Efficient continuous vacuum microwave drying machine

A vacuum microwave drying and high-efficiency technology, which is applied in dryers, drying solid materials, drying, etc., can solve problems such as inconsistent product moisture content and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

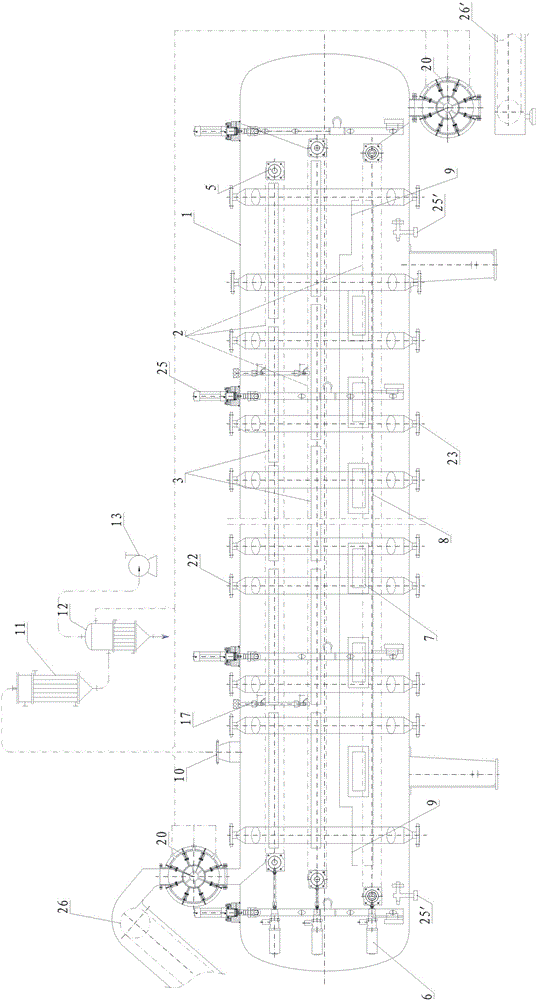

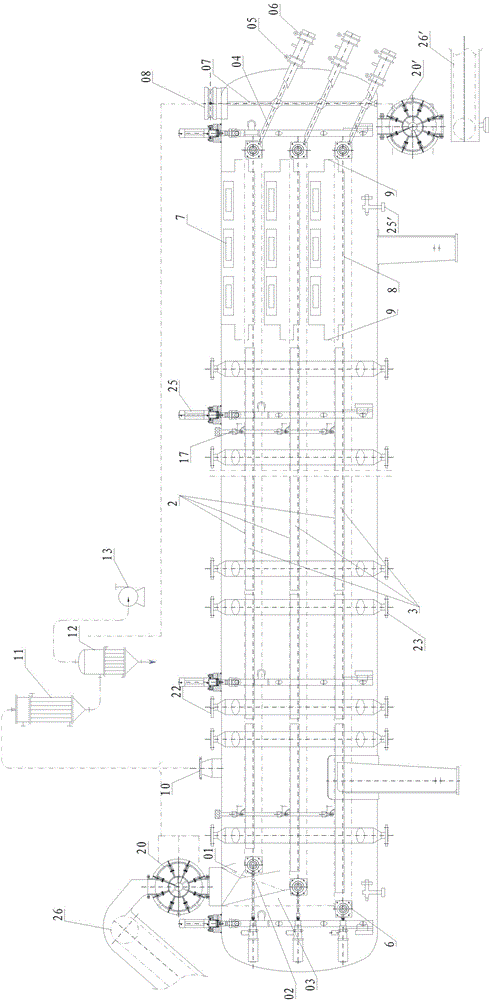

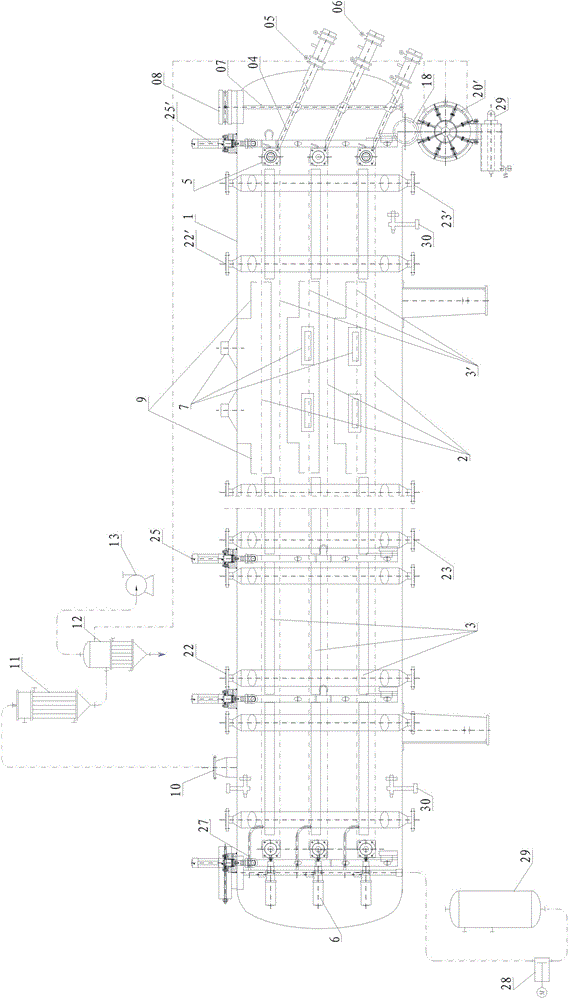

[0041] Further describe structure and working process of the present invention below in conjunction with accompanying drawing:

[0042] Such as figure 1 As shown: a high-efficiency continuous vacuum microwave dryer for processing solid materials in the present invention, its working process: the materials for processing solid materials are sent to the drum-type sealing device (20) by the feeding conveyor belt (26) to be processed, The material is evenly distributed on the material conveyor belt (2) in the vacuum chamber (1) by the uniform material device, and the heating plate (3) is installed between the upper and lower belts of the material conveyor belt (2) to dry the part. After the material is conveyed to the terminal by the first layer of material conveyor belt (2), it will fall onto the second layer of material conveyor belt (2), and can be dried under the heating action of the first and second layer of heating plates (3). ≤85% most of the moisture, when the moisture i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com