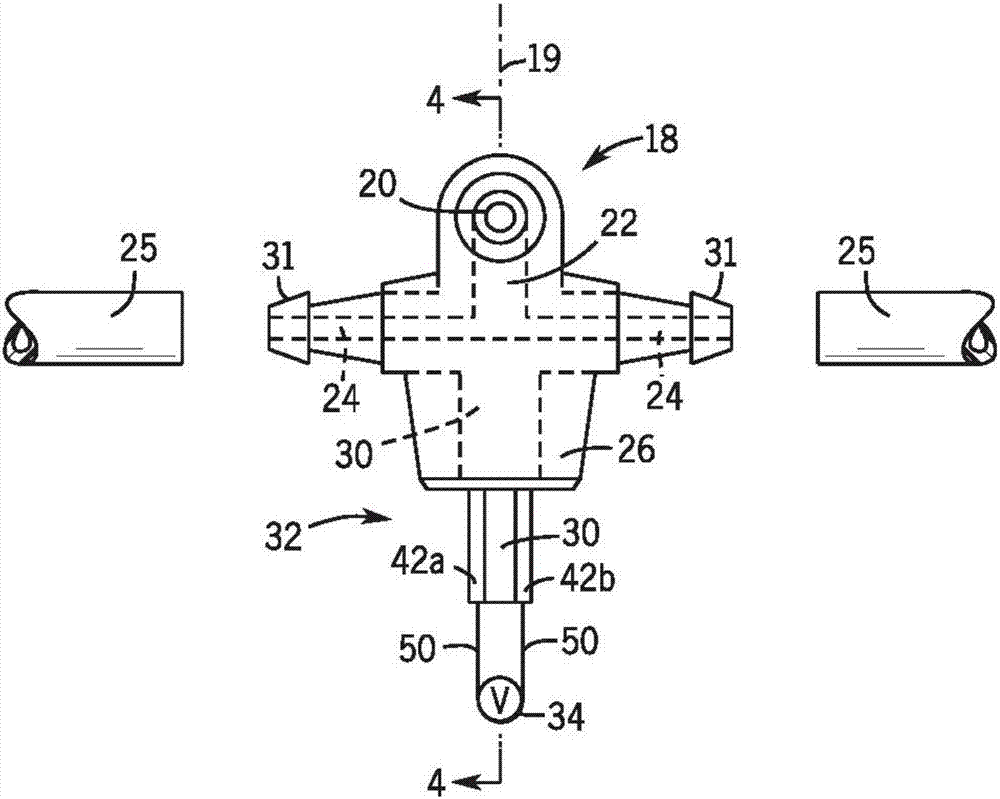

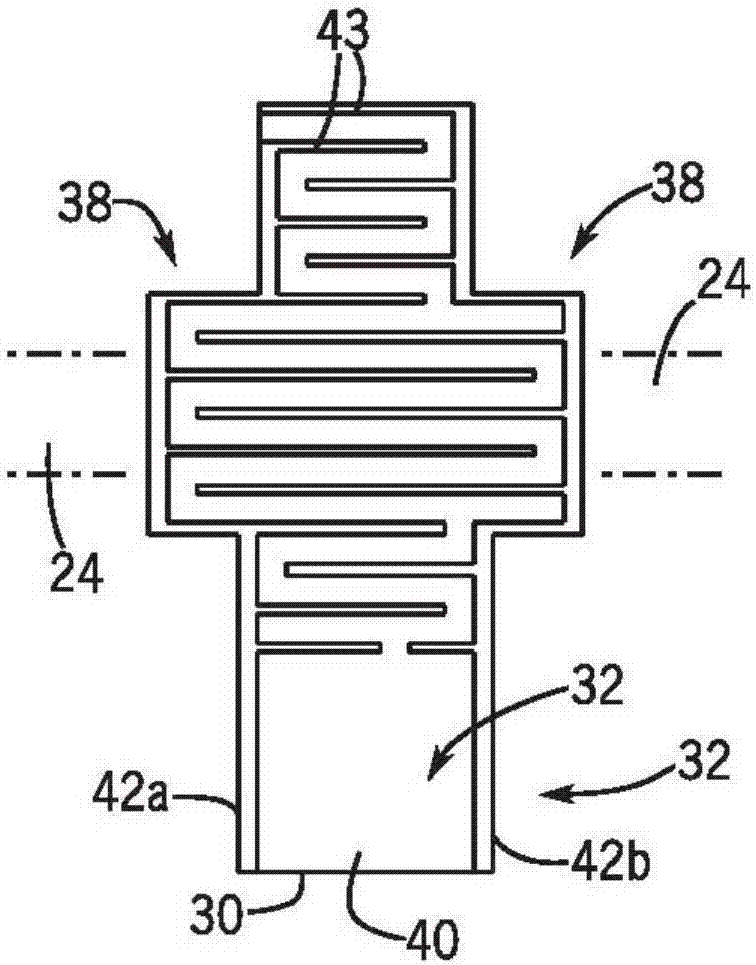

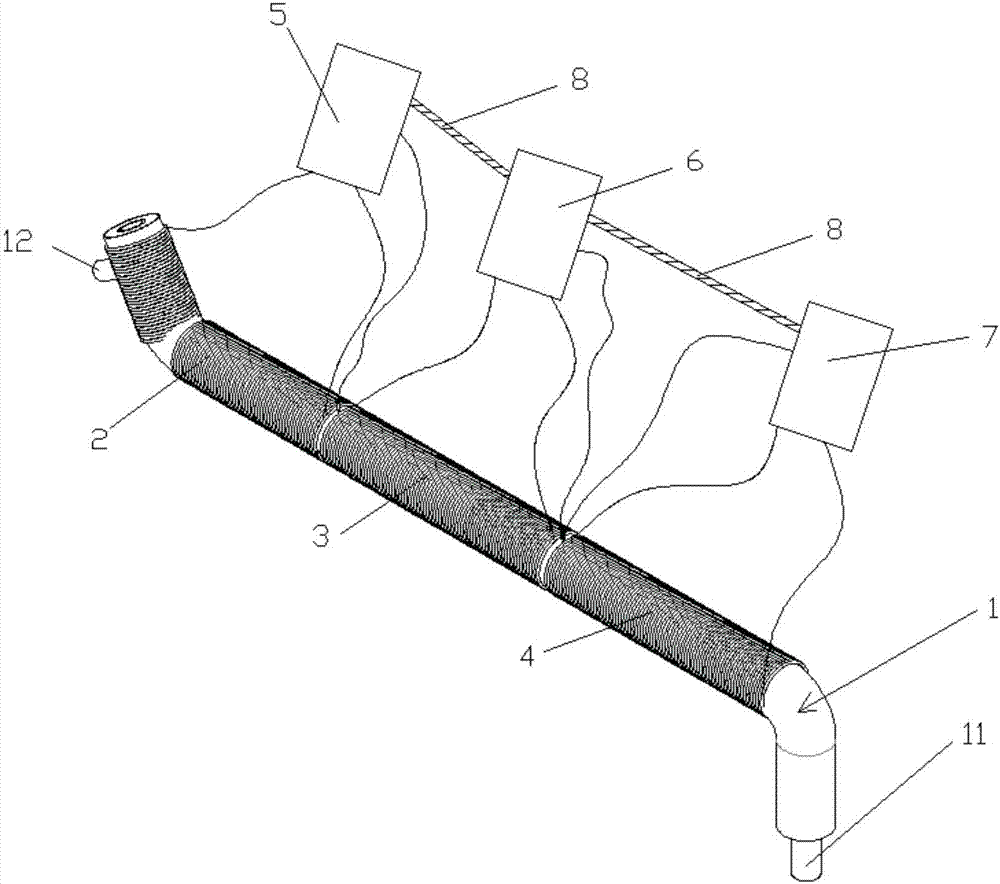

Conformal heater for windshield washer nozzle

InactiveCN107107876AFacilitate conductionThermal resistance minimizationHeating element shapesVehicle cleaningSpray nozzleEngineering

A nozzle assembly (18) for a windshield washer system or the like provides an elongate heater element(30) that can extend along a supply tube connected to the washer nozzle (20) to better transfer heat energy into the washer fluid and the nozzle for preventing nozzle clogging caused by low temperatures.

Owner:ILLINOIS TOOL WORKS INC

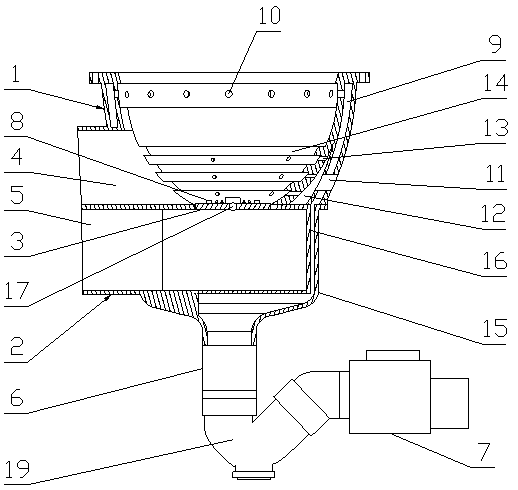

Equipment for promoting after-ripening of camellia fruits and camellia seeds

The invention discloses equipment for promoting after-ripening of camellia fruits and camellia seeds, and belongs to the field of camellia fruit and camellia seed processing. The equipment comprises an after-ripening device, supports and a screening assembly, the after-ripening device is divided into a first after-ripening assembly and a second after-ripening assembly, and the first after-ripening assembly and the second after-ripening assembly are symmetrically arranged; the supports are arranged on the two sides of the after-ripening device, the screening assembly is arranged on the supports, the first after-ripening assembly is composed of a heating chamber, shaking components, pushing components and a discharging component, the second after-ripening assembly and the first after-ripening assembly are the same in structure, the heating chamber is located below the screening assembly, the two shaking components are symmetrically arranged in the heating chamber, the two pushing components are symmetrically arranged on the left side and the right side of the heating chamber, and the discharging component is arranged in the middle of the heating chamber. According to the invention, the sizes of the camellia fruits are sieved, the successively ripened camellia fruits are processed, and the camellia oil production efficiency is improved.

Owner:GUIZHOU BOTANICAL GARDEN (GUIZHOU INST OF HORTICULTURAL SCI GUIZHOU INST OF BOTANY)

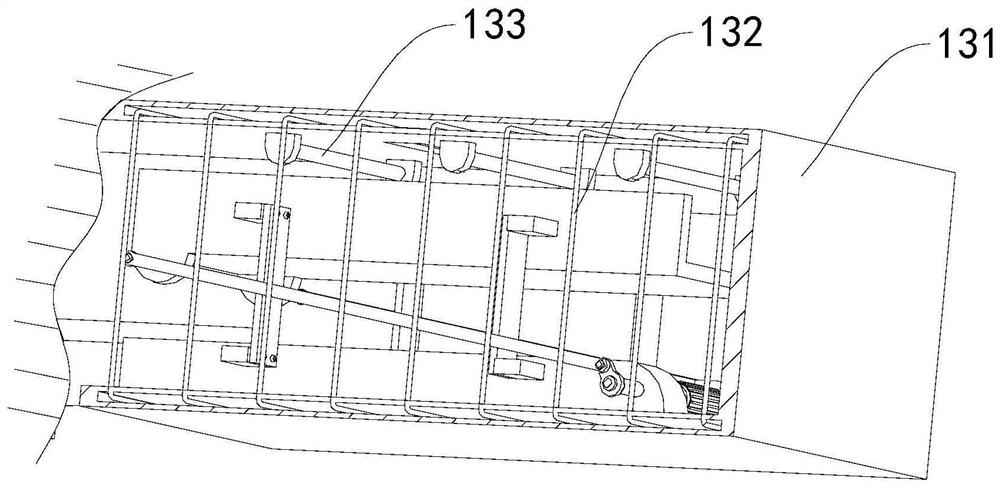

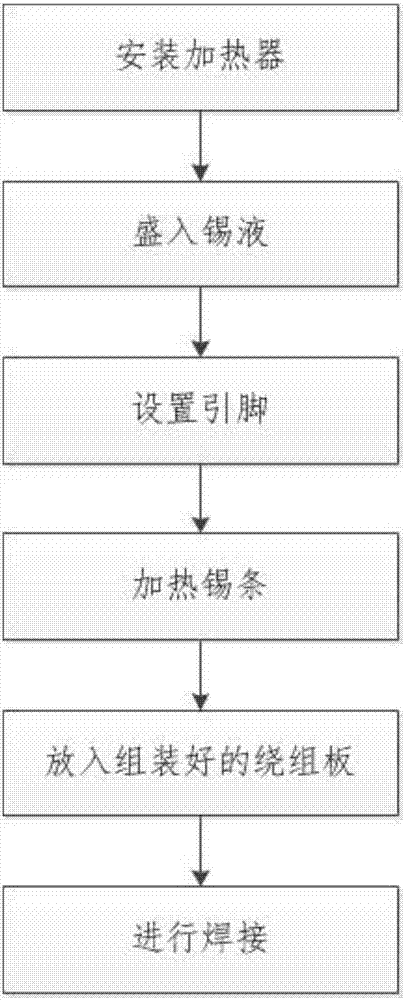

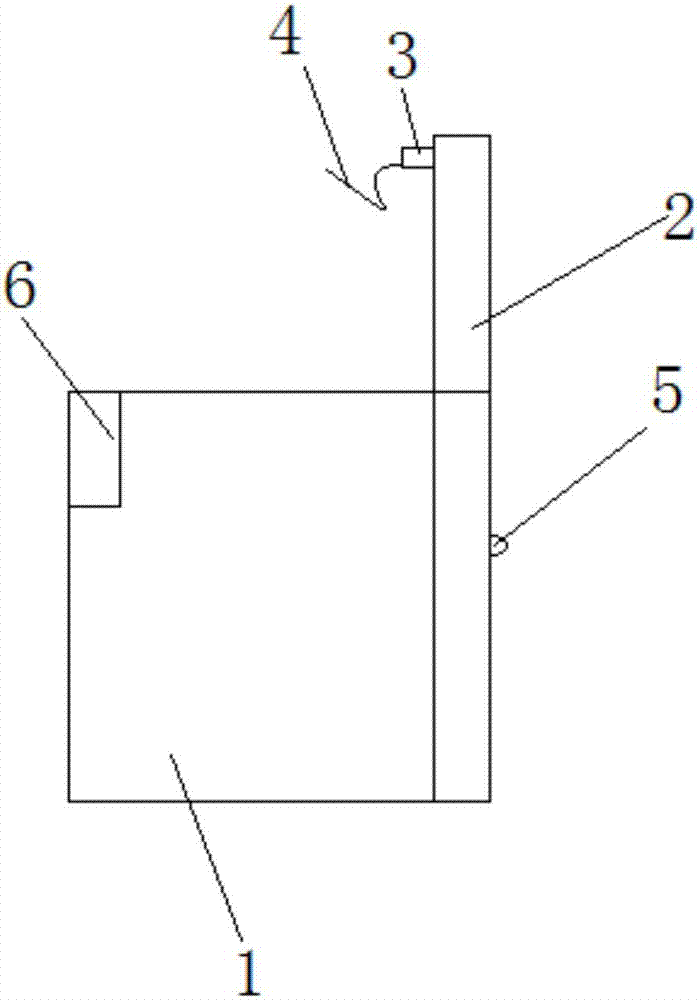

Pin welding device and method

InactiveCN107442879AHeating temperature constant temperatureUniform heating areaMetal working apparatusSoldering auxillary devicesEngineeringConductor Coil

The invention provides a pin welding device and method. In a welding process, a winding plate where a pin penetrates is placed into a device containing tin liquid, and the pin and the winding plate are welded through a heater, a buzzer, a timer and a PID controller. The purpose that the pin and the winding plate are welded is achieved by means of the PID controller and a heating plate, accordingly, the heating temperature is constant, the heating area is uniform, the speed is high, the heat efficiency is high, and operation is convenient.

Owner:邓娴

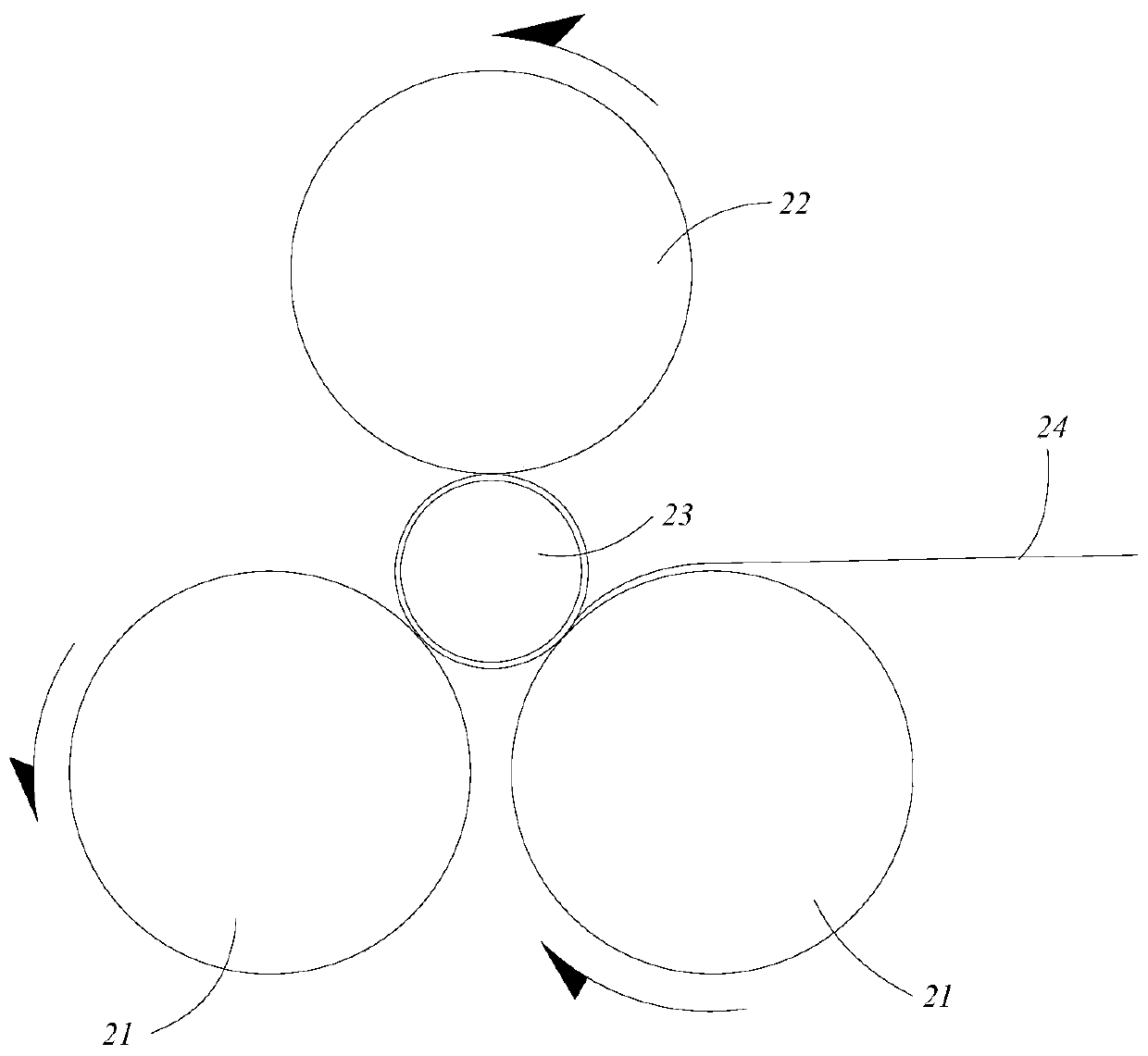

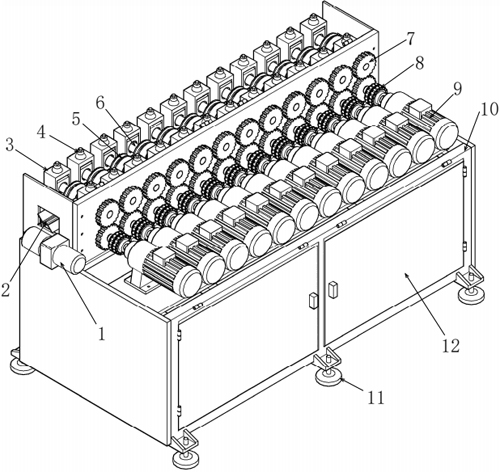

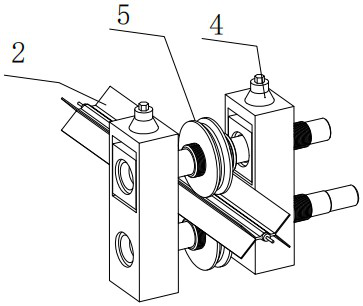

Continuous rolling pipe reducing machine for X-shaped aluminum electric heating pipe with four fins

The invention discloses a continuous rolling pipe reducing machine for an X-shaped aluminum electric heating pipe with four fins. The continuous rolling pipe reducing machine comprises a main rack andthe X-shaped pipe. An electric appliance box is arranged in the main rack, and leg cups are arranged at the bottom of the main rack. A row of wave box motors is arranged on the upper end face of theelectric appliance box, and the axis of a mold on the left side is connected with a lower pressing wheel shaft. The tail end of the inner side of an upper pressing wheel shaft and the tail end of theinner side of the lower pressing wheel shaft are connected with gears, and the vertically adjacent gears are engaged with each other. The tail end of the inner side of the lower pressing wheel shaft is connected with a rotary shaft of each wave box motor through a connector. A discharging motor is arranged on the upper side of the front end of the main rack, and the X-shaped pipe is arranged between wheel molds. According to the continuous rolling pipe reducing machine for the X-shaped aluminum electric heating pipe with the four fins, continuous diameter reduction is carried out on the machined pipe through 12 molds, one-time continuous rolling is achieved, and the machined product is good in density, high in straightness, flat and smooth in surface and more even in heating area; and moreenergy is saved, the production efficiency is greatly improved, and the production efficiency is more than then times that of a traditional production process.

Owner:陈健明

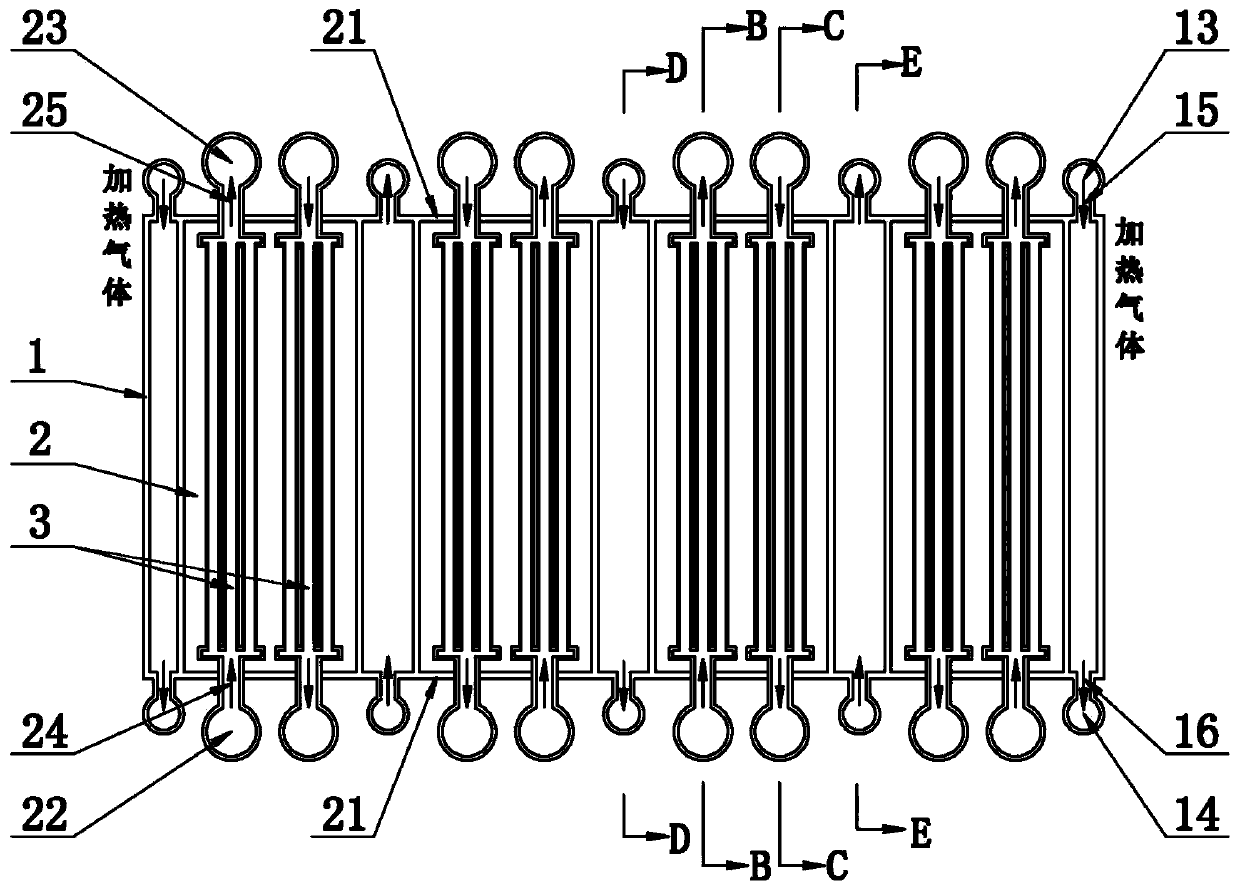

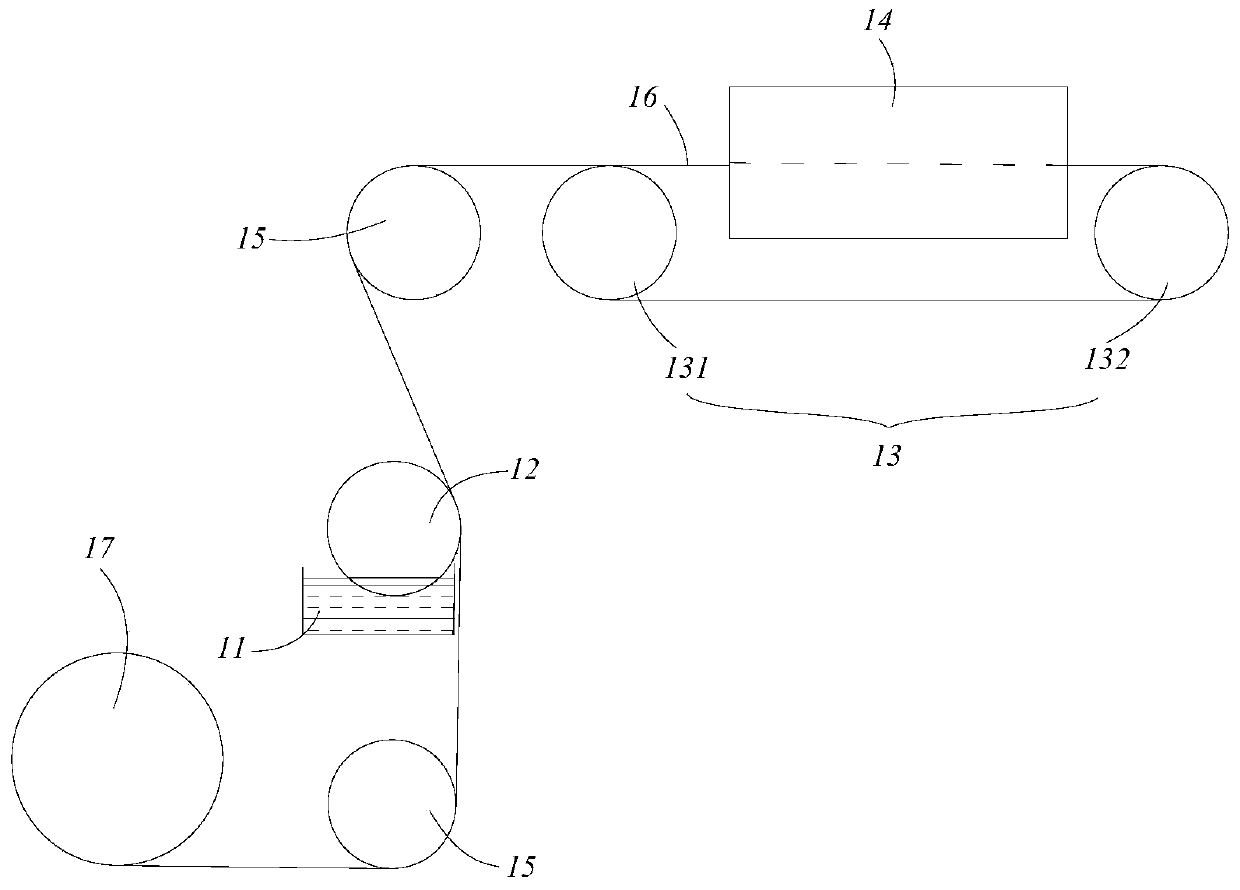

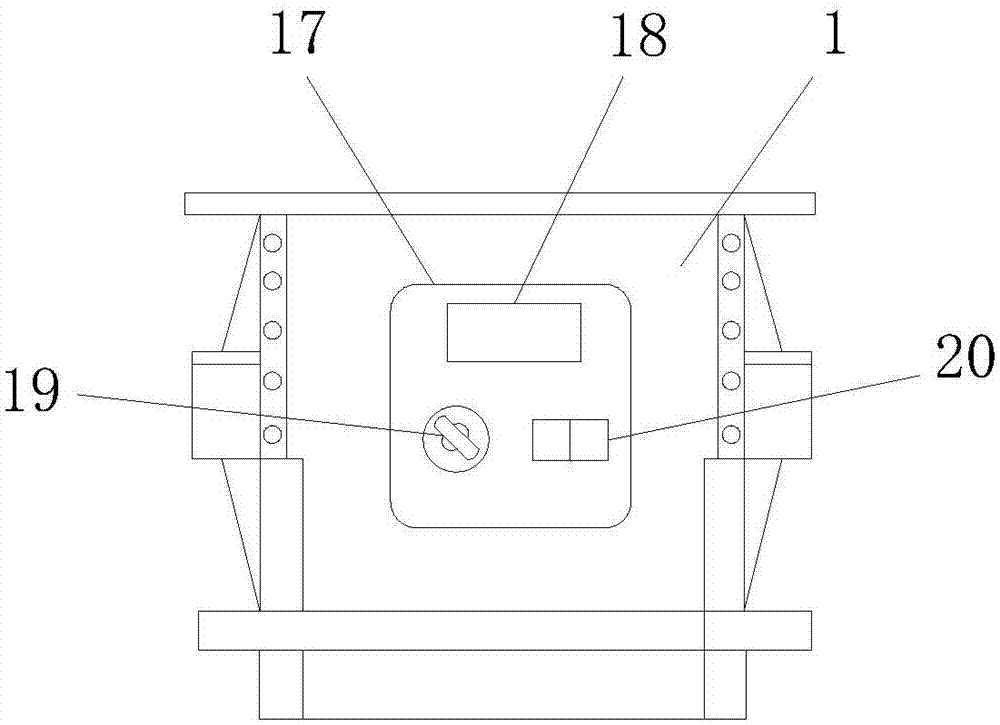

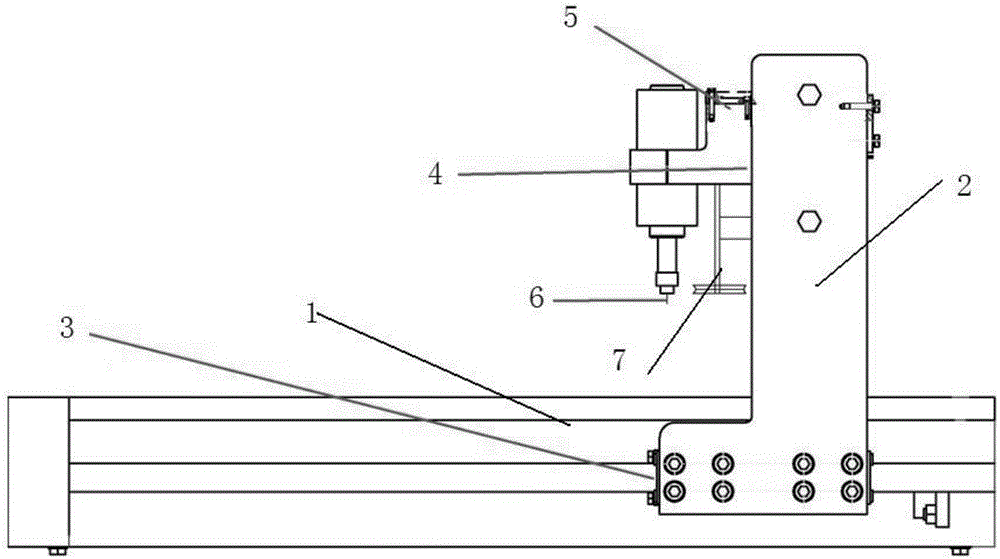

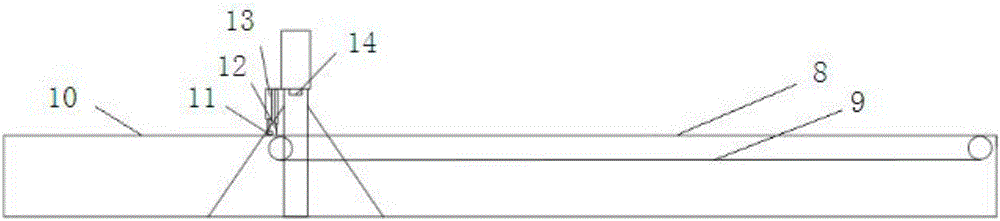

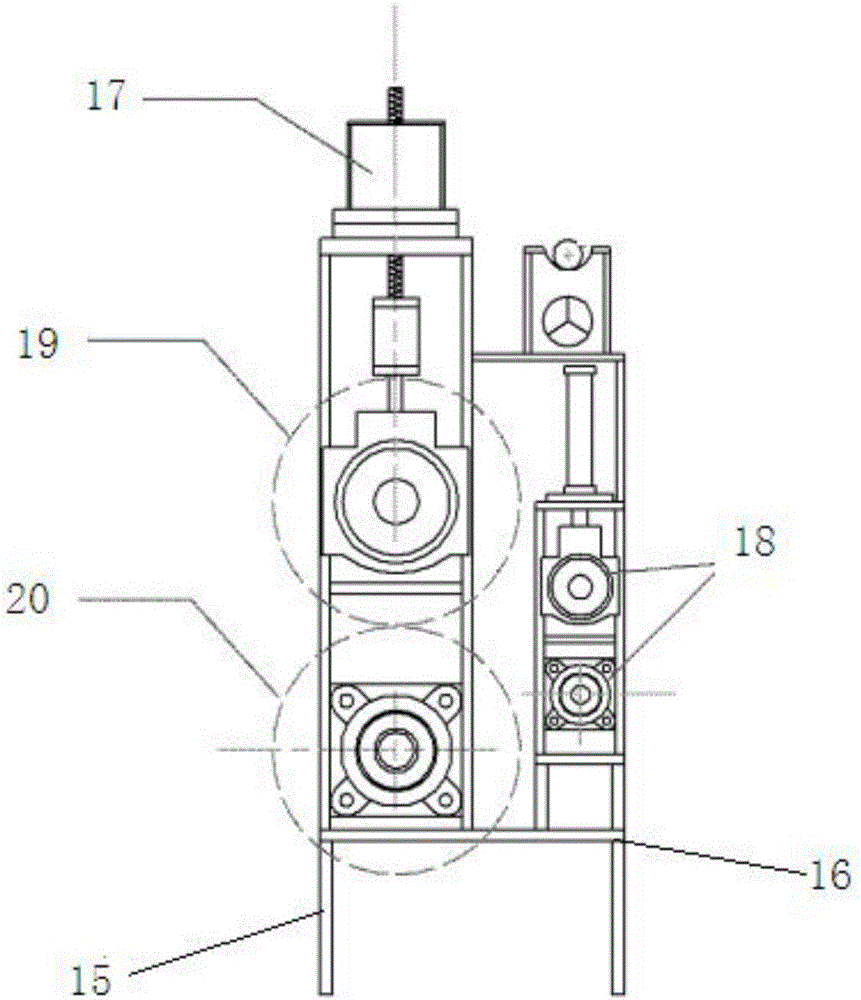

A High Efficiency Continuous Vacuum Microwave Dryer

ActiveCN105258480BAdjustable drying temperatureSmooth runningEngine sealsPharmaceutical product form changeMicrowaveLiquid state

The invention discloses an efficient continuous vacuum microwave drying machine and belongs to the field of drying processing machines which can keep the vacuum degree under the condition of continuous feeding and discharging of materials in a solid state or a semi-liquid state or other states of food products, Chinese herbal machine products, chemical products and agricultural and sideline products. The efficient continuous vacuum microwave drying machine is mainly provided with a feeding conveying belt, a rotary drum type feeding / discharging sealing device, a vacuum chamber, a heating device, a microwave magnetic-control device, a material conveying belt, a material turning device, a vacuum recovering system and a cleaning device. According to the drying machine, by the adoption of a steam and microwave combined heating drying way, energy and time can be saved by over 20%-30% compared with a single microwave heating drying way or a single steam heating drying way; the material turning device and the cleaning device for processing solid materials and semi-liquid materials are arranged, a condensation recovering device is added into the vacuum system, in this way, fragrant gas can be collected and converted into liquid, beneficial gas, poisonous and harmful gas, inert gas, gas prone to oxidation, combustible and explosive gas and the like can be recycled, high quality and high benefits of processed products can be achieved, environment protection is facilitated, and social comprehensive benefits are also facilitated.

Owner:陈长清

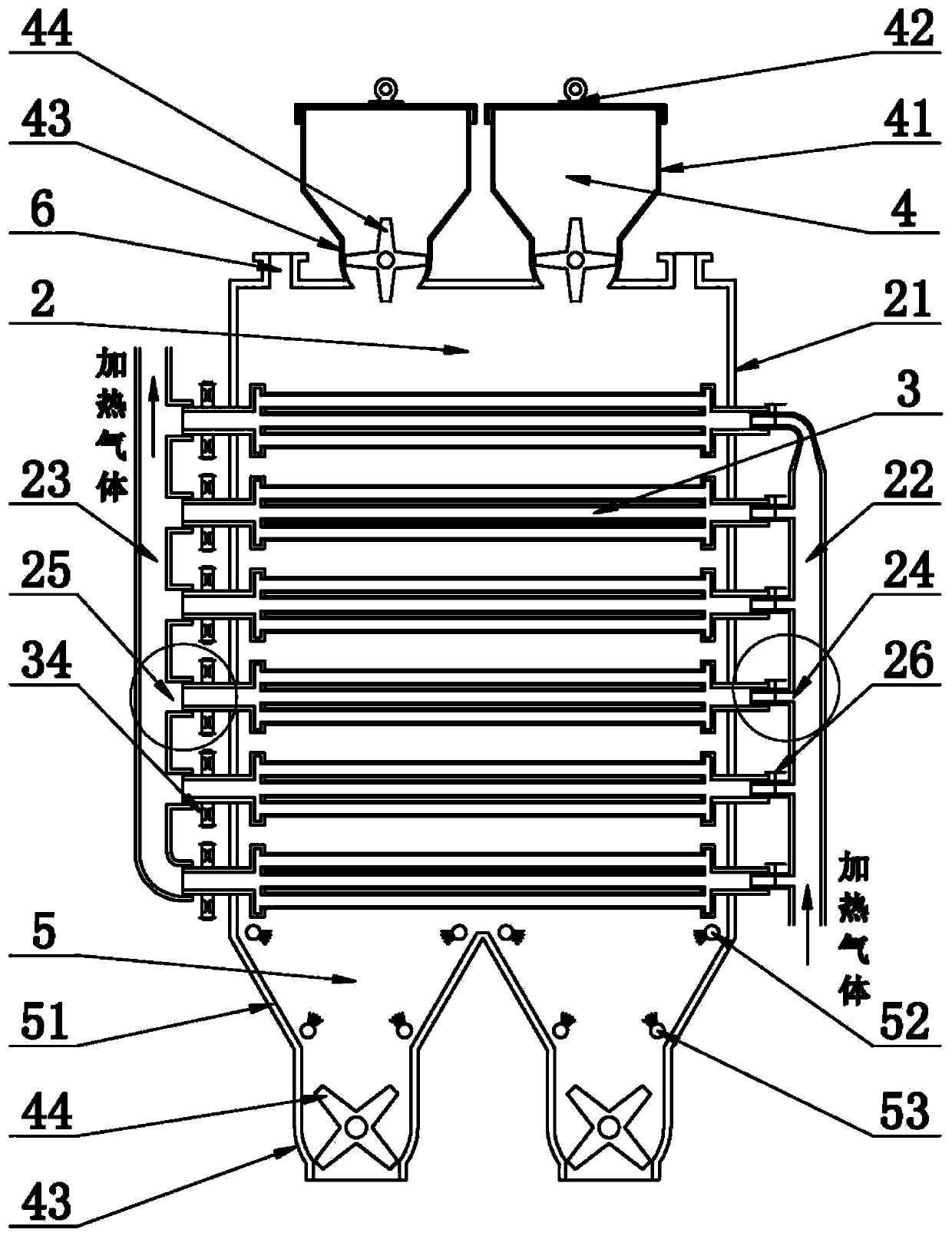

Heat conduction oil type double-cylinder hot melting kettle convenient for replacement of inner containers

A heat conduction oil type double-cylinder hot melting kettle convenient for replacement of inner containers comprises hot melting kettle bodies, a gas type stove, an automatic temperature control system and an independent power station. Each hot melting kettle body comprises one inner container, a speed reducer, a stirring shaft, stirring blades, a smoke exhaust pipe, a heat conduction oil storing tank, a heat insulating layer, a protection hearth, a shell, a feeding port and a discharging pipe, an annular cavity is formed between the circumference of the side wall of a stirring barrel and that of the inner wall of the corresponding inner container, a bottom cavity is formed between a baseplate of each stirring barrel and the bottom of the inner wall of the corresponding inner container, and each inner container and the corresponding protection hearth are detachably and fixedly connected through bolts at a connecting block; an opening-closing device is arranged on the outer side wall of each protection hearth, the gas type stove comprises a normally-open-fire stove and an abnormally-open-fire stove, the automatic temperature control system comprises a coating temperature sensor and a heat conduction oil temperature sensor, and the independent power station comprises a traveling chassis assembly, an engine, a hydraulic oil tank assembly, a hydraulic oil pump, a power generator and a heat radiator. The heat conduction oil type double-cylinder hot melting kettle enables total heating area of a coating to be large and uniform, is supportive of replacement of the inner container and can lower cost.

Owner:WELL ROAD MACHINERY CO LTD

Magnesium alloy electromagnetic energy heating liquid channel tube

PendingCN106961754AReduce manufacturing costAchieve heating effectCoil arrangementsElectromagnetic generatorInsulation layer

The invention discloses a magnesium alloy electromagnetic energy heating liquid channel tube. The magnesium alloy electromagnetic energy heating liquid channel tube comprises a liquid channel tube body and an electromagnetic generator. The magnesium alloy electromagnetic energy heating liquid channel tube is characterized in that the liquid channel tube body is provided with a double-sided silk blanket, a piece of glass fiber cloth, and an electromagnetic induction coil, which are sequentially arranged along a radial direction. The double-sided silk blanket is disposed on the outer wall of the liquid channel tube body in a coiled manner, and the glass fiber cloth is disposed on the double-sided silk blanket in a wrapped manner. The electromagnetic induction coil is disposed on the outer edge of the glass fiber cloth in a coiled manner, and is electrically connected with the electromagnetic generator. The magnesium alloy electromagnetic energy heating liquid channel tube is advantageous in that by adopting the high frequency alternating current generating magnetic field of the electromagnetic induction coil, the magnetic field reaches the liquid channel tube after passing through the thermal insulation layer of the double-sided silk blanket; because of collision between the metal molecules of the liquid channel tube under the action of the high frequency electromagnetic field, heat energy is generated; heating effect is achieved, heating areas are uniform, consumed electric energy is less, and production costs of enterprises are saved.

Owner:昆山宏格工业设备有限公司

Circulation drying device for agricultural and sideline products

InactiveCN107228556ASmooth runningEasy to operateDrying gas arrangementsDrying machines with progressive movementsTemperature controlLiquid-crystal display

The invention discloses a circulation drying device for agricultural and sideline products. The circulation drying device for the agricultural and sideline products comprises a conveyor belt; conveyor wheels are arranged inside the conveyor belt, and a speed regulator is mounted on the left side of the conveyor belt; six sets of support frames are mounted on the bottom of the conveyor belt; a drying box is mounted on the conveyor belt, and drying machines are correspondingly arranged on the left side and the right side of the drying box; baffles are fixed to the side wall of the drying box, and air inlets are formed in the baffles; a motor is mounted on the top of the drying box, and the motor is rotatably connected with stirring rods through a main shaft; a feeding inlet is formed in the left lower portion of the drying box; and a control panel is embedded in the front surface wall of the outer shell of the drying box, and the control panel is correspondingly provided with a liquid crystal display panel, a temperature control knob and a start switch. The circulation drying device for the agricultural and sideline products can sample and detect the water content of the agricultural and sideline products on the conveyor belt at any time, and adjust the running speed of the conveyor belt at any time according to the different water contents, so as to ensure the best quality of the air-dried agricultural and sideline products.

Owner:合肥念萍电子商务有限公司

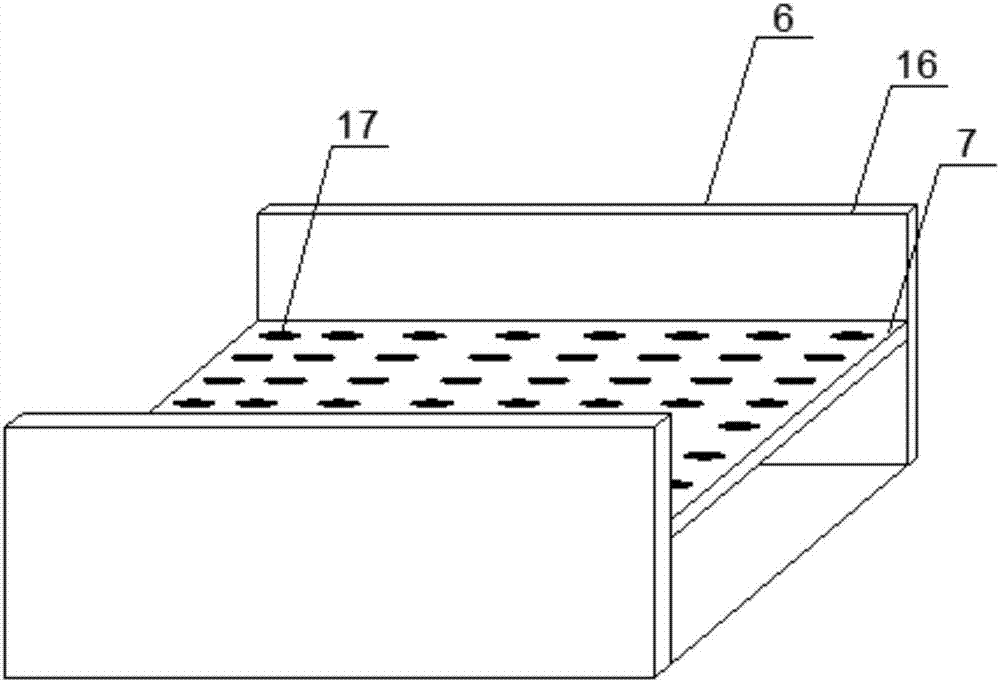

Production process of a structural core material set

ActiveCN104786294BEasy maintenanceReduce labor costsOther plywood/veneer working apparatusWood veneer joiningNumerical controlPunching

The invention discloses a production technology of a structural core material set. The production technology includes the following steps that first, cork wood is machined; second, a PVC board is machined; third, the cork wood and the PVC board are spliced. In the first machining step, firstly, a cork wood board is machined according to a drawing, flat cut according to required thickness and sanded so that the surface of the cork wood can be smooth; coating, cloth attachment, punching and grooving are performed; the cork wood enters a numerical control saw so that the procedures of synchronous lineation, edge cutting and angle cutting can be performed; soot blowing and laying repairing are performed so that the cork wood board can be obtained. In the second machining step, the PVC board is machined according to a drawing, flat cut according to the required thickness and sanded so that the surface of the PVC board can be smooth; cloth attachment, punching and grooving are performed; the PVC board enters a PVC board numerical control machining device so that the procedures of synchronous lineation, edge cutting and angle cutting can be performed; soot blowing and laying repairing are performed so that the PVC board can be obtained. The numerical control device is adopted for machining in the production technology, the production efficiency of products is improved, the defective rate is decreased, and production cost is saved.

Owner:ZHEJIANG LIANYANG NEW MATERIAL

Heating device for catalyst for converting carbon tetrachloride into chloroform

InactiveCN109589889AUniform heating areaImprove heating efficiencyChemical/physical/physico-chemical processesSurface mountingLiquid storage tank

The invention discloses a heating device for a catalyst for converting carbon tetrachloride into chloroform. The heating device comprises a placing base; a groove is formed in the outer wall of the placing base, and a device box is placed in the groove; the inner surface of the device box is provided with a heating plate, and the outer surface of the heating plate is provided with an accommodatingbox; the outer surface of the upper end of the accommodating box is fixedly provided with a liquid injection pipe, and the outer surface of the liquid injection pipe is rotatably provided with a pipesleeve piece; an exhaust pipe is arranged on a position close to one side of the liquid injection pipe, and the outer surface of the exhaust pipe is rotatably provided with a gas pipe sleeve piece; the outer surface of the gas pipe sleeve piece is sleeved with a transmission pipe, and the outer surface of one end of the transmission pipe is provided with a gas storage tank; and the outer surfaceof the upper end of the gas storage tank is provided with a gas pressure meter. The heating device for the catalyst for converting carbon tetrachloride into chloroform, disclosed by the invention, isprovided with the device box, the heating plate, the gas storage tank and a liquid storage tank and is more uniform in heating area, high in efficiency, also good in heat insulation effect and capableof realizing liquid-gas separation and extraction and bringing a better use prospect.

Owner:JIANGSU LEE & MAN CHEM

A photovoltaic pavement system

ActiveCN108755327BImprove cooling effectGood effectPaving gutters/kerbsTemporary pavingsSnowpackHot weather

The invention discloses a photovoltaic pavement system. The photovoltaic pavement system comprises a general control unit, a roadbed, a photovoltaic pavement and drainage troughs on both sides of thephotovoltaic pavement. The photovoltaic pavement comprises a plurality of photovoltaic panel modules. The photovoltaic pavement system is characterized in that the roadbed is provided with a support part, the support part is used for supporting the photovoltaic module, a water collecting channel is formed between the roadbed and the support part, a water collecting tank is provided with water collection tanks at intervals, the support part is paved with the photovoltaic panel modules, a circulating water pipe is disposed between the photovoltaic panel module and the support part, a heat collector is arranged at the water collecting tank, and the circulating water pipe is communicated with the heat collector through a first water pump. The photovoltaic pavement system realizes cooling of the photovoltaic pavement in the hot weather, and melting of the snow and the ice layer on the photovoltaic pavement in the cold weather. The support part transforms the bending moment stress generatedby the load on the photovoltaic panel module into compressive stress or transforms the most of the bending moment stress into compressive stress and prolongs the service life of the photovoltaic panelmodule and the service life of the whole photovoltaic pavement.

Owner:榛硕(武汉)智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com